035-18550-001-A-0902

2Unitary Products Group

TABLE OF CONTENTS

NOMENCLATURE. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . 4

REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

AGENCY APPROVALS. . . . . . . . . . . . . . . . . . . . . . . 4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LIMITATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ROOF-TOP LOCATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

GROUND LEVEL LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . .6

RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . . .6

CLEARANCES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

COMPRESSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

COMPRESSOR CRANKCASE HEATER. . . . . . . . . . . . . . . . . .9

POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . . .9

POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PHASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

WIRE SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

REFRIGERANT PIPING . . . . . . . . . . . . . . . . . . . . . . . . .11

GENERAL GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

LINE SIZING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SERVICE VALVES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

EXTENDING THE SERVICE PORTS . . . . . . . . . . . . . . .13

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

EVACUATING AND CHARGING. . . . . . . . . . . . . . . . . . .15

ALTERNATE CHARGING METHODS . . . . . . . . . . . . . . . . . . .16

BALANCE POINT SETTING . . . . . . . . . . . . . . . . . . . . . .16

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CRANKCASE HEATER. . . . . . . . . . . . . . . . . . . . . . . . . .17

PRE-START CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

INITIAL START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PHASING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SYSTEM SEQUENCE OF OPERATION. . . . . . . . . . . . . 18

COOLING OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HEATING OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

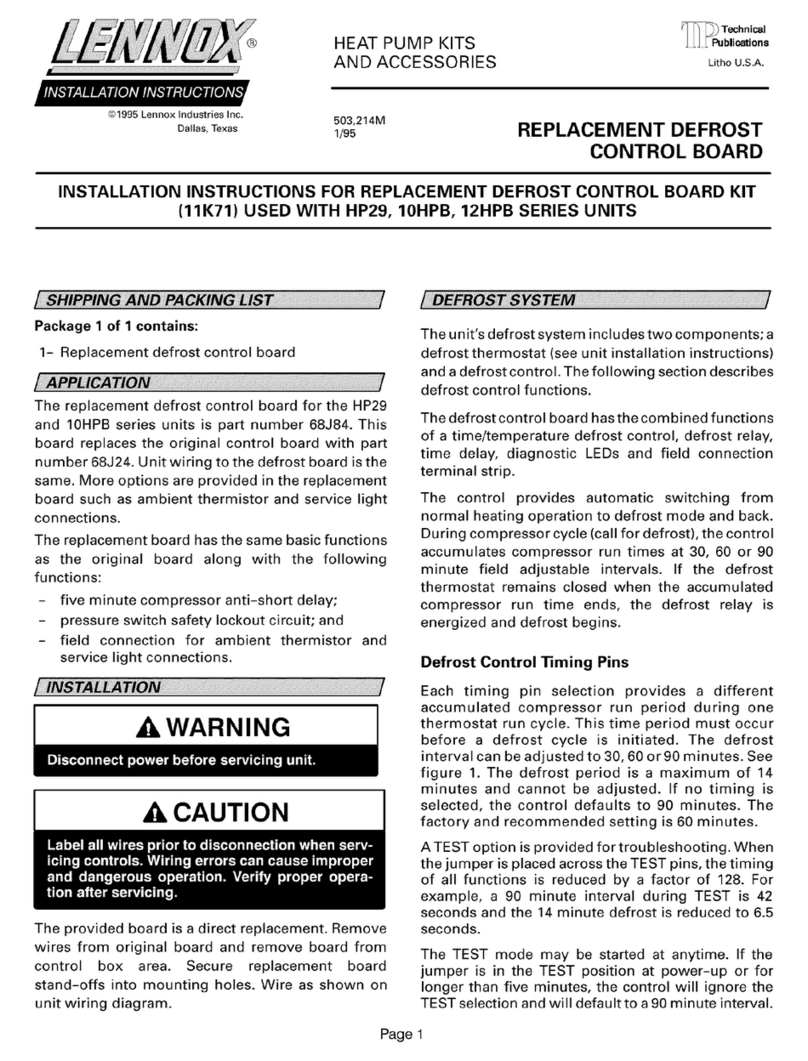

DEFROST CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

OPERATION BELOW 0ºF OUTDOOR TEMPERATURE. . . . 20

EMERGENCY HEAT OPERATION . . . . . . . . . . . . . . . . . . . . 20

SAFETY FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SECURE OWNER’S APPROVAL . . . . . . . . . . . . . . . . . . 21

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

REPLACEMENT PARTS. . . . . . . . . . . . . . . . . . . . . . . . . 21

NOTICE TO OWNER . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LIST OF FIGURES

Fig. # Pg. #

1 CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . . . . . . 6

2 TYPICAL RIGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 POINT LOADS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

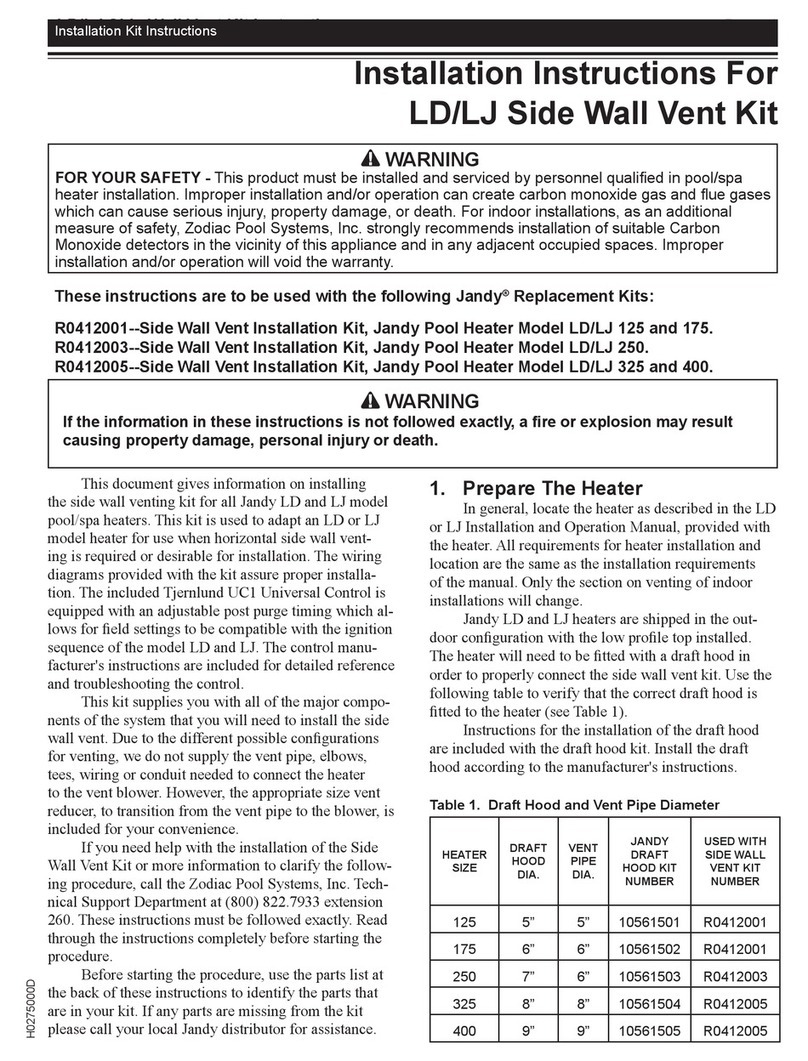

4 UNIT DIMENSIONS AND CLEARANCES. . . . . . . . . . 8

5 TYPICAL FIELD WIRING . . . . . . . . . . . . . . . . . . . . . 10

6 FIELD PIPING DIAGRAMS . . . . . . . . . . . . . . . . . . . . 12

7 EXTENDING THE SERVICE PORTS . . . . . . . . . . . . 15

8 REFRIGERANT FLOW DIAGRAM . . . . . . . . . . . . . . 15

9 CHARGING CURVE EF-10

(COOLING MODE) . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LIST OF TABLES

Tbl. # Pg. #

1 PHYSICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 UNIT APPLICATION DATA. . . . . . . . . . . . . . . . . . . . . 5

3 ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 LIQUID LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 VAPOR LINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 REFRIGERANT LINE CHARGE . . . . . . . . . . . . . . . . 12