4

MANUAL OF THERMOSTAT XW60L

Please read this ma ual before usi g

1.AVERTISSEMENT

•War i g: disco ect all electrical co ectio s

before a y ki d of mai te a ce.

•The i strume t must ot be ope ed.

•In case of failure or faulty operation send the instrument

back to the distributor or to with a

detailed description of the fault.

2.DESCRIPTION

Model XW60L is microprocessor based controllers suitable

for applications on medium or low temperature refrigerating

units. They are provided with 4 relay outputs to control

compressor, defrost, fans for the evaporator and the lights.

They are also provided with 2 NTC probe inputs, for

temperature control, the second for end defrost temperature

control.

The regulation is performed according to the temperature

measured by the thermostat probe with a positive differential

from the set point: if the temperature increases and reaches

set point plus differential the compressor is started and then

turned off when the temperature reaches the set point value

again.

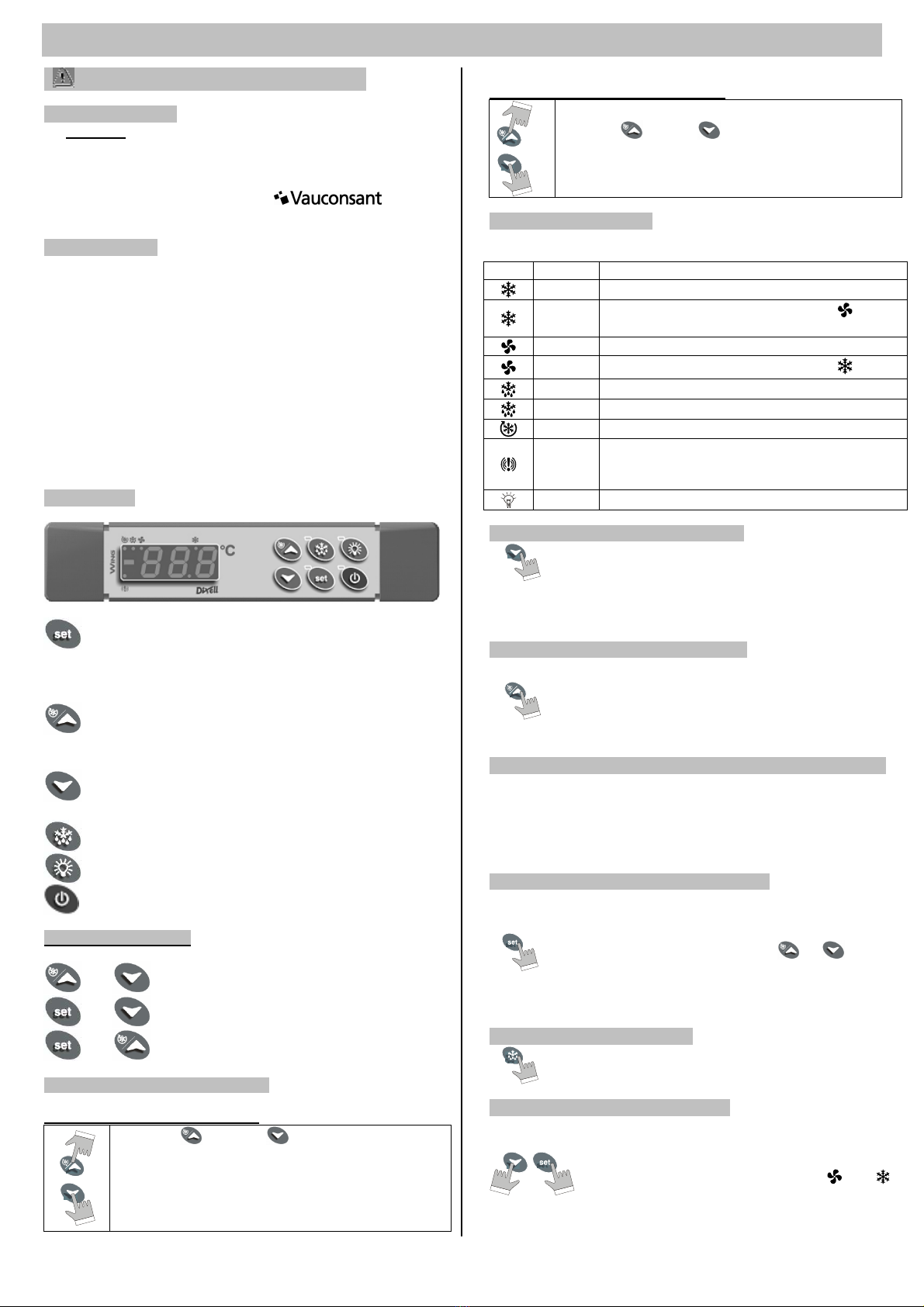

3.KEYBOARD

To display and modify target set point; in

programming mode it selects a parameter or confirm

an operation.

By holding it pressed for 3s when max or min

temperature is displayed it will be erased.

To see the max. stored temperature; in programming

mode it browses the parameter codes or increases the

displayed value. By holding it pressed for 3s the fast

freezing cycle is started.

To see the min stored temperature; in programming

mode it browses the parameter codes or decreases the

displayed value.

By holding it pressed for 3s the defrost is started.

Switch ON and OFF the light of the cold room.

Switch ON and OFF the instrument.

KEY COMBINATIONS

+

To lock and unlock the keyboard.

+

To enter the programming mode.

+

To it the programming mode.

3.1 To lock a d u lock the keyboard

HOW TO LOCK THE KEYBOARD

Keep the and the keys together for more

than 3 s. The "POF" message will be displayed and

the keyboard is locked. At this point it is only

possible the viewing of the set point or the MAX or

Min temperature stored and to switch ON and OFF

the light, the auxilary output and the instrument.

HOW TO UNLOCK THE KEYBOARD

Keep the and the keys pressed together for

more than 3 s. The "POn" message will be displayed

and the keyboard is unlocked.

3.2 Mea i g of the LED

Each LED function is described in the following table :

LED MODE FONCTION

ON The compressor is running

Flashing Programmation phase ( flashing with )

Anti short cycle delay enabled

ON The fan is running.

Flashing Programmation phase ( flashing with )

ON The defrost is enabled.

Flashing Drip time in progress

ON The fast freezing cycle is enable

ON

Alarm signal

In “Pr2” indicates that the parameter is also

present in “Pr1

ON The light is on

3.3 How to see the mi temperature

Press and release the key.

The “Lo” message will be displayed followed by the

minimum temperature recorded.

By pressing the key or waiting for 5s the normal

display will be restored.

3.4 How to see the max temperature

Press and release the o key.

The “Hi” message will be displayed followed by the

maximum temperature recorded.

By pressing the o key or waiting for 5s the normal

display will be restored.

3.5 How to reset the max a d mi temperature recorded

To reset the stored temperature, when max or min

temperature is displayed, press SET key until “rST” label starts

blinking.

N.B. : After the i stallatio RESET the temperature

stored .

3.6 How to see a d modify the set poi t

Push and immediately release the SET key: the

display will show the Set point value.

The SET LED start blinking.

To change the Set value push the or arrows

within 10s.

To memorise the new set point value push the SET

key again or wait 10s.

3.7 To start a ma ual defrost

Push the DEF key for more than 2 seconds and a

manual defrost will start.

3.8 To e ter i parameters list Pr1

To enter the parameter list “Pr1” (user accessible parameters)

operate as follows:

Enter the Programming mode by pressing the

Set and DOWN key for few seconds ( and

start blinking).

The instrument will show the first parameter

present in “Pr1”.