3

Index

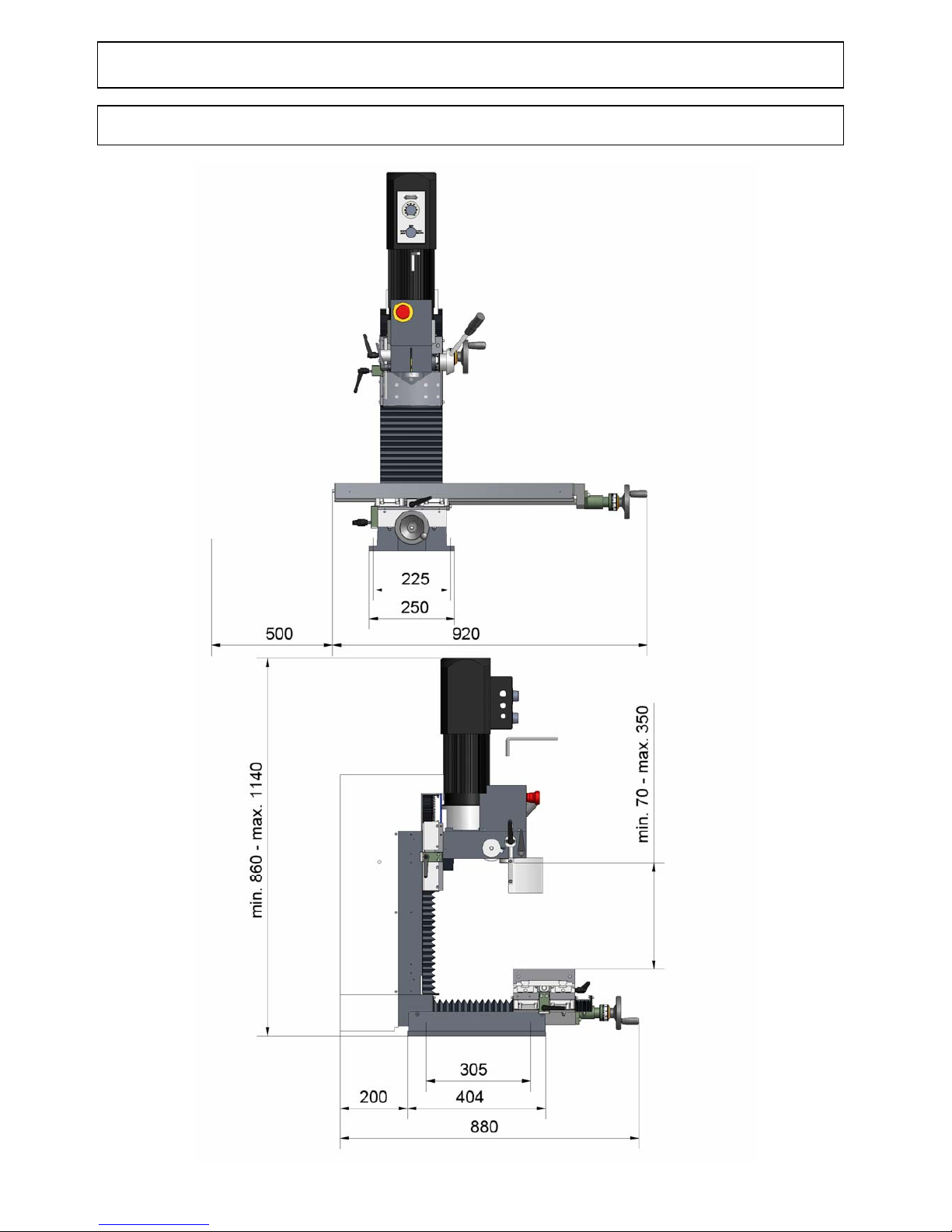

CC-F1200 – CC-F1200 high speed – CC-F1210 – CC-F1210 high speed

13.2 Electronics – Protective cover with 1.4 kW motor 30

13.3 Protective cover 31

13.4 Milling head with 1.4 kW motor 32

13.6 Milling head high speed with 2.0 kW motor 36

13.9 Z-column with vertical slide and trapezoid thread spindle 42

13.10 Z-column with vertical slide and ball screw 44

13.19 Lateral drive for Z-spindle complete 61

13.20 Z-spindle with CNC drive complete 62

13.24 Cross support with trapezoid thread spindle 70

13.32 X-spindle 80

13.33 Y-spindle 82

13.36 Control console nccad with 1.4 kW motor 88

13.37 Control console nccad with 2.0 kW motor 90

13.38 Support arm for control console 92

F1410 LF– F1410 high speed

13.1 Electronics – protective cover with 1.4 kW motor 29

13.3 Protective cover 31

13.4 Milling head with 1.4 kW motor 32

13.5 Milling head high speed with 2.0 kW motor 34

13.12 Z-column with trapezoid thread spindle 48

13.13 Vertical slide with trapezoid thread spindle 50

13.14 Z-column with ball screw 52

13.15 Vertical slide with ball screw 54

13.18 Z-spindle complete 60

13.19 Lateral drive for Z-spindle complete 61

13.25 Top slide 72

13.26 Cross slide with trapezoid thread spindle 73

13.27 Cross slide with ball screw 74

13.30 X-spindle 77

13.31 Y-spindle 78

13.34 X-spindle with automatic feed 84

13.35 Y-spindle with automatic feed 86

CC-F1410 LF– CC-F1410 high speed

13.2 Electronics – protective cover with 1.4 kW motor 30

13.3 Protective cover 31

13.4 Milling head with 1.4 kW motor 32

13.6 Milling head high speed with 2.0 kW motor 36

13.16 Z-column with ball screw 56

13.17 Vertical slide with ball ball screw 58

13.19 Lateral drive for Z-spindle complete 61

13.20 Z-spindle complete 62

13.28 Top slide 75

13.29 Cross slide 76