5

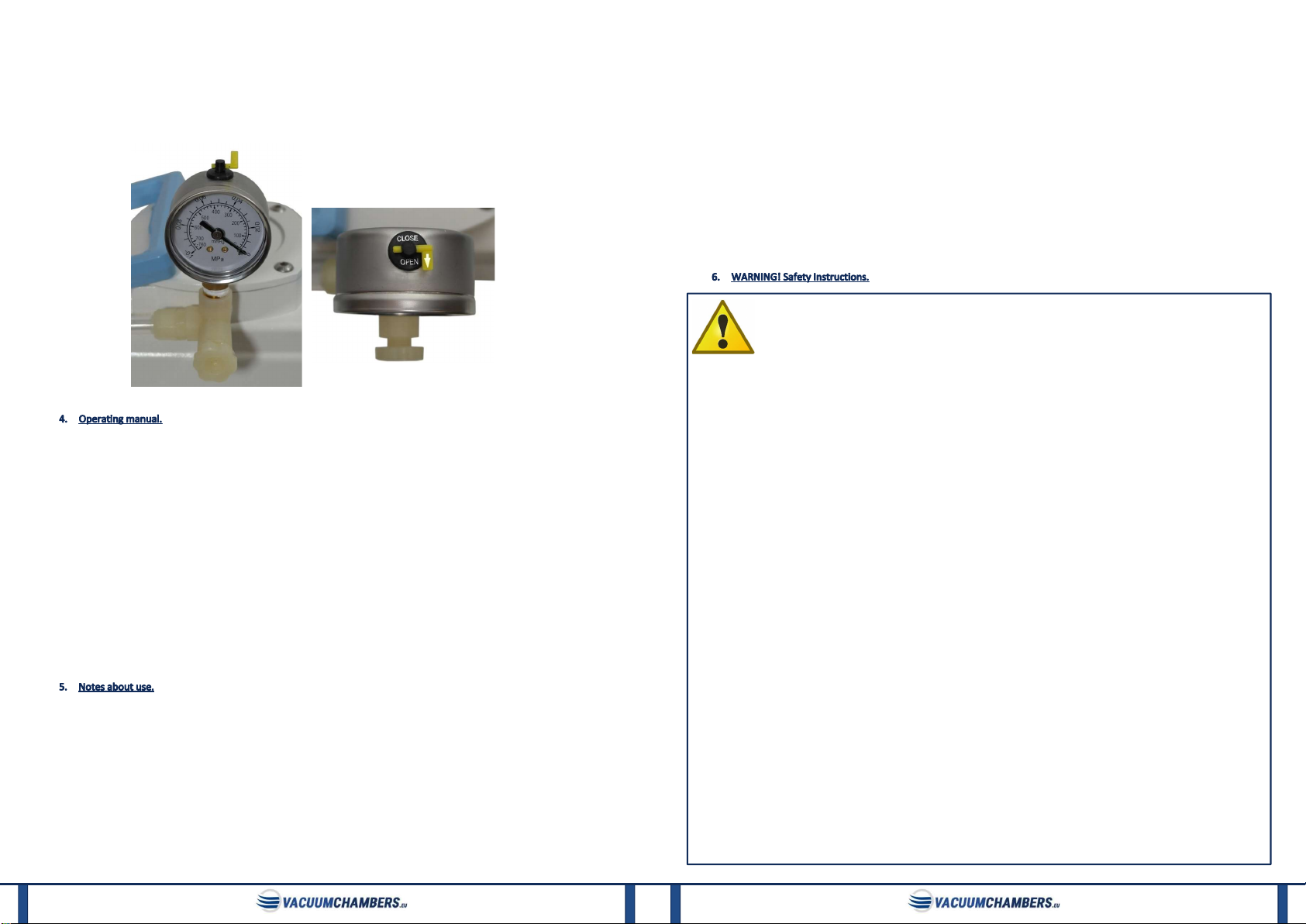

A. Vacuum gauge.

The vacuum gauge indicates the pressure in the air intake pipe. For this indication to be correct, it is necessary to unseal the

vacuum gauge. To do this, set the yellow flag of the vacuum gauge (Photo 3), located on top of the gauge, in the open position.

Turn the flag so that the arrow, visible on the flag, points towards the inscription "OPEN". Inscription is visible on the black rubber

plug of the vacuum gauge. Photo 3 B. shows the yellow flag correctly positioned for work. Positioning the yellow flag in the other

direction or toward the word "CLOSE" closes the vacuum gauge, which may result in inaccurate pressure indications.

Photo 3: Vacuum gauge with yellow flag (A. – side view, B – correct setting of the yellow flag during operation).

1) Connect the pump to the vacuum system or to the components it is to work with (the vacuum pump also can be started when

no other components are connected to it).

2) Connect the pump's power cord to the mains supply.

3) Start the pump by turning the switch to the "ON" position.

4) Make sure that the yellow flag of the vacuum gauge plug is in the "OPEN" position (Photo 3 B.).

5) Check the pressure on the vacuum gauge.

6) If necessary, adjust the suction power of the pump using the pressure regulator knob.

Turn the pressure regulator knob anticlockwise to increase pressure in the air intake pipe (reduce pump suction power). Turn

the pressure regulator knob clockwise to decrease the pressure in the air intake pipe (increases pump suction power). The

pressure change is indicated by the vacuum gauge.

For the vacuum pump type DVPGM100A when working as a compressor: Turn the pressure regulator knob anticlockwise to

reduce pressure in the air exhaust pipe (reduce air compression). Turn the pressure regulator knob clockwise to increase

pressure in the air exhaust pipe (increases air compression).

7) After finishing work, turn of the pump by switching its switch to the „OFF” position.

8) If the device will not be used for a long time, disconnect the power cord from the mains supply.

The device should stand on its feet, on a horizontal and stable surface, in a dry, clean, low-dust and well-ventilated place. The

distance of the side surfaces of the pump from other objects should not be less than 5cm. The distance between the front

and back of the pump from other objects should not be less than 10 cm. If the pump will be installed inside any device or

furniture, provide air inlet to the device from the pump side cover.

The diaphragm vacuum pump is equipped with an internal cooling system. This allows the pump to run continuously for 24

hours.

The pump works without oil. Do not fill the pump with oil nor lubricate it, as this may damage it.

Do not connect to device a pipe with an inside diameter smaller than the fitting inside diameter.

Do not allow corrosive gases or particulate material to enter the pump.

If in the pumped gases may be present water vapour, oil contamination or other liquids, an additional filter should be used

to prevent these contaminants from entering the pump.

6

The rate of pressure drop during venting gradually decreases. However, if it is not possible to achieve a negative pressure at

the level declared by the distributor, it may indicate the vacuum set leak.

The efficiency of the device can be adversely affected at high altitudes, due to lower atmospheric pressure.

If motor fails to start, or it slows down under load, turn it off and unplug it. Make sure that the pump parameters written on

pump housing correspond to the power supply parameters.

In the event of overheating or noisy work of the pump, stop the pump immediately and check the pump for malfunctions.

Before perform any service or maintenance work, equalize the pressure inside the device with the ambient pressure. For

example, by disconnecting a vacuum chamber from the pump.

If the vacuum pump will not be used for a long period of time, cover the pump and then put it in a dry and safe place.

To use vacuum pump type DVPGM100A as a compressor - connect the silicone hose to the pump exhaust pipe. This allows to

compress blown out air and thus create a pressure. The vacuum gauge, supplied with the device, shows the pressure value

on the air intake pipe. It does not indicate the pressure in the air exhaust pipe. The vacuum gauge is not suitable to indication

pressure higher than 0 bar relative pressure. To indicate pressure generated by the pump it is necessary to install pressure

gauge. The maximum pressure generated by pump type DVPGM100A is 2 bar relative pressure.

Read the operating manual before use.

There are warning decals on the vacuum pump. Read them before starting work and follow them.

Before each use of the vacuum pump, it is necessary to check its technical condition, in particular the power

cord of the vacuum pump.

Perform servicing and maintenance of the vacuum pump periodically.

Carry out all maintenance work when the pump is not hot and is not running.

The general rules for the use of equipment working under voltage must be observed.

To avoid risk of electrocution do not use this product in area where it could come in contact with water or other liquids.

Before starting work, make sure that the parameters of the power source correspond to the pump requirements specified

on the pump.

Do not try to obtain higher pressure or vacuum than those recommended. Refer to the operating parameters given on the

housing of the device.

Before starting the pump, make sure that pump side covers are free from obstructions.

Make sure that the pump complies with the technological requirements, processes and purposes for which it is to be used.

Make sure that the pump is not exposed to chemicals that could damage it. The customer is solely responsible for selecting

the appropriate pump for the working conditions.

Do not pump flammable, explosive and toxic gases. Do not pump gases that are extremely moist or contain deposits or

dust. If the pumped gases have a harmful effect on health or have a bad effect on the environment, an extension pipe can

be installed at the pump exhaust (if possible). Handle the gases in accordance with environmental standards.

The temperature of pumped gases should not be higher than +55°C.

Use the pump in a safe, well-ventilated place, on a flat stable surface.

Avoid excessive pollution of the working environment by dust, powders, small solids or water, as heavy contamination can

damage the pump or cause its corrosion.

Do not expose the device to rain or excessive moisture.

Some parts of the vacuum pump can get very hot during operation. To prevent burns, never touch the pump housing during

operation or immediately after switching it off.

Never place in close proximity to the vacuum pump flammable, explosive, and susceptible to high temperature objects.

In case of failure, immediately disconnect the device from the power supply.

Do not repair the vacuum pump by yourself.

Never put fingers or other objects inside the pump impeller cover. Keep your hair, clothing, gloves and other objects that

could get into the impeller, away from moving parts.

Do not subject any parts of the human body to vacuum or pressure.

The device should be operated by trained technicians, mentally and physically able to operate the vacuum pump.

Keep children and animals away from operating area of the device.

Be foreseeable, watch what you are doing, and be reasonable when using the device. Do not use the device when you are

tired or under the influence of drugs, alcohol or medication.