Page | 4 Ascento Group Australia 37 Export St, Lytton, Brisbane, QLD 4178 P: 1800807604

TROUBLESHOOTING CHECKLIST (CAUTION: SHUT OFF POWER TO PUMP)

Check the following before requesting service or repair.

PROBLEMS & POSSIBLE CAUSES

20. Light Flashes “No Water” or “Failure”

* This normally indicates that the pump has no water, either because the tank is empty or the pump has “lost prime” – run dry. This is normal

if the tank is empty, or the pipe has an airlock in it, or the suction pipe has a leak in it and it has let air into the suction pipe. It does not usually

mean the pump is faulty. Refer to point 19 a) to h) of the instructions.

21. Pump does not run

* After pump has been idle for some time, the pump turbine may become jammed. Turn off the power supply and unplug from the power

outlet, then put a small screwdriver through the fan cover at the back of the electric motor (ensure power is off) and gently move the fan, in

order to turn the motor. Remove the screwdriver and turn the power back on and re-test, if not successful you might need to repeat the same

process again.

* Circuit breaker or Safety Switch is off or fuse has blown –check what has caused this and isolate that device.

* Water level in tank is too low - Top up or use alternative supply.

* Electrical components have been flooded - Contact a licensed electrician to rectify.

* Pump plug is not connected properly, or has been flooded or wet - Isolate power at main switch, remove plug & allow to dry. If the problem

continues, contact a licenced electrician to check what is the cause.

* If all of the above are OK, then check the motor overload switch.

* If the overload switch has activated, investigate why this has occurred before turning it back on.

22. Pump runs but does not deliver water.

* Check valve is installed backwards. Arrow on valve should point in direction of flow.

* Discharge shut-off valve (if used) may be closed.

* Impeller or volute openings are fully or partially clogged. Disconnect from the power supply, and if you are competent to do so, disassemble

pump and clean. If not, have a pump technician do it for you.

* Pump is air-locked. Start and stop several times by turning the power off & on a couple of times. If this does not work, see below regarding

re-priming the pump

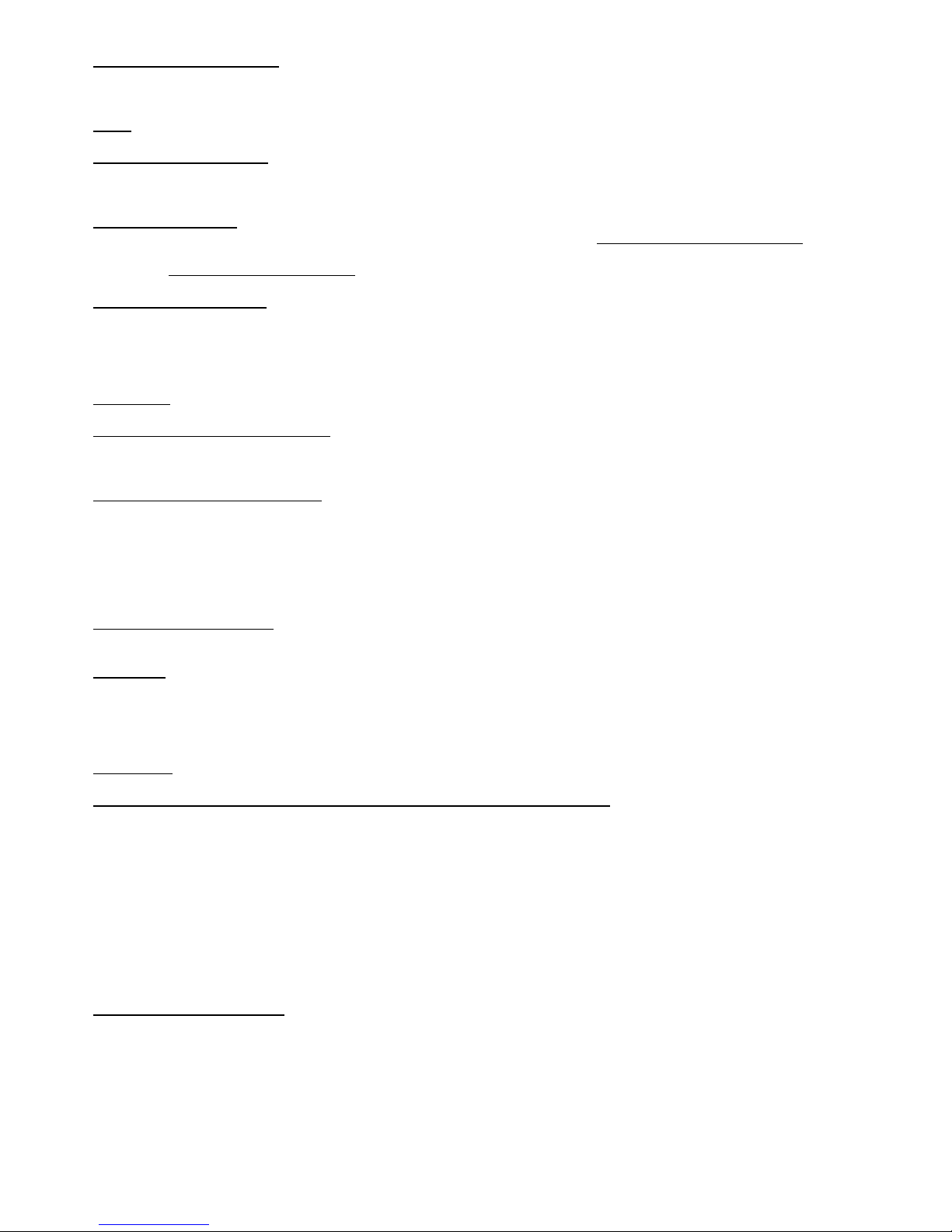

* Vertical pumping distance is too high. Reduce distance or upgrade to a larger pump.

23. Pump runs and does not stop or runs when no taps in use

* Leak in pipework or leaking toilet cistern or underground pipe leak (wet soil, muddy, grass growing well !)

* Toilet cisterns can leak internally and you may be unaware due to the way they are designed –this is very common. Test the cisterns by

turning off the stop-cock that is under the toilet cistern, on all the toilets, does the pump now stop cycling? If so, it is the cistern that is at

fault, not the pump.

* Pressure controller Fault - Press Restart, If that does not help then turn the power off and on again.

* If this fails to rectify the problem, call your dealer for service, or call us on 1800807604

Note that a call out fee and labour costs apply, if it is not found to be warranty.

24. Pump not pumping properly

* Too high head or pump under specified - Check specifications.

* Too low water level - Check the water levels

* Loss of prime - Check foot valve (if fitted), re-prime the pump.

* Leakage of inlet pipe - Check the inlet pipe is not taking in air, check all joints.

* Inlet Pipe has rise and fall (Dips). Fix suction pipe so it is either perfectly straight and level OR rises all the way to the pump.

* If a check valve has been installed directly on the discharge of the pressure controller, this may cause the Pressure controller to malfunction.

Move the check valve to a different position.

25. Pump runs but delivers only a small amount of water.

* Pump is air-locked. Start and stop several times by turning the power off & on a couple of times.

* Vertical pumping distance is too high. Reduce distance or upgrade to a larger pump.

* Foot valve blocked - Clean or replace the FOOT valve

* Too low water level - Check the suction and water levels

* Impeller or volute openings are fully or partially clogged. Disconnect from the power supply, and if you are competent to do so, disassemble

pump and clean. If not, have a pump technician do it for you

26. Low Flow from Pump

*Check the two items above, first.

* Then if problem persists, turn the power off and remove the pressure controller and check for obstructions in it. If this has occurred refer to

point 1. of the installation that you install a suction screen or a prefilter between the tank and the pump (in the suction line)

27. Fuse blows or circuit breaker trips when the pump starts.

* Fuse size or circuit breaker may be too small. (Must be an approved power circuit refer to 10. of the installation instructions)

* Impeller or volute opening are fully or partially clogged. Disconnect from the power supply, and if you are competent to do so, disassemble

pump and clean. If not, have a pump technician do it for you.

* If none of the above, the Motor may be defective, have it checked by a qualified technician or call us if in warranty 1800807604.

28. Motor runs for a short time, then stops.

* Impeller or volute opening are fully or partially clogged. Disconnect from the power supply, and if you are competent to do so, disassemble

pump and clean. If not, have a pump technician do it for you.

* Fit a pre-filter to prevent re-occurrence - refer to point 1. of the installation that you install a suction screen or a prefilter between the tank

and the pump (in the suction line)

* Motor may be overheating. Ensure there is good ventilation for the motor.