2

INSTRUCTION OF USE AND MAINTENANCE

GENERAL POINT

Refrigerating components

Well : Refrigeration by a ventilated evaporator located in the

well.

Well bain-marie pulsated air

One or two stainless steel resistance shield with blades,

located in a box.

Option crawl heating halogen

Heating and lighting by halogen lights.

Lighting

Lighting by fluorescent tube.

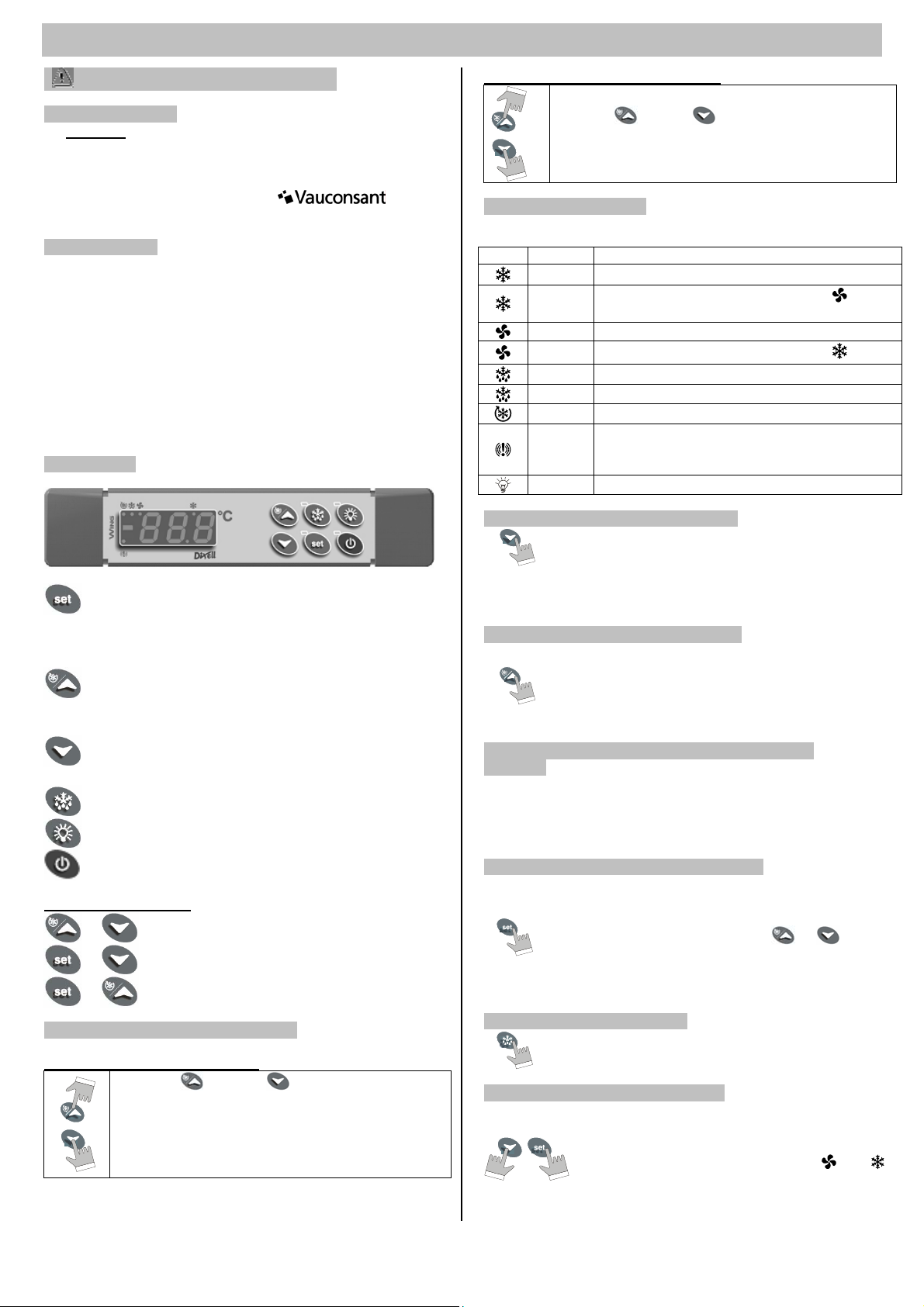

Controls

A 4 positions switch to select the function mode desired.

Froid : High precision control by thermostat Dixell XR40 with

digital display ( to refer to the note of the thermostat provided

hereafter ).

Chaud : High precision control by thermostat Dixell XT110C

with digital display ( to refer to the note of the thermostat

provided hereafter ).

Halogen lamp : Variator

Fluorescent tub : a switch on/off

Controls located on the control’s panel

Protection

By main power fuse holder.

INSTALLATION

To set up the drop-in unit

Settle the black neoprene watertight joint on the perimeter

of the drop-in unit before the definitive installation.

To embed the well ventilated in cutting envisaged.

Electric connection

Before plugging in the unit, control imperatively the

voltage rating : it should be the same voltage as

indicated on the unit.

The electric power line providing the refrigerated unit with

electricity should be protected by a differential circuit breaker

located on the main electric distribution panel.

To connect the incoming line to the fuse holder located in the

electric box.

To connect the plug of the self evaporating tray.

Compressor connection

To connect the refrigerating circuit, in accordance with the

refrigerating diagram, provided hereafter.

To connect the two strikers by tighten with adequate spanner,

the tightening became hard during the impact of the strikers, the

tightening must be continued to have a good airtightness. A

wrong tighten of the strikers can generate a flight of the

refrigerating gas and failure of the equipment.

It is recommended to check the airtightness of the

strikers with detector of flight, after the tighten of the

strikers.

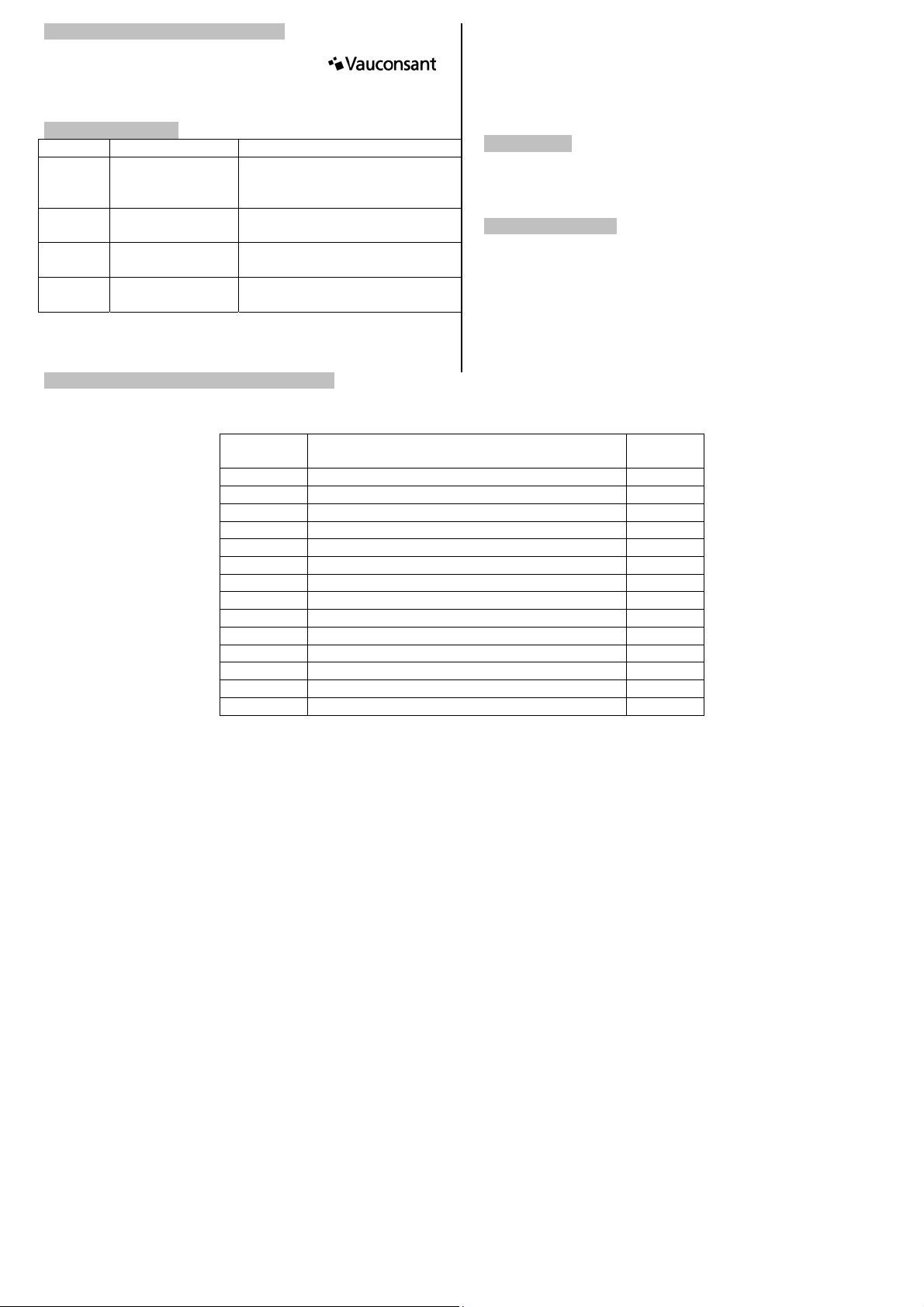

To set up the self evaporating tray

The self evaporating tray must be placed under the unit, at

the place designed, by means of the clips initially installed.

The installation twist of the self evaporating tray must be

connected to the plug of the electric box, according the

standard of unit, the twist of the self evaporating tray can be

situed in the face or in the back of the unit.

Astainless steel sheet deflector located in the self

evaporating tray, allow to direct the water vapour. The sheet

must be located in the middle of the self evaporating tray ( the

same distance in each side).

The deflector must be located to have the good direction of

the inclination, like described in the following diagram.

UTILISATION

To put into service

Powering up the unit two hours before usage.

Switch on the function mode desired : Chilled ventilated air

function, Hot ventilated air function, Dry Bain Marie

function.

The corresponding thermostat turn on.

The thermostat is adjusted in the factory after testing.

When the desired temperature is obtained, the power unit

automatically turns off.

Positionner le commutateur sur la position 0 pour arrêter le

fonctionnement du reverso.

Dry Bain-marie function

150 mm deep gastronorm GN 1/1 trays should be

used.

With the parameters programs in factory, the food’s

temperature is maintened above +65°C which is the minimum

temperature defined by Health Departments.

To be able to hold this temperature, it is essential to bring

food to a temperature ranging between +70°C and +80°C.

Lightning

Press the switch on/off to turn on or turn off the lighting

Turn to the right the variator to turn on the halogen lamps.

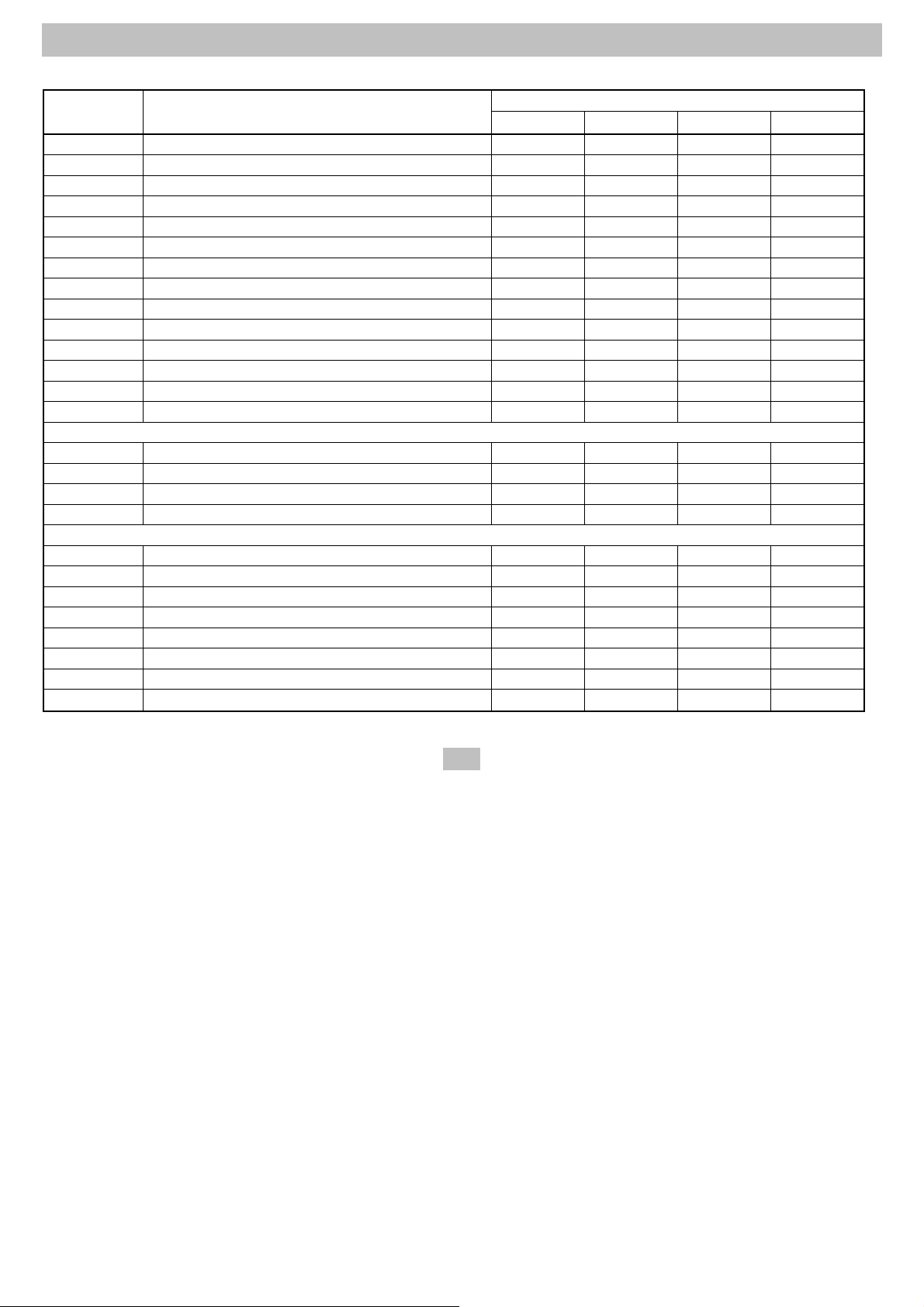

Adjusting the thermostat

Refer to the manual for details.

Automatic defrosting

This function is programmed in the thermostat/

Adjusted in the factory: the defrosting engages every hour

throughout one ten maximum minute.

To modify the adjustment, refer the manual of the

thermostat.

Cleaning

To be performed when the unit is shut down (the unit is

turned off).

Once a day, wash the top, the refrigerated well and the

external sides of the unit.

Use a sponge moistened with a soapy water or special

cleaning products to clean the stainless steel. Rinse off with

water. Dry preferably with lint-free cotton cloths.

Do not use floor cleaning products or acids, even diluted,

chlorinated or scouring products, which may cause corrosion to

stainless steel.

Do not use any abrasive products (steel wool, etc…).

Do not clean the refrigerated unit by spraying with water,

using a soap gun, or under high pressure jets.

MAINTENANCE

The installer should check all the electric connections during

the initial start up of the unit (and then once a year).

Clean the condenser every six months.

Grease the condenser blower shaft once a year.

deflecto