In case of replacement of parts, use only original spare parts.

You should always use personal protective elements to perform actions on the devices.

The installation and maintenance of air conditioning equipment may be dangerous because within these

devices there are pressurized refrigerant gas and electrical devices. Therefore the installation, initial start-up

and subsequent maintenance must be carried out by authorized and qualified personnel only.

In case of leakage of refrigerant fluid, it is mandatory to ventilate the room, considering also that refrigerant

fluid when exposed to flame produces toxic gas.

When refilling the system, after eventual leakage and repair, be sure that inside the refrigerant circuit does

not enter any substance, such as air, other than the specified refrigerant (R410A). The presence of air or

other foreign substances in the circuit of refrigerant may cause an abnormal increase of pressure or

breakage, resulting in personal injury.

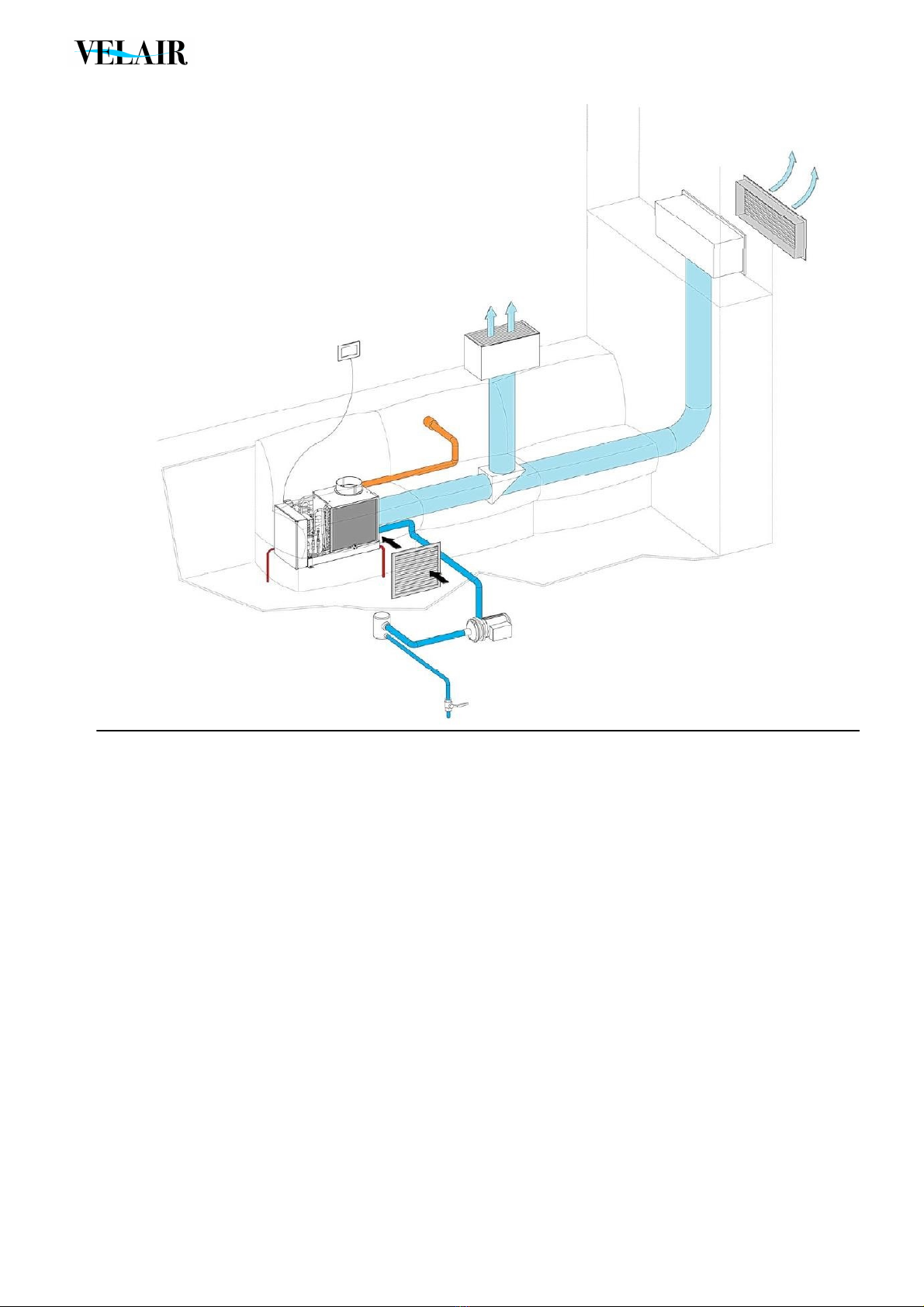

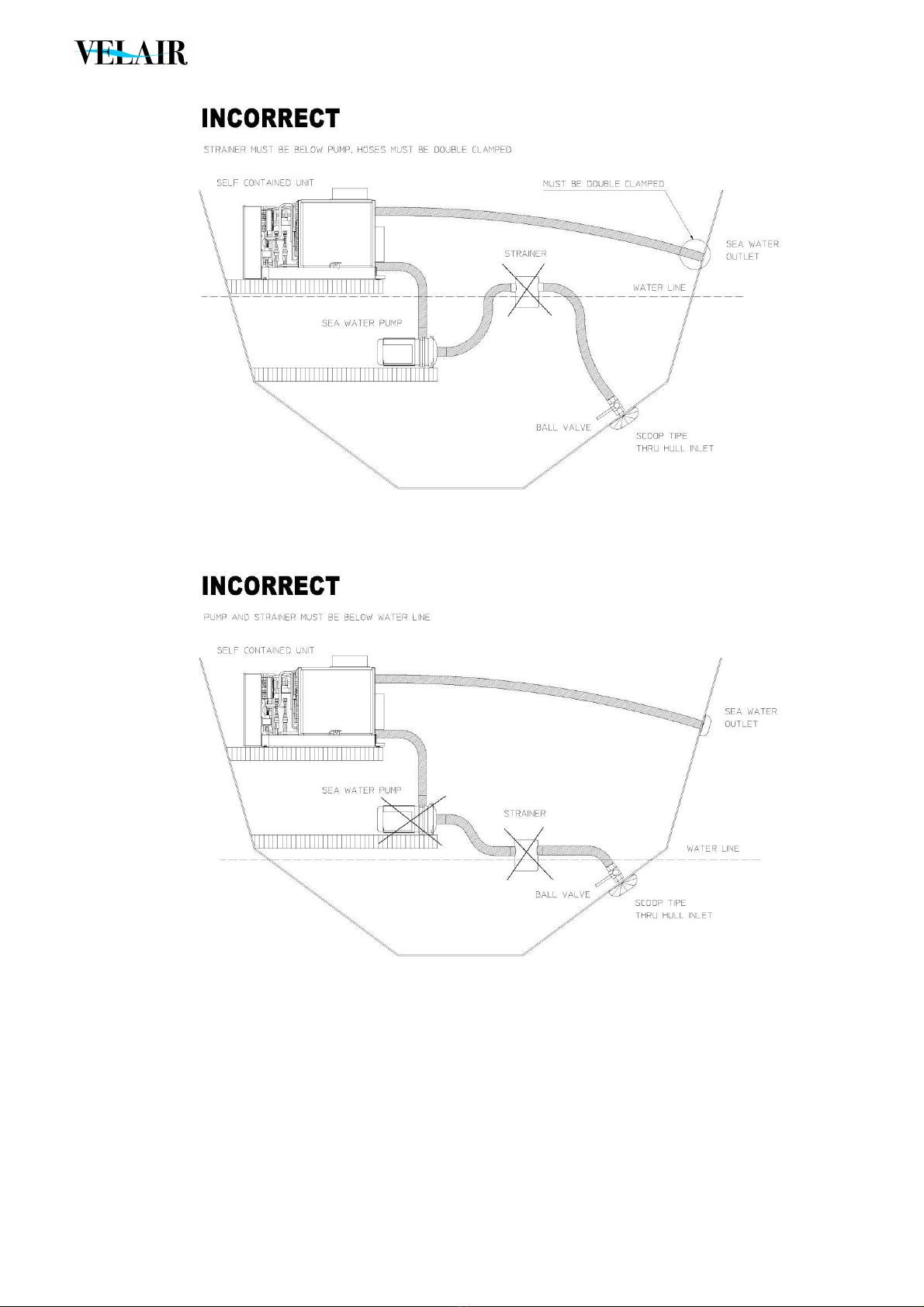

In the case of water spills from sweater circuit, switch off immediately compressor and seawater pump and

shut off Manual Valves in order to stop the seawater flow.

During the cold period if the unit is not in use, drain all the hydraulic circuits connected to the unit, as well as

seawater condenser to prevent them from freezing.

Some parts of the appliance produce heat during operation. The room installation must ensure adequate

ventilation and proper heat dissipation.

3.1.2

PROHIBITIONS

We remember that the use of products that use electricity and water involves the observance of some

basic safety rules such as:

•

It is forbidden the use by children and unassisted disabled people.

•

Do not touch the appliance when barefoot or with wet or damp parts of the body.

•

It is prohibited any operation before disconnecting the unit from the mains supply by moving the

power switch to "off".

•

Do not modify safety devices or adjustment without permission and instructions from the

manufacturer.

•

Do not pull, detach or twist the electrical cables coming from the appliance, even if it is

disconnected from the mains power supply.

•

It is forbidden to open the access panels to the internal parts of the unit without having first

disconnected the unit from the mains by putting the system power switch to "OFF position".

•

Do not dispose, abandon or leave within the reach of children the packaging material because it

can be a potential source of danger.

•

It is forbidden to use refrigerant and water pipes for grounding the unit.

•

It is forbidden to disperse R-410A into atmosphere: R410A is a fluorinated greenhouse gas, referred to

in the Kyoto’s Protocol, with a Global Warming Potential (GWP) = 1975.

3.1.3

RESPONSIBILITY

UFLEX S.r.l. disclaims any liability for damage to people, animals or property resulting from the installation, use

or maintenance improper of the product, or due to failure of compliance with standards and directives

mentioned in this manual.