IMPORTANTSAFETYPRECAUTIONS VER1.0

1-01

1. Before returning an instrument to the customer, always make a safety check of the entire instrument,

including, but not limited to, the following items.

a. Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1) Protective

shields are provided on this chassis to protect both the technician and the customer. Correctly replace all missing

protective shields, including any removed for servicing convenience. (2) When reinstalling the chassis and/or

other assembly in the cabinet, be sure to put back in place all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fishpapers, adjustment and compartment covers/shields, and isolation

resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective

devices correctly installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or child might be able to insert their fingers

and contact a hazardous voltage, Such opening include, but are not limited to, (1) spacing between the picture

tube and the cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an improperly fitted and/or

incorrectly secured cabinet back cover.

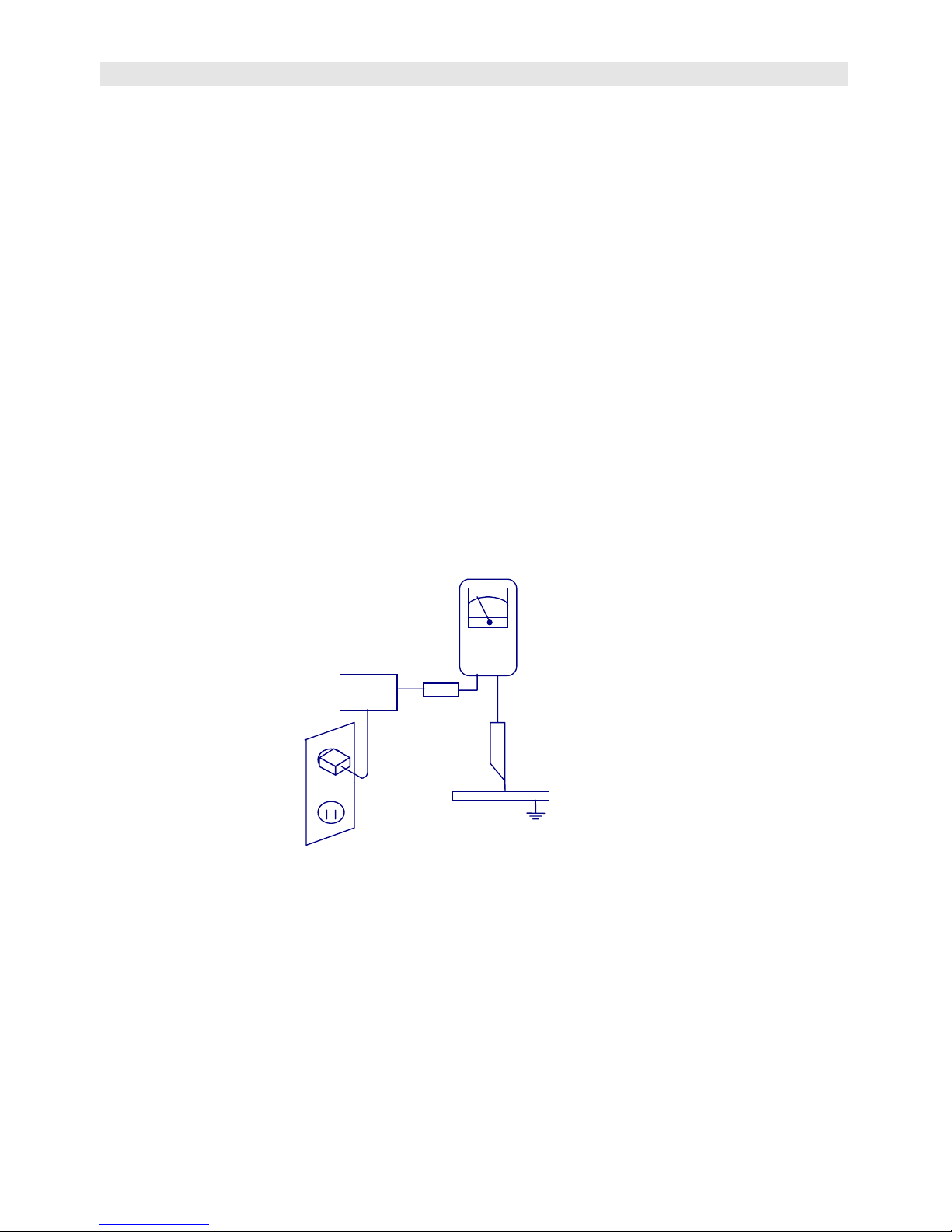

c. Leakage Current Hot Check—

——

—With the instrument completely reassembled, plug the AC line cord directly into a

120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institutes (ANSI) C101.1 Leakage Current for Appliances

and Underwriters Laboratories (UL) 478. With the instrument AC switch first in the ON position and then in the

OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of

the instrument (antennas, handle bracket, metal cabinet, screwheads, metallic overlays, control shafts, etc.),

especially any exposed metal parts that offer an electrical return path to the chassis. Any current measured must

not exceed 3.5 milliamp. Reverse the instrument power cord plug in the outlet and repeat test. ANY

MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK

HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE CUSTOMER.

2. Read and comply with all caution and safety-related notes on or inside the Monitor cabinet, on the Projection

Monitor chassis, or on the picture tube.

3. Design Alteration Warning—

——

—Do not alter or add to the mechanical or electrical design of this unit. Design

alterations and additions, including, but not limited to, circuit modifications and the addition of the items such as

auxiliary audio and/or video output connections might alter the safety characteristics of this Projection Monitor

and create a hazard to the user. Any design alterations or additions will void the manufacturer’s warranty and will

make you, the service, responsible for personal injury or property damage resulting therefrom.

DEVICE

UNDER

TEST