0513 IH-1027PAGE 2 OF 11

SAFETY INSTRUCTIONS

GENERAL SAFETY

1. Read the manual and understand all safety

instructions before operating the stapler. If you have

questions, contact Uline at 1-800-295-5510.

2. Never use flammable gases as a power source for

the stapler. Only use filtered, compressed air.

3. Never use gasoline or other flammable liquids to

clean the stapler. Vapors left on the stapler could

ignite and cause the stapler to explode.

4. Do not exceed 110psi of air pressure when

operating the stapler.

5. Disconnect the stapler from the air supply before

making adjustments, cleaning or clearing jams and

when not in use.

6. Do not pull the trigger when carrying or holding the

stapler.

7. Never carry the stapler by the hose or pull on the

hose to move the stapler.

8. Always wear protective equipment; i.e., safety

glasses, hearing protection and head protection.

9. Do not use a check valve or any other fitting which

allows air to remain in the stapler.

10. Do not place your hand or any other body part in

the staple clinching area or adjustment window

when connecting or disconnecting the air supply.

11. Never point the stapler at yourself or anyone else

LUBRICATION & MAINTENANCE

1. Lubricate the stapler prior to initial operation.

2. Disconnect the stapler from the air supply prior to

servicing.

3. Turn the stapler so that the inlet is facing up and put

one drop of high-speed spindle oil, UNOCOL RX22,

or 3-in-1 oil, into air inlet. Never use detergent oil or

additives.

4. Operate the stapler briefly after adding oil.

5. Wipe off excessive oil at the exhaust. Excessive

oil will damage the O-rings. If inline oiler is used,

manual lubrication through the air inlet is not

required on a daily basis.

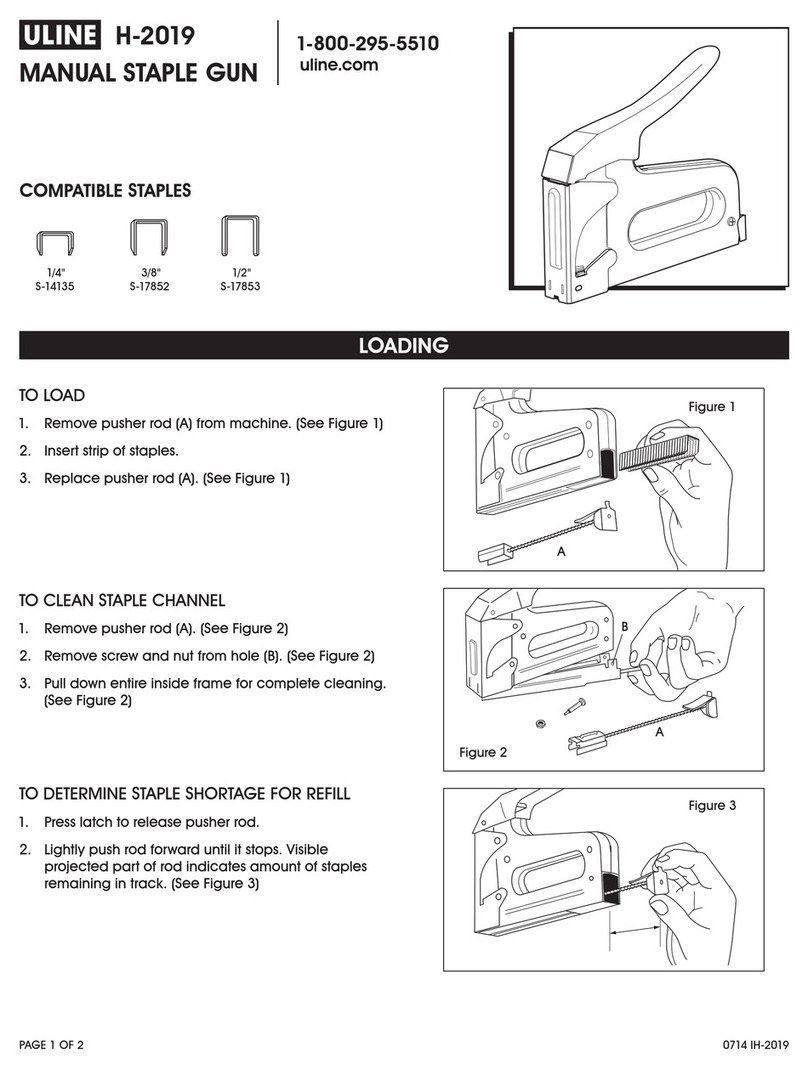

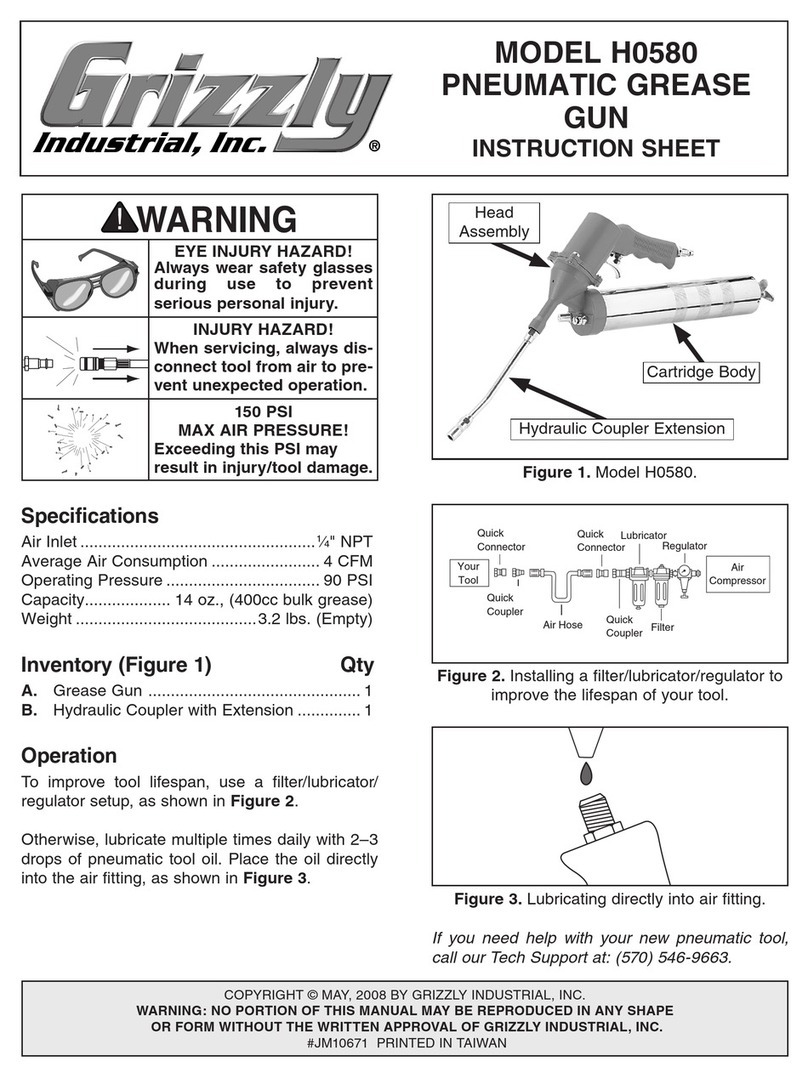

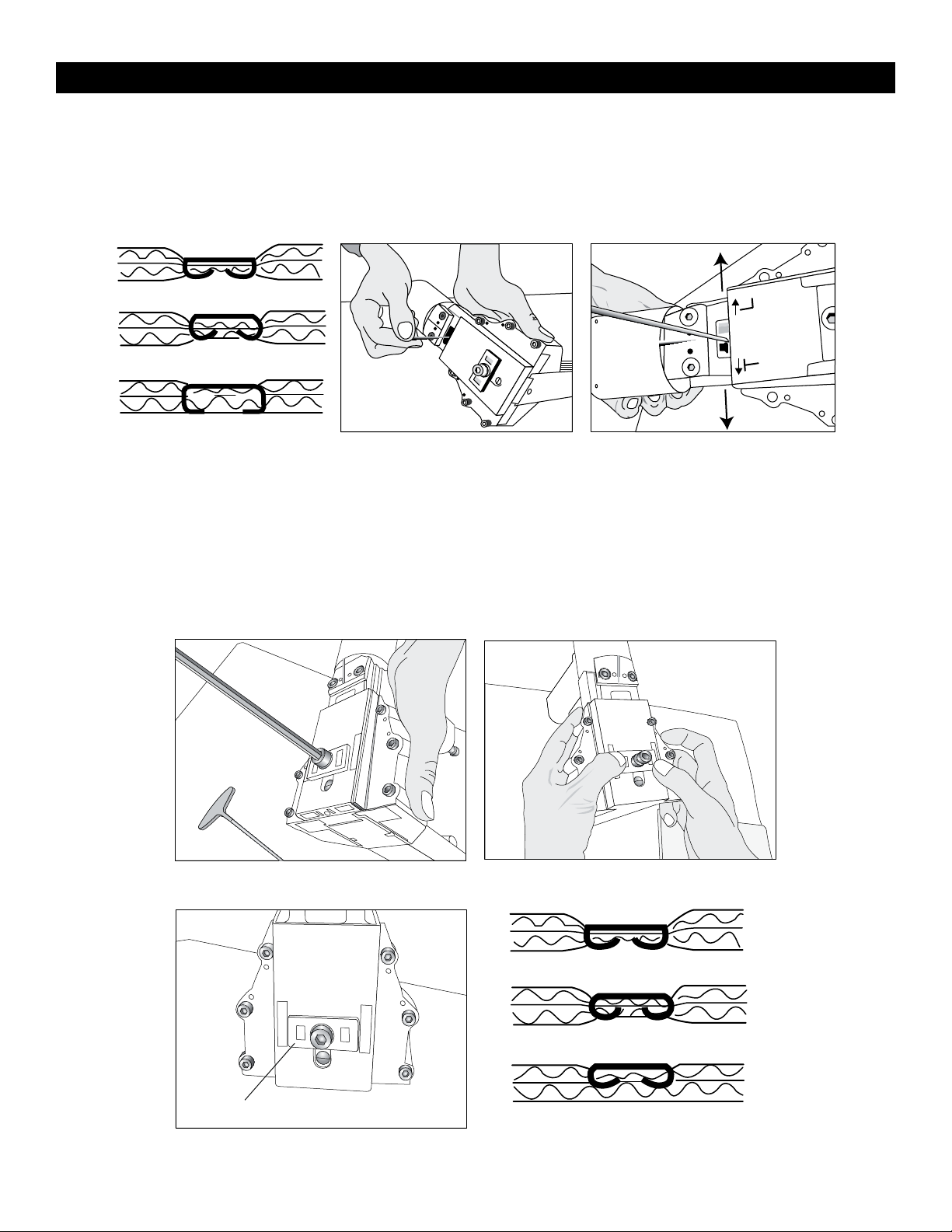

AIR SUPPLY AND CONNECTIONS

NOTE: The following illustration shows the

correct mode of connection to the air supply

system which will increase the efficiency and

life of the stapler.

1. Many air stapler users find it convenient to use an

inline oiler to provide oil circulation through their

stapler. Check oil level in the oiler daily.

2. A filter is recommended on your air compressor.

Check the filter and drain on a daily basis.

Quick

Connector

Quick

Coupler

Air Hose

Connector Oiler

Quick

Coupler

Regulator

Filter

Compressor