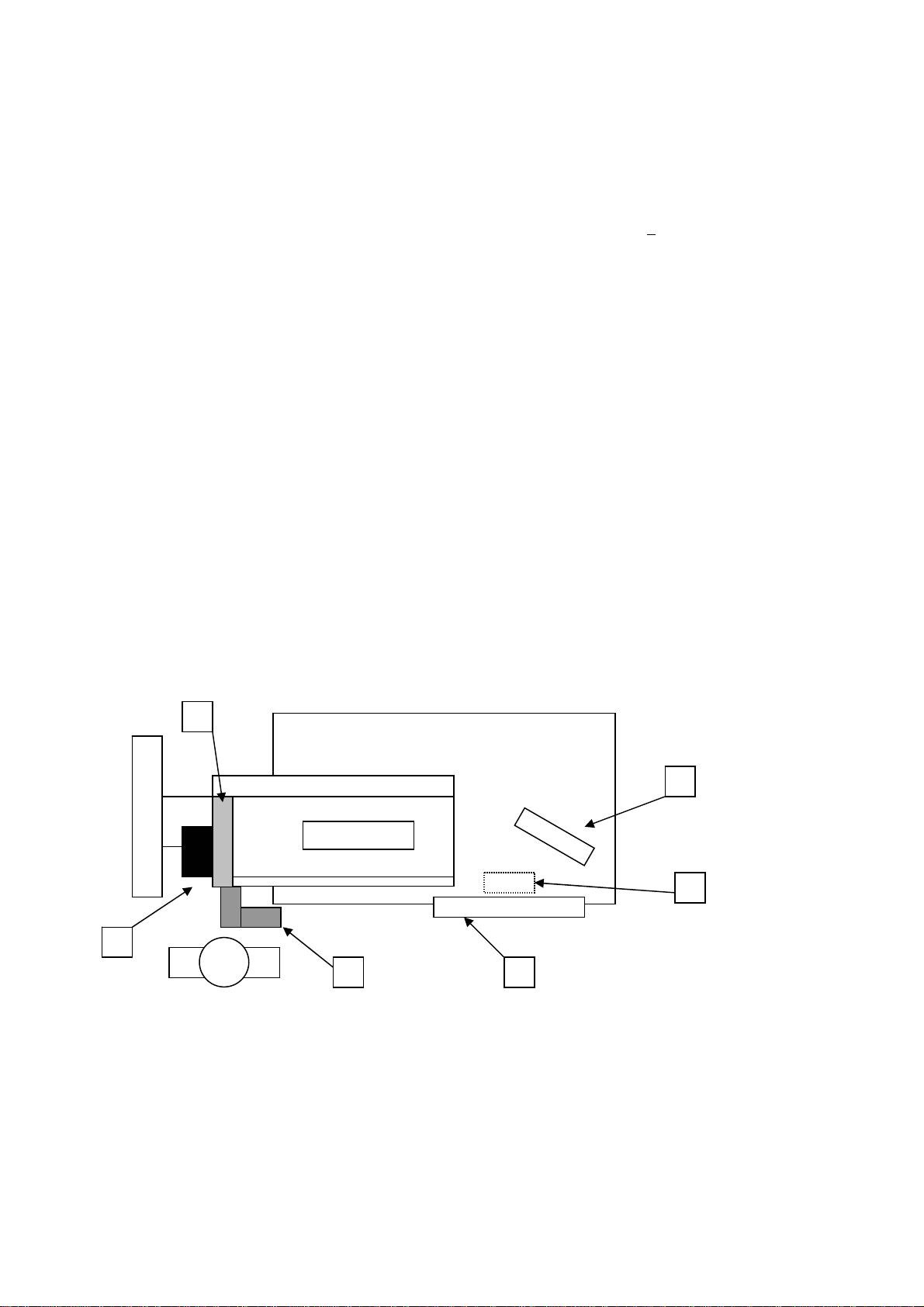

3022CS AUTOMATIC UNIT

3

10.1.PHOTOCELLS............................................................................................................................................................. 34

10.2. SAFETY SENSOR...................................................................................................................................................... 34

10.3. PHOTOCELLS SETTINGS......................................................................................................................................... 35

11. ELECTRO VALVES ........................................................................................................................................................... 36

11.1.CUTTING ..................................................................................................................................................................... 36

11.2.UNSTITCHING............................................................................................................................................................. 36

11.3.PINCER........................................................................................................................................................................ 36

11.4.SAFETY....................................................................................................................................................................... 36

11.5.PRESSER FOOT LIFTER............................................................................................................................................ 36

11.6.NEEDLE COOLING ..................................................................................................................................................... 36

12. SAFETY MICRO SWITCH................................................................................................................................................. 36

13. CYLINDERS....................................................................................................................................................................... 37

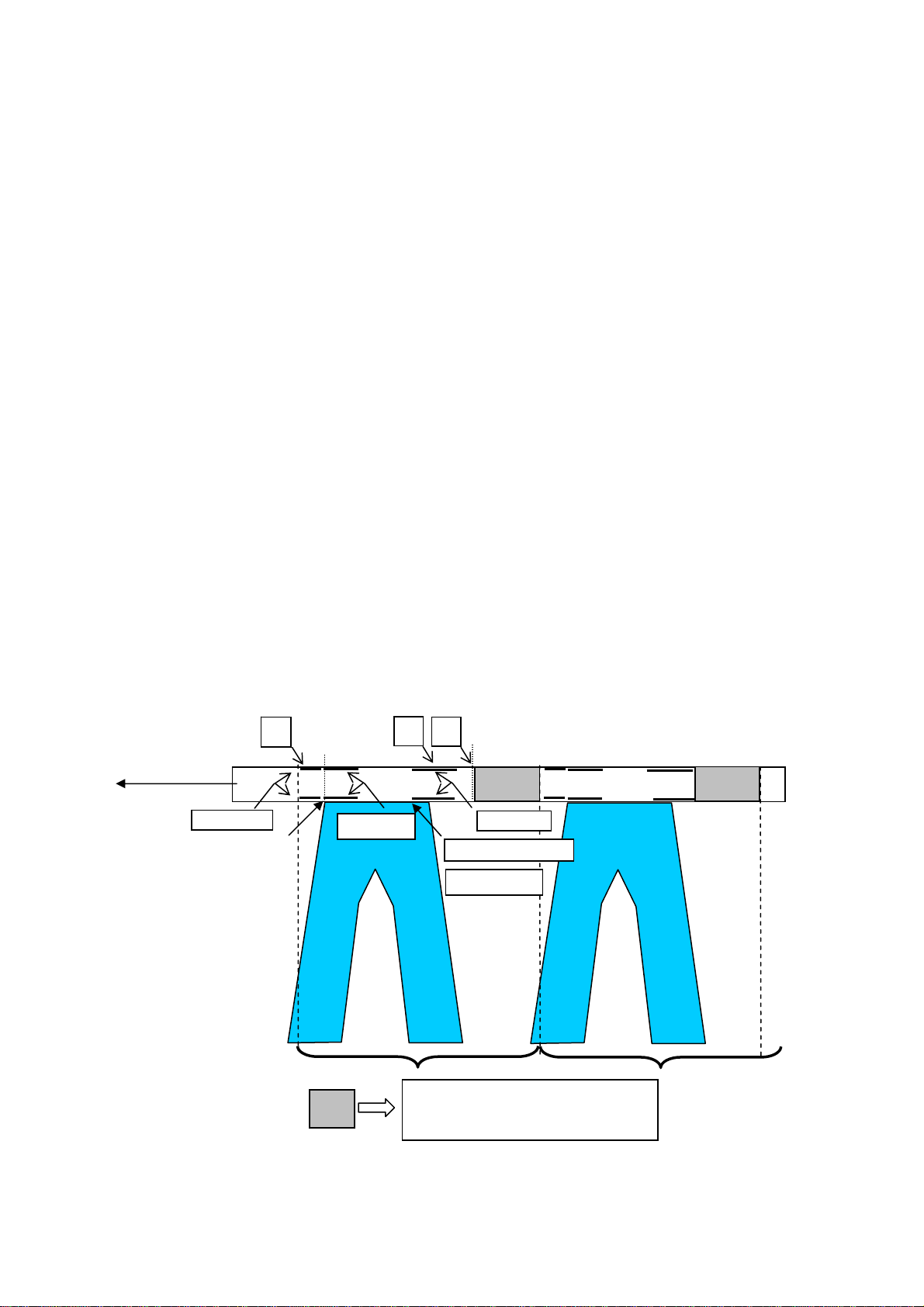

13.1.CUTTING ..................................................................................................................................................................... 37

13.2.SAFETY CUTTING ...................................................................................................................................................... 37

13.3.PRESSER FOOT LIFTER............................................................................................................................................ 37

13.4.PULLER ....................................................................................................................................................................... 37

13.5.UNSTITCHING............................................................................................................................................................. 37

14. PULLING MATERIAL DEVICE........................................................................................................................................... 38

14.1.UPPER RUBBER ROLLER - PULLER......................................................................................................................... 38

14.1.1.ADJUSTING OF THE POSITION.......................................................................................................................... 38

14.1.2.CHANGE THE RUBBER ROLLER........................................................................................................................ 38

14.1.3.VARIABLE PULLEY............................................................................................................................................. 38

14.2.LOWER TOOTHED ROLLER ...................................................................................................................................... 39

15. FOLDER............................................................................................................................................................................. 39

15.1.POSITION.................................................................................................................................................................... 39

15.2.WORKTABLE HEIGHT................................................................................................................................................ 39

15.3.INCLINATION OF THE BORDER HOLDER ................................................................................................................ 39

16. BAND GUIDE..................................................................................................................................................................... 40

17. ADJUSTMENT OF THE PRESSER FOOT PRESSURE .................................................................................................. 40

18. ADJUSTMENT OF THE MECHANICAL EQUIPMENT ...................................................................................................... 41

18.1 CUTTING DEVICE....................................................................................................................................................... 41

18.1.1 ADJUSTMENT OF THE MOVABLE KNIFE POSITION........................................................................................ 41

18.1.2 ADJUSTMENT OF THE CUTTING PRESSURE................................................................................................... 41

18.1.3 UPPER KNIFE CHANGE...................................................................................................................................... 41

18.1.4 LOWER KNIFE CHAGE........................................................................................................................................ 42

18.2.UNSTITCHING DEVICE .............................................................................................................................................. 42

18.2.1 UNSTITCHING LATTEN ADJUSTMENT.............................................................................................................. 42

18.2.2. CYLINDER-SLIDE SUPPORT ADJUSTMENT .................................................................................................... 42

19. MECHANICAL ADJUSTMENT OF THE SEWING HEAD.................................................................................................. 43

19.1.NEEDLE BAR HEIGHT................................................................................................................................................ 43

19.2.NEEDLE PLATE........................................................................................................................................................... 44

19.3.POSITION AND HEIGHT OF THE GUIDING SLIT NEEDLE PLATE........................................................................... 44

19.4.ECCENTRIC FOR THE TRANSLATION MOVEMENT OF THE NEEDLE BAR .......................................................... 45

19.4.1.POSITION............................................................................................................................................................. 45

19.4.2.MOVEMENT LENGTH.......................................................................................................................................... 45

19.5. NEEDLE BAR PENDULUM POSITION ..................................................................................................................... 46

19.6.ECCENTRIC OF THE LOOP STARTINGS MOVEMENT............................................................................................ 47

19.6.1.POSITION............................................................................................................................................................. 47

19.7. DISTANCE BETWEEN LOOPER- NEEDLE............................................................................................................... 49

19.8.SPREADER PHASE .................................................................................................................................................... 50

19.8.1.POSITION............................................................................................................................................................. 50

19.8.2.LENGTH OF MOVEMENT.................................................................................................................................... 51

19.8.3.POSITION OF THE SPREADER MOVEMENT PIN.............................................................................................. 52

19.8.4.POSITION OF THE SPREADER .......................................................................................................................... 52

19.8.5.POSITION OF THE SPREADER PINS................................................................................................................. 52

19.9.STITCH LENGTH......................................................................................................................................................... 53

19.10.ADJUSTMENT OF THE LOWER ROLLER PROFILED PLUGS............................................................................... 53

20. CLEANING......................................................................................................................................................................... 54

21. LUBRICATION................................................................................................................................................................... 54

22. ELECTRICAL CONNECTION........................................................................................................................................... 55

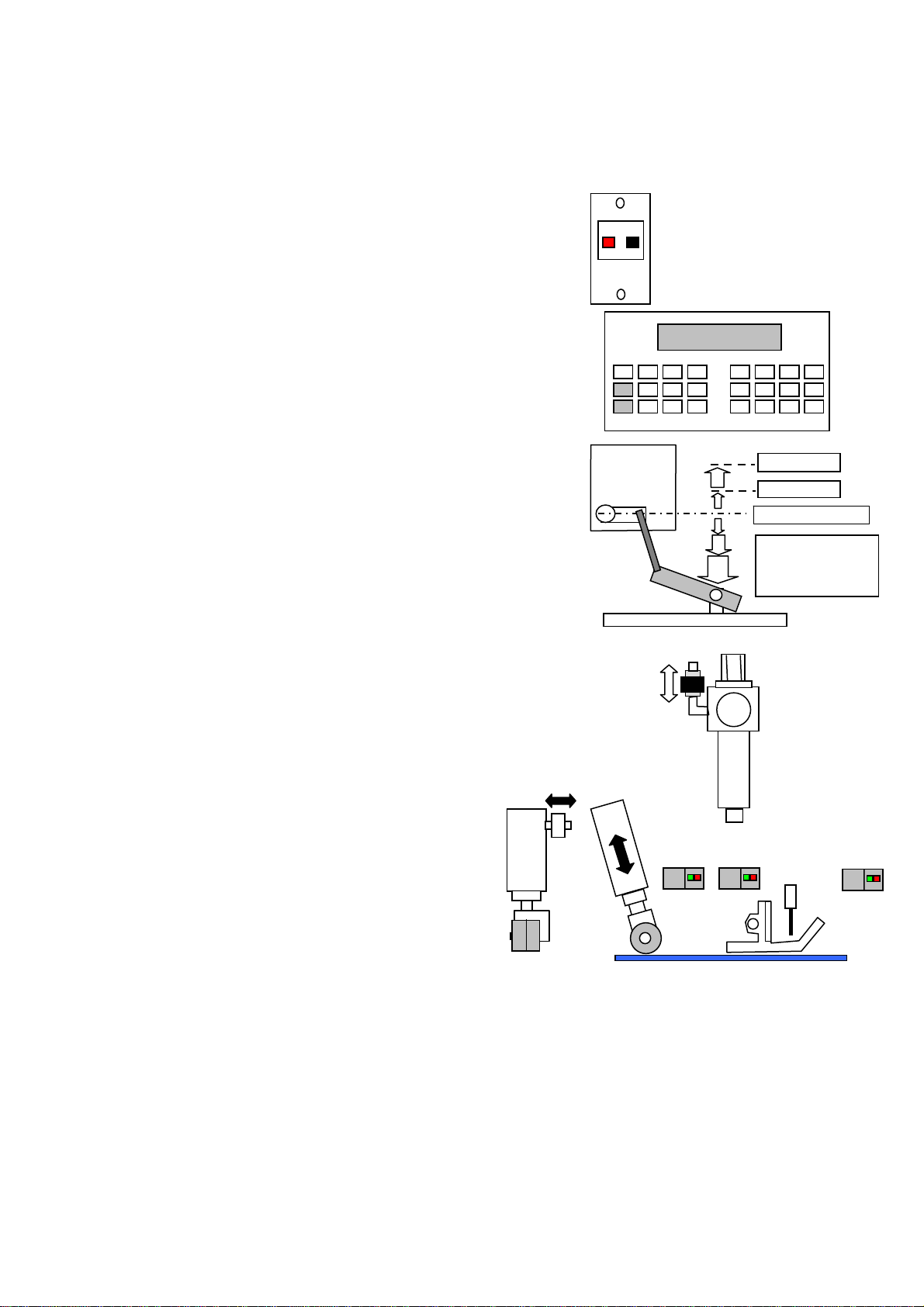

22.1. LS01 PANEL............................................................................................................................................................... 55

22.1.1.INPUTS - 15 POLES CONNECTOR....................................................................................................................... 55

22.1.2.OUTPUTS - 9 POLES CONNECTOR...................................................................................................................... 55

22.1.3.OUTPUTS - 13 POLES CONNECTOR ON THE TABLE......................................................................................... 55

22.3.CARD OF THE GAC03 AND OFM30 STEP BY STEP MOTOR RUNNING ............................................................. 57

23. PNEUMATIC STANDARD SCHEME................................................................................................................................. 58

24. PNEUMATIC SCHEME FOR PRESSER FOOT AND PULLER LIFT AT THE SAME TIME.............................................. 59