Table of contents

J.M. Voith SE Co. KG/VTA| Instruction Manual

6

-performance universal joint shaft

anual (Translation) G853 en 07/2013, Version1

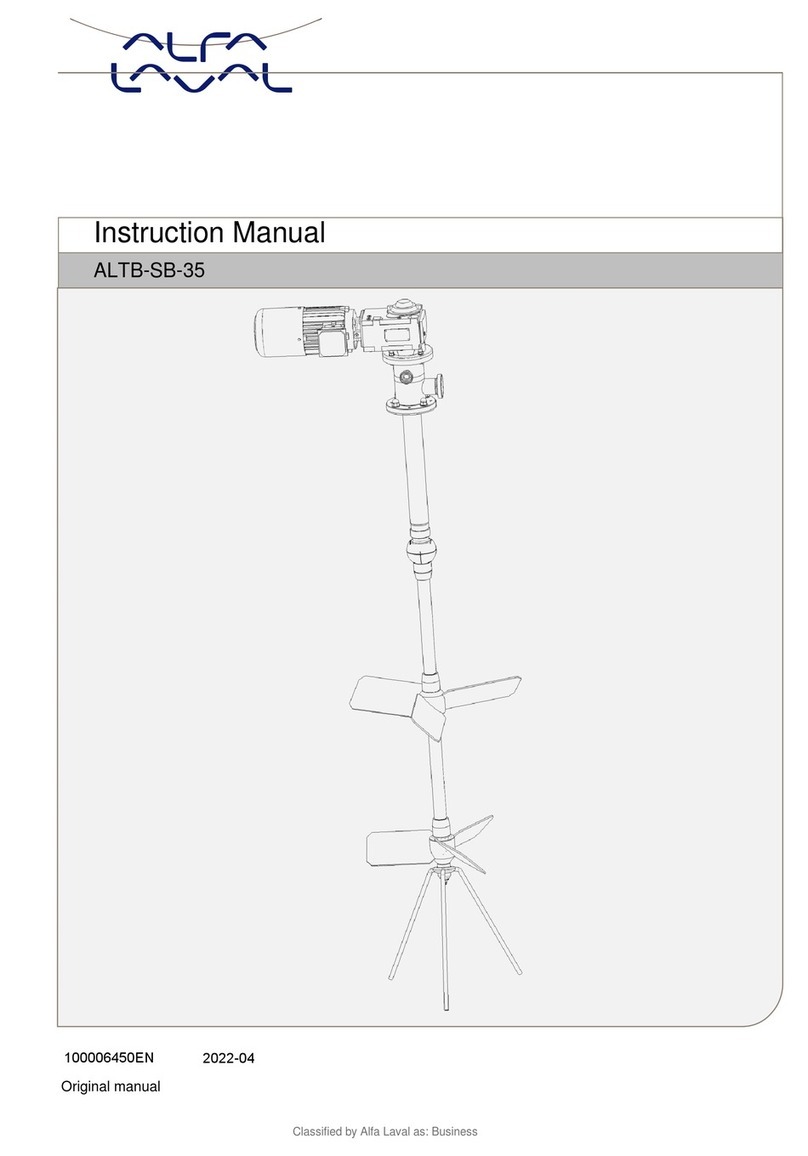

Fig. 3.1: Structure of the universal joint shaft (example of type

RT)............................................................................ 22

Fig. 3.2: Nameplate of an ATEX-certified universal joint shaft23

Fig. 3.3: Schematic structure of temperature monitoring ....... 24

Fig. 3.4: Z arrangement.......................................................... 25

Fig. 3.5: W arrangement......................................................... 25

Fig. 4.1: Attaching the universal joint shaft............................. 32

Fig. 6.1: Dimensions of the connecting flange and bolted

connections ............................................................... 36

Fig. 6.2: Dimensions of a stud screw ...................................... 41

Fig. 6.3: Universal joint shaft .................................................. 44

Fig. 6.4: Checking the difference in joint angle between the

faces of the connecting flanges................................ 46

Fig. 6.5: Permissible differential angle (with Z arrangement). 46

Fig. 6.6: Seals for Hirth serration............................................ 49

Fig. 6.7: Checking radial offset and flange distance (with use in

paper machines)....................................................... 50

Fig. 9.1: Checking axial clearance of the journal cross set on

two levels.................................................................. 58

Fig. 9.2: Checking deflection play of the center part.............. 59

Fig. 9.3: Reading off deflection dimension ............................. 60

Fig. 9.4: Lubrication points of the universal joint shaft ........... 62

Tab. 1.1: Target groups ............................................................. 7

Tab. 1.2: Other applicable documents....................................... 9

Tab. 1.3: Symbols and markings............................................. 10

Tab. 1.4: Meaning of the danger levels ................................... 11

Tab. 1.5: Meaning of the safety symbols................................. 12

Tab. 2.1: Personal protective equipment................................. 21

Tab. 6.1: Dimensions of the connecting flange and bolted

connections (key)....................................................... 37

Tab. 6.2: Dimensions of the connectingflange and bolted

connections ............................................................... 40

Tab. 6.3: Permissible differential angle (with Z arrangement). 46

Tab. 6.4: Permissible differential angle (with W arrangement) 47

Tab. 6.5: Permissible radial offset and flange distance (for use

in paper machines)................................................... 50

Tab. 8.1: Eliminating errors ...................................................... 54

Tab. 9.1: Intervals for maintenance work and inspections ...... 58

Tab. 9.2: Checking axial clearance of the journal cross set....59

Tab. 9.3: Permissible deflection ratio....................................... 60

Tab. 9.4: Permissible lubricant quantity for the re-lubrication of

standard center parts................................................ 64