UGIN DENTAIRE 1

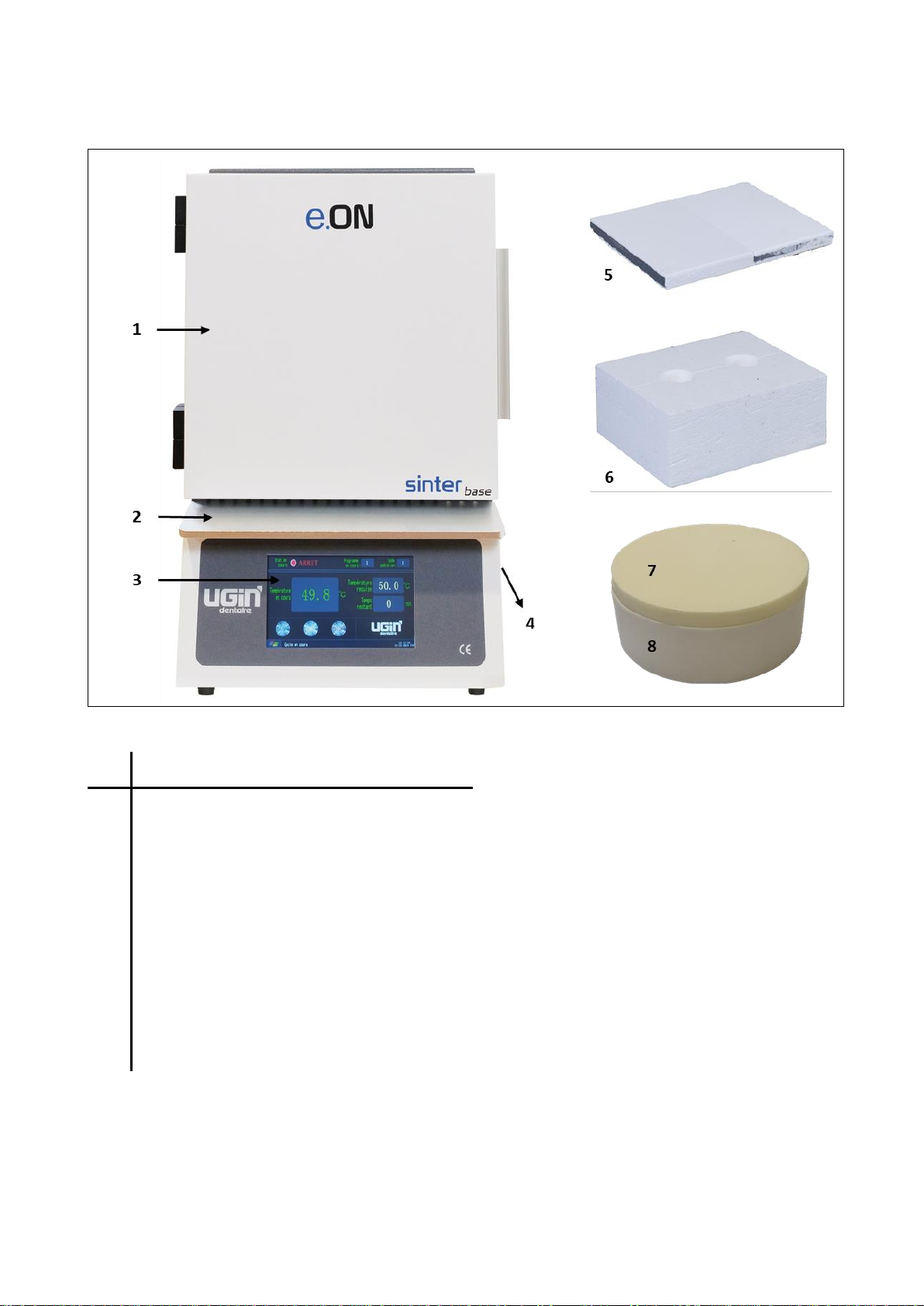

e.ON sinter base

A. EQUIPEMENT DESCRIPTION .................................................................................................................2

B. WIRING DIAGRAM ................................................................................................................................3

C. INSTRUCTIONS FOR USE .......................................................................................................................4

1. SAFETY INSTRUCTIONS ........................................................................................................................4

1.1. USE .................................................................................................................................................4

1.2. SAFETY INSTRUCTIONS ...................................................................................................................4

1.3. WASTE DISPOSAL............................................................................................................................6

2. EC DECLARATION OF CONFORMITY.....................................................................................................6

3. TECHNICAL INFORMATION ..................................................................................................................7

3.1. TECHNICAL DATA............................................................................................................................7

3.2. CONDITIONS OF USE, TRANSPORT AND STORAGE .........................................................................8

3.3. ACCESSORIES ..................................................................................................................................8

4. INSTALLATION......................................................................................................................................9

4.1. UNPACK ..........................................................................................................................................9

4.2. INSTALLATION ................................................................................................................................9

4.3. BEFORE START-UP ..........................................................................................................................9

5. START-UP...........................................................................................................................................10

6. USE AND CONFIGURATION................................................................................................................11

6.1. WORKING INTERFACE...................................................................................................................11

6.2. CONTROL KEYS..............................................................................................................................11

6.3. REAL-TIME CURVE (CURRENT CYCLE) ...........................................................................................11

6.4. INTERFACE PROGRAM EDITOR .....................................................................................................12

6.4.1. CHANGE SETTINGS........................................................................................................................12

6.4.2. PROGRAMMING INSTRUCTIONS...................................................................................................13

6.4.2.1. EXAMPLES OF CALCULATION ................................................................................................14

6.5. PARAMETER SETTING ...................................................................................................................14

6.6. PROGRAMS...................................................................................................................................15

6.6.1. PROGRAM PRE-RECORDERED No. 1 .............................................................................................15

6.6.2. PROGRAM PRE-RECORDERED No. 40 –DECONTAMINATION PROGRAM.....................................15

6.7. POSITIONING THE ELEMENTS AND STARTING THE CYCLE ............................................................16

6.7.1. POSITIONING OF ELEMENTS AND TRAY FOR SINTERIZING ...........................................................16

6.7.2. CLOSING THE CHAMBER...............................................................................................................17

6.7.3. CLOSING THE PLATFORM AND START CYCLE ................................................................................17

7. ADVICES - PRECAUTIONS FOR USE.....................................................................................................18

8. MAINTENANCE ..................................................................................................................................20

8.1. HEATING ELEMENT REPLACEMENT ..............................................................................................21

8.2. TROUBLE-SHOOTING ....................................................................................................................22

Non-contractual visual

Translation into English from original in French