I pg 30

Turbotemp 125 Pool and Spa Heater Installation and User’s Guide

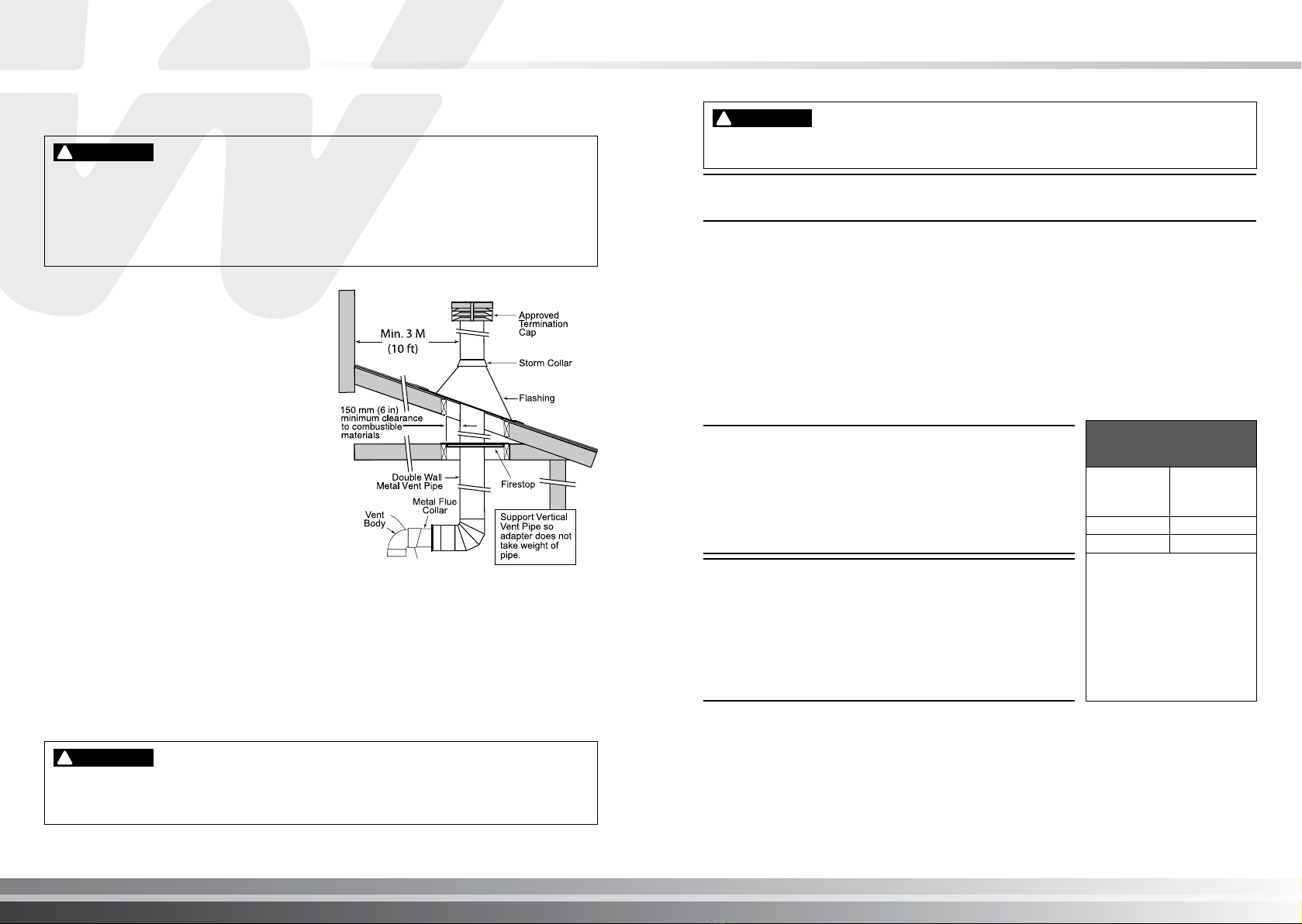

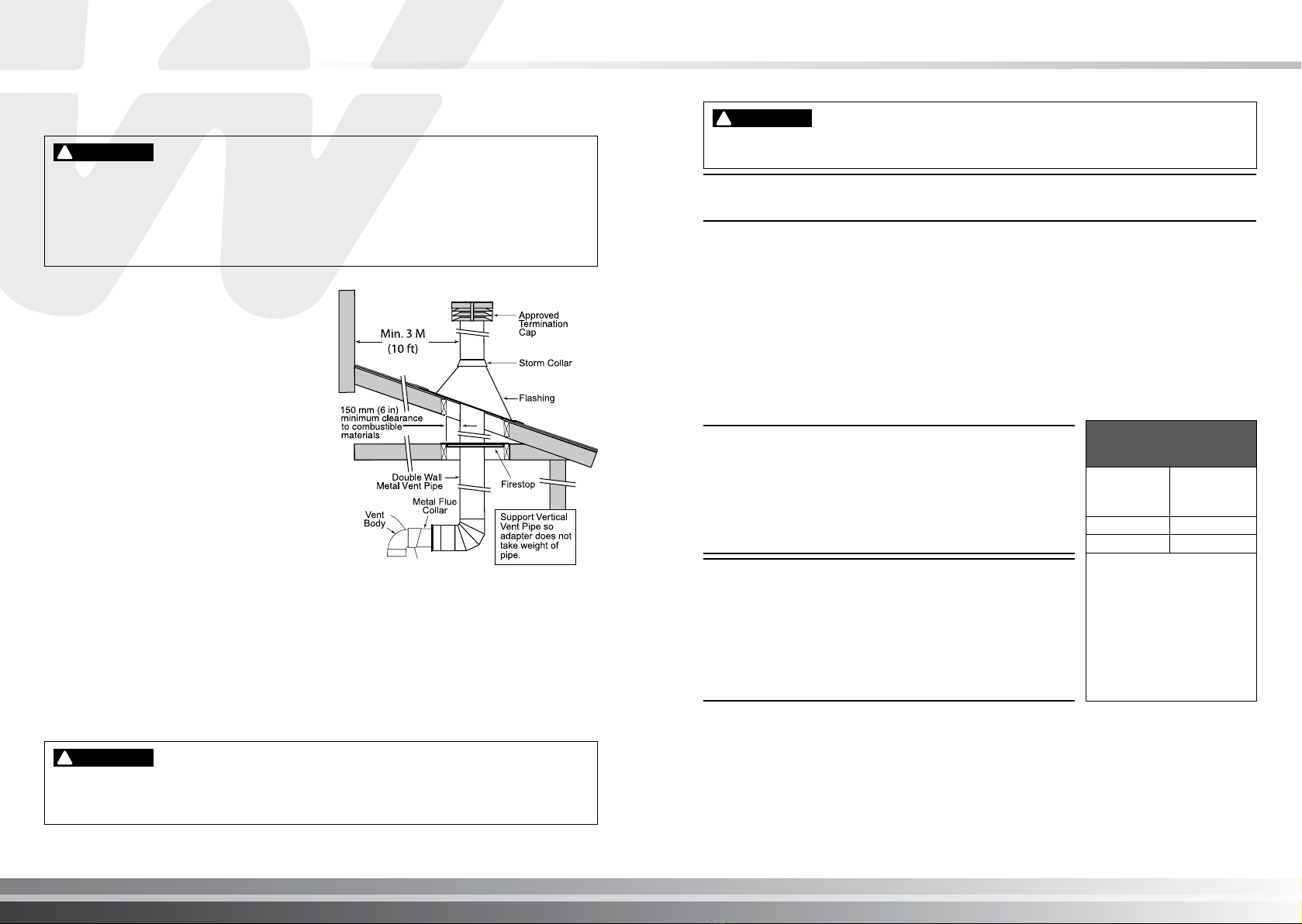

3. Attach the vent pipe to the metal Flue Collar

with sheet-metal screws.

4. Install vent pipe so that it can expand

and contract freely as the temperature

changes. Support the vent pipe according to

applicable codes and the vent manufacturer’s

instructions. Pipe support must allow the vent

pipe free movement out and back, from side

to side, or up and down as necessary, without

putting a strain on the heater or vent body.

Slope horizontal pipe down to condensate

trap at least 2 cm per meter (1/4 in per foot).

Install approved condensate drains at low

points where condensate might collect.

Plumb condensate drains to a drain through

hard piping or high temperature tubing such

as silicone rubber or EPDM rubber – do not

use vinyl or other low temperature tubing.

Follow drain manufacturer’s installation

instructions.

5. Use approved re stop for oor and ceiling

penetrations. Use approved thimble for

wall penetrations. Use an approved roof

ashing, roof jack, or roof thimble for all roof

penetrations. Do not ll the space around the

vent (that is, the clear air space in the thimble

or re stop) with insulation. The roof opening

must be located so that the vent is vertical.

6. Do not run the heater vent into a common

vent with any other appliance.

Risk of re or asphyxiation if vent is not assembled according to manufacturer’s instructions or

if vent parts from different manufacturers are mixed. Vent parts from different manufacturers

ARE NOT interchangeable. Mixing parts from more than one manufacturer may cause leaks

or damage to vent. When assembling a vent, pick one manufacturer and be sure that all vent

parts come from that manufacturer and are specied by the manufacturer for your system.

Follow manufacturer’s instructions, local code requirements and local code standards.

!

WARNING

Fire Hazard. Do not vent the heater directly into a masonry chimney. Installation into a

masonry chimney must use a chimney liner which must meet local code standards and all

local code requirements.

!

WARNING

Risk of fire, carbon monoxide poisoning, or asphyxiation. It is recommended to use a CO

Monitor and Fire Alarm in rooms that contain gas red appliances.

!

WARNING

NOTE

After installation, installer must check for correct and safe operation of the heater.

HORIZONTAL OR VERTICAL VENTING - USING SINGLE-WALL STAINLESS

GAS VENT (See Figures 26, 27 and 28)

Vent the heater either horizontally or vertically using an optional vent adapter of the 150 mm

(6 in) or 102 mm (4 in) special gas approved stainless steel vent pipes. Installation must be in

accordance with AS/NZS 5601.1 and/or local codes and ordinances. The heater, when installed,

must be electrically grounded and bonded in accordance with local codes. Do not use a draft

hood with this heater. Install the vent according to the vent manufacturer’s detailed instructions.

Note: Keep a 150 cm (6 in) minimum clearance between the vent pipe and combustible surfaces.

Follow the vent manufacturer’s instructions and code requirements. Do not place any insulating

materials around the vent or inside the required clear air space surrounding the vent. See Table

8 for maximum permissible vent lengths.

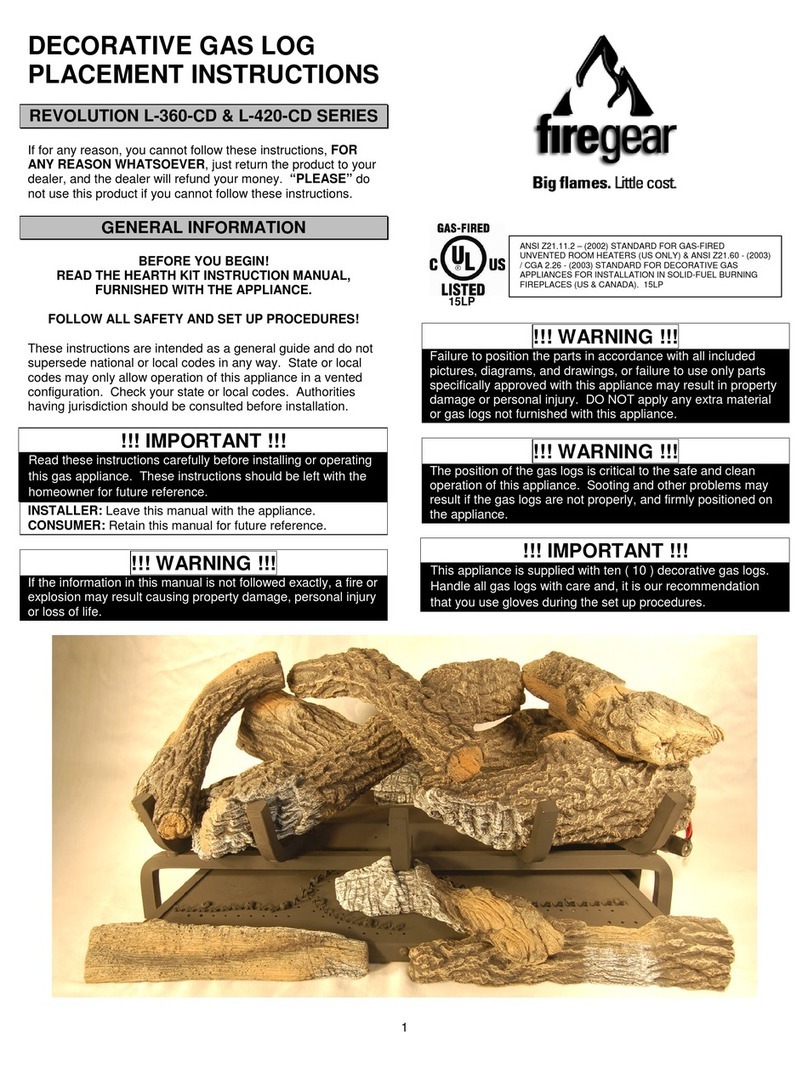

NOTE

The allowable vent runs for each vent pipe diameter are

different and can not be exceeded.

Each 90-degree elbow reduces the maximum horizontal vent

run by 3.6 m (12 feet) and each 45-degree elbow in the vent

run reduces the maximum vent run by 1.8 m (6 feet). See

Table 8 for the maximum vent lengths using 90° elbows.

150 mm (6 in.)

Special Gas Vent

(Vertical or Horizontal)*

No. of 90°

Elbows

Maximum

Length in

Feet (M)

0 11.6 m (38 ft.)

1 8 m (26 ft.)

*Minimum vent length is

0.34M (1 ft.) or in

accordance with vent

manufacturer’s instruction,

and local and national codes.

Horizontal vents 1 m (3 in) or

less in length do not require

a condensate tee, but must

slope down toward the outlet

at 2 cm to the meter (1/4 in / ft.)

to allow condensate to drain.

NOTE

It is recommended vent runs over 5.4 m (18 feet) may need to

be insulated to reduce condensation related problems and/

or the use of a condensate trap in the vent run close to the

heater may be necessary in certain installations such as cold

climates. Horizontal vents 1 m (3 feet) or less in length do not

require a condensate tee. Note: The Turbotemp heater is

suitable for through-the-wall venting.

Flue gases may escape into the dwelling with any cracks or loose joints in the vent pipe,

or improper vent installation. The vent pipe must be of a sealed-seam construction and for

operating temperatures less than 204° C (400°F). Vent pipe construction will be according to

local code standards, approved non-corrosive material, such as stainless steel. A condensate

trap may be needed. The use of “Approved” thimbles, roof jacks and/or side vent terminals are

required; and the proper clearances to combustible materials must be maintained in accordance

with type of vent pipe employed—in the absence of a clearance recommendation by the vent

pipe manufacturer, the requirements of the Uniform Mechanical Code should be met.

See page 14 for ventilation air requirements for the Turbotemp heater.

NOTE: After installation, installer must check for correct and safe operation of the heater.

Figure 25.

– Typical Metal Vent Pipe Installation

(Vertical Venting)

Table 8.