1. WARNING 2. NOTE

3. SPECIFICATION

Voltage: 220V-240V 50/60Hz,1000W

Air Temperature: 35℃(D=10CM,Room Temp.=25℃)

Air Velocity: 100M/S

3

Air Flow: 130M /H

Drying Time: 12S

Sensor Range: 5-15CM

Protection Level: IPX1

Electric Isolation: CLASS 1

Brush Motor: 30000RPM

Noise(at 1M): 70dB

Cabinet Material: Stainless Steel 304

4. INSTALLATION

. This product is intended for installation

by a qualified service person.

. Disconnect power at the service breaker

before installing or serving.

. Failure to properly ground unit could

result in severe electrical shock.

. All units must be supplied with a 3-wire

service. The ground wire must be

connected to the dryer’s backplate.

Do not install dryer over washbasin.

If the power supply cord is damaged, it

must be replaced by the manufacturer or its

service agent or similar qualified person

in order to avoid a hazard. Means for

disconnection must be incorporated in the

fixed wiring in accordance with the current

wiring regulations.

Installation must be carried out in

accordance with the current edition

of the local wiring regulations code

having jurisdiction. Installation should

be performed only by a qualified

electrician.

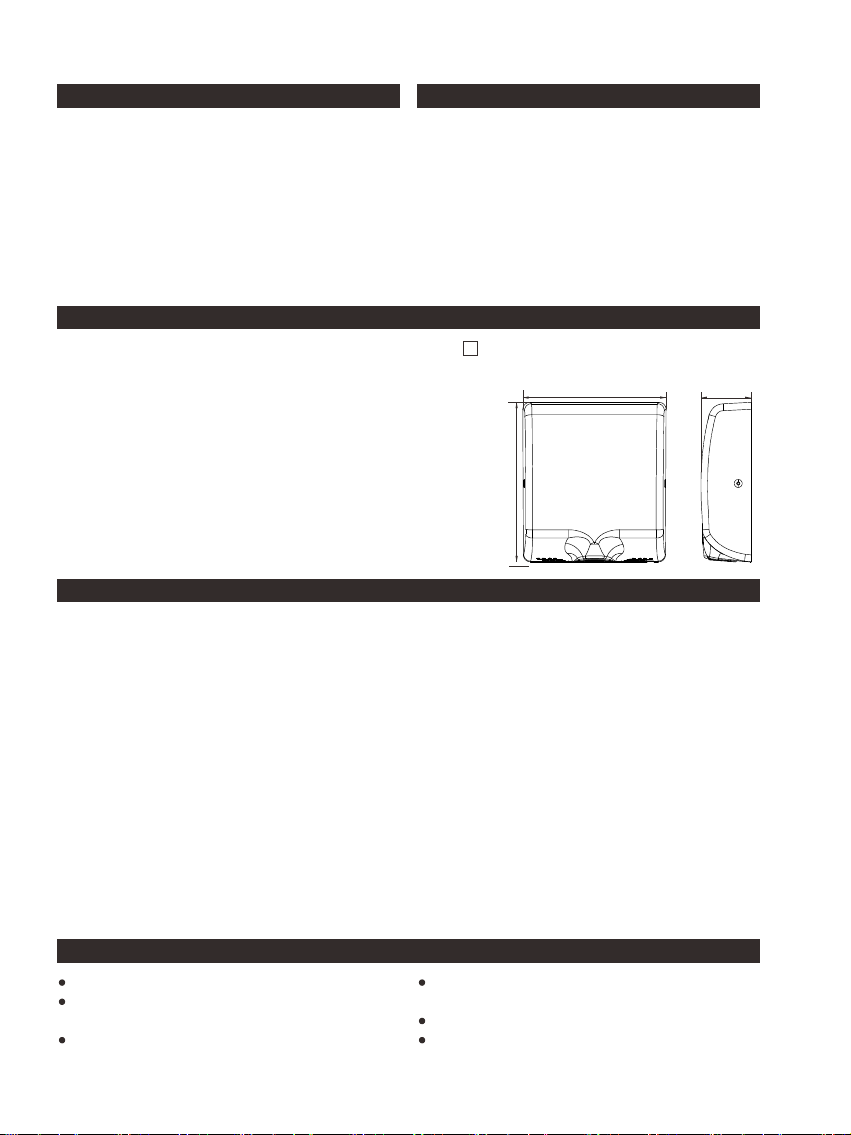

Place template against wall at

desired height(see mounting height

recommendations) and mark locations

of 4 mounting holes Dia. 8mm(5/16").

Remove and retain 2 side security hex

cover screws and cover. Then mount

the hand dryer base on the wall.

Before replacing cover, there is an

option to run dryer heater on(1000W)

or heater off(600W). The switch is

clearly marked. Replace cover.

Do not over-tighten screws.

Connect the hand dryer plug to the

power supply.

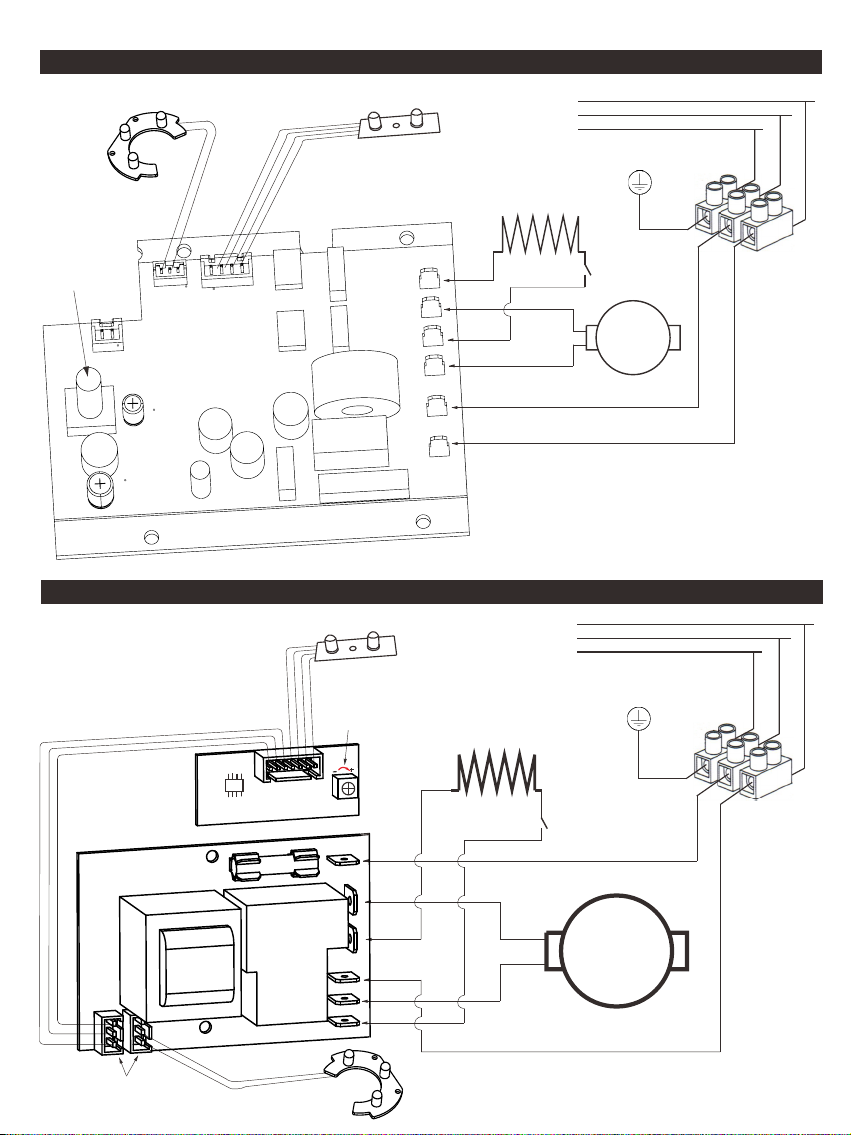

If hand dryer is supplied in hard wired:

a. Connect the live wire(Coloured

Brown, Red, or Black) to the terminal

block marked “L”.

b. Connect the neutral wire(Coloured

Black, Blue) to the terminal block

marked “N”.

c. Connect the ground wire(Coloured

Green or Yellow) to the terminal block

marked “E”.

It is proposed to move the HEPA filter

if needed when does installation.

5. OPERATION

No-touch operation.

There is a blue LED light to guide user

to the air flow.

Shake excess water from hands.

Place hands under the outlet to start

operation.

Rub hands lightly and rapidly.

Stops automatically after hands are

removed.

1.

2.

3.

4.

5.

6.

7.

99MM

286MM

321MM