Twyford X62 Series User manual

Please keep these instructions for future reference

X62 Tap Range

This instruction booklet covers:

X625205CP, X625215CP, X625255CP, X625265CP,

X625122CP, X625126CP, X625135CP

Contents

Thank you for choosing Twyford. We have designed this product with your enjoyment in

mind. To ensure that it works to its full potential, it needs to be fitted correctly. These

fitting instructions have been created to give you all of the information you need and, if you

need any further help, please do not hesitate to give us a call on 0844 412 5951

Important Safety Information 04

General Specifications 04

Dimensions 05-11

Installation Requirements 12

Installation 12-14

Basin & Bath Pillar Taps 12

Bath Filler & Bath Shower Mixer 13

Basin Mixer, Mini Basin Mixer & Bidet Mixer 14

Flow Limiters 15

Maintenance 16

Troubleshooting 17

Guarantee 18

Notes 19

03

04

Important Safety Information

Please read these instructions thoroughly and retain for future use.

All products manufactured and supplied by Twyford are safe provided they are installed

correctly, used correctly and receive regular maintenance in accordance with these

instructions.

If you are in any doubt about your ability to install this product safely you must employ the

services of an experienced qualified plumber.

Remove all packaging and check the components for damage before starting installation.

Before starting any installation please consider the following: Prior to drilling into walls,

check that there are no hidden electrical wires, cables or water supply pipes. This can be

checked with the aid of an electronic detector.

If power tools are used do not forget to: - Wear eye protection

- Unplug equipment after use

This product must not be modified from the original design as this will invalidate the guarantee.

These fittings need to be installed in accordance with and meet the requirements of the Water

Supply (Water Fittings) Regulations 1999 and Scottish Byelaws 2004.

General Specifications

Maximum static pressure – 10.0 bar

Nominally equal (balanced) inlet supply pressures are recommended for optimum performance of

mixer taps.

Designed to comply with BS EN 200 for single taps / combination taps for water systems of type 1

and 2 general technical specifications; and to be used within systems designed to BS 6700.

BS 6700 recommends the temperature of stored water should never exceed 65°C. A stored water

temperature of 60°C is considered sufficient to meet all nominal requirements and will minimise

the build up of lime scale in hard water areas.

Operating Pressure Range (bar) Min Max

Bidet Mixer (X625135CP) 0.2 5.0

Mini Basin Mixer (X625122CP) 0.4 5.0

Basin Taps (X625205CP) 0.2 5.0

Bath Taps (X625215CP) 1.0 5.0

Basin Mixer (X625126CP) 0.3 5.0

Bath Filler (X625255CP) 1.0 5.0

Bath Shower Mixer (X625265CP) 1.0 5.0

Dimensions

05

Deck Mounted Bidet Mixer & Clicker Waste – X625135CP

Build of Materials

1 * Instructions 1 * Clicker Waste

1 * Deck Mounted Bidet Mixer 1 * Plinth for Bidet Mixer

2 * ½” Female BSP x M10 Flexi hoses (350mm) 1 * Securing Bracket

Note: Maximum surface thickness to fit tap to is 44mm

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Standard Mixed 5.1 8.7 12.7 18.3 22.7 29.4

06

Dimensions

Deck Mounted Mini Basin Mixer & Clicker Waste – X625122CP

Build of Materials

1 * Instructions 1 * Clicker Waste

1 * Deck Mounted Mini Basin Mixer 1 * Plinth for Mini Basin Mixer

2 * ½” Female BSP x M10 Flexi hoses (350mm) 1 * Securing Bracket

Note: Maximum surface thickness to fit tap to is 44mm

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Standard Mixed 3.2 5.1 7.3 10.5 12.2 16

Flow Limiter Fitted (Part No: XS9075XX) 1.9 3.20 4.80 6.50 6.70 7.00

07

Dimensions

Deck Mounted Basin Mixer with Clicker Waste – X625126CP

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Standard Mixed 5.2 9.2 13.7 19.7 24.2 31.8

Flow Limiter Fitted (Part No: XS9075XX) 2.22 3.70 5.35 6.7 6.40 6.50

Build of Materials

1 * Instructions 1 * Clicker Waste

1 * Deck Mounted Basin Mixer 1 * Plinth for Basin Mixer

2 * ½” Female BSP x M10 Flexi hoses (350mm) 1 * Securing Bracket

Note: Maximum surface thickness to fit tap to is 44mm

08

Dimensions

½” Basin Pillar Taps – X625205CP

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Standard 7.2 11.2 16.0 22.7 27.9 36.0

With Flow Limiters Fitted (Part No: XS9006XX) 2.9 4.8 5.2 5.6 6 6

Build of Materials

1 * Instructions 2 * ½” Basin Pillar Taps

2 * Rubber Washers 2 * ½” Back Nuts

Note: Maximum surface thickness to fit tap to is 33mm

09

Dimensions

¾” Bath Pillar Taps – X625215CP

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Mixed Standard 6.9 11.2 15.4 22.3 27.6 35.3

Build of Materials

1 * Instructions 1 * Bath Filler Deck with ¾” Inlets

2 * Rubber Washers 2 * ¾” Back Nuts

Note: Maximum surface thickness to fit tap to is 33mm

10

Dimensions

Deck Mounted Bath Filler – X625255CP

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Mixed Standard 9.4 15.9 23.1 32.7 37.8 46.03

Build of Materials

1 * Instructions 1 * Bath Filler Deck with ¾” Inlets

2 * Rubber Washers 2 * ¾” Back Nuts

Note: Maximum surface thickness to fit tap to is 33mm

11

Dimensions

Deck Mounted Bath Shower Mixer – X625265CP

Flow Rate (litre’s per minute) 0.2 Bar 0.5 Bar 1.0 Bar 2.0 Bar 3.0 Bar 5.0 Bar

Mixed Tap Outlet 7.5 12.8 18.6 26.6 32.6 42.7

Handset 2.5 6.5 9.5 15.0 18.8 25.4

Flow Limiter fitted in Handset (Part No: XS9008XX) 2.3 4.4 6 8 7.5 6.8

Build of Materials

1 * Instructions 1 * Bath Shower Mixer with ¾” Inlets

1 * Handset 1 * Shower head holder & Fixings

1 * 1.5 Metre Shower Hose 2 * ¾” Back Nuts

2 * Rubber Washer

Note: Maximum surface thickness to fit tap to is 33mm

Installation Requirements

12

Installation

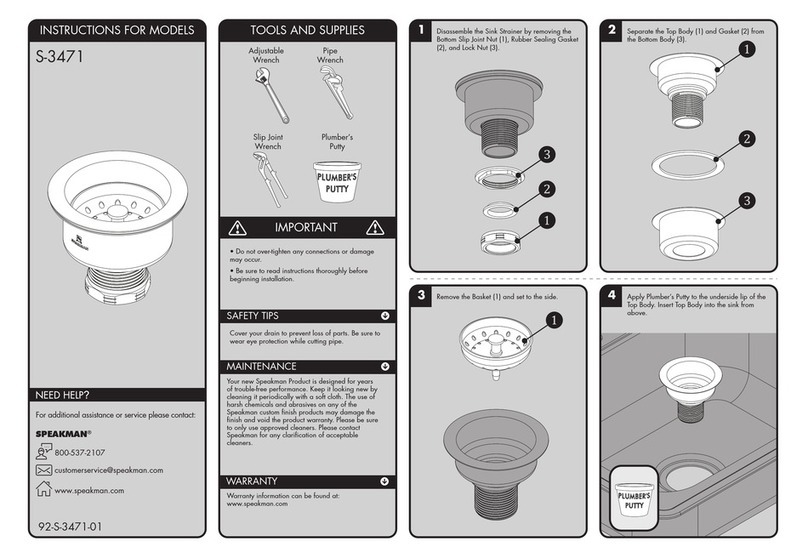

(X625205CP, X625215CP)

Identify all components are present prior to

starting the installation.

1. Slide the plinth onto the threaded tail and

fit the tap body to the basin / bath.

2. Slide the washer onto the threaded tail

and secure the tap to the basin / bath by

tightening the backnut. A suitable

spanner may be required to fully tighten

the backnut,

3. Connect the hot and cold water supplies

to the threaded tails using either a ½” or

¾” BSP connector or preferably an

isolation valve for future servicing

convenience (not supplied).

4. Turn on water supplies and turn both

taps to the on position, letting the water

flow for a few minutes and purging all air.

5. Check all joints and connections for any

leaks.

Basin & Bath Pillar Taps

IMPORTANT - PLEASE READ

This product has been tested to the Water Regulations Advisory Scheme (WRAS) and satisfies the

requirements of the Water Supply (Water Fittings) Regulations 1999 and current bylaws.

For full Installation Requirements & Notes (IRN) please visit www.wras.co.uk/directory.

Washer

Backnut

Drawings for illustration purposes only

Plinth

13

Deck Mounted Bath Filler and Bath Shower Mixer

Identify all components are present prior to starting

the installation.

1. Fit the mixer body to the bath ensuring that the

plinth and washer are between the body and

bath.

2. Secure the mixer to the bath using the washers

and plastic backnuts below the bath.

Tighten the backnuts onto the threaded tails.

A suitable spanner may be required to fully

tighten the backnut.

3. Connect the hot and cold water supplies to the

threaded tails using a ¾” BSP connector or

preferably an isolation valve for future servicing

convenience (not supplied).

4. Bath Shower Mixer only - fit the shower hose to

the hose outlet using the small sealing washer,

and the handset to the hose using the small

washer.

5. Fit the wall bracket (not shown) to the wall using

the fixings supplied, ensuring the handset and

hose reaches it.

6. To switch from bath to shower mode, pull the

diverter knob up, to revert back to bath filling

mode push the diverter knob back down.

7. Turn on water supplies and turn both handles into

the on position, letting the water flow for a few

minutes and purging all air.

8. Check all joints and connections for any leaks.

Prior the drilling into walls, check there no

hidden electrical wires, cables or water supply pipes

with the aid of an electronic detector.

If you use power tools do not forget to:

• Wear eye protection

• Unplug equipment after use

Drawings for illustration purposes only

Washer

Backnut

Plinth

Hose screws in from

underneath

Installation continued

(X625255CP, X625265CP)

14

Basin Mixer/Bidet Mixer/Mini Basin Mixer

Installation continued

(X625126CP, X625122CP, X625135CP)

Flexi Tails

‘C’ Shaped

Rubber

Washer

‘C’ Shaped

Metal

Washer

Fixing

Rods

Fixing

Nuts

Drawings for illustration purposes only

Plinth

Identify all components are present prior to starting

the installation.

1. Screw the flexi tails into the bottom of the mixer

body by hand only (DO NOT OVERTIGHTEN).

2. Screw the fixing rods into the bottom of the mixer

body.

3. Place the plinth over the hole in the basin,

ensuring the washer is fitted between the plinth

and the basin. Feed the flexi tails through hole in

basin.

4. Slide ‘C’ shaped rubber washer and ‘C’ shaped

metal washer onto the fixing rods up to the

underside of the basin.

5. To secure the mixer in place tighten the fixing

nuts onto the fixing rods until they are fully

tightened against the ‘C’ shaped metal washer.

The fixing nuts can be tightened with a suitable

spanner.

6. Connect the flexi tails to the hot and cold water

supplies.

7. Turn on water supplies, lift the mixer handle

upwards and operate in both directions, letting

the water flow for a few minutes and purging air.

8. Fit the clicker waste ensuring a rubber washer is

fitted between the basin and the waste. Use a

pure silicon sealant where necessary. Place the

other rubber washer under the basin and secure

by tightening the backnut, in order to fill the

basin, the button in the middle of the waste

needs to be pressed down. To release the water,

press the button again.

9. Check all joints and connections for any leaks

15

Flow limiters pillar taps

Twyford’s Pillar Taps use push fitted flow limiters which are inserted into the threaded inlet area of the

Taps. To install: The flow limiter should be inserted into the threaded tail of the tap with the arrow

pointing upwards and the ‘O’ ring at the base. Make sure you isolate the water supply before

disconnection.

Flow limiters bath shower mixer taps

Twyford’s Bath Shower Mixer Taps use flow limiters which are inserted via the threads in between

the shower outlet on the tap and the hose inlet. To install: Insert the flow limiter and adapter in

between the shower outlet on the body and the shower hose making sure the rubber washers are

used.

Flow limiters

On Twyford’s Basin and Mini Basin Mixer, the flow restrictor is incorporated into the flow

Straightener in the spout.

Removal

Using a suitable spanner carefully unscrew the flow straightener from the tap spout.

Refitting

Make sure the rubber washer is positioned in between the spout and the flow straightener,

carefully screw in the flow straightener into the tap spout and when hand tightened, very

carefully nip up the flow straightener using a suitable spanner. DO NOT OVERTIGHTEN.

Threaded inlet

Flow Limiter

Flow Straightener/Limiter

Image for illustration purposes

Image for illustration purposes

16

General Cleaning

Your fitting has a high quality finish and should be treated with care to preserve the visible surfaces.

All finishes will degrade if not cleaned correctly. The only safe way to clean your product is to wipe

with a soft damp cloth. Stains can be removed using washing up liquid.

All bathroom cleaning products (powders and liquids) will damage the surface of your fitting, even the

non-scratch cleaners.

Note: Never use abrasive detergents or disinfectants or those containing alcohol, hydrochloric acid

or phosphoric acid.

Maintenance

We advise that your fitting is regularly serviced in hard water areas to

maintain optimum performance.

If your fitting begins to leak the following should be carried out;

1. Isolate both hot and cold water supplies to the tap by either:

a) Turning the water supply off at the mains stopcock

b) Turning off the isolation valves to the tap.

2. Remove the handle to reveal the concealed spline adapter.

3. Using a suitable spanner remove the valve from the tap body.

4. Clean the valve and the seating inside the tap body.

5. If necessary replace the valve.

6. Replace the valve into the tap body and tighten fully using a

suitable spanner.

7. Replace handle assembly.

8. Turn on water supply, purge all air and check for leaks.

9. Contact our helpline should if problem persists.

Aerator

Spline Adapter

Valve

Tap Body

Drawings for illustration purposes only

Cleaning Shower Head Holes

To maintain the shower head, particularly in hard water areas, rub the nozzles clean with a damp cloth

to remove any residue or scale from around the tips.

17

Symptom Cause Remedy

No flow or poor flow

rate.

Partially closed stop or service

valve in water supply pipework to

the tap.

Open stop or service valve.

Head of water is below the

minimum distance required.

Refer to the Specification section

for minimum pressures required.

Possible airlock / blockage in

supply pipework

Remove water supplies from the

fitting and flush the system to

remove any airlocks / debris.

Cartridge / Valve not opening

fully.

Service fitting. Refer to

maintenance section on page 10.

Water dripping for a

few seconds after the

tap has been turned

off.

This is caused by ‘capillary

action’ and residual water in the

spout being siphoned out. This

should only last for a couple of

seconds.

Constant dripping /

leaking when the tap is

not in use.

Cartridge / Valve not fully

shutting off.

Service fitting and replace

cartridge / valve. Refer to

maintenance section on page 10.

Fitting does not turn on. Water supplies not turned on. Check that the water supplies to

the fitting are turned on.

Closed stop or service valve. Open stop or service valve.

Water does not come

out of the showerhead

when using the bath

shower mixer.

Diverter mechanism not fully

open.

Open the diverter mechanism

fully by pulling the diverter knob

up.

Insufficient water pressure /

header height.

Refer to the specification section

for minimum pressures required.

Troubleshooting

18

At Twyford, we want to make things as easy as

possible for our customers. That’s why we design

products that are easy to fit and use, and that are

quality tested to make sure they won’t let you down.

It’s also why we offer solid guarantees on all

products, effective from the date of purchase, to

give you peace of mind.

These Twyford taps are covered by a 5 year

guarantee.

Guarantee Terms and Conditions

This guarantee is in addition to your statutory and

other legal rights and is subject to the following

conditions:

• The product was purchased within the United

Kingdom or Republic of Ireland.

• The guarantee applies solely to the original

purchaser with proof of purchase.

• The installation must allow ready access to all

products for the purpose of inspection,

maintenance or replacement.

• Repair under this guarantee does not extend

the original expiry date. The guarantee on any

replacement parts or products ends at the original

expiry date.

• Any part found to be defective during the

guarantee period will be replaced without charge,

providing that the product has been installed in

accordance with the instructions given in this guide

and used as the manufacturer intended.

The guarantee does not cover damage or defects

caused by:

General wear and tear (including special non-

chrome finishes; components such as filters,

• seals, ‘O’ rings and washers)

• incorrect installation

• repair using non-Twyford parts

• accidental or wilful misuse

• corrosion and the use of inappropriate

cleaning products.

• system debris including the build up of

limescale (which can be controlled

through regular servicing and maintenance).

The guarantee does not cover compensation for

loss of use of the product or consequential loss of

any kind.

In the interests of continuous product improvement,

Twyford reserves the right to alter product

specifications without notice.

The Twyford Product Guarantee does not affect

your statutory rights as a consumer.

Need help?

If this product does not function correctly

when first used, contact Twyford Customer

Service on 0844 412 5951 or 01270 871 480

where our expert team of advisors will be

able to offer you help and advice.

Problems during the guarantee period

In the unlikely event that you encounter any

problems with the product during the

guarantee period, contact Twyford Customer

Service on 0844 412 5951 or 01270 871 480 with

your proof of purchase and we will work to resolve

the problem quickly.

Technical support hotline

(Tel: 0844 412 5951) with access to fully trained

advisors who can offer installation advice, talk you

through quick maintenance checks, or recommend

the best course of action to fix any problems with a

product

Contact Us

For any queries please contact us or visit our

website for further information:

Email: customerservice@twyfordbathrooms.com

Website: www.twyfordbathrooms.com

Telephone: 0844 412 5951 or 01270 871 480

Twyford Guarantee

19

Notes

FI (X62 RANGE) – REV. D1

This instruction booklet covers:

X625205CP, X625215CP, X625255CP, X625265CP, X625122CP ,X625126CP, X625135CP

Twyford

Lawton Road

Alsager

Stoke-On-Trent

ST7 2DF

UK

UK Technical Helpline

Telephone: 0844 412 5951

Or 01270 871480

Email: customerservice@twyfordbathrooms.com

Website: www.twyfordbathrooms.com

This manual suits for next models

7

Table of contents

Other Twyford Kitchen & Bath Fixture manuals

Popular Kitchen & Bath Fixture manuals by other brands

Range Master

Range Master Aquatrend TRE1PO instructions

baliv

baliv WA-2520 manual

Sanipex

Sanipex BAGNODESIGN Chiasso BDM-CHS-452 Series installation guide

Lefroy Brooks

Lefroy Brooks X1-1998 Installation, operating, & maintenance instructions

DURAVIT

DURAVIT B.1 Series Instructions for mounting and use

Kraus

Kraus Turino KFD1-24GWH installation manual