Document No. 6957-193 June 2006 Revision 2.3 ©Copyright Stoneridge Electronics

Ltd Manufacturers of VEEDER-ROOT Tachographs

2

1.

INTRODUCTION.............................................................................. 4

1.1

What does the Tachograph Programmer do?........................................................ 4

1.2

With which Tachograph Types can the Programmer be used ?............................. 4

1.3

How do I use This Manual?.................................................................................... 4

1.4

What version of Tachograph Programmer Software does this Manual Support ?.. 5

2.

PREPARATION FOR USE............................................................... 6

2.1

Power Supply......................................................................................................... 6

2.1.1

Battery Charging ............................................................................................ 6

2.2

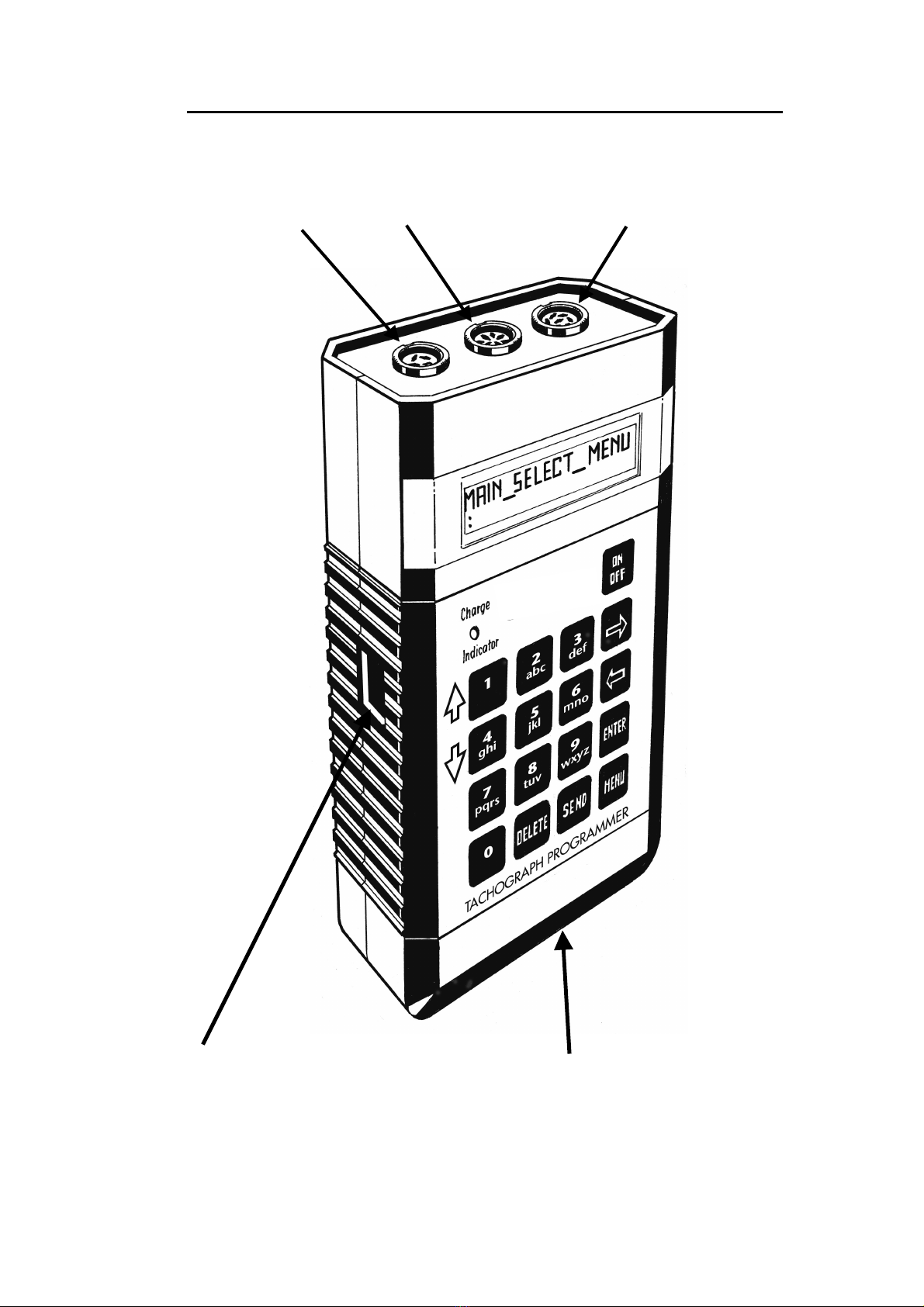

Connectors ............................................................................................................ 6

2.3

Connection Harnesses........................................................................................... 8

2.4

Functions of the Keys ............................................................................................ 8

2.5

Switching On.......................................................................................................... 8

2.6

Diagnostics Menu .................................................................................................. 9

2.6.1

Diagnostics Menu - Function Descriptions .................................................... 9

2.6.2

Diagnostics Menu - Operation of Functions.................................................. 10

2.7

Selection of tachograph type ............................................................................... 12

2.8

Selection of Pulser type (Stoneridge VR8300/1400) ............................................ 12

2.9

Selection of SENDER TYPE (Stoneridge VR2400).............................................. 13

3.

PROGRAMMER FUNCTIONS ....................................................... 14

4.

FUNCTION DESCRIPTIONS......................................................... 17

4.1

Enter PIN Code.................................................................................................... 17

4.2

W-factor (Vehicle Characteristic Coefficient) Determination ................................ 17

4.2.1

Rolling Road (Hartridge or similar) ............................................................... 19

4.2.2

Fixed Distance Method No. 1 ....................................................................... 20

4.2.3

Fixed Distance Method No. 2 ....................................................................... 23

4.3

Bench Test (Connections) ................................................................................... 25

4.4

Distance Test....................................................................................................... 27

4.5

Speed Simulator .................................................................................................. 28

4.6

Revs per minute pulse test .................................................................................. 29

4.7

Clock Test............................................................................................................ 30

4.7.1

Clock Test – Motometer, Stoneridge VR2400/SE5000, Kienzle 1324/DTCO

and Actia Smartach ..................................................................................................... 30

4.7.2

Clock Test – Stoneridge VR8400/8300 Series and Kienzle 1314/1318/1319 31

4.8

Pair/Test Tacho. .................................................................................................. 32

4.9

Tacho Control...................................................................................................... 32