VISIPORT DiscAir TURBO DA175T User manual

Table of contents

Popular Fan manuals by other brands

Omega Altise

Omega Altise OP408R Operation, maintenance and safety instructions

Genvex

Genvex ECO 375 TS installation manual

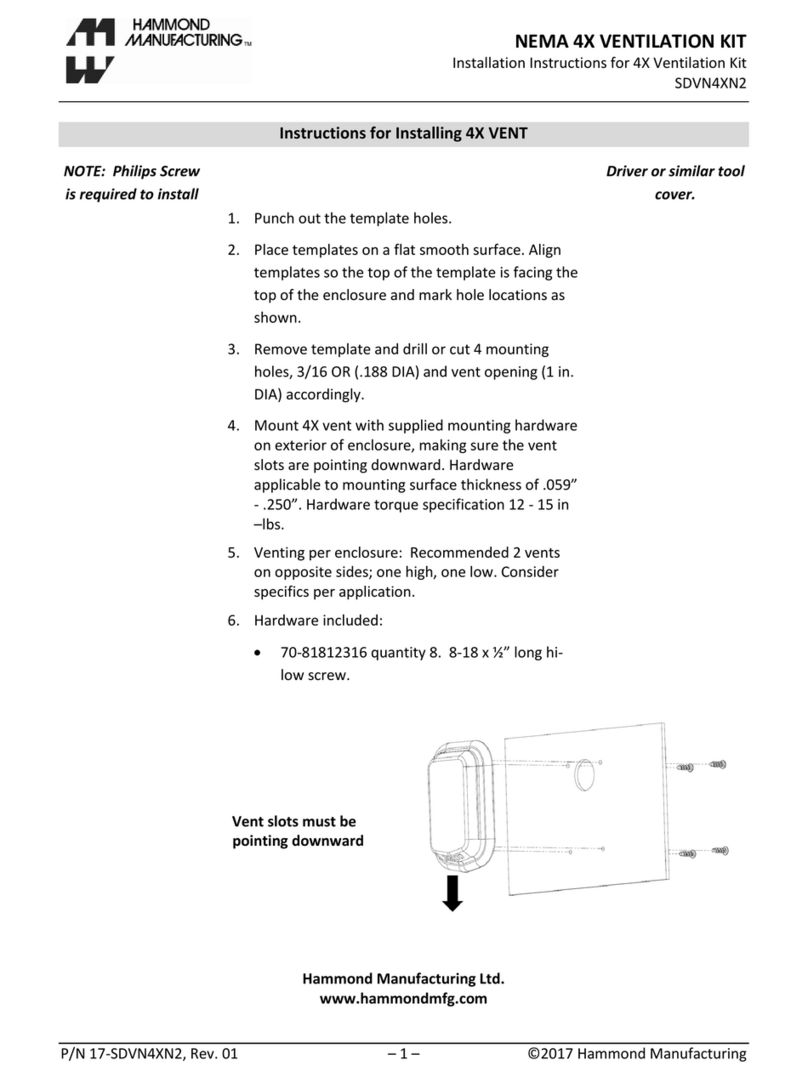

Hammond

Hammond SDVN4XN2 installation instructions

Ebmpapst

Ebmpapst K2E200-AD08-02 installation guide

Ebmpapst

Ebmpapst A3G630-AC52-58 operating instructions

Ebmpapst

Ebmpapst R4E250-AH01-05 operating instructions

Ebmpapst

Ebmpapst A4D500-AJ03-02 operating instructions

Ebmpapst

Ebmpapst A4E350-AF20-05 operating instructions

Ebmpapst

Ebmpapst A2S130-AB03-15 operating instructions

Maxxair

Maxxair ICF72 Installation operation maintenance warranty manual

System air

System air KBR Installation,operation and maintenance instruction

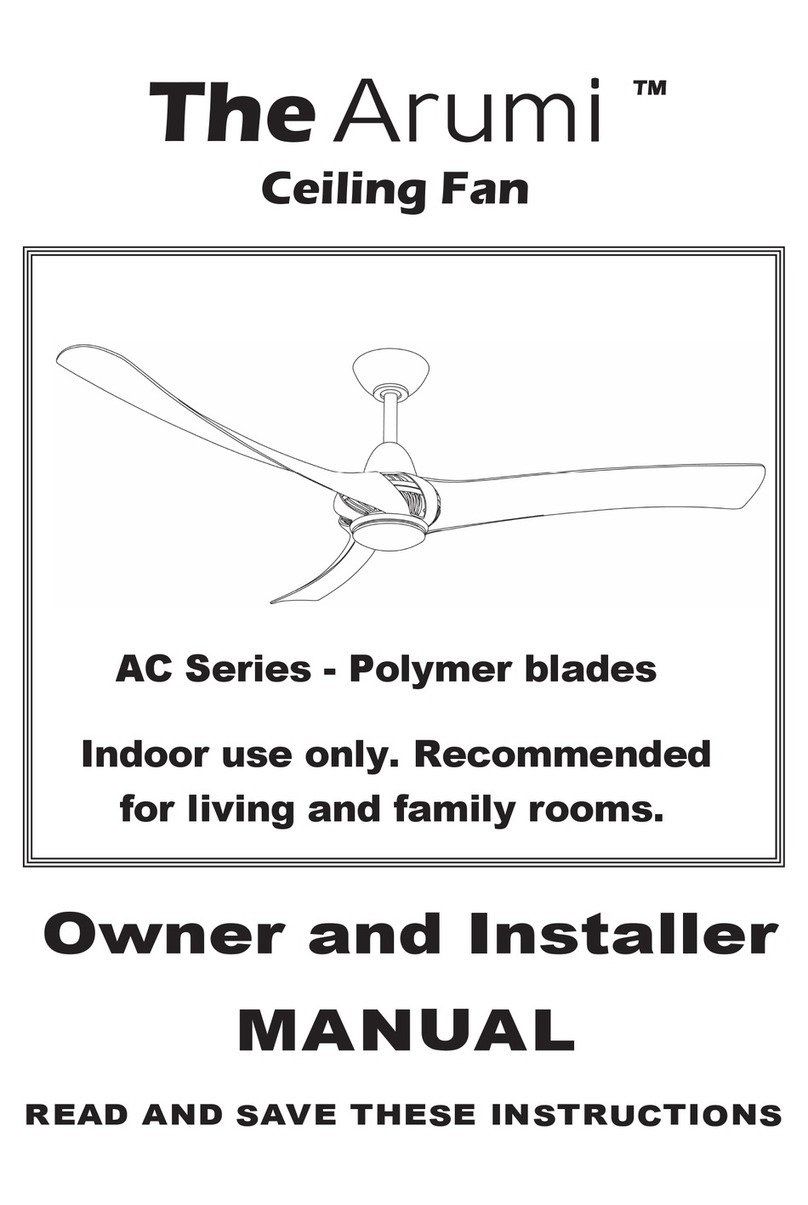

Three Sixty

Three Sixty Arumi AC Series Owner's and installer's manual

Magicfx

Magicfx Stage Fan User and installation manual

Maxxair

Maxxair CX1500 RED installation instructions

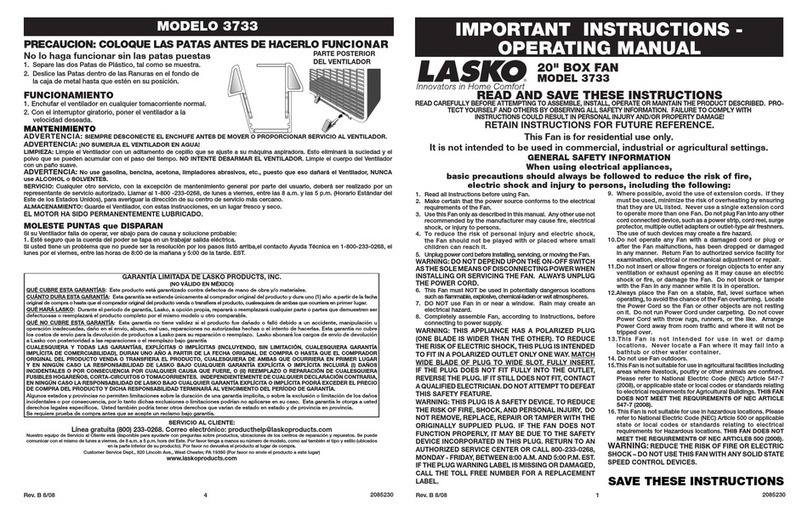

Lasko

Lasko 3733 Important instructions & operating manual

NuTone

NuTone ROOMSIDE Series quick start guide

Minka-Aire

Minka-Aire uchiwa Instruction manual warranty certificate

Honeywell

Honeywell HYF1101E4 User instructions