UES AG · Breuershofstr. 48 · 47807 Krefeld · Germany

Tel.: 0049-2151-72950 · Fax: 0049-2151-729578 · info@ues-ag.net · www.ues-ag.net

Contents

Introduction....................................................................................................................................................................5

Safety Instructions.........................................................................................................................................................6

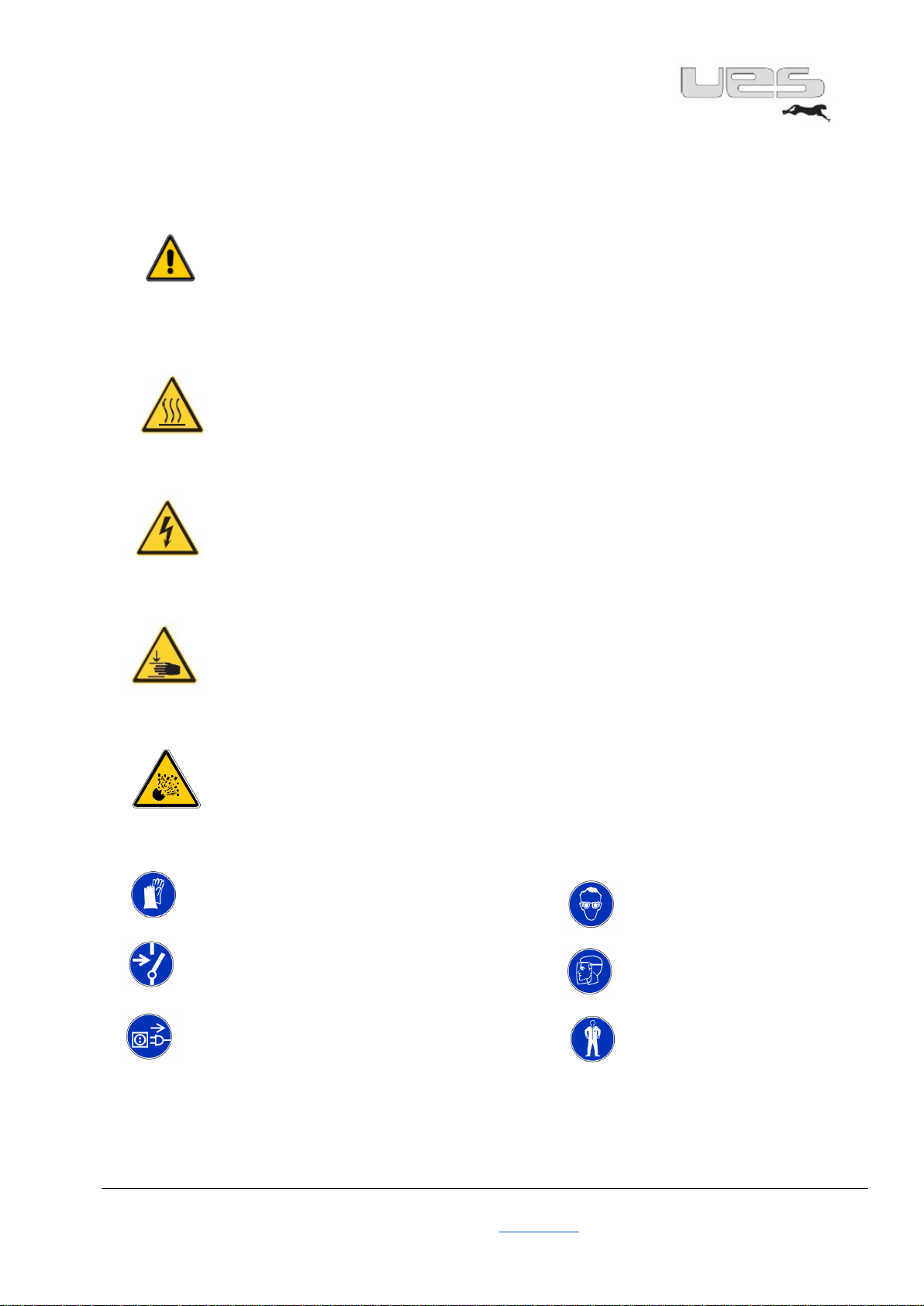

Safety symbols..............................................................................................................................................................8

Example of a hot glue system........................................................................................................................................9

Installation ...................................................................................................................................................................10

Assembly and mounting of the tank system ................................................................................................................10

Connection of the tank system ....................................................................................................................................11

Electrical connection....................................................................................................................................................11

If the perfectMelt/perfectMelt SE is connected to 230 volt the following compulsory .................................12

specifications must strictly be adhered to:...................................................................................................12

Terminal Block X1 control contact...............................................................................................................................13

Air connection..............................................................................................................................................................14

Hose connection..........................................................................................................................................................14

Application head connection........................................................................................................................................15

Service ........................................................................................................................................................................16

Commissioning............................................................................................................................................................18

Setting the pump pressure ..........................................................................................................................................19

Automatic pressure release.........................................................................................................................................19

Individual settings........................................................................................................................................................20

Menu overview ............................................................................................................................................21

Pump ...........................................................................................................................................................21

Options ........................................................................................................................................................22

Service.........................................................................................................................................................23

Format .........................................................................................................................................................25

Timer (time switch)......................................................................................................................................26

Standby (temperature reduction).................................................................................................................................28

Maintenance................................................................................................................................................................29

Position of the sensors of the heating units.................................................................................................30

Position of the sensors of the heating units.................................................................................................31

Bleeding the system....................................................................................................................................................32

Changing the filter .......................................................................................................................................................33

Basic cleaning .............................................................................................................................................................34

Mechanical malfunctions .............................................................................................................................................35

Problems with the glue application..............................................................................................................................35

Socket assignment on UES systems, depending on the model...................................................................................36

perfectMelt replacement parts....................................................................................................................................37

Recycling.....................................................................................................................................................................38

Mains connection.........................................................................................................................................................39

Connecting digital outputs ...........................................................................................................................................39

Connecting digital inputs .............................................................................................................................................39

Fuses...........................................................................................................................................................................40

Pump connection.........................................................................................................................................................40