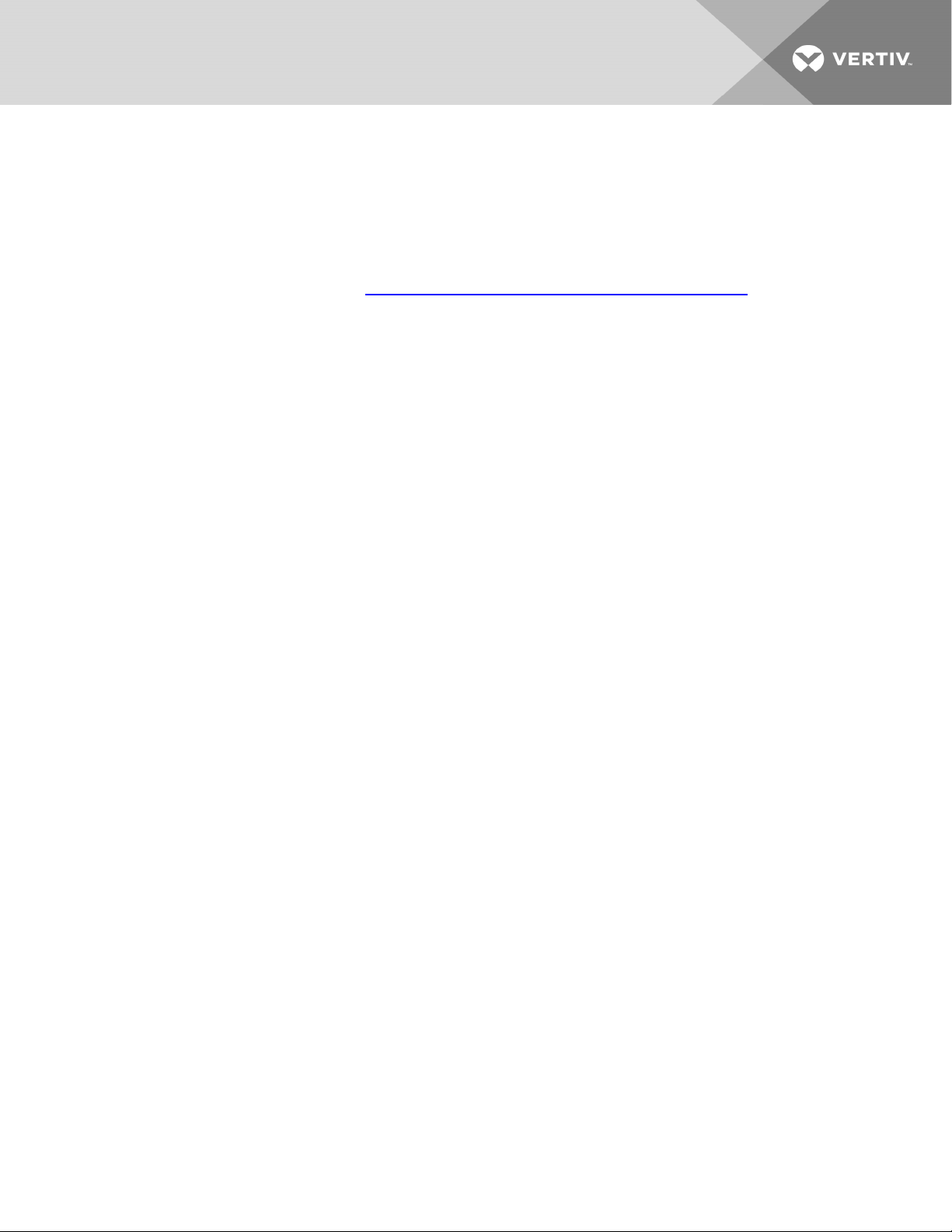

1.1 Model Nomenclature

Table 1.2 below, describes each digit of the model number.

1 2 3 4 5 6

V R C 1 0 0

Table 1.1 VRC Model-number Example

Digit and Description

Digits 1, 2, 3 = Base unit

•VRC = Vertiv™ Rack Cooler

Digit 4 = System type

•1 = Self-contained cooling module

•2 = Split-system indoor cooling module

•3 = Split-system heat-rejection module

Digits 5, 6 = Power supply

•00 = 120V / 1ph / 60Hz

•01 = 208/230V / 1 ph / 60 Hz

Table 1.2 Model-number Digit Definitions

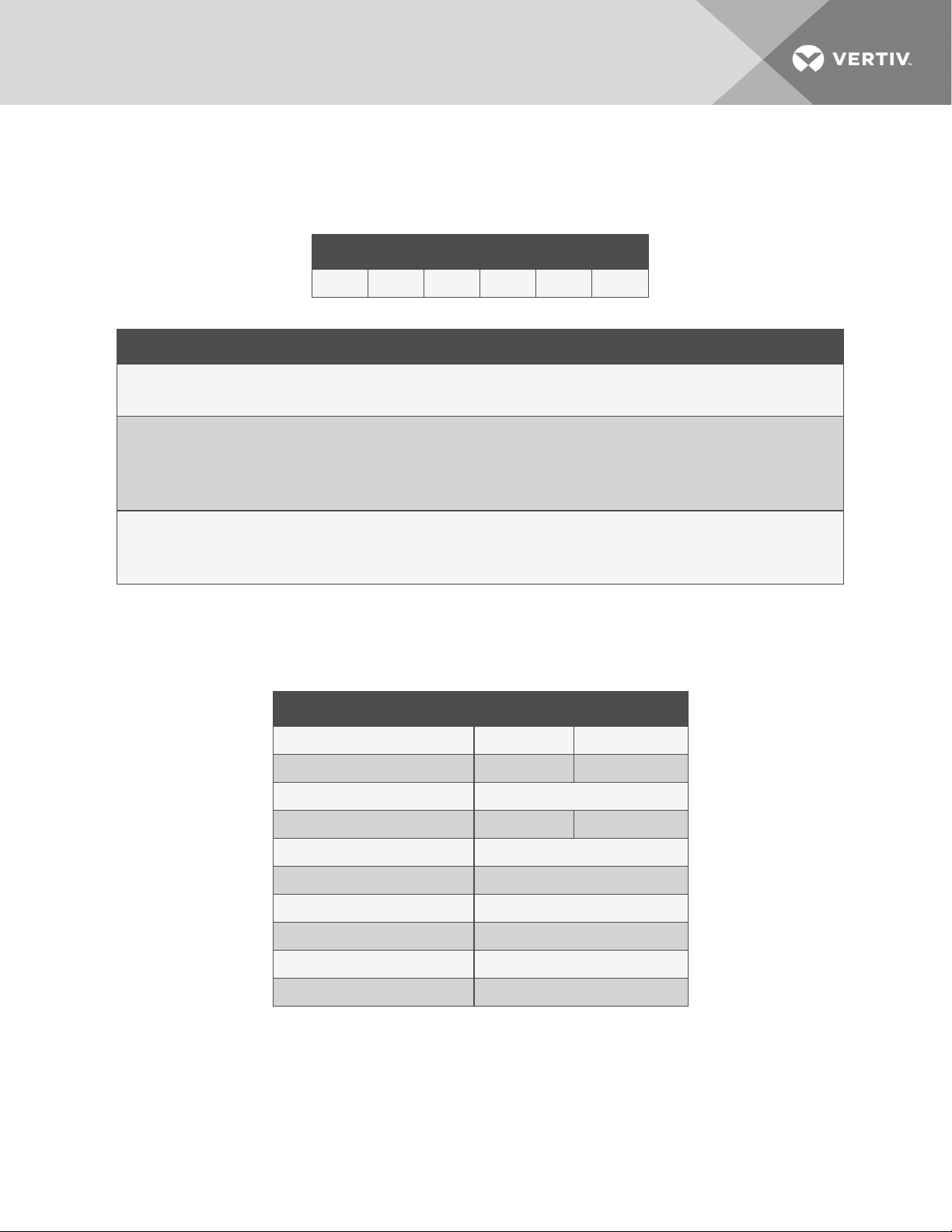

1.2 Specifications

Table 1.3 below, lists the mechanical and electrical specifications of the VRC by model.

Model: VRC100 VRC101

Cooling capacity, kW 0.9 to 3.3 0.9 to 3.3

Air volume, CFM (CMH) 450 (770) 465 (790)

Unit dimensions W xDx h, in.(mm) 17.4x38.5x17.28 (442x978x439)

Voltage, VAC L+N+G , 120 L1+L2+G, 208/230

Frequency, Hz 60

Color EG7021 (black)

System-protection grade IP20

Unit weight, lb (kg) 143.4 (65)

Shipping weight, lb (kg) 218.3 (99)

Noise level <66dB(A)

Table 1.3 Specifications by Model Number

1 Vertiv™ VRC 5