Twyford Sola TMV3 User manual

Sola Thermostatic Basin Mixer - TMV3

SF1139CP

Installation and Maintenance Instructions

In this procedure document we have endeavoured to make the information

as accurate as possible.

We cannot accept any responsibility should it be found that in any respect

the information is inaccurate or incomplete or becomes so as a result of

further developments or otherwise.

Twyford Bathrooms Registered Office

Geberit House

Academy Drive

Warwick

CV34 6QZ, UK

Part of the Geberit Group

Telephone: 01926 516800

Email: [email protected]

Website: www.twyfordbathrooms.com

1

Contents

Thank you for choosing the Twyford Safe Touch thermostatic basin tap.

Subject Page

Introduction and Safety 2

Components 3

Technical Data 4

Dimensions 4

Installation 5

Calibration 6

Cartridge Replacement 7

Aftercare and Spout Removal 7

TMV3 Section

Introduction 8

Technical Specification 9

Application 9

Installation 9

Commissioning 10

Maintenance 12

Twyford Guarantee 14

2

Introduction

This installation guide has been produced for the Sola Safe Touch thermostatic basin tap with

removable spout. These instructions cover the installation, operation and maintenance. Please

read the enclosed instructions before commencing the installation of this product, please note;

We recommend that the installation of any Twyford product is carried out by an

approved installer.

The installation must be carried out strictly in accordance with the Water Supply (Water Fitting)

Regulations 1999 and any local authority regulations.

If in doubt we recommend that you contact WRAS - Water Regulations Advisory Scheme on

Tel: 0333 207 9030, your local water authority - details available on the WRAS website or

the Chartered Institute of Plumbing and Heating Engineers on Tel: 01708 472 791.

All products MUST be re-commissioned to suit site conditions to ensure optimum performance

levels of the product are obtained.

Safety

Twyford thermostatic basin taps must be installed and commissioned correctly to ensure that

water is supplied at a safe temperature to suit the users.

The mixers are pre-set using ideal conditions to 38°C.

The maximum mixed temperature takes account of the allowable tolerances inherent in

thermostatic mixers and temperature losses.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5˚C as a comfortable bathing

temperature for children. In premises covered by the Care Standard Act 2000, the maximum

mixed water outlet temperature is 43˚C.

Products

Sola Safe Touch TMV3 Thermostatic Basin Mixer Tap with

Removable spout and Copper Tails SF1139CP

Check Content

Before commencing remove all components from packaging and check each component with

the contents list.

Ensure all parts are present, before discarding any packaging. If any parts are missing, do not

attempt to install your Sola mixer tap until the missing parts have been obtained.

3

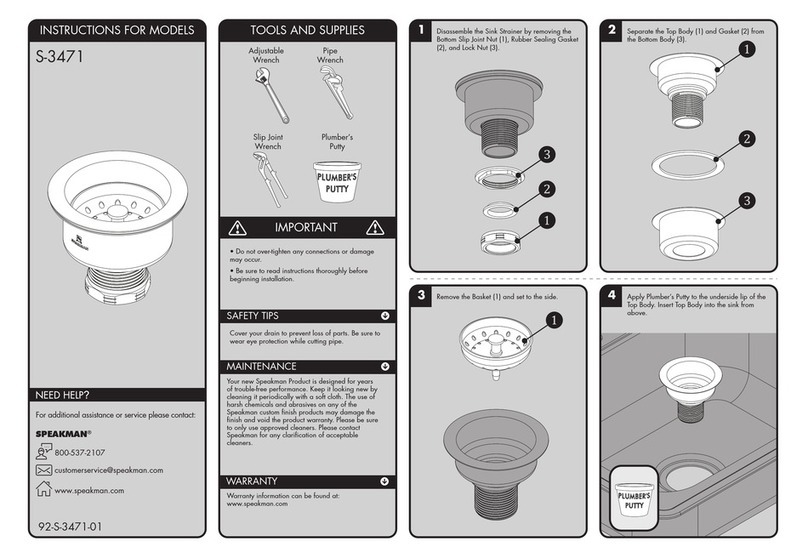

Item Qty Component

1 1 Body

2 1 Detachable spout

3 1 Nozzle

4 1 Grub screw

5 1 Indice

6 1 Retaining screw

7 1 Handle

8 2 Temperature stop ring

9 1 Thermostatic cartridge

10 1 Seat

11 1 Sealing ring

12 1 Horse shoe plate

13 1 Threaded rod

14 1 Retaining nut

15 2 350mm copper tail

integral with body

16 2 Check valve and filter

17 2 Isolating valve and sealing

washer

1

10

5

6

7

8

9

11

12

13

14

15

16

2

3

4

17

Components

4

Technical Data

This Sola Safe Touch thermostatic mixer tap is suitable for installations on all types of

plumbing system, including gravity supplies, fully pumped, modulating combination boiler,

unvented water heater and unbalanced supplies i.e. Cold Mains & Tank Fed Hot. They are not

suitable for non-modulating combination boilers.

Max Inlet Pressure (Static) 12 bar Max Unbalanced Pressure Ratio 15:1

Max Inlet Pressure (Dynamic) 5 bar with flow regulator

Max Inlet Temperature 85˚C Max Unbalanced Pressure Ratio 5:1

Min Inlet Temperature 10˚C without flow regulator

Pre Set Factory Temp Setting 38˚C Min Temp Differential to

Min Operating Pressure (Dynamic) 0.2 bar ensure fail-safe between hot

Temperature Stability ±2˚C and cold supplies 10˚C

Dimensions

75

156

Ø50 100

132

39

148

5

Installation

The Sola Safe Touch thermostatic basin tap is

designed for installing on one hole basins.

The SF1139CP tap is supplied with two 350mm long

copper tails.

Fit check valves with integral filter (16) to the two

copper tails and fit the isolation valves (17) to the

check valves using the sealing washers provided.

Ensure the check valves are connected correctly,

with the flow direction arrow pointing in the direction

of the water flow.

The isolating valves (17) have compression

connections to ease the connection to copper tube.

Screw the threaded rod (13) into the threaded hole

in the base of the body taking care not to over

tighten.

The cold supply must be connected to the right

hand side and the hot to the left hand side of the

mixer when viewed from the front.

Ensure that the ‘O’ ring seal (11) is located in the

base of the tap prior to fitting the mixer to the basin.

Once in place using the horse shoe retaining plate

(12) secure in position, taking care not to over

tighten the retaining nut (14).

For optimum mixing performance where the hot and

cold pressures are not equal, pressure regulating

valves should be installed directly upstream of the

tap so that the water supply pressures can be

regulated and equalised.

Installation

11

12

13

14

15

16

17

6

Calibration

The Sola Safe Touch mixer tap has a factory set outlet temperature of 38˚C via the security

setting. This is based on a balanced supply pressure and a stable hot water inlet temperature

of 65˚C.

However, the calibration point MUST be checked and re-set as necessary to suit site

conditions.

Care must be taken when re-calibrating the tap as INCORRECT CALIBRATION CAN CAUSE

INJURY.

• Remove the indice (5), retaining screw (6), handle (7).

• Remove both rings (A & B) from the cartridge.

• Temporarily refit the handle (7).

• Using a digital thermometer increase or reduce the mixed water outlet temperature until 38˚C

is established and stabilised.

• Remove the handle (7) and refit the temperature stop rings (A) as shown in Fig 1 onto

the splined section of the cartridge at the maximum temperature position.

• Temporarily refit the handle (7) and rotate clockwise until the water flow stops, refit

temperature stop ring (B) as shown in Fig 2.

• Refit the handle in the reverse order.

• Check calibration temperature.

PLEASE NOTE THAT ONCE CALIBRATED, THE SECURITY SETTING WILL ONLY BE 38˚C

UNDER THE SUPPLY CONDITIONS USED FOR CALIBRATION.

B - Cold

A

B

A - Hot

Fig. 1 Fig. 2

7

Aftercare and Spout Removal

Periodically the spout and nozzle should be removed,

cleaned and disinfected to remove any build up of

debris, deposits or bio film which may affect the

performance of the tap.

Ensure the tap is turned off before commencing.

Using a suitably sized spanner remove the nozzle (3)

from the spout.

Unscrew the grub screw (4) and pull the spout (2) from

the tap body (1).

Throughly clean and disinfect the nozzle and spout.

Check the condition of the ‘O’ ring on the tap body if

damage replace with a new one.

To ease assembly lubricate the ‘O’ ring with a WRAS approved silicone based grease.

Re-assemble in the reverse order.

Twyford taps have a high quality finish and should be treated with care.

An occasional wipe with a mild washing-up liquid on a soft damp cloth followed by a thorough

rinsing is all that is required.

Do not use an abrasive or chemical household cleaner as this may cause damage.

Cartridge Replacement

Isolate both the hot and cold water supplies

Remove the indice (5), and unscrew retaining screw (6).

Remove the handle (7) and the temperature stop rings (8).

Using a suitable spanner unscrew the cartridge (9).

Replace with a new cartridge and assemble in the reverse

order.

Re-calibrate following the procedure in the Calibration

section

5

6

7

8

9

1

2

3

4

8

Outlet Temperature Adjustment Range 30˚C to 50˚C

Temperature Stability ±2˚C

Maximum Hot Inlet Temperature 85˚C

DO8 Working Pressure Range 1.0 to 5.0 bar : High Pressure

Min Temp Differential (Mix to Hot) for Fail-Safe 10˚C

Max. Pressure Inlet Differential 5 : 1

Sola TMV3 Thermostatic Basin Tap

Introduction

The Sola safe touch thermostatic basin tap has been specifically designed and manufactured to

meet the requirements of BS 7942: 2000 and NHS D08. The valve has been independently

tested and approved as a TYPE 3 valve under the TMV3 scheme.

Technical Specification / Conditions for use TMV3 Valves

NOTE: Valves operating outside these conditions cannot be guaranteed by the Scheme to

operate as Type 3 valves.

Approvals

TMV3 Scheme Approval Number: Details Available on Request

WRAS Scheme Approval Number: Details Available on Request

Fail Safe Function

The Sola thermostatic basin tap is designed to stop the mixed water flow in the event of either the

hot or cold water supply failing when installed in accordance with these instructions. To ensure full

closure of the mixed water flow the minimum temperature differential between the hot water inlet

to the tap and the mixed water outlet MUST be at least 10˚C.

Operating Pressure Range High Pressure Low Pressure

Maximum Static Pressure 10 bar 10 bar

Flow Pressure, Hot and Cold 1 to 5 bar 0.2 to 1 bar

Hot Supply Temperature 55˚C to 65˚C 55˚C to 65˚C

Cold Supply Temperature 5˚C to 20˚C 5˚C to 20˚C

9

Application

The Sola thermostatic mixer tap has been independently tested by Buildcert Limited and certified

as meeting the requirements of the NHS D08 specification under the TMV3 Scheme as being

suitable for use on the following designations;

Wash Hand Basin HP-W

Temperature Setting

Ensure that the basin tap is commissioned under normal system conditions. The basin tap MUST

be commissioned to suit site conditions and the desired outlet temperature set by the installer;

i With normal supply conditions established and the hot and cold water supplies running,

open the basin tap to its maximum temperature and leave running.

ii Remove the indice, retaining screw and handle by pulling away from the tap and the

temperature stop ring, see diagram on page 6.

iii Fully open the flow control and allow the outlet temperature to stabilise.

iv Temporarily refit the handle and using a digital thermometer it is possible to increase or

reduce the mixed water outlet temperature until 38˚C is re-established, by slowly rotating

the handle.

v Remove the handle and refit the temperature stop ring onto the splined section of the

cartridge at the maximum temperature position.

vi Refit the handle in the reverse order.

Installation

IMPORTANT - The following instructions must be read prior to the installation of any Sola basin

tap. The installer should also be aware of their responsibility and duty of care to ensure that all

aspects of the installation comply with all current regulations and legislation.

Flushing through water systems using certain chemicals may wholly or partially remove the

lubricant from the internal workings of the valve, which may adversely affect its performance. We

recommend that following a flushing of the system with chemicals, valves are checked for correct

operation.

1 It is essential that before installing an Sola thermostatic basin tap to ensure that the supply

conditions of the system, to which the tap is intended to be fitted, are checked to confirm

compliance with the parameters as quoted within the Technical Specification and conditions

on which the approval is granted i.e. verify supply temperatures, supply pressures, risk

assessment.

2 Consideration must be made for the possibility of multiple / simultaneous demands being

made on the supply system whilst the basin tap is in use, all practical precautions must be

made to ensure that the basin tap is not affected. Failure to make provision within the pipe

sizing etc. will affect the performance of the tap.

10

Installation

3 The supply system to which the Sola thermostatic basin tap is to be installed into must be

thoroughly flushed and cleaned to remove any debris, which may have accumulated during

the installation. Failure to remove any debris will affect the performance and the

manufacturer’s warranty of the product.

In areas that are subject to aggressive water, provision must be made to treat the water

supply prior to the supply entering any product.

4 The maximum flow rate of the tap will only be achieved when the supply conditions are

achieved as quoted within the Technical Specification, with a flow condition under 1 bar

differential pressure.

5 This thermostatic mixer tap has been designed for basin mounting. It is essential that

access to the tap is not obstructed for commissioning, testing, or any future maintenance

that may be required.

6 The hot and cold water supplies must be connected to the tap strictly in accordance with

these instructions i.e. hot water supply to the hot port of the tap.

7 In a situation where one or both of the water supplies are excessive, it is possible to fit a

pressure reducing valve or a flow regulator to reduce the pressure(s) to within the limits as

quoted previously.

8 Any thermostatic basin tap must be fitted with a back flow prevention device, such as check

valves (supplied) to prevent the cross contamination of supplies.

9 Independent filters/check valves and isolation valves must be fitted in conjunction with the

SF1139CP basin tap, as close as practically possible to the water supply inlets.

The SF1139 has an integral filter and check valve in the check valve housing on the hot and

cold supplies.

10 It is essential that the Sola thermostatic basin tap should not be installed in situations

where there is a possibility of the tap being deprived of water or where demands for water

are greater than the actual stored supplies.

11 To ensure that the performance levels of the Sola thermostatic basin tap is maintained

(in the event of cold water failure), the temperature of the hot water supply at the point of

entry to the valves must be a minimum of 10˚C above the commissioned mixed water

discharge temperature.

12 The Sola thermostatic basin tap must not be subject to any extreme temperature variations

either during the installation or under normal operating conditions.

11

Commissioning

IMPORTANT - The following instructions must be read and understood prior to commissioning

the Sola thermostatic basin tap. If under any circumstances there are aspects to the installation /

system which do not comply with the specification laid down, the tap MUST NOT be put into

operation until the system / installation complies with our specification. However if all these

conditions are met, proceed to set the temperature as follows;

1 Ensure that the system is thoroughly cleaned and free from any debris prior to the

commissioning the Sola thermostatic basin tap.

2 Commissioning the temperatures must be carried out using a suitably calibrated

thermometer preferably a digital thermometer.

3 In the absence of other temperatures being specified, we recommend the outlet

temperature quoted in Table 1 are used.

Table 1

4 Each basin tap must be commissioned taking into consideration any fluctuations, which

may occur within the system due to simultaneous demands. It is advisable that any outlets

which are connected to the same supply as the basin tap are opened during the setting of

the mixed water temperature. During commissioning it is advisable to ensure that the water

temperatures are established before any attempt to commission.

5 Once the supply temperatures are stable and the normal operating conditions are

established, the tap can be commissioned. The temperature setting can be adjusted

following the procedure described earlier in the Temperature Setting section.

We suggest that the following sequence is followed when commissioning the valve:

5.1 Set the mixed water temperature to the required temperature.

5.2 Measure and record the temperature of the hot and cold water supplies at the

connection to the tap.

5.3 Measure and record the temperature of the water discharging from the basin tap.

5.4 Isolate the cold water supply to the tap and monitor the mixed water temperature.

5.5 Measure and record the maximum mixed water temperature and the final

temperature.The final temperature found during the test should not exceed the value

quoted in Table 2.

5.6 Record all the equipment used during the commissioning.

Table 2

Application Maximum Set Mixed Water Temp.

Wash Hand Basin 43˚C

Application Recommended Set Mixed Water Temp.

Wash Hand Basin 41˚C

12

Commissioning

6 Ensure that the application, in which the basin tap will be used, is appropriate for the

approved designation. The above information must be recorded and updated on every

occasion when any work is carried out on the basin tap.

Maintenance

To ensure the Sola thermostatic basin tap maintains a high level of protection, we advise the

following in service testing is conducted (the same equipment used to commission the basin tap

initially must be used in the following tasks).

1 After a period of between 6 and 8 weeks from commissioning carry out the following;

1.1 Record the temperature of the hot and cold water supplies.

1.2 Record the temperature of the mixed water from the basin tap.

2 If the mixed water temperature has changed significantly from the previous test results (e.g.

>1˚K), record the change and before resetting the mixed water temperature check that:

2.1 All the strainers are clean.

2.2 All the check valves are in good working order.

2.3 The isolation valves are fully open.

3 If the mixed water temperatures are acceptable, carry out the following:

3.1 Record the temperature of the hot and cold water supplies.

3.2 Record the temperature of the mixed water from the basin tap.

3.3 Isolate the cold water supply to the mixing valve and monitor the mixed water

temperature.

3.4 Record the maximum temperature achieved as a result of (3.3) and the final

temperature (the final temperature should not exceed the values quoted in table 2)

3.6 Record the equipment used during these tests.

4 If the mixed water temperature is greater than the values quoted in table 2 or the maximum

temperature exceeds the corresponding values from previous test results by more than 2˚K,

the basin tap must be serviced.

5 After a period of between 12 to 15 weeks from commissioning, carry out the sequence of

tests as described in Maintenance sections 1, 2, 3 and 4.

13

Maintenance

6 Dependant upon the results obtained from the first two series of tests; there are a number of

possible outcomes:

6.1 If no significant change in the mixed water temperatures (e.g. ≤ 1˚K) is recorded

between commissioning and Maintenance sections 1 or between commissioning and

Maintenance sections 5, the next in service testing should be carried out at a period of

24 to 28 weeks after initial commissioning.

6.2 If a small change (e.g. 1 to 2˚K) in the mixed water temperature is recorded in only one

of these periods, necessitating adjustment of the mixed water temperature, then the

next in service can be deferred to 24 to 28 weeks after commissioning.

6.3 If small changes (e.g. 1 to 2˚K) in the mixed water temperature are recorded in both of

these periods, necessitating adjustment of the mixed water temperature, then the next

in service test can be deferred to 18 to 21 weeks after commissioning.

6.4 If significant changes (e.g. > 2˚K) in the mixed water temperature are recorded in both

of these periods necessitating service work, then the next in service test should be

carried out at 18 to 21 weeks after commissioning.

7 The general principle to be observed after the first 2 or 3 in-service tests is that the intervals

for future tests should be set to those which previous tests have shown can be achieved

with no more than a small change in mixed water temperature.

8 In all areas periodic maintenance of the valve and associated fittings i.e. strainers, check

valves will ensure optimum performance levels are maintained.

Spares

A full range of spares are available for this product from Twyford.

PLEASE NOTE: Only genuine spares should be used.

Please leave this Manual for the User

14

Twyford Guarantee

At Twyford, we want to make things as easy as

possible for our customers. That’s why we

design products that are easy to fit and use,

and that are quality tested to make sure they

won’t let you down. It’s also why we offer solid

guarantees on all products, effective from the

date of purchase, to give you peace of mind.

Twyford mixer taps are covered by a parts only

2 year guarantee.

Guarantee Terms and Conditions

This guarantee is in addition to your statutory

and other legal rights and is subject to the

following conditions:

• The product was purchased within the

United Kingdom or Republic of Ireland.

• The guarantee applies solely to the original

purchaser with proof of purchase.

• The installation must allow ready access to

all products for the purpose of inspection,

maintenance or replacement.

• Repair under this guarantee does not

extend the original expiry date. The

guarantee on any replacement parts or

products ends at the original expiry date.

• Any part found to be defective during the

guarantee period will be replaced without

charge, providing that the product has been

installed in accordance with the instructions

given in this guide and used as the

manufacturer intended.

The guarantee does not cover damage or

defects caused by:

• General wear and tear (including special

non-chrome finishes; components such as

filters, seals, ‘O’ rings and washers).

• Incorrect installation.

• Repair using non-Twyford parts

• Accidental or wilful misuse

• Corrosion and the use of inappropriate

cleaning products.

• System debris including the build up of

limescale (which can be controlled

through regular servicing and

maintenance).

The guarantee does not cover compensation

for loss of use of the product or consequential

loss of any kind.

In the interests of continuous product

improvement, Twyford reserves the right to

alter product specifications without notice.

The Twyford Product Guarantee does not

affect your statutory rights as a consumer.

Need help?

If this product does not function correctly when

first used, contact Geberit Technical

Department on 01926 516800 where our

expert team of advisors will be able to offer you

help and advice.

Problems during the guarantee period

In the unlikely event that you encounter any

problems with the product during the

guarantee period, contact Geberit Technical

Department on 01926 516800 with your proof

of purchase and we will work to resolve the

problem quickly.

Technical support hotline

(Tel: 01926 516800) with access to fully trained

advisors who can offer installation advice, talk

you through quick maintenance checks, or

recommend the best course of action to fix any

problems with a product.

Contact Us

For any queries please contact us or visit our

website for further information:

Website: www.twyfordbathrooms.com

Telephone: 01926 516800

E & O.E 05-07-18

Twyford

Lawton Road

Alsager

Stoke-on-Trent

ST7 2DF

UK

UK Technical Helpline

Telephone: 01926 516800

or 01270 879777

Email: [email protected]

Website: www.twyfordbathrooms.com

This manual suits for next models

1

Table of contents

Other Twyford Kitchen & Bath Fixture manuals

Popular Kitchen & Bath Fixture manuals by other brands

Range Master

Range Master Aquatrend TRE1PO instructions

baliv

baliv WA-2520 manual

Sanipex

Sanipex BAGNODESIGN Chiasso BDM-CHS-452 Series installation guide

Lefroy Brooks

Lefroy Brooks X1-1998 Installation, operating, & maintenance instructions

DURAVIT

DURAVIT B.1 Series Instructions for mounting and use

Kraus

Kraus Turino KFD1-24GWH installation manual