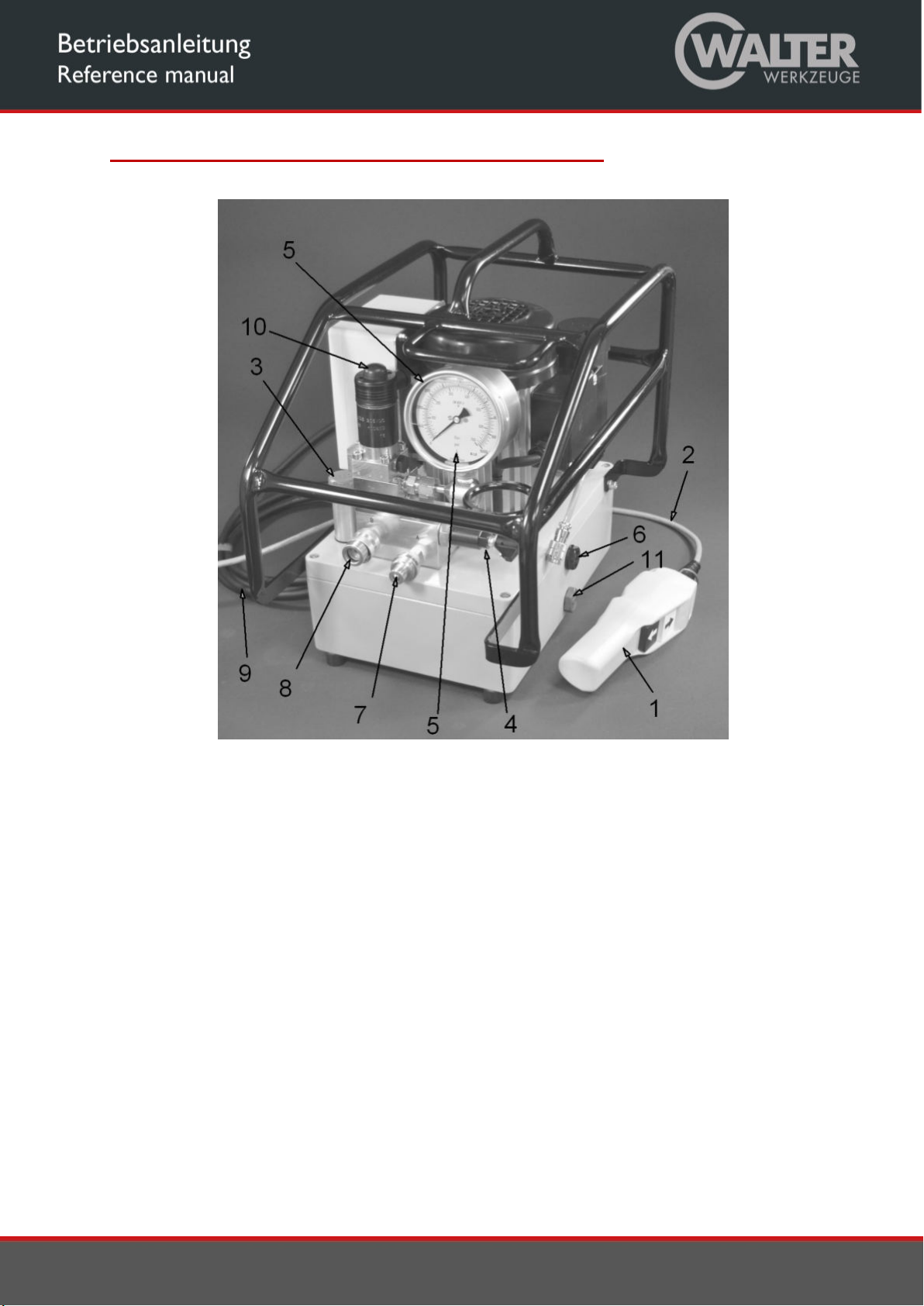

5

Specified Conditions of Use

This device is exclusively intended for professional use as a drive mechanism for hydraulic torque tools in line with

the description and safety instructions given in these Operating Instructions.

Any other use is considered to be improper!

In particular the use of the machine as a drive for all other hydraulic devices such as presses, hoisting

cylinders, hydraulic shears, spreaders, etc. is improper use!

Improper use of the device or modifications to the device undertaken by the end-user exclude any liability

on the part of the manufacturer and invalidate the Declaration of Conformity!

In this case the user is liable for damages resulting from the use of the device.

Residual risks

Danger due to hot surfaces: The surface of the oil cooler (if fitted)

becomes hot; keep a safe distance; the warning symbol is attached to the cooler

Danger due to noise: maximum noise level 82 dB(A); the end-user must make personal protective

equipment (ear-protectors) available.

Notes on Transport

Transport of the machine ready for operation:

a. by hand: up to 30 kg with 1 person

above 30 kg with two persons

b. with industrial trucks: use suitable hoisting equipment

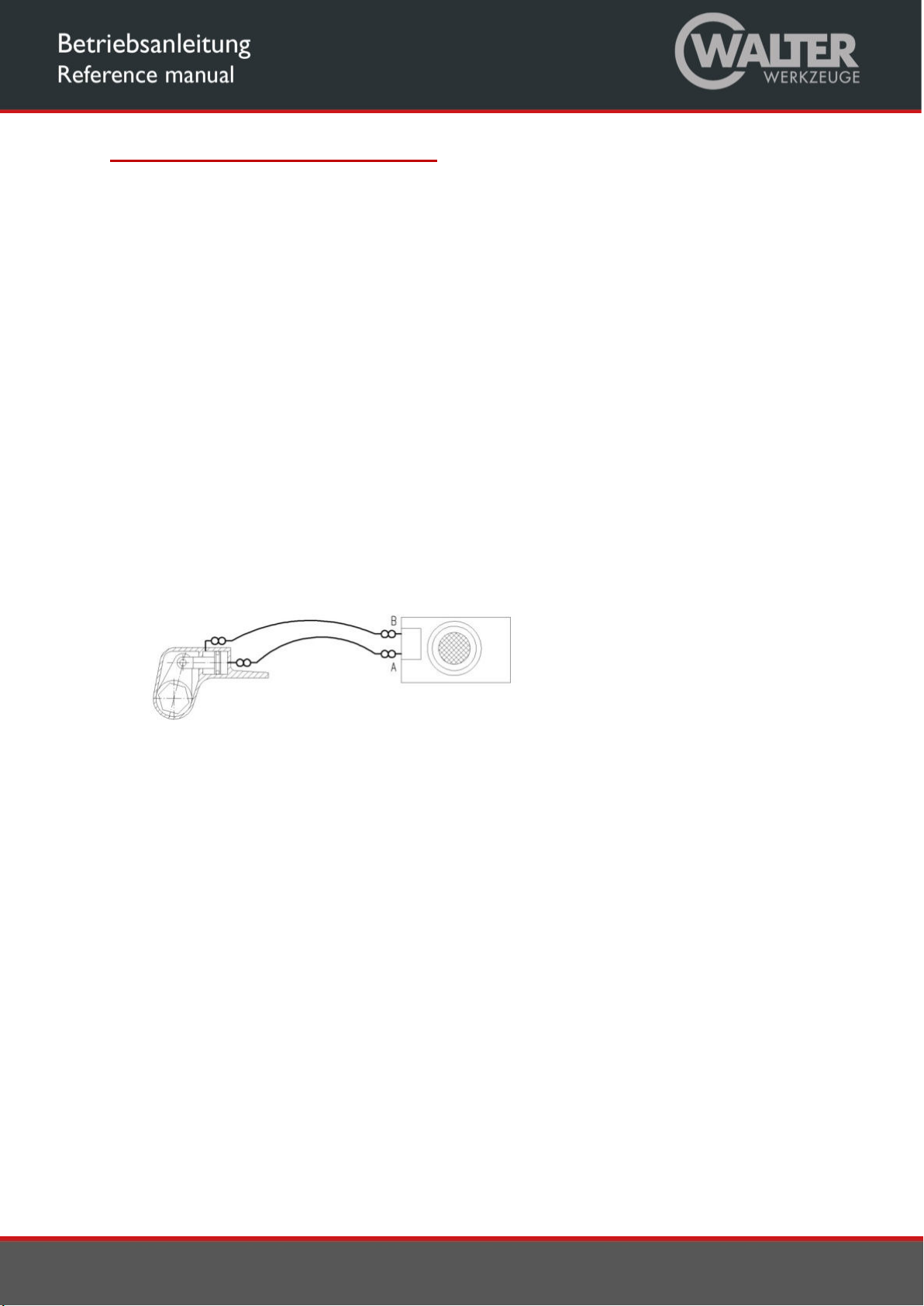

c. hanging: use suitable slings (no chains, no metal ropes). Attachment

point for slings as shown in Figure 2

Fig. 2

Use and Conditions for Storage

Ambient temperature: -10 to +40°C for use and storage

Protect from rain during use and storage.

Modification of the conditions of use only after consultation with the manufacturer.

Power supply connections: (delivery with earthed pin plug). In the event of modification to the mains

connection, protection against shock must be guaranteed by installing a protective earth system.