Unitrol SOFT TOUCH 9381-34WDS/115 User manual

1

SOFT TOUCH for NON-UNITROL

FREQUENCY CONVERTER CONTROLS

9381-34WDS/115, 9381-34WDS/24DC

9381-34YDS/115, 9381-34YDS/24DC

UNITROL ELECTRONICS, INC.

702 LANDWEHR ROAD

NORTHBROOK, IL 60062

847-480-0115

techsupport@unitrol-electronics.com

2

3

Thank you for purchasing this Unitrol SOFT

TOUCH system. It is designed to protect your

resistance welder operator from serious elec-

trode pinch point injury.

Having trouble or need answers to your ques-

tions? Unitrol supplies free phone support for

the life of this and all our products.

You can contact us:

By Phone:

Monday - Friday 9:00 - 5:00 CT: 847-480-0115.

By Email:

techsupport@unitrol-electronics.com

By Regular Mail:

Unitrol Electronics, Inc.

Technical Support

702 Landwehr Road

Northbrook, Illinois 60062

4

MODEL NUMBER AND OPTIONS AS CHECKED BELOW

SERIAL NUMBER:

MODEL TYPE VALVE

VOLTAGE

OPTIONS

9181-34BPA

Timed bypass. Includes security lock selec-

tor switch, 2 = LED indicator lights, face-

plate. Closes electrodes under low force,

delays, and brings electrodes to welding

force.

9381-34JB3/PMCO

SOFT TOUCH protecon for the RETRACT

stroke. Supplied to operate PMCO welders

with “li” cylinders. Includes RAM POSI-

TION proximity switch and mounng

bracket

kit. Requires addional eld bracketry to

match welder

9381-34JB3

SOFT TOUCH protecon for RETRACT

stroke on standard cylinders that use for-

ward

pressure to go out of RETRACT. Includes

proximity switch and mounng bracket kit.

Requires addional eld bracketry to

match welder

9381-34F2 FORGE DELAY funcon that connects to

exisng Back Pressure (Bucking Pressure)

regulator.

9181-34LSB

Limit Switch. Allows use of a ram position

or continuity. Includes security lock selec-

tor switch, 2 = LED indicator lights, face-

plate. Does NOT include a proximity switch

or mounting bracket kit. Use with custom-

er-supplied PNP proximity switch.

9181-34LSC

Limit Switch used as a redundancy with

continuity. Always in operation and not

keylock selected. Includes RAM POSITON

proximity switch and mounting bracket kit.

May require additional field bracketry to

match welder. Can be turned off by mov-

ing a jumper on the control board .

9381-34WDS/115 CYLINDER OR DIAPHRAGM

HEAVY WEIGHT RAM 115AC

9381-34WDS/24DC CYLINDER OR DIAPHRAGM

HEAVY WEIGHT RAM 24DC

9381-34YDS/115 CYLINDER OR DIAPHRAGM

LIGHT WEIGHT RAM 115AC

9381-34YDS/24DC CYLINDER OR DIAPHRAGM

LIGHT WEIGHT RAM 24DC

5

WARRANTY

Unitrol Electronics provides a 5-year limited warranty to cover all of this SOFT TOUCH sys-

tem. The warranty periods are determined using the date the new control was originally

shipped from Unitrol Electronics. All warranty coverage is FOB Northbrook. Illinois.

This warranty, except for exclusions shown herein covers the following items:

DURING YEAR #1: All parts (exclusive of fuses) that fail due to manufacturing defects.

Necessary labor to repair control that has failed due to manufacturing defects.

DURING YEAR #2: 80% cost of all parts (exclusive of fuses).

80% cost of necessary labor to repair control that has failed due to manufacturing defects.

DURING YEAR #3: 60% cost of all parts (exclusive of fuses).

60% cost of necessary labor to repair control that has failed due to manufacturing defects.

DURING YEAR #4: 40% cost of all parts (exclusive of fuses).

40% cost of necessary labor to repair control that has failed due to manufacturing defects.

DURING YEAR #5:

20% cost of all parts (exclusive of fuses).

20% cost of necessary labor to repair control that has failed due to manufacturing defects.

EXCLUSIONS TO WARRANTY

Any expense involved with repair of control by other than Unitrol Electronics personnel that

has not been authorized in advance and in writing by an officer of Unitrol Electronics.

All costs for freight, to and from Unitrol Electronics, are excluded from this warranty

All field service labor, travel expense, and field living expenses associated with field service

are excluded from this warranty.

No coverage, parts or labor, is offered for components that have failed on control not being

used as specified in Unitrol Electronics published literature, technical sheets, and this direction

book.

No warranty coverage will be made on controls that are being used contrary to specifications,

that were mechanically or electronically altered by customer or installer, or that were physical-

ly damaged after shipment from Unitrol Electronics.

Damages to a control by lightning, flood, or mechanical damage are excluded from this war-

ranty.

Unitrol Electronics assumes no liability for damage to other equipment or injury to personnel

due to a failure in the Unitrol Electronics control.

Unitrol Electronics shall not be responsible for any consequential damages of whatever kind.

Expenses involving alteration or installation of a Unitrol Electronics control are not covered in

this warranty.

NO OTHER UNITROL ELECTRONICS INC. WARRANTY, WRITTEN OR

IMPLIED, COVERS THIS CONTROL UNLESS IN WRITING AND SIGNED

BY AN OFFICER OF UNITROL ELECTRONICS, INC. PRIOR TO SHIP-

MENT OF PRODUCT.

6

TABLE OF CONTENTS

1VERIFY YOUR SOFT TOUCH SENSOR BOARD IS CORRECT

2HOW SYSTEM OPERATES

3INSTALLATION, 9181-34W HEAVY WEIGHT SERIES

4INSTALLATION OF SCR DRIVER BOARD

5CONNECTING SCR FIRING CABLE

5CONNECTING CONTROL CABLE

6WIRING CONTROL

7INSTALLING SECONDARY CURRENT PICKUP COIL

8CONTROL CABLE WIRING CHART

9HOOKUP FOR 9381-34WDS/115, 9381-34YDS/115

10 HOOKUP FOR 9381-34WDS/24DC, 9381-34YDS/24DC

11 RETRACT OPTION 9381-34JB3/PMCO

13 RETRACT OPTION 9181-34JB3

15 TIMED DELAY OPTION 9181-34BP

16 DEPTH SWITCH OPTION, 9181-34LSA, 9181-34LSB

18 DEPTH SWITCH OPTION 9181-34LSC

19 PNEUMATIC HOOKUP, 9181-34Y LIGHT WEIGHT

20 PNEUMATIC HOOKUP, 9181-34W HEAVY WEIGHT

21 ADJUSTING SOFT TOUCH VALVES

22 SETTING MAXIMUM DETECT TIME SWITCHES, BLANK TIME

23 SETTING AND TESTING ELECTRODE CLOSING FORCE

24 SETTING SYSTEM READING SENSITIVITY

25 START-UP PROCEDURE

26 TROUBLE SHOOTING CHART

29 SETTING SYSTEM READING SENSITIVITY

27 BUCKING PRESSURE OPTION 9181-34F2

28 LED INDICATOR LIGHTS

1

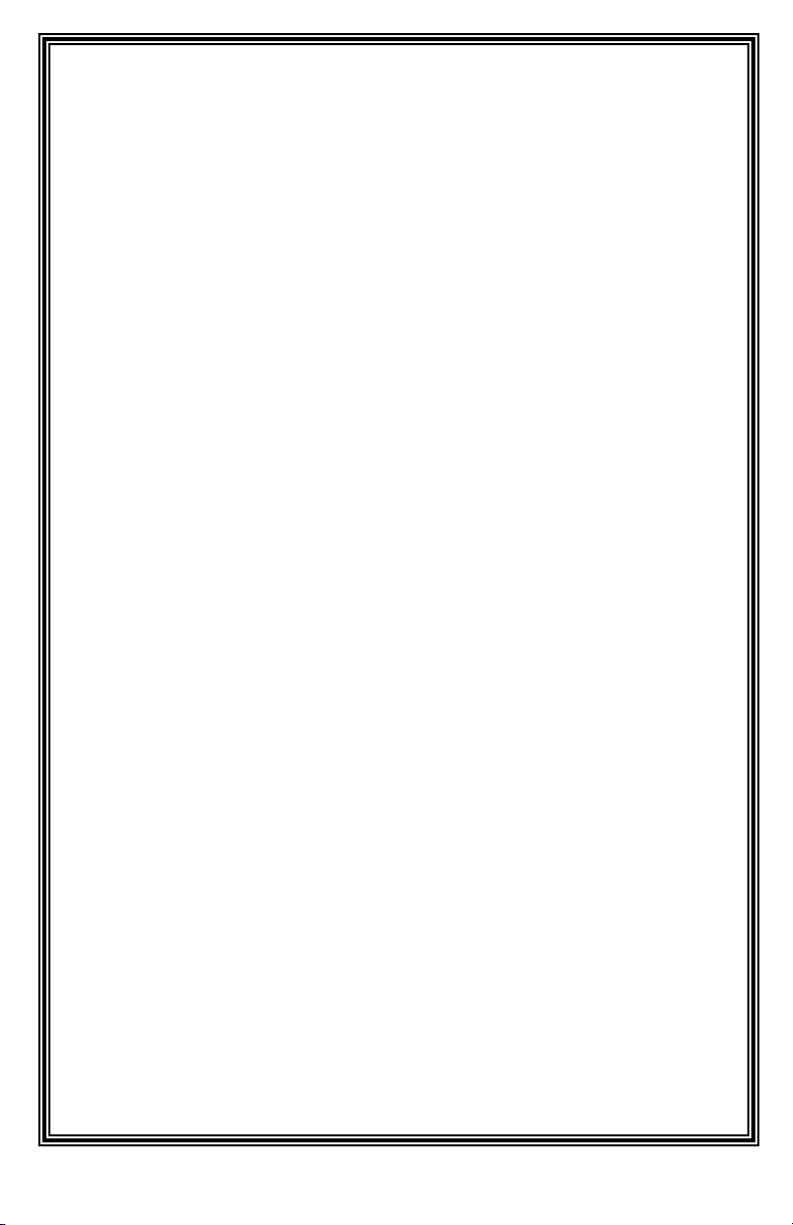

VERIFY YOUR SOFT TOUCH SENSOR BOARD IS CORRECT

The SOFT TOUCH sensor board can be configured in several ways. Before

turning power on, check to be sure that the mode and valve voltage matches

your welder.

1. TYPE OF WELDING CONTROL. This board can be set to operate various

types of welders. For a Frequency Converter welder, set the four side switches

to the positions shown below.

FOR 115VAC FOR 24VDC

SOLENOID VALVES SOLENOID VALVES

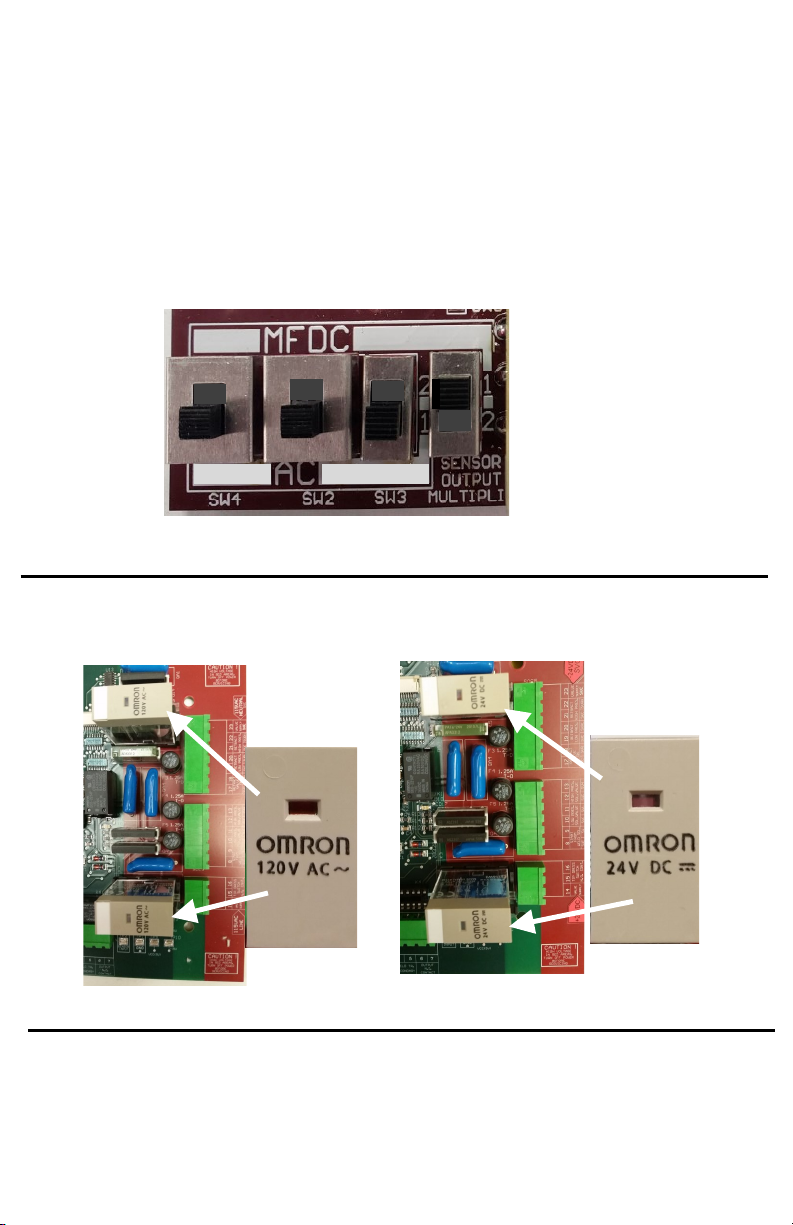

2. SOLENOID VALVE VOLTAGE. Be sure that the two tall relays, K2 and K3,

show the same voltage on the top printing as the solenoid voltage of your

welding control. If they are not correct, contact Unitrol to swap relays.

2

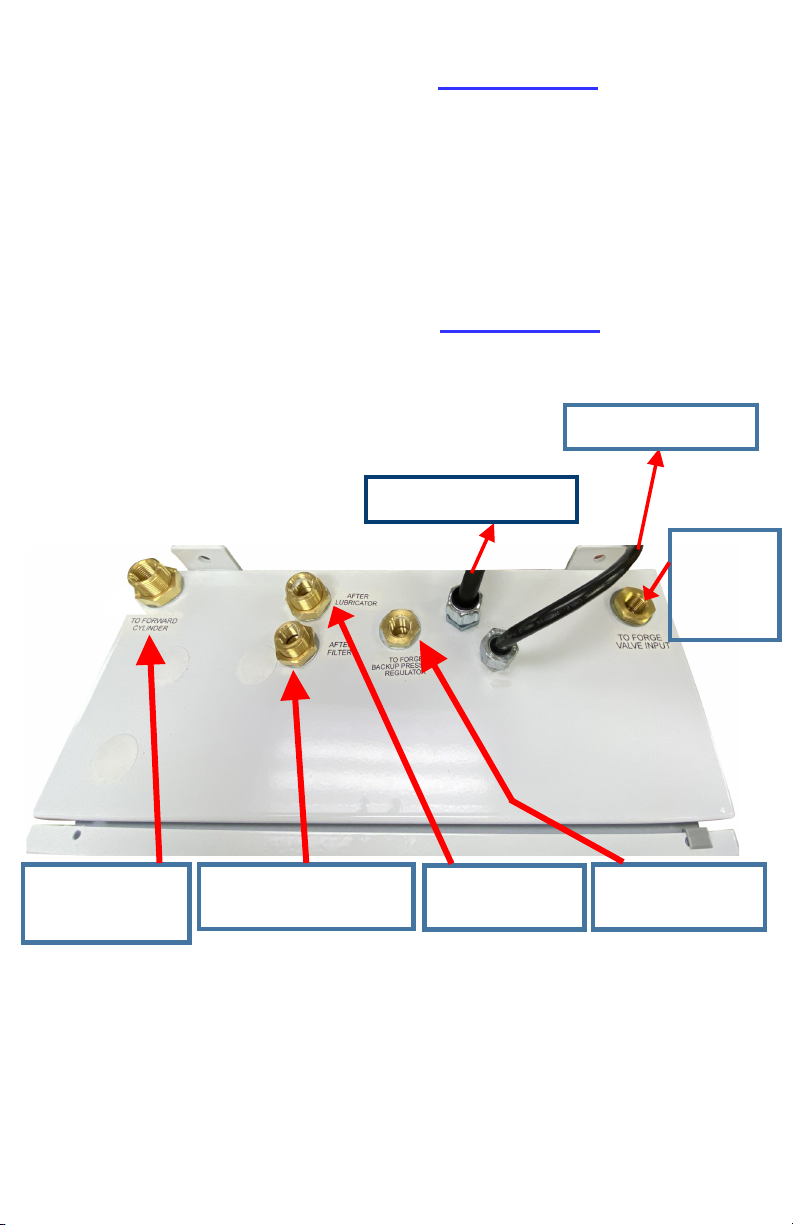

INSTALLATION

Note that this system REPLACES the

existing weld solenoid valve.

1. Mount the control in a convenient location using the four mounting tabs on

the back of the box.

2. Remove hoses from the existing welding solenoid valve. This solenoid valve

will not be used with this this control.

3. Connect hoses from the control to the air cylinder as shown in the photo be-

low.

HOSE CONNECTION FOR 9181-34W SERIES CONTROL

Note that this system REPLACES the

existing weld solenoid valve.

Connect to point

aer airline oiler

(weld pressure)

Connect to diaphragm

or air cylinder port that

opens the electrodes.

Connect to point between air

lter/water trap and input to

welding pressure regulator

Connect to diaphragm

or air cylinder port

that closes the elec-

trodes.

TOP OF CABINET

INSTALL FILTERS ON

BOTTOM OF CABINET

TO EXISTING

RETRACT

VALVE INPUT

FOR

9381-34JB

OPTIONS

TO SCR CONTACTORS

TO WELDING CONTROL

3

HOW THE SYSTEM OPERATES

When the solenoid valve output from the welding control

goes HIGH, this voltage goes to the 9280-TS7 SOFT TOUCH de-

tecon board, terminal #9.

The output terminal #11 (SVL) goes HIGH to turn on solenoid

valve SVL . This closes the electrodes under low force.

Relay K2 iniates the SIMPLICITY control on

the door of the cabinet.

Aer the me set on the TRACE DELAY TIME pushwheels (25

cycles is a good starng me), the SIMPLICITY control starts to

re the new SCR contactor into one primary winding of the

welder transformer connuously at very low heat as set on

the TRACE % pushwheels. 1% is normally a good seng. Note

that this delay allows enough me for the electrodes to close

before starng the ow of current to eliminate sparking.

If the electrodes touch the metal being welded, current will

now ow in the welder’s secondary loop and is detected by

the Rogowski secondary current pickup coil connected to the

9280-TS7 board. This will

1. Turn on SVH to put the welding pressure air on the top of

the welder’s diaphragm or cylinder. At the same me, it

starts a me delay of about 0.1 seconds and then turns on

solenoid SVF that switches pressure on the underside of

the diaphragm or piston to back-up pressure.

2. Energizes relay K1 to stop the SIMPLICITY control from r-

ing the SCR contactor.

3. Close the output relay connected to terminals 6-7 on the

9180-TS7 board to close the second stage or pressure

switch input on the welding control to start the welding

procedure.

SOFT TOUCH PINCH POINT

PROTECTION SYSTEM

FOR INSTALLATION ON NON-UNITROL

3Ø FREQUENCY CONVERTER CONTROLS

4

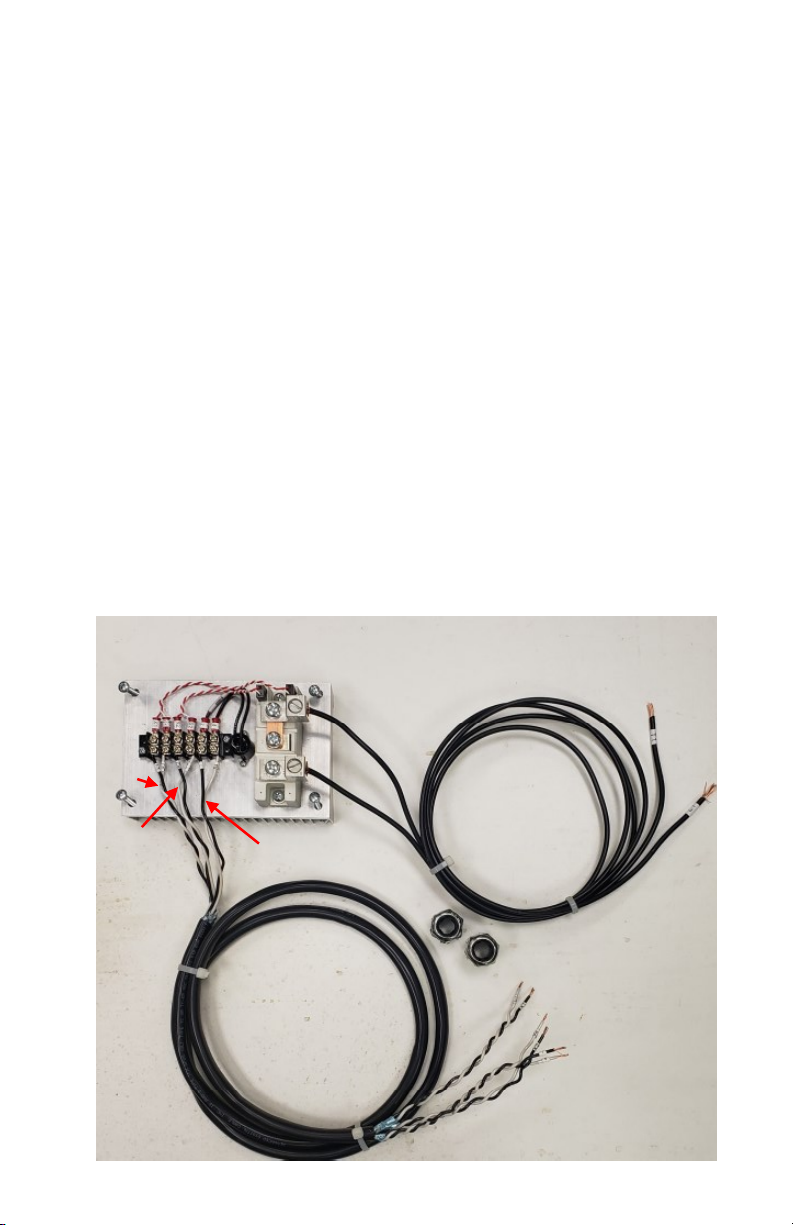

INSTALLATION OF SCR DRIVER BOARD

This SOFT TOUCH system is supplied with a separate aluminum heat sink with a

high-voltage SCR contactor installed. The SCR contactor is used to drive the

transformer windings operated by exisng SCR-A during the SOFT TOUCH inial

sequence to produce a TRACE signal as explained on page 3.

Mount this panel, using the screws and nuts provided, in a convenient locaon

inside the welder’s enclosure that houses the three SCR contactors . Locate the

panel as close to the SCR contactor as praccal. Wire it per direcons on page 6.

Drill a 7/8” diameter (1/2” knockout) hole in the welding control cabinet and in-

stall one of the strain relief ngs in this kit with the nut inside the enclosure.

Push the 6-wire cable through this strain relief and ghten the nut. Route the

other end of this cable to the SOFT TOUCH enclosure and install it using the sec-

ond strain relief ng.

Connect G1/K1 and G2/K2 to these terminals on the SIMPLICITY control.

Connect the third pair to terminals 5 and 6 on the SIMPLICITY control.

CRITICAL: If cable is shortened, check the pairs by looking on

the white wire in each twisted pair for the pair number (1 one,

2 two, 3 three). Double check by verifying connuity on each

pair. Serious damage can occur if the wires are connected to

the wrong terminals.

4

CABLE PAIR 1

CABLE PAIR 2

CABLE PAIR 3

This manual suits for next models

3

Table of contents

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual