Unverferth UM410 User manual

Grain

Handling

Digi-Star Scales

Installation and Parts

Models UM410 & UM520

Scale Serial #40000 and Higher

Part No. 266900

Scales - Models 410 and 520 — Introduction

2

Foreword

This symbol identifies important safety messages. When you see it, read the message that

follows and be alert to the possibility of personal injury.

Remember, safety instructions stated in this manual are for your protection. Read them care fully

and follow them closely when working around or using this machine.

Read and study this manual completely before attempting to operate this implement. Take

this manual to the field for handy reference when operating, adjusting, or servicing your

machine.

When referenced, “Right-Hand” (RH) and “Left-Hand” (LH) side of the machine are determined

by standing behind the machine and facing in the direction of travel.

Scales - Models 410 and 520 — Introduction

3

Product Information

When ordering parts or when requesting further information or assistance, always give the fol-

lowing information:

• Machine name

• Model number

• Serial number

• Axle Type

• Tire Size

All products manufactured by Unverferth Mfg. Co., Inc. are warranted to be free from material

and workmanship

defects for one full year from time of consumer delivery. Your local dealer will

gladly assist you with any warranty questions.

Please fill out and retain this portion for your records.

Purchase Date _____________Model _________________Serial No._______________________________

Dealer ____________________________________ City ____________________________________________

Dealer Contact _______________________________ Phone ______________________________________

• Theinformation,specifications,andillustrationsinthemanualarebasedoninformationavailable

at the time it was written. Due to continuing improvements in the design and manufacture of

Unverferth products, all specifications and information contained herein are subject to change

without notice.

Scales - Models 410 and 520 — Introduction

4

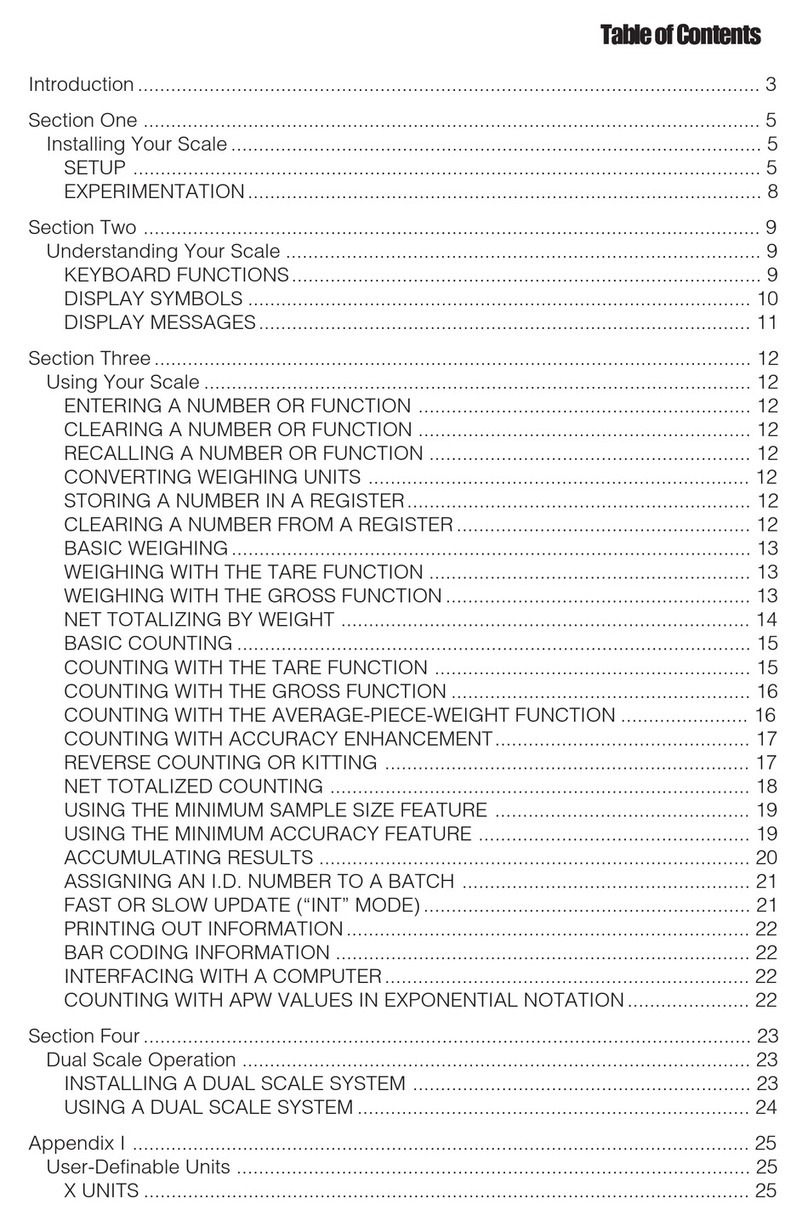

Table of Contents

Section I

Safety

General Hazard Information ............................................................................................................ 1-2

Following Safety Instructions .......................................................................................................... 1-3

Before Servicing.............................................................................................................................. 1-3

Before Operating ............................................................................................................................. 1-3

During Operation ............................................................................................................................. 1-4

Preparing for Emergencies.............................................................................................................. 1-4

Wearing Protective Equipment ........................................................................................................ 1-4

Section II

Set Up

General Set Up Instructions....................................................................................................... 2-3

Scale Kit Installation

J-Block Installation - All Models ........................................................................................ 2-4

Scale Indicator Installation - All Models ............................................................................ 2-5

3-Point Scales with Spindles .............................................................................................. 2-6

Hitch Assembly.............................................................................................................. 2-6

Axle Load Cell Installation............................................................................................ 2-8

3-Point Scales wtih Compression Cells .............................................................................. 2-9

Hitch Assembly.............................................................................................................. 2-9

Axle Load Cell Installation.......................................................................................... 2-10

Axle Load Cell and Riser Installation......................................................................... 2-12

5-Point Scales Tandems.................................................................................................... 2-14

Hitch Assembly............................................................................................................ 2-17

Axle Load Cell Installation.......................................................................................... 2-18

5-Point Scales Tracks........................................................................................................ 2-19

Layout for Models with Track .................................................................................... 2-19

Hitch Assembly............................................................................................................ 2-20

Axle Load Cell Installation.......................................................................................... 2-21

5-Point Single Tires........................................................................................................... 2-22

Hitch Assembly............................................................................................................ 2-23

Axle Load Cell Installation.......................................................................................... 2-24

Power Connection ....................................................................................................... 2-25

Load Cell Connection ........................................................................................................ 2-26

Scales - Models 410 and 520 — Introduction

5

Table of Contents

Section II

Set Up

Routing Scale Cables - Models with Walking Tandems ......................................................... 2-27

Rotational Sensor Mounting Instructions - UM520 Auto-Log Scale

Single-Auger Grain Carts................................................................................................ 2-30

Brent Models: 782, 882, 1082, 1182, 1186, 1282, 1386, V700, V800, V1000,

V1100, V1300, V1500

Unverferth Models: 760, 860, 1015, 1017, 1019, 1050, 1060, 1115, 1117, 1119,

1160, 1315, 1317, 1319, 1519, 7250, 8250, 9250

Killbros Models: 735, 835, 1035, 1135

Parker Models: 742, 842, 1042, 1142

Double-Auger Grain Carts

Models 1110, 1310, 1196, 1396, 1596, 2096 -

Serial Number B34930099 and Lower................................................................. 2-33

Models All Double-Auger Grain Carts -

Serial Number B34930100 and Higher ................................................................ 2-35

Section III

Operation & Maintenance

Wheel, Hub and Spindle Disassembly and Assembly.................................................................... 3-2

Scale Calibration and Set Up Number Charts UM410 & UM520 ................................................. 3-4

Scale Calibration and Set Up UM410 ............................................................................................ 3-9

Scale Calibration and Set Up UM520 ............................................................................................ 3-12

Downloader Module (Optional) ........................................................................................................ 3-12

Scale Kit Operation......................................................................................................................... 3-13

Scale “Short Form” Set Up & Calibration

Unverferth 410 Indicator .......................................................................................................... 3-14

Unverferth 520 Indicator .......................................................................................................... 3-16

Scale Troubleshooting...................................................................................................................... 3-17

Scales - Models 410 and 520 — Introduction

6

Table of Contents

Section IV

Parts

SCALE PACKAGE PARTS

3-Point Scales Spindles............................................................................................................. 4-6

Single Tires with 3-Point Scales Compression Cells .............................................................. 4-14

Walking Tandem/Steerable Tandems/In-Line Tandems 5-Point Scales .................................... 4-18

Tracks with 5-Point Scales...................................................................................................... 4-22

Single Tires 5-Point Scales ..................................................................................................... 4-28

Rotational Sensor Mounting Kit For UM520 Scale ................................................................. 4-32

Scales - Models 410 and 520 — Safety

1-1

Section I

Safety

General Hazard Information ............................................................................................................ 1-2

Following Safety Instructions .......................................................................................................... 1-3

Before Servicing.............................................................................................................................. 1-3

Before Operating ............................................................................................................................. 1-3

During Operation ............................................................................................................................. 1-4

Preparing for Emergencies.............................................................................................................. 1-4

Wearing Protective Equipment ........................................................................................................ 1-4

Scales - Models 410 and 520 — Safety

1-2

General Hazard Information

No accident-prevention program can be successful without the wholehearted cooperation of the

person who is directly responsible for the operation of the equipment.

A large number of accidents can be prevented only by the operator anticipating the result before

the accident is caused and doing something about it. No power-driven equipment, whether it

be transportation or processing, whether it be on the highway, in the field, or in the industrial

plant, can be safer than the person who is at the controls. If accidents are to be prevented-

-and they can be prevented--it will be done by the operators who accept the full measure of

their responsibility.

It is true that the designer, the manufacturer, and the safety engineer can help; and they will help,

but their combined efforts can be wiped out by a single careless act of the operator.

It is said that, “the best kind of a safety device is a careful operator.” We, at Unverferth Mfg.

Co., Inc. ask that you be that kind of operator.

REMEMBER:

THINK SAFETY

A CAREFUL OPERATOR IS THE

BEST INSURANCE AGAINST AN

ACCIDENT!

SIGNAL WORDS

INDICATES AN EXTREMELY HAZARDOUS SITUATION OR ACTION THAT WILL RESULT IN

SERIOUS INJURY OR DEATH.

INDICATES A HAZARDOUS SITUATION OR ACTION THAT COULD RESULT IN SERIOUS IN-

JURY OR DEATH.

INDICATES AN UNSAFE SITUATION OR ACTION THAT MAY RESULT IN PERSONAL INJURY.

Is used for instruction on operating, adjusting, or servicing a machine.

Scales - Models 410 and 520 — Safety

1-3

Following Safety Instructions

• Read and understand this operator’s manual before operating.

• All machinery should be operated only by trained and authorized personnel.

• To prevent machine damage, use only attachments and service parts approved by the manu-

facturer.

• Always shut towing vehicle engine off and remove key before servicing the

implement.

• Avoid personal attire such as loose tting clothing, shoestrings, drawstrings, pants cuffs, long

hair, etc., that may become entangled in moving parts.

• Never attempt to operate implement unless you are in the driver’s seat.

• Never enter a cart containing grain. Flowing grain traps and suffocates victims in seconds.

Before Servicing

• Avoid working under an implement; however, if it becomes absolutely unavoidable,

make sure the implement is safely blocked.

• To prevent personal injury or death, always ensure that there are people who remain outside

the cart to assist the person working inside, and that all safe workplace practices are fol-

lowed. There is restricted mobility and limited exit paths when working inside the implement.

• Ensure that all applicable safety decals are installed and legible.

Before Operating

• Do not stand between towing vehicle and implement during hitching.

• Always make certain everyone and everything is clear of the machine before beginning opera-

tion.

• Verify that all safety shields are in place and securely latched.

• Ensure that all applicable safety decals are installed and legible.

Scales - Models 410 and 520 — Safety

1-4

During Operation

• Regulate speed to eld conditions. Maintain complete control at all times.

• Never service or lubricate equipment when in operation.

• Keep away from overhead power lines. Electrical shock can cause serious injury or death.

• Use extreme care when operating close to ditches, fences, or on hillsides.

• Do not leave towing vehicle and implement unattended with engine running.

Preparing for Emergencies

• Keep a rst aid kit and properly rated re extinguisher nearby.

• Keep emergency numbers for fire, rescue, and poison control personnel near the

phone.

Wearing Protective Equipment

• Wear clothing and personal protective equipment appropriate for the job.

• Wear steel-toed shoes when operating.

• Wear hearing protection when exposed to loud noises.

• Do not wear additional hearing impairing devices such as radio headphones, etc.

Scales - Models 410 and 520 — Set Up

2-1

Section II

Set Up

General Set Up Instructions....................................................................................................... 2-3

Scale Kit Installation

J-Block Installation - All Models ........................................................................................ 2-4

Scale Indicator Installation - All Models ............................................................................ 2-5

3-Point Scales with Spindles .............................................................................................. 2-6

Hitch Assembly.............................................................................................................. 2-6

Axle Load Cell Installation............................................................................................ 2-8

3-Point Scales wtih Compression Cells .............................................................................. 2-9

Hitch Assembly.............................................................................................................. 2-9

Axle Load Cell Installation.......................................................................................... 2-10

Axle Load Cell and Riser Installation......................................................................... 2-12

5-Point Scales Tandems.................................................................................................... 2-14

Hitch Assembly............................................................................................................ 2-17

Axle Load Cell Installation.......................................................................................... 2-18

5-Point Scales Tracks........................................................................................................ 2-19

Layout for Models with Track .................................................................................... 2-19

Hitch Assembly............................................................................................................ 2-20

Axle Load Cell Installation.......................................................................................... 2-21

5-Point Single Tires........................................................................................................... 2-22

Hitch Assembly............................................................................................................ 2-23

Axle Load Cell Installation.......................................................................................... 2-24

Power Connection ....................................................................................................... 2-25

Load Cell Connection ........................................................................................................ 2-26

(Continued on next page)

Scales - Models 410 and 520 — Set Up

2-2

Section II

Set Up

Routing Scale Cables - Models with Walking Tandems ......................................................... 2-27

Rotational Sensor Mounting Instructions - UM520 Auto-Log Scale

Single-Auger Grain Carts................................................................................................ 2-30

Brent Models: 782, 882, 1082, 1182, 1186, 1282, 1386, V700, V800, V1000,

V1100, V1300, V1500

Unverferth Models: 760, 860, 1015, 1017, 1019, 1050, 1060, 1115, 1117, 1119,

1160, 1315, 1317, 1319, 1519, 7250, 8250, 9250

Killbros Models: 735, 835, 1035, 1135

Parker Models: 742, 842, 1042, 1142

Double-Auger Grain Carts

Models 1110, 1310, 1196, 1396, 1596, 2096 -

Serial Number B34930099 and Lower................................................................. 2-33

Models All Double-Auger Grain Carts -

Serial Number B34930100 and Higher ................................................................ 2-35

Scales - Models 410 and 520 — Set Up

2-3

• TIPPINGORMOVEMENTOFTHEMACHINECANCAUSESERIOUSINJURYORDEATH.BESURE

MACHINE IS SECURELY BLOCKED.

• FALLING OBJECTS CAN CAUSE SERIOUS INJURY OR DEATH. DO NOT WORK UNDER THE

MACHINEATANYTIMEWHILEBEINGHOISTED.BESUREALLLIFTINGDEVICESANDSUPPORTS

ARERATEDFORTHELOADSBEINGHOISTED.THESEASSEMBLYINSTRUCTIONSWILLREQUIRE

A SAFE LIFTING DEVICE PER MODEL AS LISTED IN THE FOLLOWING CHARTS. SPECIFIC

LOAD RATINGS FOR INDIVIDUAL LOADS WILL BE GIVEN AT THE APPROPRIATE TIME IN THE

INSTRUCTIONS.

• EYE PROTECTION AND OTHER APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT MUST BE

WORN WHILE SERVICING IMPLEMENT.

• KEEP HANDS CLEAR OF PINCH POINT AREAS.

Park the empty grain cart on a firm, level surface. Block the tires/tracks on the machine to keep

it from moving. Completely disconnect cart from tractor.

General Set Up Instructions

Scales - Models 410 and 520 — Set Up

2-4

Left-Hand Side

of Cart Shown

J-Block

(9004925)

Cable 50’

(9006047)

J-Block Installation - All Models

1. Attach the J-Block to the left vertical face of

the cart using the #8 hardware.

NOTE: Facing the J-Block to the inside of the

cart will protect the scale wire ends.

2. Attach the cable wire connector ends to the

J-Block.

NOTE: J-Block has no particular connection port

for a particular scale bar.

Scale Kit Installation

Scales - Models 410 and 520 — Set Up

2-5

Scale Kit Installation

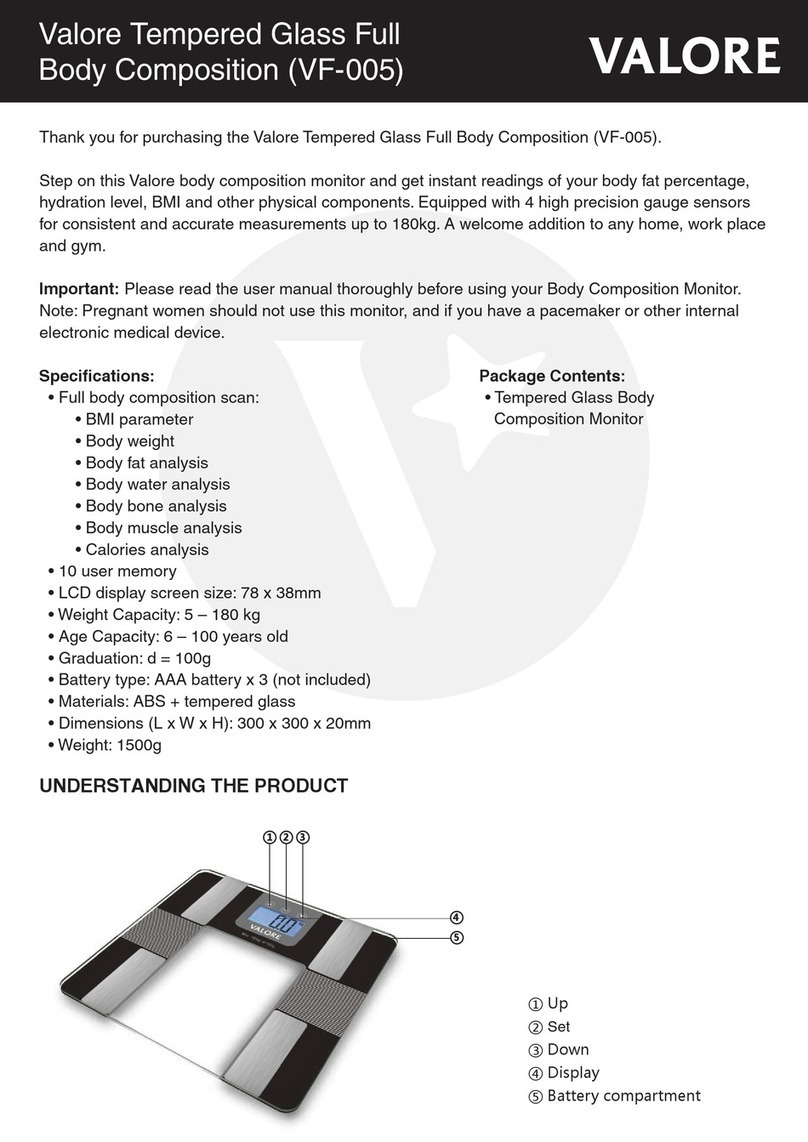

Scale Indicator Installation - All Models

1. Using the bracket provided, locate the scale indicator inside the tractor cab.

NOTE: For additional mounting exibility, optional

RAM mount kit (9005936) is available.

5 1/4 REF

2 31/32 REF

Scales - Models 410 and 520 — Set Up

2-6

Scale Kit Installation — 3-Point Scales with Spindles

FIG. 2-1

IF SPINDLE HAS 2 HOLES, USE

MOUNTING HOLE FARTHEST

AWAY FROM THE HUB.

Hitch Assembly

1. Remove the capscrew, lock washer, and nut to remove the standard hitch. Remove the

original bushing.

2. Replace with scale hitch bar, making sure to feed the scale wire through the conduit to the

J-Block.

NOTE: The bending direction decal on the end of the bar should point up. Also, the hitch bar

should be installed with the serial number decal facing up.

Scales - Models 410 and 520 — Set Up

2-7

3. Reusing the capscrew, lock washer and hex nut, assemble the scale hitch bar to the tongue.

Use the provided longer bushing.

4. Reattach the hitch casting to the scale hitch bar using hitch pin and snap rings.

NOTE: Refer to previous page and PARTS section for reference.

Scale Kit Installation — 3-Point Scales with Spindles (continued)

Brent Models:

472, 572, 576, 678

with Single & Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004902)

774, 776, 874, 876

with Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

1194, 1394, V1100 with Single Wheel/

Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

V700, V800, V1000

with Single & Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1282 with Single Wheel/Tires

(Serial Number B31290099 - Lower) Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

Unverferth Models:

5225, 6225, 7250, 8250

with Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004902)

7250, 8250 With Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004930)

9250 with 900/60x32, 35.5x32

Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

9250 with 1050/50x32

Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004907)

760, 860, 1015, 1017, 1019, 1060,

1110, 1119, 1160, with Single Wheel/

Tires

Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1115, 1310, 1315

with Single Wheel/Tires

(Serial Number B31290099 - Lower)

Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1110 with Tracks

(Serial Number B31290099 - Lower) Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

Killbros Models:

735, 835 w/Single & Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1035, 1135, 1152, 1352

with Rigid Axle Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1150, 1160, 1175, 1185

with Single Wheels Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004902)

1175, 1185 with Dual Wheels Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004930)

1195 with Single Wheels on 134” Axle

1950 with Single Wheels & Tracks Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

1195 with Single Wheels on 144” Axle Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004907)

Parker Models:

742, 842 w/Single & Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

1042, 1139, 1142

with Rigid Axle Single Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004913)

524, 624, 739, 839 w/Single Wheels Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004902)

739, 839 with Dual Wheels Replace Standard Hitch with Scale Hitch Weigh Bar 2 1/2” Dia. (9004930)

1039, 1048 with Single Wheels on

134” Axle Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

1039, 1048 with Single Wheels on

144” Axle & Tracks Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004907)

Scales - Models 410 and 520 — Set Up

2-8

Axle Load Cell Installation

• BEFORE PROCEEDING, REFER “GENERAL SET UP” PAGE 2-3 FOR PROPER WARNINGS.

1. With the cart empty, use a safe lifting device with a minimum weight rating per chart to sup-

port the weight of your grain cart. Place the safe lifting device under the axle, near the tire.

•

Replace

only 1 spindle at a time.

2. Remove wheel and tire. Refer to maintenance section for wheel removal and replacement

procedures.

3. Starting on the left-side of the cart, remove the bolt and lock nut that retains the spindle

to the axle. Using a lifting device rated for 150 lbs, replace the spindle. Coat axle contact

length of spindle shaft with anti-seize lubricant prior to installation. Install with ‘top’ decal

facing upwards. Reuse bolt and lock nut to retain spindle to axle.

4. Using a 200 lbs. rated lifting device, re-install hub assembly, removed in Step 2, onto spindle.

Install outer bearing, spindle washer and castle nut.

5. Attach the wheel(s) and tire(s) to the hub using the same rated lifting device for removal.

Tighten wheel nuts to appropriate requirements and recheck as outlined in the Wheel and Tire

section of this manual. Raise cart, remove safe lifting device and lower tire to the ground.

6. Repeat steps 2 through 5 on right-side of the cart.

SAFE LIFTING DEVICE WEIGHT

Brent Models:

472, 572, 576, 678, 774, 776,

780, 782, 874, 876, 880, 882,

V700

12,000 Lbs.

1080, 1082, V800, V1000 14,000 Lbs.

V1100 16,000 Lbs.

1194 20,000 Lbs.

1282 22,000 Lbs.

1394 24,000 Lbs.

Unverferth Models:

5225, 6225 7,000 Lbs.

760, 7250 9,000 Lbs.

860, 8250 10,000 Lbs.

1060, 1160, 9250 14,000 Lbs.

1015, 1017, 1110, 1115 16,000 Lbs.

1019, 1315 18,000 Lbs.

1119, 1310, 1319 24,000 Lbs.

SAFE LIFTING DEVICE WEIGHT

Killbros Models:

735, 1150, 1160 9,000 Lbs.

835, 1175, 1185 10,000 Lbs.

1035, 1135, 1195, 1950 14,000 Lbs.

Parker Models:

524, 624, 742 9,000 Lbs.

739, 839, 842 10,000 Lbs.

1039, 1042, 1048, 1139, 1142 14,000 Lbs.

1152 16,000 Lbs.

1352 24,000 Lbs.

Scale Kit Installation — 3-Point Scales with Spindles (continued)

Scales - Models 410 and 520 — Set Up

2-9

Scale Kit Installation — 3-Point Scales with Compression Cells

Hitch Assembly

1. Remove the snap rings and pins to remove cast hitch. Retain hardware removed.

2. Remove capscrew, lock washer and nut to remove hitch bar. Retain hardware removed.

3. Replace with scale hitch bar into the hitch bushing, making sure to feed the scale wire through

the hitch bushing also.

NOTE: The bending direction decal on the end of the bar should point up. Also, the hitch bar

should be installed with the serial number decal facing up.

4. Reusing the capscrew, lock washer and nut, assemble the scale hitch bar to the tongue.

5. Reattach the cast hitch to the scale hitch bar using hitch pin and snap rings.

NOTE: Some carts require removal of original hitch bushings. The single large bushing supplied

is installed rst, followed by routing of the scale hitch bar cable through the tongue bushing exit

hole, then installing the scale bar with bending direction decal on the end of the bar pointing up

with the serial number decal facing up.

FIG. 2-2

Brent Models:

782 with Single & Dual Wheel/Tires

(Serial Number B26270099 - Lower) Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

782 with Single & Dual Wheel/Tires

(Serial Number B26270100 - Higher) Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

780, 880, 1080 with Single &

Dual Wheel/Tires & Tracks Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

882, 1082

with Single & Dual Wheel/Tires Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

1082 with Tracks

(Serial Number B31270099 - Lower) Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

1194 with Tracks Manual Tension Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

Unverferth Models:

9250 with Tracks Manual Tension Replace Standard Hitch with Scale Hitch Weigh Bar 2 7/8” Dia. (9004903)

1110 with Tracks Manual Tension Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

Parker Models:

1152 with Tracks Manual Tension Replace Standard Hitch with Scale Hitch Weigh Bar 3 3/4” Dia. (9004910)

Scales - Models 410 and 520 — Set Up

2-10

Scale Kit Installation — 3-Point Scales

with Compression Cells (continued)

Axle Load Cell Installation

• BEFORE PROCEEDING, REFER “GENERAL SET UP” PAGE 2-3 FOR PROPER WARNINGS.

1. With the cart empty, use safe lifting device with a minimum weight rating per chart to sup-

port the weight of your grain cart. Place the safe lifting device under the frame rails.

•

Replace

only1 bar at a time. Follow Steps 2-8 before loosening hardware on any of the otherbars.

2. Remove cotter pins and axle retainer link pins.

3. Place 5, 6, or 7 ton supports under main frame rails, as close to axle as possible.

4. Raise cart allowing at least 2-3” between tires and oor.

NOTE: Carts with 24.5 tires or tracks may require spacer bars to level the cart (order two spacers

(283856). See “Axle Load Cell and Riser Installation” instructions for proper procedure.

NOTE: A metal shim (#280396) may be necessary for scale accuracy.

FIG. 2-3

SAFE LIFTING DEVICE WEIGHT

Brent Models:

780, 782 9,000 Lbs.

880, 882 12,000 Lbs.

1080, 1082 14,000 Lbs.

This manual suits for next models

1

Table of contents