Vitrex Powercut 800 User manual

Powercut 800

Bridge Saw

Safety First

Read manual before use.

Keep hands arms and face

clear of blade while its in

use. Always have safety

guard in place when machine

is switched on at the

mains. Always wear Vitrex

protective equipment when

using hand or power tools.

CONTENTS

SPECIFICATIONS ...........................................................1

SAFETY .................................................................1–2

SPECIFIC SAFETY RULES .....................................................2

SPECIAL SAFETY INSTRUCTIONS BEFORE USING MACHINE .....................2-3

ASSEMBLY ..............................................................3–4

OPERATING .............................................................4–5

MAINTENANCE...........................................................5–6

TROUBLE SHOOTING........................................................6

ACCESSORIES .............................................................6

02

CONSUMER ADVICE

• Do not dispose of

electrical products

with your normal

household waste

• Always use recycling

facilities whenever

possible

• Additional recycling

information can be

found through your local

Authority or Retailer.

• For further information

or advice, please call the

Technical Helpline on

01253 789180.

This machine has been

designed to be fully

recycled without any risk

of pollution according to

the European Directive

2002/95/EC RoHS

(Reduction of Hazardous

Substances) / WEEE

(Waste from Electrical

and Electronic Equipment).

WARNING

1. Always wear safety goggles when cutting.

2. Use splash hood for every operation for which

it can be used.

3. Disconnect saw before cleaning or changing blade.

4. Do not use any cutting blade with openings

and grooves. Use only continuous rim blades.

5. Replace damaged blade before operating.

6. Do not expose to rain or use in damp locations.

Powercut 800 Bridge Saw

Q.E.P. Co UK Ltd.

Everest Road, Lytham St Annes

Lancashire FY8 3AH

Tel +44 (0) 1253 789180

Fax +44 (0) 1253 78918

– 1 –

03

Please read this manual carefully prior to

operating and keep this manual in a safe place

for future reference.

SPECIFICATIONS

Mains voltage (Volt): 240 VAC~50Hz

Motor capacity S1: 800W

Insulation class: B

House protection class: IP54

No load speed (rpm): 2900

Max cut depth 90°/45°: 35/35mm

Max cut length: 720mm

Blade size: 200 x 22.23mm

(bore)

Table size: 1010 x 402mm

Extension: 230 x 150mm

Net weight: 31kg

SAFETY

The Powercut 800 Bridge Saw is designed for

the cutting of small and moderate size ceramic

tiles, marble and granite. This bridge saw has the

ability to cut materials at 45–90 degree angles.

GENERAL SAFETY RULES

Read these instructions carefully and keep for

future reference.

CAUTION! — To reduce the risk of accident,

electrical shock or bodily injury when using

power tools, it is recommended to always

observe basic safety precautions, including

the following:

Keep work area clear

• Cluttered areas and benches invite injuries.

Consider work area environment

• Do not expose tools to rain.

• Do not use tools in damp or wet locations.

• Keep work area well lit.

• Do not use tools in the presence

of ammable liquids or gases.

Guard against electric shock

• Avoid body contact with earthed or grounded

surfaces (e.g. pipes, radiators, ranges,

refrigerators).

• Disconnect tools from the mains when not in

use, and when changing accessories such

as blades.

• Ensure switch is in “off” position when

plugging in.

• When the tool is used outdoors, use only

extension cords intended for outdoor use and

so marked.

Keep other persons away

• Do not let people, especially children, not

involved in the work touch the tool or the

extension cord and keep them away from the

work area.

Store idle tools

• When not in use tools should be stored in a

dry locked-up place, out of reach of children.

Do not force the tool

• It will do the job better and safer at the rate

for which it was intended.

Use the right tool

• Do not force small tools to do the job of a

heavy duty tool.

• Do not use tools for purposes not intended,

for example do not use circular saws to cut

tree limbs.

Dress properly

• Do not wear loose clothing or jewellery;

they can be caught in moving parts.

• Non-skid footwear is recommended when

working as operation creates dust.

• Wear protective hair covering to contain

long hair.

Use protective equipment

• Use safety glasses.

• Use face or dust mask if working operations

create dust.

Do not abuse the cord

• Never yank the cord to disconnect it from the

socket. Keep the cord away from heat, oil and

sharp edges.

Do not overreach

• Keep proper footing and balance at all times.

Maintain tools with care

• Inspect tool cords periodically and if damaged

have them repaired by an authorized service

facility.

• Inspect extension cords periodically and

replace if damaged.

• Keep handles dry, clean and free from oil

and grease.

Stay alert

• Watch what you are doing, use common

sense and do not operate the tool when you

are tired.

Check damaged parts

• Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation.

• Do not use the tool if the switch does not turn

it on and off.

– 2 –

Warning

• The use of any accessory or attachment other

than one recommended in this instruction

manual may present a risk of personal injury.

• This electric tool complies with all relevant

safety rules.

TRANSPORTATION

• Before transporting the bridge saw, lock the

cutting unit at the middle of rail by engaging the

locking system.

• Two people are required to move the bridge

saw. The leg or the machine frame can be used

to lift the machine off the ground for moving.

SPECIFIC SAFETY RULES

• Ensure that the directional arrow marked on the

blade corresponds with the rotational direction

of the motor.

• With the machine disconnected from the power

supply, rotate the blade by hand to ensure it is

free from obstruction.

• Always keep the blade-securing arbor and

collars clean.

• Ensure that the blade-securing bolt is securely

tightened.

• Never try to cut freehand. Always ensure that

the tile to be cut is pressed rmly against the

rip fence.

• Ensure that the work piece that will be cut off

has sufcient room to move sideways. Failure

to do so may result in the off-cut binding

against the blade.

• Never cut more than one tile at a time.

• Never cut pieces too small to be held securely

against the rip fence without leaving enough

space for the hand to be a safe distance from

the blade.

• Ensure that the table & surrounding area are

clear with the exception of the tile to be cut.

• Before cutting a tile piece, let the diamond

blade run freely for a few seconds. If it makes

an unfamiliar sound or vibrates excessively,

switch it off immediately and disconnect from

the power supply.

• Let the blade reach full speed before beginning

to cut.

• Let the blade come to a complete stop before

removing any jammed or cut off material from

around the blade area.

• Never allow the blade to run dry. Failure to keep

the water tray topped up will result in possible

over-heating of the diamond blade.

• Do not expose to rain or moisture.

• Wear suitable protective equipment.

• Adopt a working position to the left of the

diamond blade.

• Ensure that cut off tile pieces are not caught by

the blade and sent ying.

• Never remove loose splinters, chips or small

pieces while the diamond blade is moving.

• Before repairing faults or removing jammed tile,

always switch the bridge saw off and pull out

the mains plug.

• Before switching on, check that all spanners

and setting tools have been removed.

• When leaving the workplace, switch off the

motor and disconnect from the mains.

• The manufacturer’s safety, working and

maintenance instructions and the dimensions

stated in the Technical Information must be

adhered to.

• The relevant regulations for the prevention

of accidents and other generally recognized

safety regulations must be followed.

Caution!

• Switch off bridge saw immediately and

disconnect from the mains if;

• the power feed lead and switch are damaged

• the motor is overheating

• smoke is emitted or there is a smell of charred

insulating material.

• Use only a diamond blade for which the

maximum possible speed is not less than the

maximum spindle speed of the bridge saw and

the material to be cut.

• Fill the cooling tank 3/4 full of water. It is quite

normal for the equipment to cause splattering

during use.

SPECIAL SAFETY

Check the following points:

1. Does the voltage of the motor correspond to

the mains voltage.

2. A grounded mains connection (wall socket)

needs to be used.

3. Are the mains lead and the mains plug in

a good condition without any loose ends

or damage.

• Avoid using long extension cables.

• Always place the cutting machine on

a at surface to prevent instability.

While using the machine:

1. Never use-cracked diamond saw blade,

replace them.

04

– 3 –

2. Be sure that the switch is in the OFF-position

before connecting the machine to the

mains voltage.

3. Always keep away the mains lead from moving

parts of the machine.

4. Do not apply side-pressure to the saw blade. It

can break the blade and cause injury.

5. Remove the plug out of the wall socket before

you open the machine.

IMMEDIATELY SWITCH OFF THE

MACHINE IN CASE OF:

• Excessive sparking of the brushes.

• Malfunction of the mains plug, socket or

damaged cables.

• Broken switch.

• Smoke or smell caused by scorched insulation.

ASSEMBLY

Read the manual carefully before installation

1. Clean the working area, open the package and

remove all packing materials, you will nd the

folded machine. (see FIGURE 1)

FIGURE 1

2. Lay the machine on its side on the ground,

assemble one leg by screwing it into the nut

welded under the main frame (see FIGURE 2),

make sure it is tightened by means of tools (see

FIGURE 3 and FIGURE4).

Following the same procedure to x other 3 legs,

and then stand the saw upright.

FIGURE 2

FIGURE 3

FIGURE 4

To stabilize and level the saw, adjust the leveling

“set screw” located on the bottom of one leg

(see FIGURE 5).

FIGURE 5

3. To assemble the handle, position the handle

against the blade guard and secure it using the

attached 3 screws.

4. The cutting unit is locked in the middle of slide

rail during shipment. Before using the saw, pull

the lock knob out of its slot and rotate and put it

into the upright slot (see FIGURE 6).

lock knob

FIGURE 6

05

– 4 –

Note: When not in use, please always make sure

the cutting unit is locked at the middle of the

slide rail to prevent it from rolling back and forth

along the bridge. Move the cutting unit until the

arrow is aimed at the marked lock position and

put the knob into the locked position. Continue

moving the cutting unit along the slide rail until

fully locked.

OPERATING

Filling The Water Tray And Draining

1. Fill the tray with water through the cutting slot.

Don’t add chemicals or detergents to the water.

2. Be sure that the water level is always

between the MAX and MIN level, so that the

saw blade turns through appropriate water.

This is necessary to cool the saw blade in a

correct way.

3. If the machine is not used, water should be

drained. Remove the plug from the bottom of tray

the water will ow out or you can take out the

tray and pour the water out.

Starting And Stopping

1. Insert the plug into a socket with a safety

contact. This must be protected with a fuse

e.g. in the terminal box. If an extension cable is

required, please note that with a cable length of

up to 20m cable with a cross-section of 1.5mm²

must be used.

2. To start the saw, press the green button

marked “I”.

3. To stop the saw, press the red button “O” (see

FIGURE 7).

FIGURE 7

Overload Protection: the motor is equipped with

a Circuit Breaker at the side face of the switch

box. If the motor is over loaded, gets too hot or

the current gets very big, the circuit breaker will

act automatically and power down the machine.

If this occurs, please wait a few minutes until the

motor has cooled down and then press the reset

button (beside the On-/Off-Switch) and the bridge

saw can be restarted.

Making A Straight Cut

1. Loosen the knob of the angle cutting guide

and position the tile on the cutting table against

the fence with the zero aligned with the notch,

so that it is in a straight line. This indicates “no

angle”, or a straight cut. The angle cutting guide

will be at a 90º angle to the fence. Tighten knob to

keep guide in position (see FIGURE 8).

FIGURE 8

2. Slide the angle guide against the tile and lock

the gauge by turning the knob.

3. Keep the tile rmly against the fence and

the angle cutting guide, slowly and smoothly

pull blade assembly handle towards you to

begin cutting. DO NOT force the motor to cut

too quickly.

NOTE: Pay attention to the width of the work

piece. If the width on “a” is more than 250mm

(see FIGURE 9) and the width on “b” is more than

550mm (see FIGURE 10), please assemble the

extension table to support the work piece.

FIGURE 9

FIGURE 10

06

– 5 –

Making a Mitre Cut

1. Loosen the knob and position the rip/miter

guide so that the correct angle you want, 0º to

45º, is lined up with the notch. Tighten knob at

that position.

2. Align the tile with rip/miter guide and hold

rmly against guide. As in above straight cut,

slowly and smoothly pull blade assembly handle

towards you to begin cutting. (see FIGURE 11)

FIGURE 11

Making A Bevel Cut

1. Loosen the knobs located on each rail end of

the bridge saw (see FIGURE 12).

2. Tilt the bridge to the desired bevel angle 0º to

45º. Be sure to line up the bevel angle degree

markings on each of the end rail stand. The

degree of bevel cut can also be seen through the

transparent window above end rail stand.

3. Tighten the knobs and follow directions above

to make cut.

FIGURE 12

Installing/Replacing the Blade

WARNING! — Disconnect the power supply

before installing or making adjustments to

the blade.

Only use a diamond saw blade with a diameter

of 200mm for Powercut 800 Bridge Saw. The

bore of the blade must be 22.23mm.

1. First, to disconnect the water supply, press

the blue ring and pull out the water supply tube

from the inlet connection on the blade guard (see

FIGURE 13).

FIGURE 13

2. Then, remove the blade guard by removing

the two securing screws (see FIGURE 14 and

FIGURE 15).

FIGURE 14

FIGURE 15

3. Ensure that the shaft and anges are clean

and re-t the blade in the opposite manner.

Directional arrows on blade MUST line up with

directional arrow on blade guard, so that material

to be cut is against the direction of rotation.

4. Replace the ange back, and adjust the blade

to get the best balance of blade.

5. Fix the lock nut tightly.

MAINTENANCE

CAUTION! — While maintaining and cleaning

the machine pull the plug from the mains socket.

• Never use water or other aggressive liquids

while cleaning electrical parts of the machine.

07

– 6 –

• Periodic maintenance of the bridge saw will

prevent unnecessary problems. Keep the

ventilation slots of the bridge saw clean to

prevent overheating of the motor.

• Dry the bridge saw as much as possible

after using.

Pump Maintenance

Warning! — Always disconnect from electrical

outlet before handling the pump.

• Do not let the pump run dry.

• Do not lift the pump by the power cord.

• Do not pump heated liquids.

• Operate in freshwater only.

• Operate pump completely submerged for

proper cooling.

intake

cover

flow

regulator

impeller

cover

impeller

motor head

outlet

FIGURE 16

A clogged or dirty intake cover will greatly

reduce performance. If the pump is used in

dirty water, raise it slightly to reduce the amount

of debris contacting the intake. If

less ow is desired, adjust the ow regulator

on the front of the pump.

Do not let the pump run when not submerged in

water. Doing so may damage the pump. Always

submerge the pump rst, and then plug in the

electrical outlet. If the pump does not function

straight away, switching the power on and off

several times will normally correct this.

To clean the pump, remove the intake cover

and the impeller. Use a small brush or stream of

water to remove any debris.

TROUBLE SHOOTING

If The Pump Fails To Operate,

Check The Following:

• Check the circuit breaker and try another power

source to ensure the pump is getting electrical

power. NOTE: Always disconnect from

electrical outlet before handling the pump.

• Check the pump discharge and tubing for kinks

and obstructions. Algae build up can be ushed

out with a jet of water.

• Check the intake cover to ensure it is not

clogged with debris.

• Remove the intake cover to access the

impeller area. Turn the impeller to ensure it is

not broken or jammed.

• Monthly maintenance will add to your

pump’s life.

NOTE: Ensure that the electrical cord loops

below the electrical outlet to form a “Drip

Loop.” This will prevent water from running

down the cord into the electrical outlet.

Replacing The Pump

If the pump still does not work, you have to

replace pump with a new one. Only use the pump

recommended by the manufacturer of the bridge

saw. Call the Technical Helpline on 01253 789180

or return to location of purchase.

The changing procedures are as follows:

1. Loosen the bolt of the pump connecting box

located on one end of main frame and remove

the cover.

2. Loosen the bolt of the pump cable lock and

take the pump plug out of connecting box (see

FIGURE 17).

FIGURE 16

3. Take out the pump and replace a new one,

install the new pump by reversing the above

procedures.

ACCESSORIES

• 45-degree angle guide

• Parallel rip fence

• Hexagonal blade wrench

• Motor shaft holding wrench

08

Table of contents

Other Vitrex Saw manuals

Popular Saw manuals by other brands

CRAIN

CRAIN 820/820V operating instructions

Powermatic

Powermatic 66 operating instructions

Laguna Tools

Laguna Tools HW110LS-30 owner's manual

MK Diamond Products

MK Diamond Products MK-212 Series Owner's manual & operating instructions

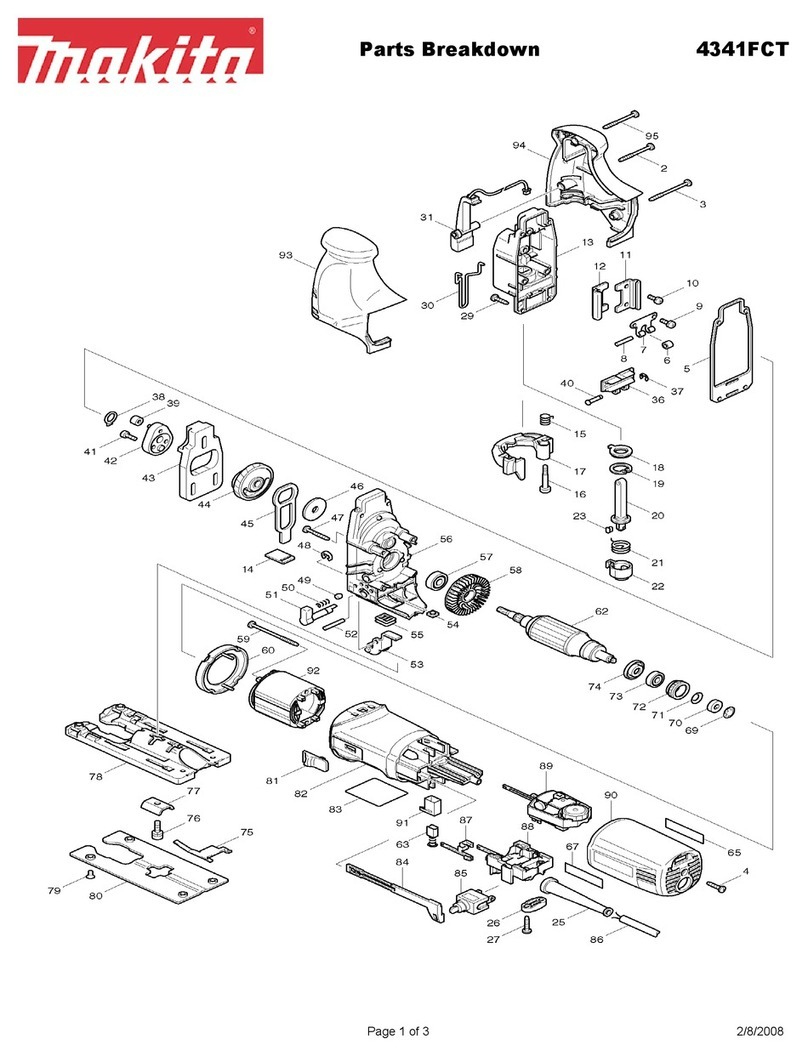

Makita

Makita 4341FCT Parts Breakdown

King Canada

King Canada KC-5006R instruction manual