UES AG · Breuerhofstr. 48 · 4 80 Krefeld

ag.net

Contents

ContentsContents

Contents

Introduction ............................................................................................................................................. 3

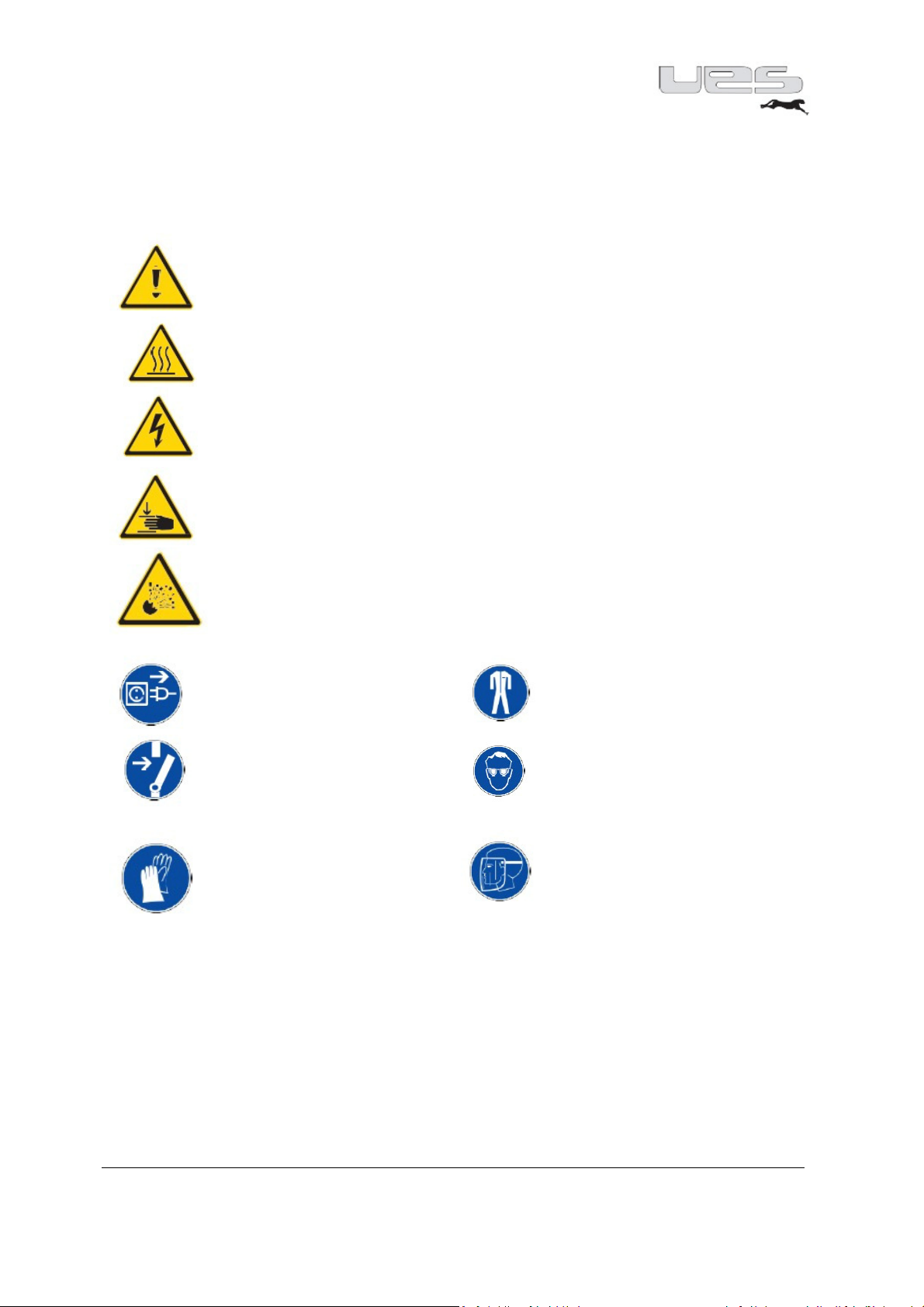

Safety Instructions ................................................................................................................................... 4

Example of a hot glue system .................................................................................................................. 6

Installation ............................................................................................................................................... 8

Checking the components ................................................................................................................... 8

Assembly and mounting of the tank system ....................................................................................... 8

Connection of the tank system ............................................................................................................... 9

Electrical connection ........................................................................................................................... 9

Air connection ..................................................................................................................................... 9

Hose connection .................................................................................................................................. 9

Application head connection............................................................................................................. 10

Add glue ............................................................................................................................................. 10

Service ................................................................................................................................................... 11

Commissioning .................................................................................................................................. 13

Setting the pump pressure ................................................................................................................ 14

Automatic pressure release .............................................................................................................. 14

Individual settings ............................................................................................................................. 15

Menu overview .................................................................................................................................. 16

Pump: ................................................................................................................................................ 16

Options: ............................................................................................................................................. 1

Service: .............................................................................................................................................. 18

Format: .............................................................................................................................................. 19

Standby (temperature reduction) ..................................................................................................... 20

Maintenance ......................................................................................................................................... 21

Bleeding the system .............................................................................................................................. 22

Changing the filter ................................................................................................................................. 23

Basic cleaning ........................................................................................................................................ 24

Mechanical malfunctions ...................................................................................................................... 25

Problems with the glue application....................................................................................................... 25

Socket assignment on UES systems, depending on the model ............................................................. 26

perfectMelt Replacement parts ............................................................................................................ 2

Recycling ................................................................................................................................................ 28

Electrical connections ............................................................................................................................ 29

Fuses ...................................................................................................................................................... 31

Technical data ....................................................................................................................................... 32

Electrical data ........................................................................................................................................ 34

Connection scheme ............................................................................................................................... 46