Voith CTO-B45202 Parts list manual

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 1 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

7

Overspeed Protector

Type: CTO-B45202

Translation of the Original version

Instruction and Operating Manual

Version 2.1

ATTENTION!

Please make sure to read this instruction manual prior to transport, installation,

commissioning, operation, etc. and keep it for further use!

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 2 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Should you have any questions concerning the

overspeed protector, please contact J.M. Voith SE & Co.

KG, Crailsheim, After-Sales Service of Product Group

Division Digital Ventures in Crailsheim, indicating the

article number and the serial number of the overspeed

protector.

J.M. Voith SE & Co. KG

P.O. Box 15 55

D-74555 Crailsheim

Switchboard: +49 (0) 7951 / 32 - 0

Fax No.: +49 (0) 7951 / 32 - 500

After-Sales Service of Product Group

Division Digital Ventures

Direct dial: +49 - 7951 / 32 - 470

Direct fax: +49 - 7951 / 32 - 605

Email: turcon@voith.com

Address for deliveries of goods:

Voith Group │ Division Digital Ventures

J.M. Voith SE & Co. KG

Voithstraße 1

D-74564 Crailsheim

This instruction manual describes the design standard of

overspeed protector type SMR A45202 with delivery as of

2019 / 02.

J.M. Voith SE & Co. KG 2019

This Instruction Manual is protected by copyright laws. It

must not be translated, duplicated (mechanically or

electronically) in whole or in part, or passed on to third

parties without the publisher's written approval.

Established/revised: 2019 / 02

Order No.: 9183626018864 en

Version: 2.1

Printed in Germany

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 3 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Contents

Instruction and Operating Manual

Page

1Technical Data ............................................................................................................................... 4

2Safety information......................................................................................................................... 6

2.1 Definition of symbols and warnings ......................................................................................... 6

2.2 Proper use................................................................................................................................ 6

2.3 Important information............................................................................................................... 6

2.4 Warranty................................................................................................................................... 8

3Function.......................................................................................................................................... 9

3.1Mechanical design ................................................................................................................... 9

3.2 Operation ............................................................................................................................... 10

3.3 Trip criteria............................................................................................................................. 10

4Packing, Storage, and Transportation....................................................................................... 12

5Installation.................................................................................................................................... 13

5.1 Mounting ................................................................................................................................ 13

5.2 Hydraulic connection.............................................................................................................. 14

5.3 Electrical Connection ............................................................................................................. 14

6Adjustments and Commissioning ............................................................................................. 15

6.1 Adjustment of turbine trip frequency...................................................................................... 15

6.2 Adjustment of UF- and If-potentiometers............................................................................... 18

7Maintenance and Repair ............................................................................................................. 22

8Decommissioning........................................................................................................................ 23

9Annex............................................................................................................................................ 24

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 4 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

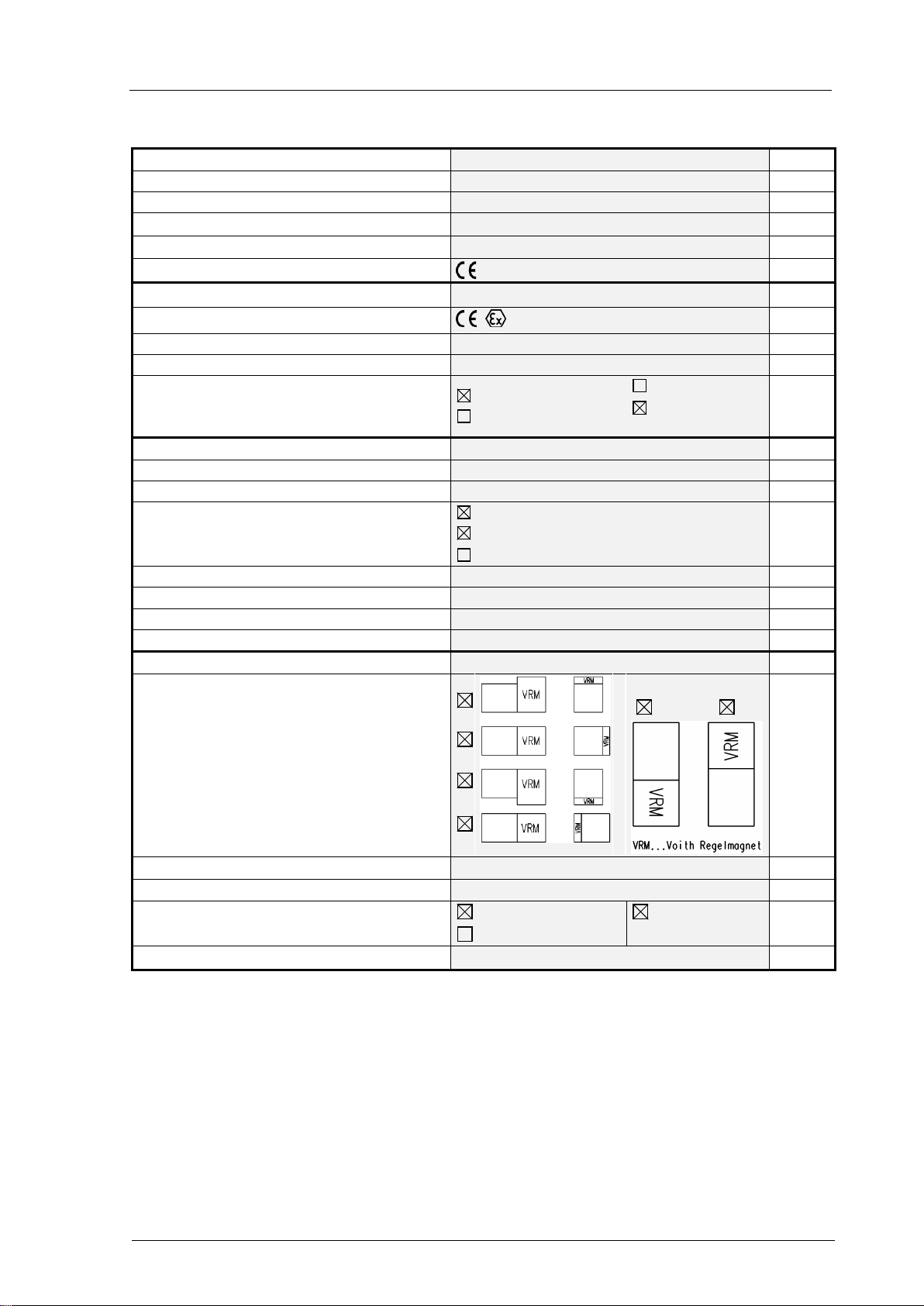

1 Technical Data

Overspeed protector type CTO-B45202

Article number

91868550

Instruction Manual No. 918 3626018864

Product identification

See nameplate

EC Declaration of Conformity

See separate document

EC marking

Protection IP 65 as per EN 60529

Explosion protection

II 2G IIC T4

Ambient temperature T

A

(operation)

-30 ... +60

°C

Ambient temperature (storage) -40 ... +90

Installation conditions Indoor installation

Outdoor installation

Offshore

Industr.

atmosph.

Hydraulic Data

Supply pressure Pmax 25 bar

Operating medium

Type Hydraulic oil as per DIN 51524

Turbine oil as per DIN 51515

High-flash point fluid1)

Oil temperature during operation

+10 … +60

°C

Cleanliness grade (ISO VG 4406)

- / 16 / 13

Viscosity (DIN 51519) ISO VG 32 … ISO VG 46

Leakage (Toil = 50 °C and P=10 bar)

< 2

l/min

Mechanical Data

Installation positions

Dimensions, fastening

See Chapter 9

Hydraulic connection

See Chapter 9

Sealing material

FPM2)

Special design4)

NBR3)

Weight approx. 14 kg

1) According to customer's request or especially for high-flash point fluids

2) Fluor-caoutchouc

3) Acrylnitril-Butadien-caoutchouc

4) according to the customer's specification and consultation with J.M. Voith SE & Co. KG │ Division Digital Ventures

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 5 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Electrical Data

Supply voltage (power) including residual ripple 24 (+10% / -15%)

5)

V DC

Current consumption

0.5 A±0.2A, max. 3 A for t < 1.5±0.5 sec

Trip-stop frequency fss 4000…10000Hz adjustable in 256 steps,

accuracy 0.25%6) , nameplate, temperature error

120ppm/K

Actual speed remote indication

4…20mA, for f=0… f

ss

Speed input Connect an inductive speed sensor, preferably

sinusoidal voltage, permissible voltage range

0.5Vrms...18Vrms (when connected), permissible

internal resistance range 600Ω…4500Ω7)

Other data

Function - Trip Simulation (partial stroke

check)

Disconnecting time with Potentiometer T4

10ms…25ms

Trip time of overspeed shutdown 40ms at Toil<40°C

8)

Trip criteria See Chapter 3.4

5) Permanent operation of CTO is allowed within this supply voltage range

6) The indication refers to the trip frequency re-measured after the adjustment, as shown on the nameplate.

7) Thei DC voltage resulting depends on the internal resistance of the speed sensor. For an internal resistance of 1000 Ω,

the DC offset voltage is 1.65V ±0.15V.

8) The tripping time is the time required by the control piston to move to its completely open position (end stop) after the

shutdown incident occurred, including a dead time of approx. 10ms. On account of the damping of the movement caused by

the pressure medium, the tripping time depends on the viscosity of the pressure medium. It can be determined by recording

the stroke of the trip-stop valve. When the trip-stop valve moves with constant speed after a trip-top initiation, them the

control piston of the CTO has reached its end position.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 6 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

2 Safety information

2.1 Definition of symbols and warnings

Symbol Damage/harm

to ... Signal word Definition Consequences

Persons

Property EX-

PROTECTION! Notes to

Ex-protection

Explosion hazard

Persons DANGER! Imminent danger Fatal or most serious

injuries (crippling)

Persons WARNING! Dangerous situation possible Fatal or most serious

injuries possible

Material ATTENTION! Harmful situation possible Possible damage to

- the product

- its environment

– Note!

Information! Application details and other

useful information Efficient in operation

2.2 Proper use

The overspeed protector is an electro-hydraulic turbine trip device to control the speed of

steam turbines. If a trip criterion occurs, the magnetic force is switched off in the electronic

component thus switching over the 3/2-way valve via a restoring spring designed with

substantial power reserves. This procedure reliably connects the way valve outlet with the

tank return line and the trip-stop valve will close. The overspeed protector is suitable for

use in Zone 1 and Zone 2 in potentially explosive atmosphere. Allowable ambient

temperature for operation is

-30°C…..+60°C.

The permissible temperature of the hydraulic oil is +10 °C … +60 °C.

The max. surface of the device is significantly determined by the temperature of the

hydraulic oil.

For the operation it is therefore vital to ensure that the max. permissible oil temperature

will not be exceeded!

2.3 Important information

The following information refers to the entire instruction manual and is to be observed in

addition to the individual instructions.

Accident prevention

It is imperative to observe the requirements of the relevant standards and regulations

when connecting an overspeed protector in explosion-proof design.

There must not be any potentially explosive atmosphere during all works performed,

such as e.g. transportation, storage, installation, electrical connection, commissioning,

test run, maintenance and servicing!

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 7 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

On commissioning or operation of the overspeed protector, spraying hydraulic oil may

get into the eyes causing blindness. Wear protective glasses for all works performed on

the overspeed protector.

The overspeed protector is a hydraulic unit. In case of improper use, operating medium

being under pressure may leak out. Any improper use may lead to the leakage of

operating medium under pressure, posing a risk to the health and life of the operating

staff. Prior to performing any work on the overspeed protector, switch off the hydraulic

supply system.

During operation, the outer surfaces of the overspeed protector and the hydraulic

connecting lines may become hot due to the operating medium. Any contact may cause

injuries by burning. Prior to performing any work on the overspeed protector, let the

overspeed protector cool down.

On commissioning or operation of the overspeed protector, the end of the piston rod

may move uncontrolled in case of failure of the hydraulic or electric energy, due to

malfunctions in the master control or on the overspeed protector. This movement may

pose a risk to both individuals and objects. Prior to performing any work on the

overspeed protector, switch off the hydraulic and electric auxiliary energy.

Electric components

are integrated in the overspeed protector which may be destroyed,

e.g. during electric welding near the overspeed protector. Prior to performing electric

welding near the overspeed protector, remove all electric connecting lines.

Environmental protection

On assembly, disassembly or improper use of the overspeed protector, operating

medium may leak out. Operating medium getting into the sewage system or open soil

causes severe environmental damages. Collect any leaking operating medium and

dispose of it in accordance with the national statutory provisions.

Painting

In case of repaints or mendings of the paint on a device, please ensure that the

maximal permissible total film thickness will not be exceeded. For devices of Gas

Groups IIA and IIB, it is 2 mm and for devices of Gas Group IIC it is 0.2 mm.

Instruction Manual

The instruction manual contains important information regarding proper handling of the

overspeed protector. Prior to installation and commissioning of the overspeed protector,

carefully read the entire instruction manual and make sure you fully understood its

content.

Keep the instruction manual in a place constantly accessible to the operating staff.

In addition to this instruction manual, have the rules governing accident prevention and

environmental protection available and observe same.

Please keep for later reference.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 8 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Staff qualification

Only trained and instructed personnel are allowed to work on the overspeed protector.

These personnel must be sufficiently trained, instructed and authorized to properly

mount, operate and maintain the overspeed protector in accordance with the safety

standards.

Installation, commissioning and operation have to be performed by a certified electrician

with experience and knowledge in the field of explosion protection.

Constructional modifications

Mounting work and structural modifications are not permitted.

The screw fitting of the cable entry on the control magnet (VRM) is secured against

distortion. Do not distort or slacken the screw fitting.

2.4 Warranty

The terms and conditions mentioned in the General Terms and conditions for Sale of

Industrial Engineering of J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim

shall apply. Warranty claims are excluded if these are due to one or several of the following

causes:

•Improper transportation, storage, installation, connection, commissioning, operation,

maintenance and repair of products of the overspeed protector.

•Failure to observe the operational and product safety regulations included in this

instruction manual.

•Use of spare parts not approved by J.M. Voith SE & Co. KG │ Division Digital Ventures,

Crailsheim.

During the warranty period, repair work on the overspeed protector may only be

performed with the approval of J.M. Voith SE & Co. KG │ Division Digital Ventures,

Crailsheim.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 9 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

3 Function

3.1 Mechanical design

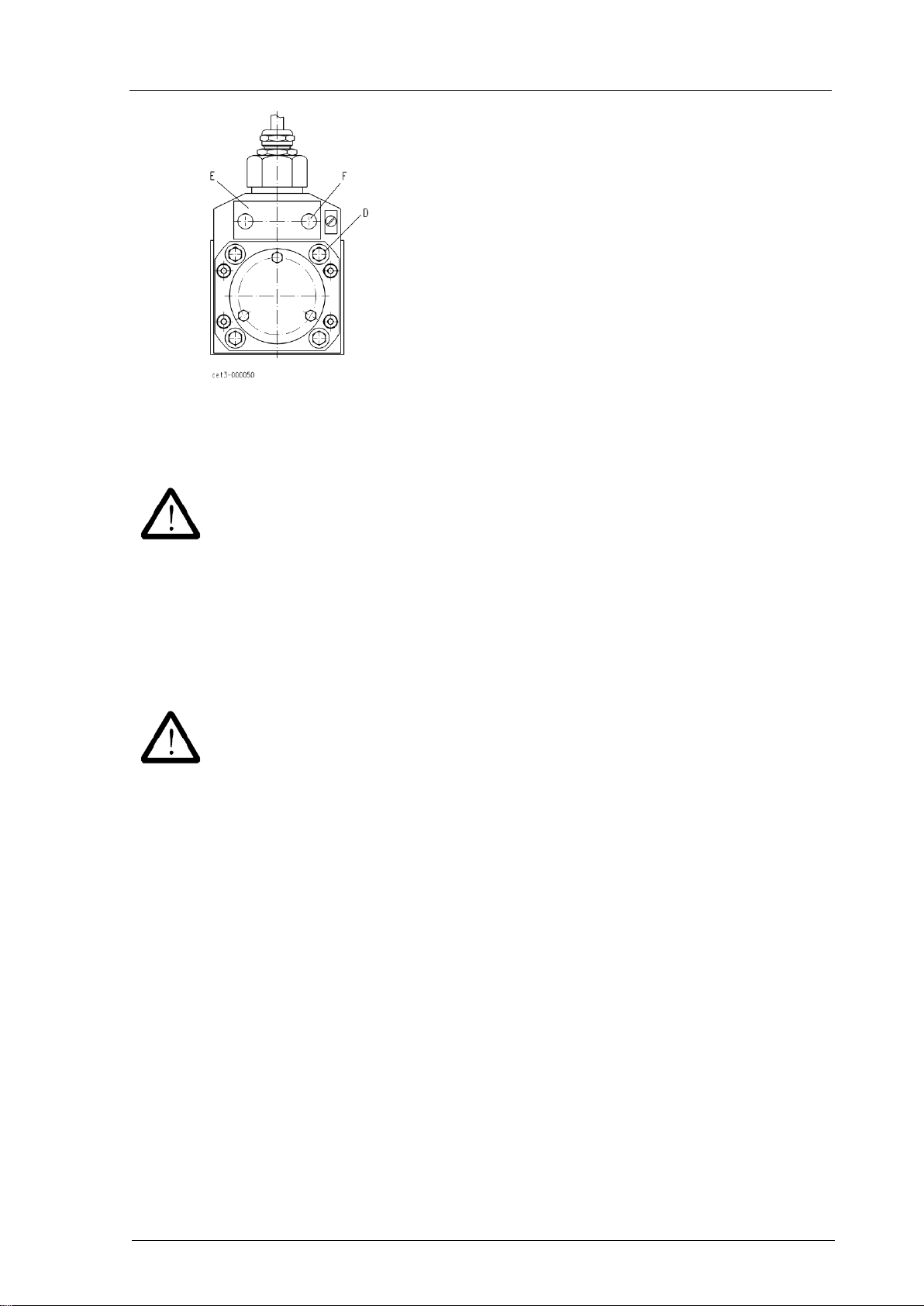

Fig. 1: Sectional view of overspeed protector

The overspeed protector consists of the main functional units:

(1) Control magnet VRM P - supply pressure

(2) Tappet for power transmission A - output

(3) Potentiometer T4 T - Tank return line

(4) Electrical connection

(5) Control housing

(6) Control piston FMag - Magnetic force

(7) Restoring spring FF- Federkraft

(8) Cover

(9) Potentiometer Uf

(10) Potentiometer If

(11) 8-fold coding switch

(12) Sealing - electronic compartment cover

(13) Sealing - pole pipe

(14) O-ring for the VRM

(15) O-ring in the potentiometer cover

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 10 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Block diagram - Overspeed Protector

Turcon®CTn

control

valve

trip-stop valve

reset

external trip

+24VDC

trip sim.

CTo

FMag

K

k

actual speed

0V

turbine

T

T P

A

mA

Fig. 2: Block diagram of the overspeed protector

3.2 Operation

A 3/2-way valve and the control magnet VRM with integrated electronics are the main

components of the overspeed protector CTO.

If no trip criteria exist, the CTO can be switched on via a reset. On doing so, relay K is

energized and thus contact k is closed. An inherently short-circuit-proof holding current

from the VRM keeps relay K energized via the closed-circuit arrangement (e.g. external

trip).

For a limited time (1.5 sec. ± 0.5 sec.), the reset actuates a maximum coil current which

generates a magnetic force FMag and adjusts the piston of the 3/2-way valve against the

progressively designed restoring spring. The coil current is then reduced and the control

piston is kept in its position. Now the supply pressure is connected with outlet A and the

trip-stop valve moves to the "OPEN" position.

In case of a trip criterion (e.g. reaching of the turbine trip frequency), the coil current in the

VRM and the magnetic force FMag become zero. The spring force FF now moves the

control piston in that position where outlet A is connected with the tank return line T.

The trip-stop valve moves into "CLOSED" position.

3.3 Trip criteria

•Wire breakage and / or short circuit on the speed sensor (for limit value, see Chapter 1,

Electrical data, speed input)

•Exceeding the set trip frequency (see Chapter 9, Table 1, Adjusting values - trip

frequency)

•Interruption of the closed-circuit arrangement (e.g. external trip) (see Fig. 2)

•Short circuit at the holding current output (+24 V towards relay)

•Temperature in the electronic compartment of the VRM ≥80 °C

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 11 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

•Power supply >30 V (overvoltage triggering at 29.5V - 32V)

(this criterion is omitted for Article No. TCR.9186855001)

•Power supply <18 V (under voltage at 16-18V)

(this criterion is omitted for Article No. TCR.9186855001)

•Trip simulation = partial stroke test - trip-stop valve

The "trip simulation" does not cause a real turbine trip but the internal release frequency

threshold is reduced for a short time whereas the CTO is released internally for this

time, and thus a tiny movement of the trip-stop cylinder can be seen. The internal

release is not signalled outwards and thus, no real shutdown is activated externally.

The trip simulation allows a functional test of the trip-stop valve during operation when the

turbine speed is greater than/equal to 23% (+0%, -10%) of the set trip frequency. Only then

the CTO can be released internally.

If a trip criterion causes a real turbine trip, the turbine speed has to fall below a reclosure

limit equivalent to max. 55% of the set trip frequency. Only then the CTO can be restarted.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 12 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

4 Packing, Storage, and Transportation

Packing

The overspeed protector is supplied in a special packaging. All hydraulic connections are

sealed with protective plugs.

Storage and preservation

The outer surfaces of the overspeed protector are electro-plated. On delivery, the inner

parts of the overspeed protector, which are not surface-coated, are moistened with

preservation oil.

Within Europe, this preservation is sufficient as corrosion protection for about 8 months,

provided the overspeed protector is stored in a dry location.

If it is intended to store the overspeed protector for a longer period of time, special

precautions have to be taken. Coordinate such precautions for each individual case with

J.M. Voith SE & Co. KG │ Division Digital Ventures, Crailsheim.

The ambient conditions for storage must be within the limits indicated in Chapter 1.

Transportation

It is not allowed to transport the overspeed protector in an explosive atmosphere! This

also applies to the transportation of spare parts!

Improper transportation or lifting of the overspeed protector may cause damage to

property and personal injuries.

Observe, in particular, that constraining forces do not act on the cable entry of the

control magnet (VRM) and that the connecting line is not damaged.

For transportation purposes, it is not allowed to keep the overspeed protector

connected to the connecting line.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 13 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

5 Installation

Installation and operation of the overspeed protector is only allowed for the conditions

stated in Chapter 1.

Do not install the overspeed protector in an explosive atmosphere!

During operation, explosive atmosphere may get into the way valve via the tank.

Therefore, the hydraulic tank must not be set up in zone 0.

Only personnel satisfying the qualifications according to Chapter 2.3 are allowed to

work on the overspeed protector.

Improper installation of the overspeed protector may cause malfunctioning and

premature failure of the overspeed protector.

Cleanliness is imperative during

both installation and connection. Prevent any impurities

(dust, metal chips, etc.) from getting into the interior of the overspeed protector or into

the piping system. Any such impurities may cause damage to the overspeed protector.

During the installation period, cover and protect the overspeed protector and, in

particular, the electric and hydraulic connections.

5.1 Mounting

Any work on the overspeed protector may only be performed in de-energized condition

and with the oil supply system switched off. During installation, the oil and power supply

for the overspeed protector has to be secured against unintentional switching-on.

Mount the overspeed protector according to the permissible installation position.

Recommended fastening bolts

2 socket head screws M12, ISO 4762, property class 8.8

Tightening torque MA = 60 Nm, thread oil-moistened.

Select the screw length according to the installation situation.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 14 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

5.2 Hydraulic connection

Flanging of the overspeed protector to a hydraulic consumer is effected via connecting

bores at the overspeed protector bottom.

O-rings are used for sealing the connecting flange.

For position and dimensions of the connections, please see Chapter 9.

Wear protective glasses when connecting the overspeed protector hydraulically.

Pay attention to the correct pressure stage when selecting pipes, flexible tubes, unions,

and flanges.

Immediately replace any damaged pipes and flexible tubes.

When assembling the pipes, ensure that they are not fastened to any moving equipment,

but rather to fixed structures free from vibration.

Alterations in length caused by temperature variations must not apply constraining forces

to the overspeed protector.

Fixing and hydraulic connection to a connecting flange is made via the hydraulic part.

O-rings are used for sealing. The customer's connecting surface has to correspond to

Ra ≤ 1.6 µm and Rmax ≤ 6.3 µm.

Residual oil (up to 0.2 l) may leak out when removing the screw plugs. Collect the oil in

a suitable container and dispose of it properly.

Do not use fibrous or hardening sealing compounds, such as hemp or mastic, for

sealing the connections and pipe unions.

5.3 Electrical Connection

For wiring diagram, see Chapter 9.

Only a certified electrician with experience and knowledge in the field of explosion

protection is allowed to connect the way valve module electrically in accordance with

the electro-technical rules and legal provisions of the country of manufacture. When

connecting the overspeed protector within the explosion hazardous area, the electric

feed-in lines have to be connected in housings according to a standard type of

protection as per EN 60079-0, section 1.

Work on the electrical system or with operational equipment is only to be completed by

electrical technicians or by trained personnel under the guidance and supervision of an

electrical technician according to technical electrical regulations and the legal

regulations of the respective country.

Signal and supply lines provided by the customer to the overspeed protector need to be

screened and laid separately from each other.

When connecting the customer's lines, please avoid parallel running of lines with the

lines of the current converter assemblies.

Poor connecting points do not guarantee a reliable operation of the overspeed

protector.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 15 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

6 Adjustments and Commissioning

Prior to delivery, the overspeed protector has been tested and adjusted at

J.M. Voith SE

& Co. KG │ Division Digital Ventures. The settings are documented in the supplied test

report.

6.1 Adjustment of turbine trip frequency

Any trip frequency adjustment represents a potentially dangerous manipulation of the

equipment and only skilled personnel, authorized by

the manufacturer or the supplier, is

allowed to do it. Any maladjustment may cause imminent danger to life and severe

damage to properties. In any case, any adjustment of the turbine trip frequency has to

be documented. Confirmation of the new adjustment by means of a documented trip

test is mandatory before operating the turbine.

For safety reasons, the overspeed protector is set to the minimum trip frequency possible

of approx. 3800 Hz. For the exact value, please see the relevant test report submitted to

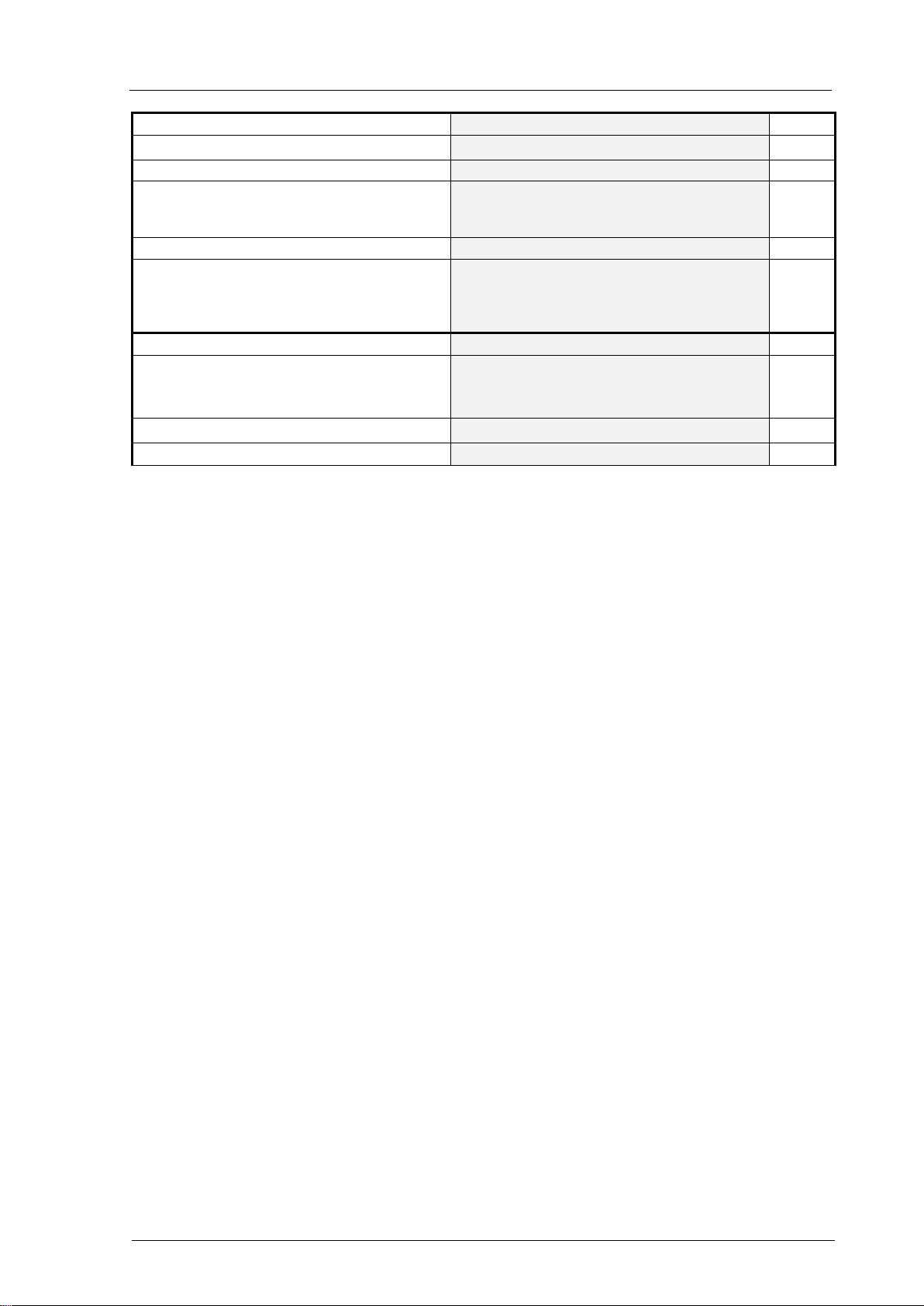

you.

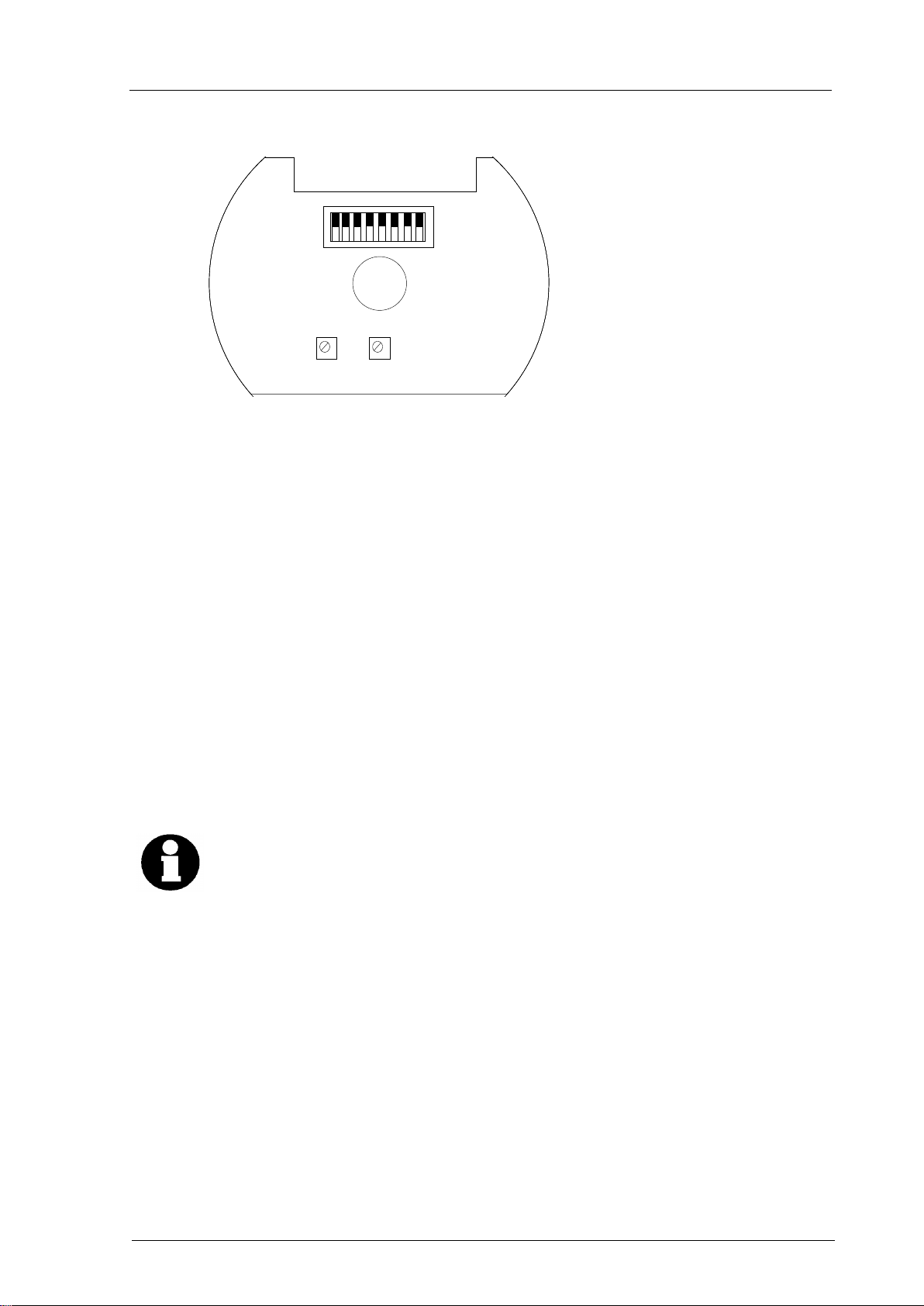

The turbine trip frequency is set by means of an 8-fold DIP coding switch which is

protected on the electronics that is integrated in the control mangnet A (VRM) (see Fig. 5).

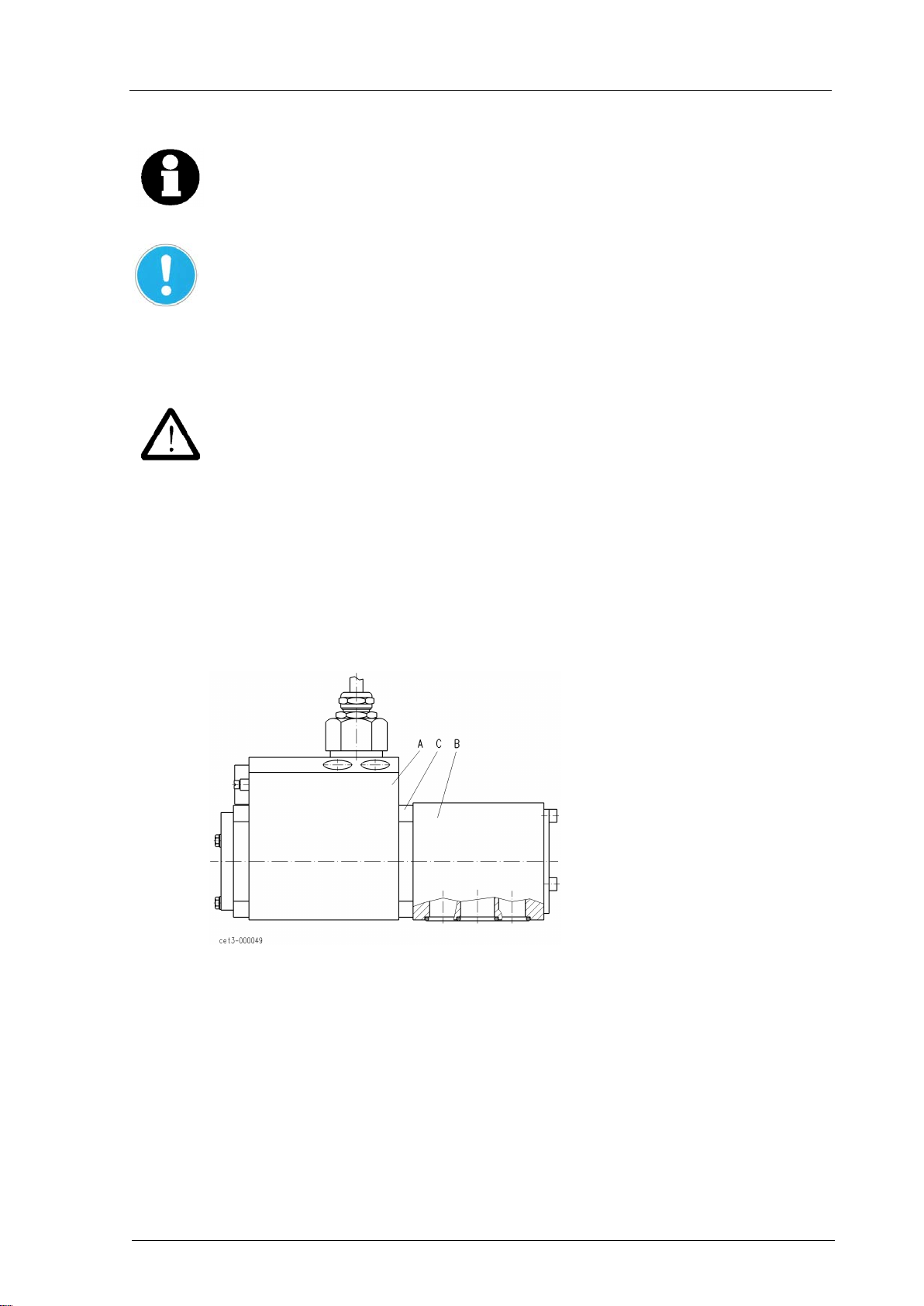

Fig. 3

Prior to commissioning, please ensure that the pipes and the hydraulic system have

been cleaned. Cleanliness of the operating medium must correspond to the cleanliness

grade stated in Chapter 1. Cleaning and flushing operations essential to the operating

medium must not be performed with the overspeed protector connected. Operation of

the overspeed protector with contaminated operating medium is not permitted and may

damage the overspeed protector.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 16 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Fig.: 4

Disconnect the VRM from the hydraulic component B in order to get to the coding switch.

To do so, loosen the 4 screw nuts D (10 mm width across flats) and pull off the VRM from

the hydraulic component B.

In the course of the further procedure described, the pressure-tight and explosion-

protected enclosure of the VRM will be opened and explosion protection will no longer

be effective. Therefore, make sure in advance that there is no explosive atmosphere or

may form as long as cover C is not remounted and secured by the screws.

Unscrew the 4 Allan screws (5 mm width across flats) used to fix cover C (see Fig. 3) and

remove the cover. On account of the seal in cover C, it is not easy to move. It may

therefore be helpful to first turn the cover and then lift it using a screwdriver until some air

can get into the electronic compartment underneath. Then it will be easy to remove the

cover.

The cylindrical component (diameter 80 mm) and the bore (diameter 12 mm) of cover C

are part of the pressure-tight, explosion-

protected enclosure and must not be damaged,

as well as the bore and cylinder sections of the magnet housing belonging to these

surfaces. Do not damage the anticorrosion protection of the relevant surfaces. In case

of damaged surfaces or incomplete anticorrosion protection, the explosion protection is

no longer granted and the overspeed protector has to be replaced.

Fig. 5 shows the top view onto the electronics installed underneath cover C with coding

switch SS1 and UF- and If-potentiometers.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 17 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Uf If

SS1

ON

12345678

OFF

ON

8 7 6 5 4 3 2 1

VO ITH

E528

Fig.: 5

Shifting the respective individual switch 1 - 8 of SS1 adjusts the required turbine trip

frequency whereas OFF position corresponds to 0 and ON position to 1.

The switch combination to be adjusted is an 8-bit binary number (finary number 0000 0000

to 1111 1111 = decimal number 0-255), calculated as follows, based on the required trip

frequency:

trip frequency [Hz]- 3800 Hz

Decimal number SS1 = −−−−−−−−−−−−−−−−−−−−−−−−−−−

27.333 Hz

Convert this decimal number into a binary number and set it directly as switch combination

at SS1, whereas 1 = ON and 0 = OFF, and also set the least significant number on the

right at switch 1 and the most significant on the left at switch 8.

A more convenient method is to enter into Table 1 attached with the desired trip frequency

and to directly take from there the switch combination to be adjusted.

If you use the actual speed remove indication, readjust the 4 mA value using the If-

potentiometer for speed 0 after adjustment of the trip frequency. See Chapter 6.2, If-

potentiometer.

After setting the coding switches at SS1, remount cover C and fix it using the 4 Allan

screws. Make sure that the O-ring in the cover and the two small O-rings in the pole pipe

are mounted, not damaged and greased (see Fig. 1). Relock the 4 Allan screws using the

circlips.

Now push the VRM onto the hydraulic component, at the control housing of which the O-

ring between the hydraulic component and the VRM has to be mounted correctly.

After the overspeed protector is again ready for operation, a test of the readjusted trip

frequency is mandatory. On account of rounding errors and/or manufacturing tolerances, it

may be necessary to increase or reduce the binary number set by 2. Should this be the

case, please proceed again as outlined above. A trip frequency test has to be performed

and documented at any rate after completion of the settings. This test should be performed

in warm condition (CTO should be operated for about 30 min. at an oil temperature of

approx. 50 °C).

After that, seal the overspeed protector, thus securing the setting.

See section A-A of the outline drawing in Chapter 9, Annex.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 18 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

6.2 Adjustment of UF- and If-potentiometers

Uf-potentiometer (please see Fig. 5)

The Uf-potentiometer is provided to adjust the turbine trip frequency reference, it is set at

the factory and sealed. Any adjustment is prohibited!

If-potentiometer (please see Fig. 5)

This potentiometer needs to be adjusted only if you want to use the actual speed remote

indication. The limit of 20 mA actual speed remote indication is permenantly assigned to

the turbine trip frequency and is corrected automatically on adjustment of the turbine trip

frequency. The initial value of 4 mA is to be assigned to 0 Hz.

On adjustment of the turbine trip frequency (see Chapter 6.1), however, also the

assignment of 4 mA initial value changes at the same time. It is possible to re-adjust this

4 mA initial value to 0 speed by means of the If-potentiometer. To do so, remove the

locking compound of the If-potentiometer and renew it after the adjustment.

For this purpose, the output of the actual speed remote indication is put on an mA-meter.

At 0 speed, the If-potentiometer is turned until the mA-meter indicated 4.0 mA. Turning the

potentiometer clockwise will increase the mA-signal.

In case of a trip of the CTO, the actual speed remote indication returns to 0 mA due to the

external switch-off of the 24V CTO supply. In case this external switch-off of the 24V

supply is prevented erroneously, the actual speed indication increases to higher values and

the allocation of the speed to the actual speed signal is no longer correct during this state.

After a proper reconnection of the CTO, this state eliminates on its own.

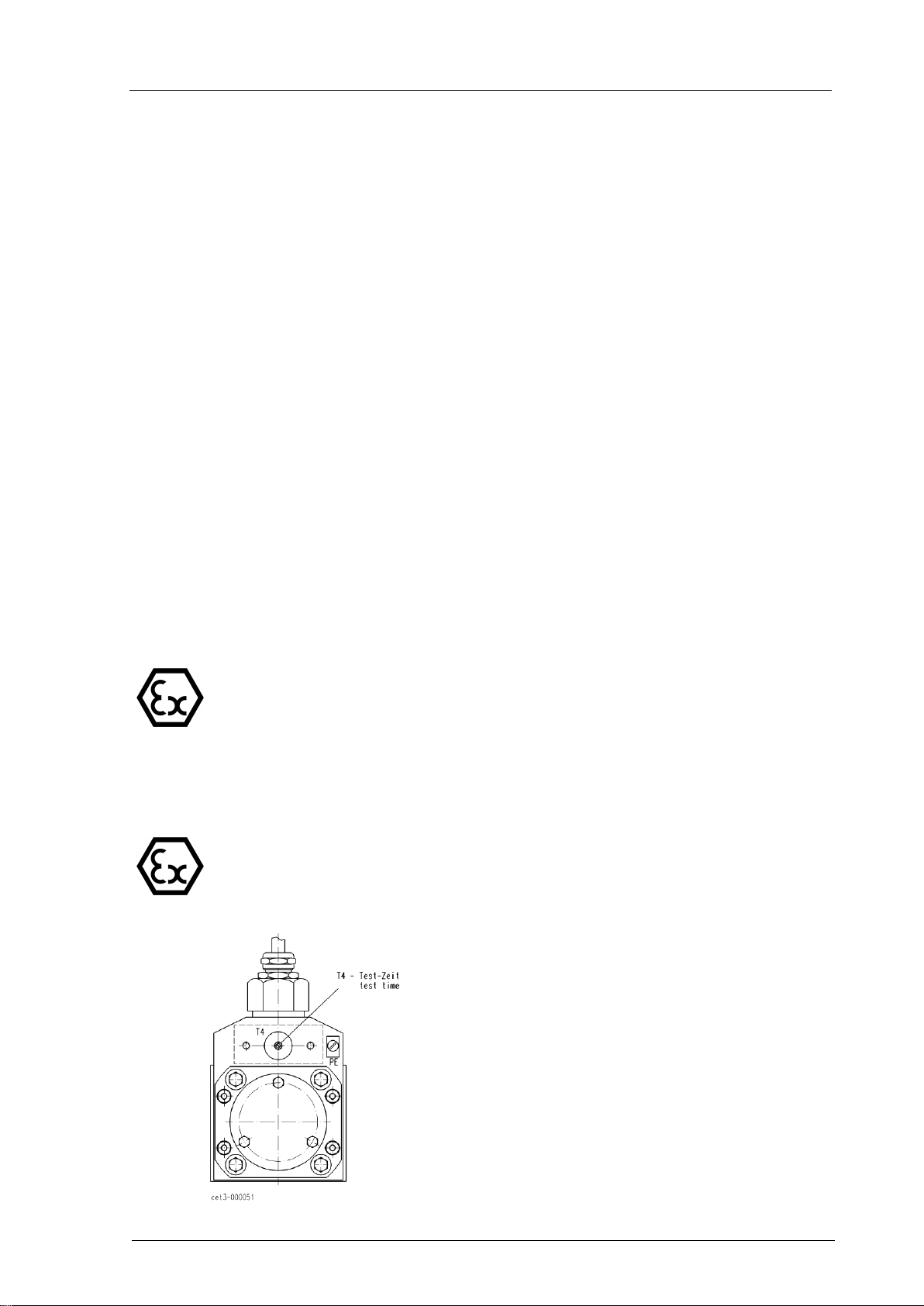

T4-potentiometer (please see Fig. 6 and Fig. 4)

The T4-potentiometer is used to set the trip time of the trip simulation function (partial

stroke test with trip-stop cylinder. The potentiometer is in the VRM and protected by a

cover.

Following the procedure described below, the pressure-tight, explosion protected

enclosure of the VRM will be opened and the explosion protection will no longer be

effective. Therefore, it has to be checked before that there is no explosive atmosphere

or may form as long as cover E is not remounted and secured by screws F.

Loosen the 2 Allan screws F (5 mm width across flats, see Fig. 4) in order to get to the T4-

potentiometer. The remove cover E. On account of the O-ring (see Fig. 1) in cover E it

might be somewhat hard to remove it.

The cylindrical part of the cover and the enclosure bore form part of the pressure-tight

enclosure for explosion protection. The cylindrical surface of the cover and the

associated surface of the enclosure bore must not be damaged. The corrosion

protection of these surfaces needs to be completely preserved!

Fig.: 6

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 19 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

Turning the T4-potentiometer will adjust the trip time, elapsing after releasing the "trip

simulation" pushbutton = partial stroke test - trip-stop valve (see Fig. 2, and for functional

description, see Chapter 3.49. Thus, the trip time is adjustable.

The temporary trip time is extended by turning the potentiometer clockwise.

The potentiometer is factory-set to the minimum possible trip time. Repeated pushing and

releasing the pushbutton "trip simulation" adjusts the potentiometer. The potentiometer is

adjusted in steps clockwise and the trip-stop valve is observed. The trip time is set correctly

when the trip-stop valve performs a little stroke towards the closing direction, but does not

yet have a negative influence on the turbine operation.

Doing so, it is possible to check the function of the overspeed protector and trip-stop valve

in intervals to be determined by pushing and releasing the "trip simulation" button during

turbine operation.

After adjustment of the temporary trip time, remount cover E and fix it using the 2 Allan

screws F. Observe that the O-ring is inserted in the cover, undamaged and greased. Lock

the 2 Allan screws using the circlips.

Instruction and Operating Manual

Overspeed Protector CTO-B45202

2019 / 02

J.M. Voith SE & Co. KG │ Division Digital Ventures

Page: 20 / 25

918 3626018864 en

D – 74564 Crailsheim

Version: 2.1

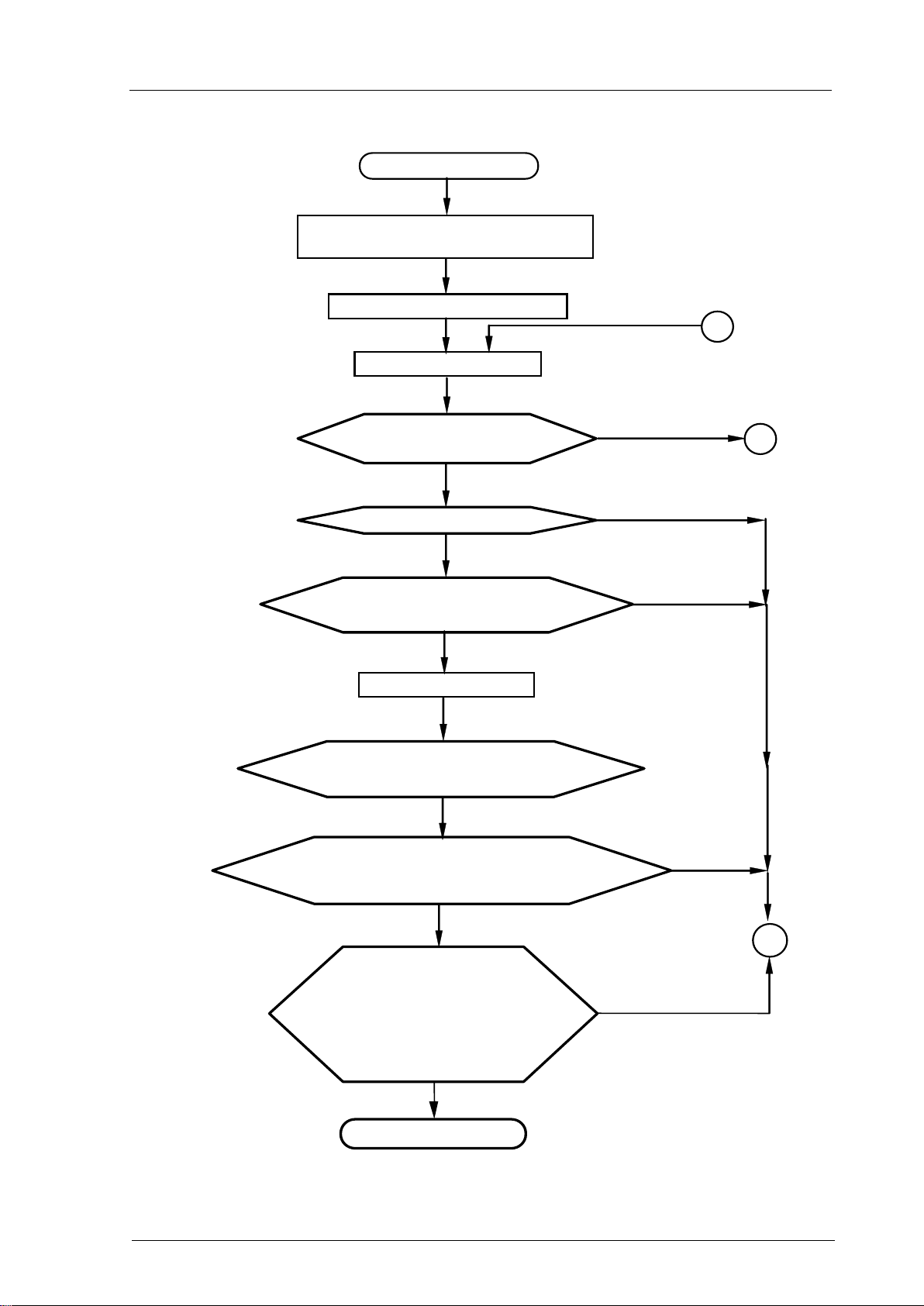

6.3 Commissioning

Commissioning START

Check cables and hydraulic lines

according to wiring diagram

Connect to supply voltage

Press the "Reset button"

Are the trip signals for the

speed controller and for external processing

reset?

Does the hydraulic valve open fully?

Does the hydraulic valve close, the

speed controller signal “trip“ and is the external trip signal

available after opening of external trip loop?

Press the "Reset button"

Disconnection when / on:

-exceeding SS frequency

-external trip loop is interrupted

-overvoltage

-undervoltage

-interruption or short circuit of speed

pick up

-short circuit of coil connections of

external relay K

END of commissioning

Does the stroke of the trip-stop cylinder collapse for a

short time when operating the trip-sim. pushbutton? (you can adjust

the time to trip the overspeed protection by means of the T4

potentiometer see chapter 6.2)

Bring turbine speed close to rated speed

or achieve the same by simulating the

actual speed

no

yes

yes

no

A

yes

yes

C

no

no

no

yes

yes

B

This manual suits for next models

1

Table of contents

Other Voith Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Muller

Muller HYDRO-GUARD 300 Series Operating instructions manual

TRAK

TRAK VMC10 Site preparation guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS Spindler Industrial ICP 607A61 Installation and operating manual

Dedoes

Dedoes Alliance A7 Assembly instructions

Huawei

Huawei LUNA2000-97KWH-1H1 quick guide

PCB Piezotronics

PCB Piezotronics 356A01/NC Installation and operating manual