Page 3of 11

2 INSTALLATION

2.1 General Requirements.

The product must be installed only by a competent person and in accordance with all

manufacturer’s instructions contained herein, and all current legislation, regulations,

standards, codes and by-laws applicable to the territory of installation.

The product must be installed vertically (not on its side) and in a frost-free, interior location.

Ensure adequate clearances and access around the product for the purposes of installation,

service and maintenance. The installation location must not prevent component parts being

removed for the purposes of service or replacement.

The appliance must be installed on a floor area that is level and capable of supporting the

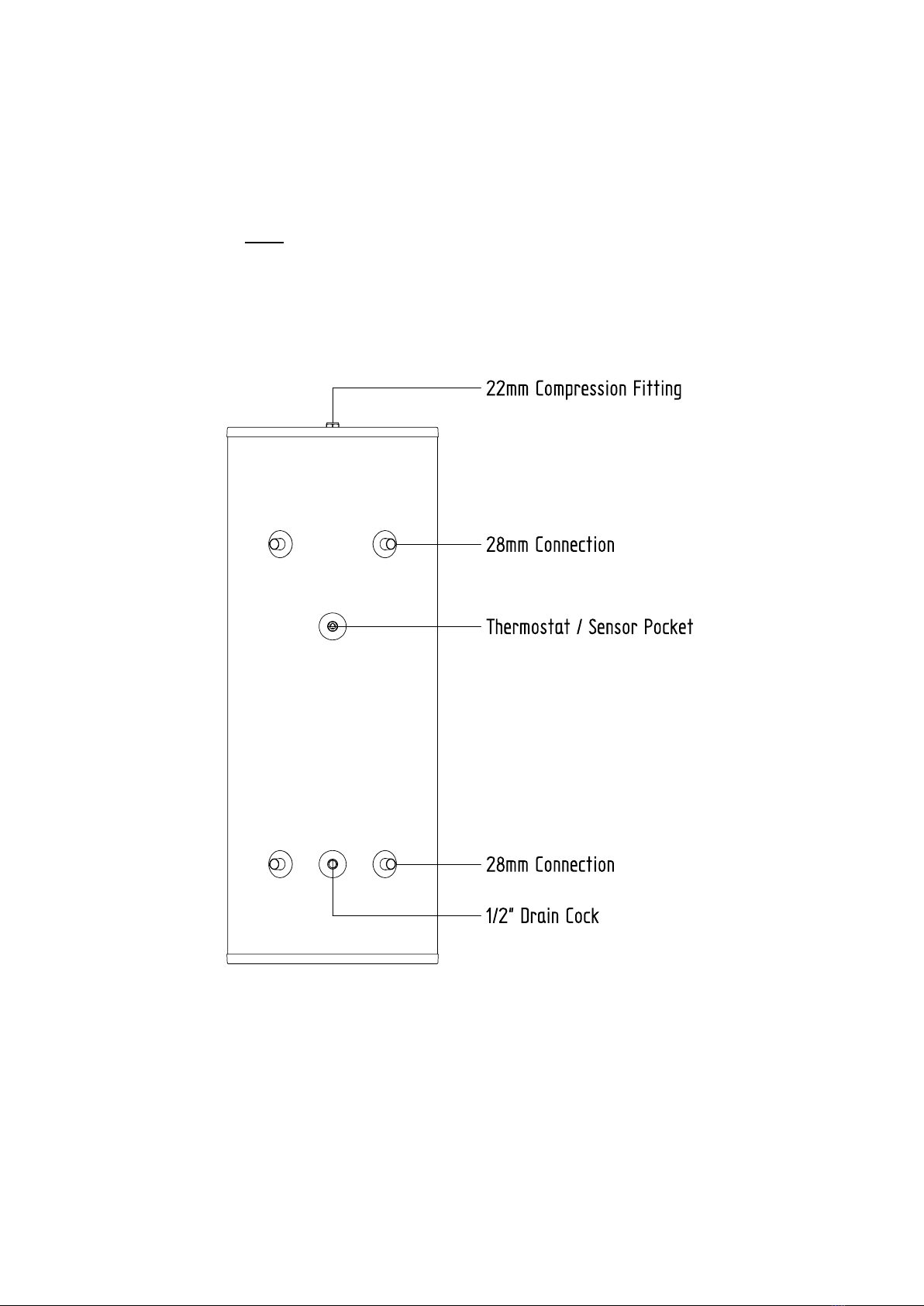

product when it is full of water. See Figure 1 and associated table for details of product

weights.

Connection to the product is via compression fittings only (not supplied).

It is recommended that the flow and return pipework connected to the product is fitted with

isolation valves, e.g., quarter-turn ball valves (not supplied), for easier maintenance.

The heating system to which the product is fitted must be installed to current HVAC codes of

practice. Before installing the product to a new or existing heating system, the system must

be thoroughly flushed to clear all deposits or other foreign matter such as solder, steel wool

and copper filings. The heating system must be cleansed, flushed, neutralised and protected

from corrosion in accordance with BS12828, BS12831, BS14336 and BS7593 using suitable

cleansing agent(s) and inhibitor(s) and carried out in accordance with the cleanser/inhibitor

manufacturers’ instructions.

The heating system must be dosed with corrosion inhibitor to the concentration specified by

the inhibitor manufacturer and in consideration of the total volume of the heating system

including all components, pipework, appliances, expansion capacity and this product.

Inhibitor concentration within the heating system must be monitored and maintained as part

of the annual service of the heating system, or upon any occasion when water is lost from

and restored to the heating system. Failure of this product or its components due to corrosion

or the presence of corrosion deposits within the heating system will not be covered by the

related product guarantee.

Heating system pressures must not exceed the maximum permitted. See Figure 1 and

associated table for details. The heating system must incorporate appropriately rated

pressure relief valve(s).

Ensure that the volume of the buffer tank is appropriate to the intended heating system

requirements and performances. Buffer tank capacity must be calculated by a competent

person using recognised principles and sizing formulae.

When sizing the heating system expansion vessel, the storage volume of the buffer tank must

be taken into consideration.