Von Duprin HH KAW 9847 User manual

*24203424*

24203424

Devices covered by these instructions:

HH 98/9947 Concealed Vertical Rod Exit Device

HH CD98/9947 (Cylinder Dogging) Concealed Vertical Rod Exit Device

HH EL98/9948 (Electric Latch Retraction) Concealed Vertical Rod Exit Device

Special tools needed:

5/64” hex wrench

#10-24 tap

Drill bits: #25, 1/8”, 1/4”,

5/16”, 13/32”

Index:

Screw chart ............................. 2

Door preparation chart............ 3

Device installation ................ 4-5

Optional equipment ............. 7-8

Cut device.............................. 8

Please give these instructions to building owner after device is installed

Frame preparation .................. 5

Adjust rods .............................. 6

Concealed Vertical Rod Exit Device for Metal Door Applications

HH (KAW) 98/9947

Installation Instructions

2

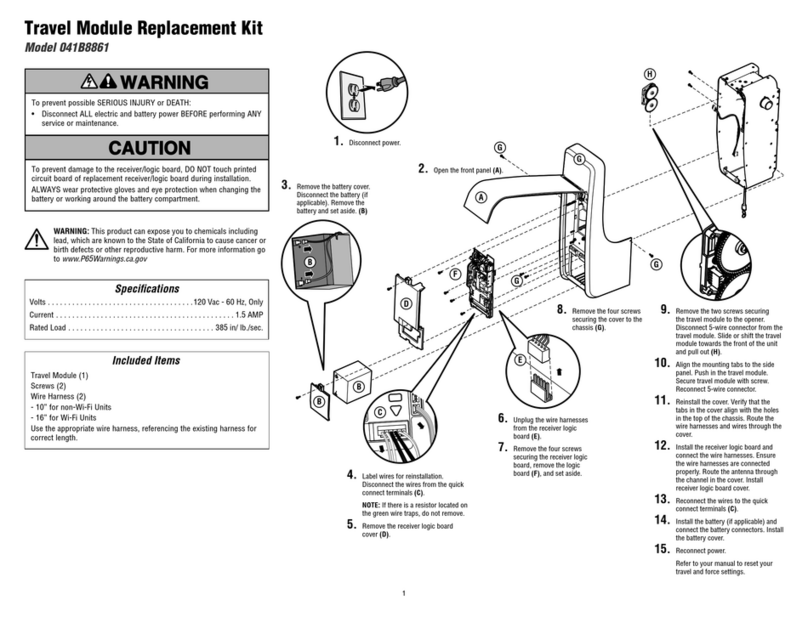

SCREW CHART

#10-24 x 1”

#10-24 x 1-1/2”

Surface mount or

Sexbolts (2-1/4” door)

Sexbolts (1-3/4” door)

#10-24 x 3/4”

#10-24 x 1-1/8”

A

B

C

E

F

G

H

D

#8-18 x 3/8” Thread cutting

Surface mount or

Sex bolts (2-1/4” door)

#10-16 X 3/8” Thread cutting

Centercasecover

Sexbolts (1-3/4” door)

Endcap

-Packagedwithtrim -

#10-24 x 1-3/8”

#10-24 x 1-7/8”

990 trims (1-3/4” door)

990 trims (2-1/4” door)

Latch screw

HH guide

#10-32 X 3/8”

#12-24 X 1/2”HH strike

#8-32 X 5/16” Retaining clip

Retainingclip

Rod adjusting screw

3

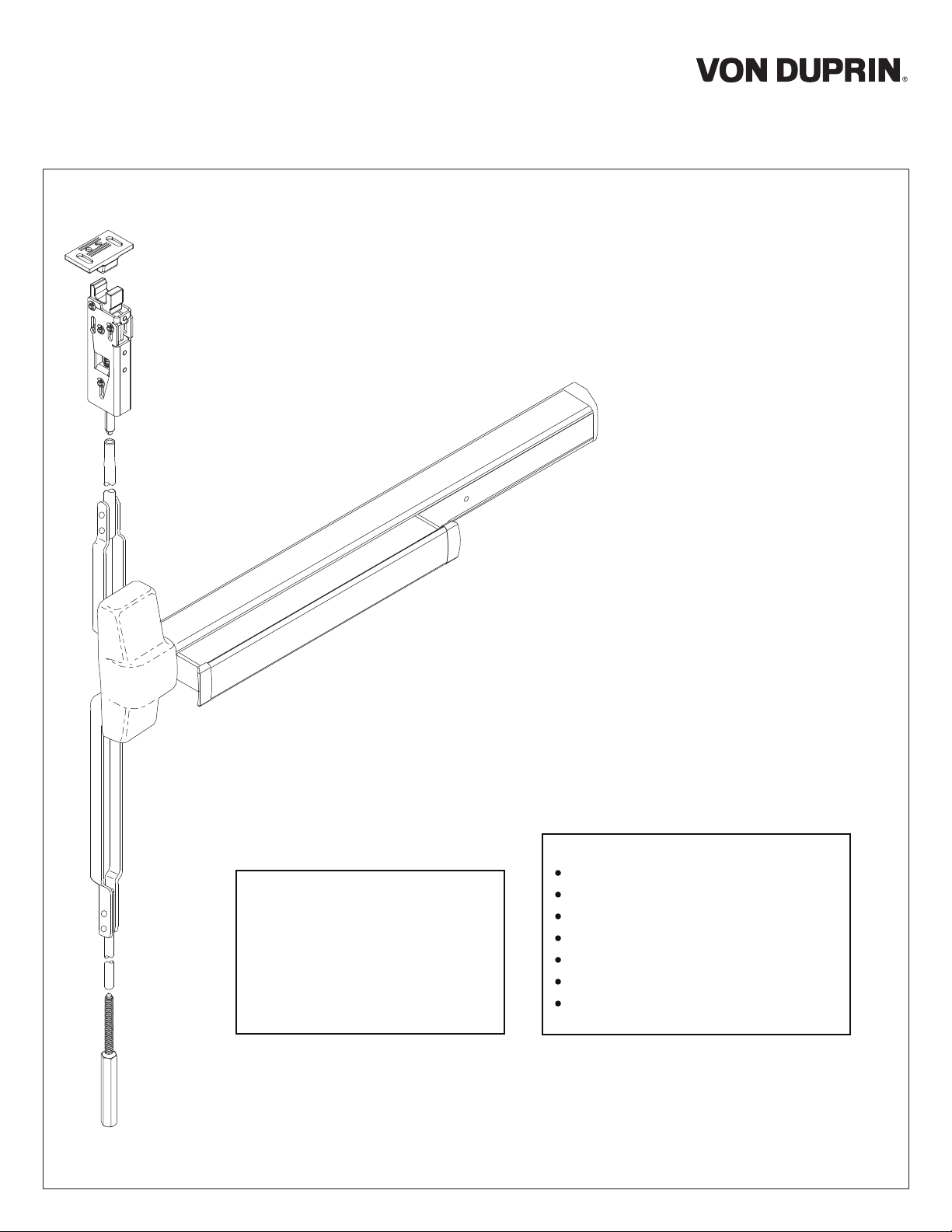

DOOR PREPARATION CHART

Go to instructions on next page before using preparation chart

X

X

C

L

*End cap bracket - 2 holes

*Prepare holes after lock side of device

is mounted and hinge side is equal

distance to bottom of door

Center case - 4 holes

Surface mount Sex bolts or 990 trims

#25 Drill

#10-24 tap

1/4” Drill (device side)

13/32” Drill (trim side)

Door Cut-outs

TopPreparation Bottom Preparation

For HH 98/9947

Trace cut-outs from

plastic template

(cut device side only)

Outside cylinder applications:

Mark with template and cut-out:

Metal door (cut device side)

Wood door(cut thru)

Surface mount Sex bolts or 990 trims

#25 Drill

#10-24 tap

1/4” Drill (device side)

13/32” Drill (trim side)

C

L

9/16"

3/4"

1-1/32"

2-3/8"

1-1/2"

1/8"

1" Cutout on inside

face only

1/4" radius

#9 (0.196") drill, c'sink 82°

to 13/32" dia., 5 holes,

inside face only

1-3/8"

7/8"

C

L

Rod type latch

location

C

L

4

1 Draw Horizontal Device Center Line (C

L)

C

L

RHR shown

(LHR opposite)

39-5/8”

to bottom of

door

2 Determine Correct Backset, then Mark 4 Holes for

Device Center Case Using Template

98/9947

(non-fire rated device)

single or double door

C

L

Mark 4

holes

2-3/16”

backset

C

L

3 Prepare Door per Preparation Chart on Page 3

See trim instructions

for pull side door

preparation. Line X-X

in trim instructions is

same as device C.

L

4 If Using an Outside Cylinder, Check NL Drive Screw

and Install Tailpiece Guide

With NL drive screw removed, key locks and unlocks lever, knob,

or thumb piece. For trims listed below,

REMOVE NL drive screw.

996L 696TP 990TP

996K 697TP

With NL drive screw installed, key retracts latch bolt.

DO NOT remove

NL drive screw for the following applications:

NL, EO, DT trims and 98/99-2 double cylinder devices (i.e. TP-2,

L-2, and K-2).

If trim being installed is "BE" (i.e. 996L-BE), trim lock tumbler on

back of device must be in

UP position before device is installed.

This allows trim to be unlocked at all times.

*

*996L-BE

*996K-BE

*E996L

*E996L-BE

*696TP-BE

*697TP-BE

*990TP-BE

NL drive screw

Factory installed on

back of center case

Correct

Orientation

(RHR shown)

Incorrect

Orientation

trim lock

tumbler in

UP position

If necessary,

remove drive

screw and

rotate cam

until trim lock

tumbler is in

UP position,

then reinstall

drive screw

360˚

5 Assemble Rods and Latches and Adjust Length for

Proper Door Height

Top

length

Bottom

length

Fine tune the

overall length

by threading

latch in or out

of rod

Follow red and blue instruction cards with

rods to set initial rod length

5

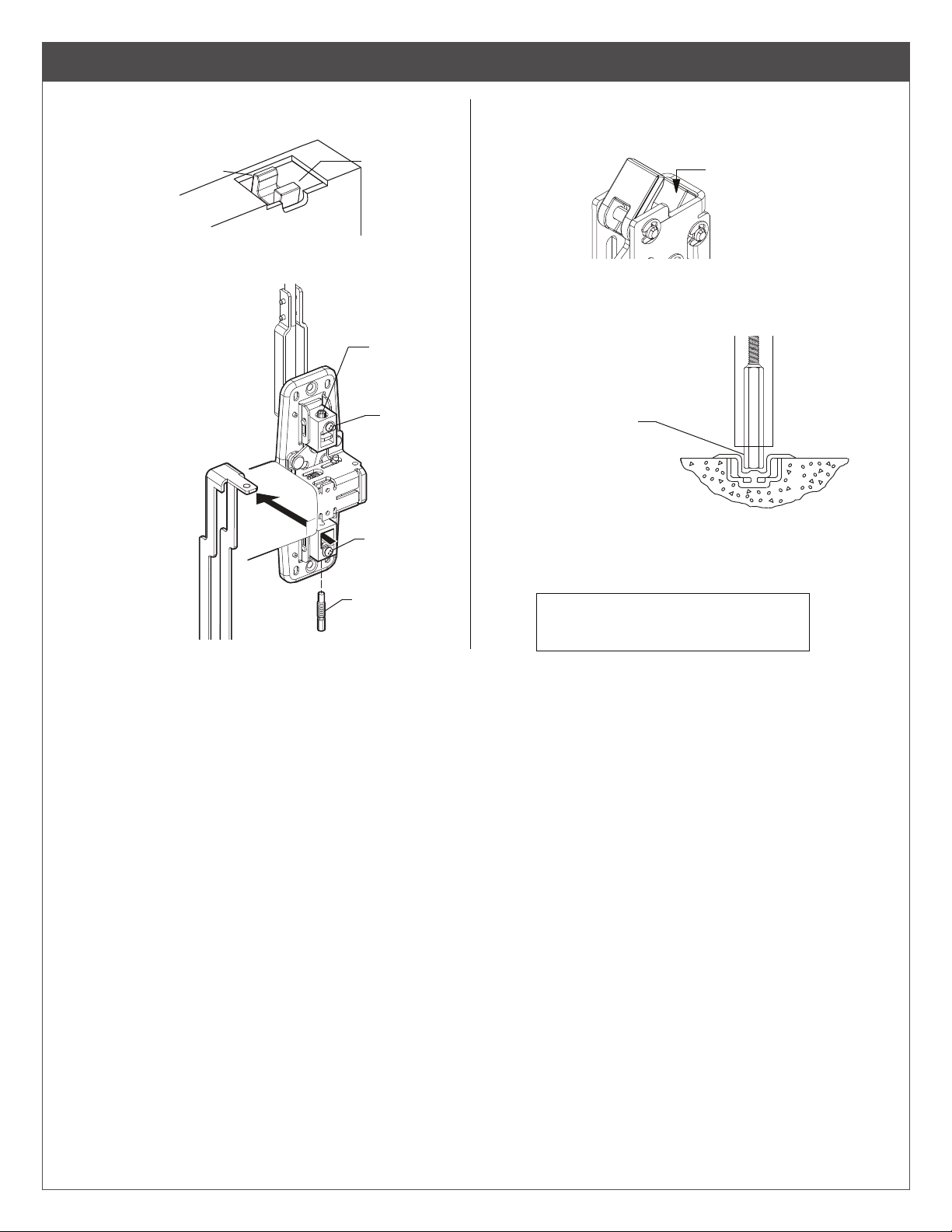

6 Install Rods and Latches as Shown

D

G

F

Bottom rod

& bolt

Top rod

& latch

Top rod

Bottom

rod

Device aligns with

mounting holes

which were

prepared in step 3.

7 Secure Device to Door as Shown, then Hang Door on

Frame

B

C

A

See “Screw Chart”

on page 2 for screw

types and sizes

Center

case

2” Minimum clearance

(with end cap removed)

If device is too long for

door, see “Cut Device”

on back cover

Mounting

bracket flush

Trim

(optional)

Device equal

height to bottom of

door on each end

Mark and prepare

2 mounting holes

and secure screws

(see page 3)

8 Prepare and Install Top Strike

3/4"3/4"

3/4"

of top latch

2x #16drill

tap 12-24

Blade

stop

is set

2x #16 drill & tap 12-24

use strike astemplate

once finalstrike location

9 Install bottom strike or prepare threshold.

1/8" 5/8"

STRIKE

C

1/4"

1"

2 3/4"

L

29/32"

385-A bottom strike

Threshold application

Flat threshold

application

Remove material as

necessary to accommodate

5/8” latch bolt throw

Stop

Latch case C

L

3/4"

10 Adjust Rods and Install Center Case Cover

J

Center case

cover

Remove protective

film from pushbar

See “Adjust Rods” on page 6 for

adjustment procedure

6

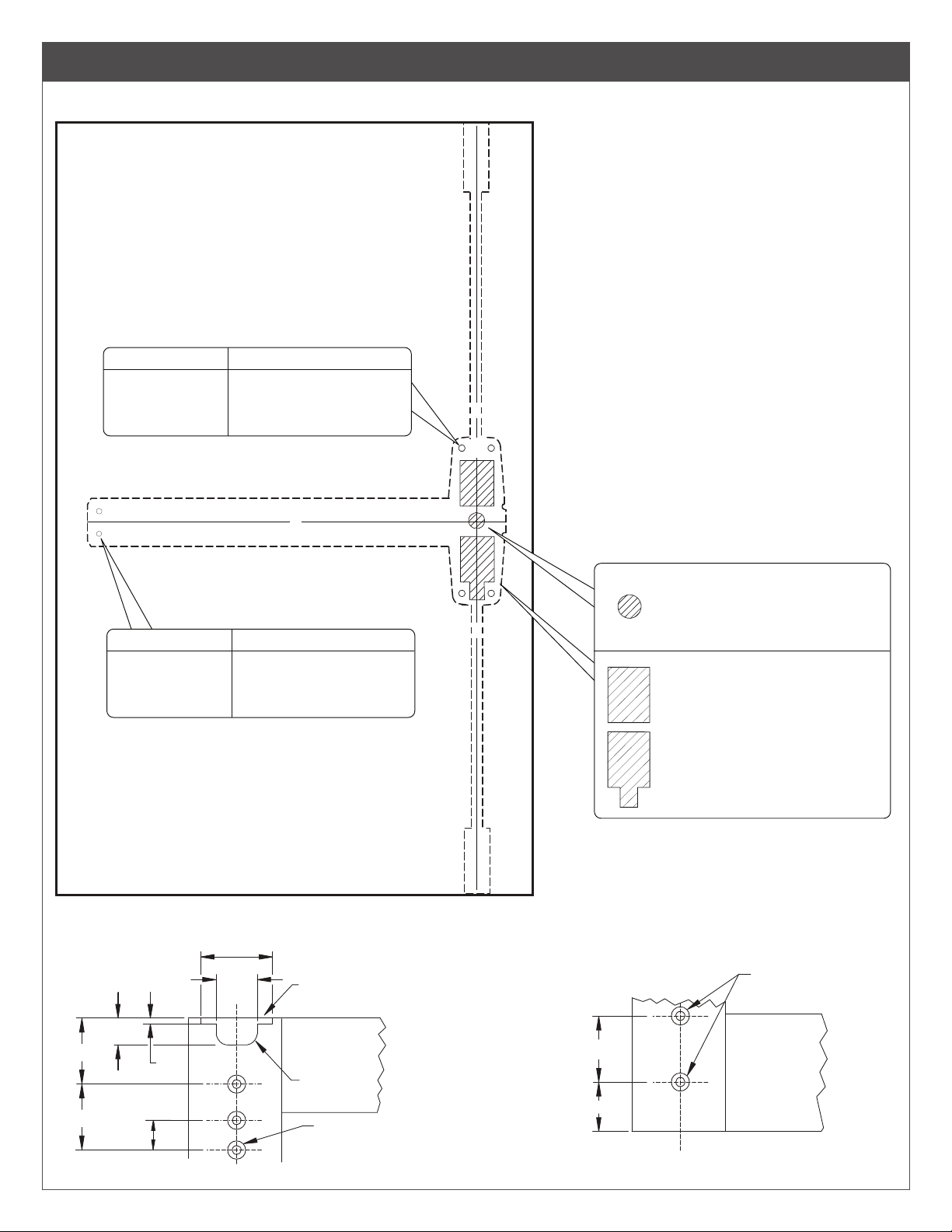

ADJUST RODS

Install bottom adjusting screw through bottom

rod (Figure 2).

With top latch bolt still retracted, adjust bottom bolt

so that bolt clears floor and bottom strike.

Turn bottom locking screw in. Do not over-tighten.

Open door and verify top latch bolt

is fully extended (Figure 1).

Loosen bottom locking

screw (Figure 2).

Disconnect bottom

vertical rod by removing

bottom adjusting screw.

Loosen top locking screw.

Rotate top adjusting screw

clockwise until top latch

bolt drops

(Figure 3).

Turn top

locking screw

in. Do not

over-tighten

Release pushbar.

Depress pushbar and ensure

latchbolt falls.

1.

2.

3.

4.

Depress pushbar and dog

device

5.

6.

7.

8.

9.

10.

11.

12.

Check device operation by opening and closing door

several times from the inside.

Redo adjustment procedure if :

- Top latchbolt does not retract

- Bottom bolt does not clear

floor and bottom strike

13.

Bottom

latch bolt

(clears floor

and strike)

Figure 2

Bottom

adjusting

screw

Top

locking

screw

Top

adjusting

screw

Bottom

locking

screw

Figure 3

Figure 4

Top latch bolt Shown fully

extended

Figure 1

Latch bolt retracted

(flush with latch case)

7

OPTIONAL EQUIPMENT

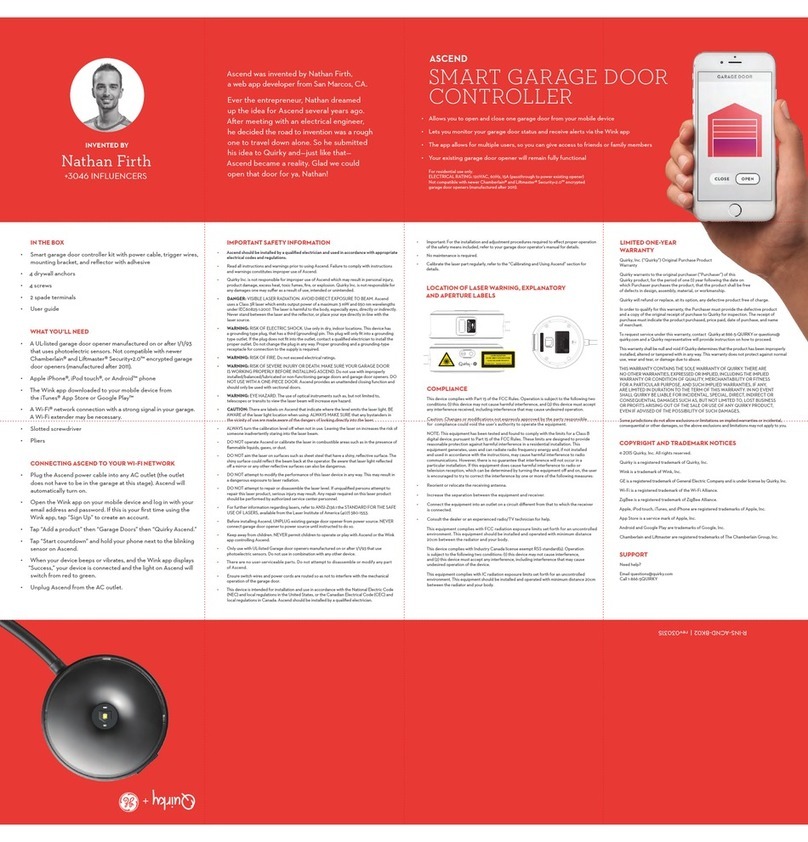

1. Remove mortise cylinder cam and reinstall in reverse (Figure 6).

2. Insert key and rotate cam to install the cylinder to the cover plate (Figure 7).

3. Remove key to slide cover plate in position in the mechanism case.

Std. mortise

cylinder

Mortise

cylinder

cam

Std. mortise

cylinder

Mortise

cylinder

cam

CD function conversion

Figure 6

Figure 7

Std. mortise

cylinder

Cylinder

collar

Dogging

plate cover

Offset toward

pushbar

Cylinder

locating washer

Cylinder

lock nut

Mechanism

case

Turn cylinder key clockwise approx. 1/8

turn for standard dogging

Dogging procedure

Depress pushbar

CD (CYLINDER DOGGING)

© Allegion 2018

Printed in U.S.A.

24203424 Rev. 02/18-c

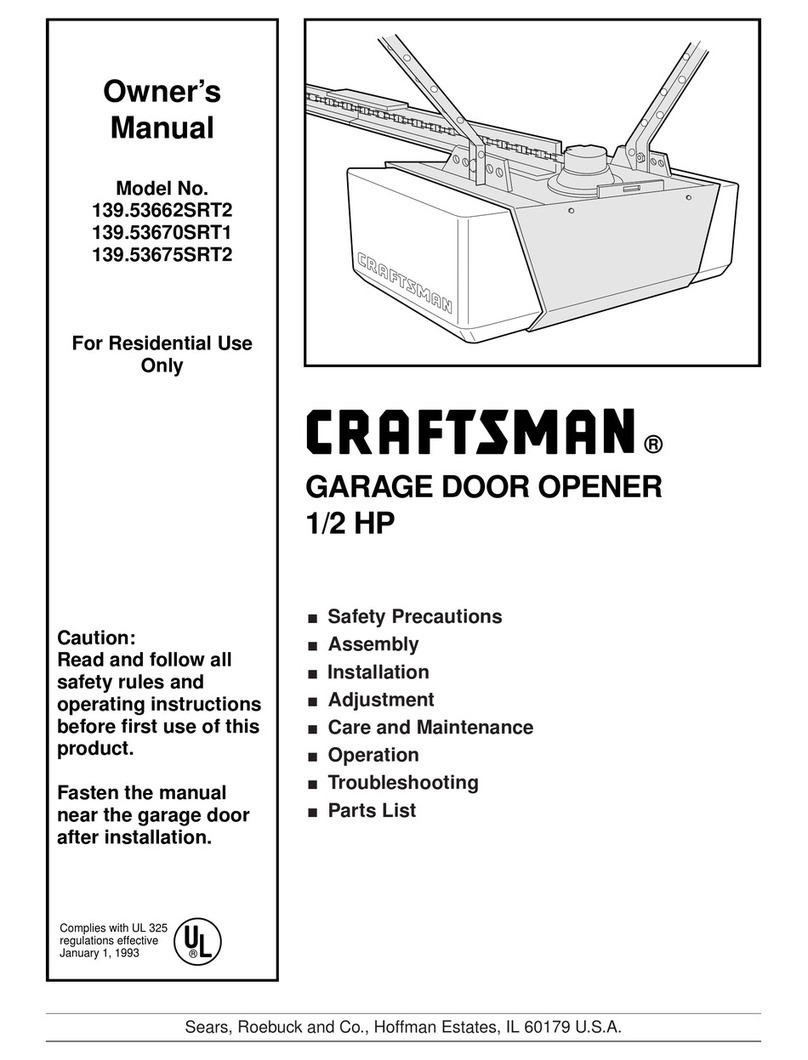

CUT DEVICE

1 Measure amount to cut o device.

2” Minimum clearance

(with endcap removed)

dengilaeciveD

gnitnuomhtiw

seloh

”61/5

Note

If 5/8” diameter wire access hole

has been predrilled in door, cut

device 5/16” from center of hole.

2 Tape and mark area being cut.

Tape

Cover plate

(flush to pushbar)

Pushbar

Remove anti-rattle clip

3 Cut device square.

Cut device square

and remove all

burrs

NOTE: Device must

be cut squarefor

proper end cap fit

4 Slide anti-rattle clip into device.

elttar-itnA

edisnipilc

”2

.nim

Customer Service

1-877-671-7011 www.allegion.com/us

This manual suits for next models

1

Table of contents

Popular Garage Door Opener manuals by other brands

Craftsman

Craftsman 139.3050 quick start guide

Quirky

Quirky ASCEND installation instructions

Beam Labs

Beam Labs beamUP Series product manual

Overhead door

Overhead door legacy 650 Programming and operating manual

Linear

Linear LDCO801 Homeowner's instructions

Chamberlain

Chamberlain Power Drive Security+ HD200CD owner's manual

Craftsman

Craftsman 139.53662SRT2 owner's manual

Overhead door

Overhead door 555 Installation instructions and owner's manual

Chamberlain

Chamberlain Security+ 1215EM FS2 owner's manual

Multi-code

Multi-code 1090 installation instructions

Challenger

Challenger 9300M Installation and owner's manual

Roger

Roger AYRON Series INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER