WATERRA HYDROLIFT-2

OWNER'S MANUAL

WATERRA HYDROLIFT-2

ASSEMBLY & OPERATION

Assembly & Operation

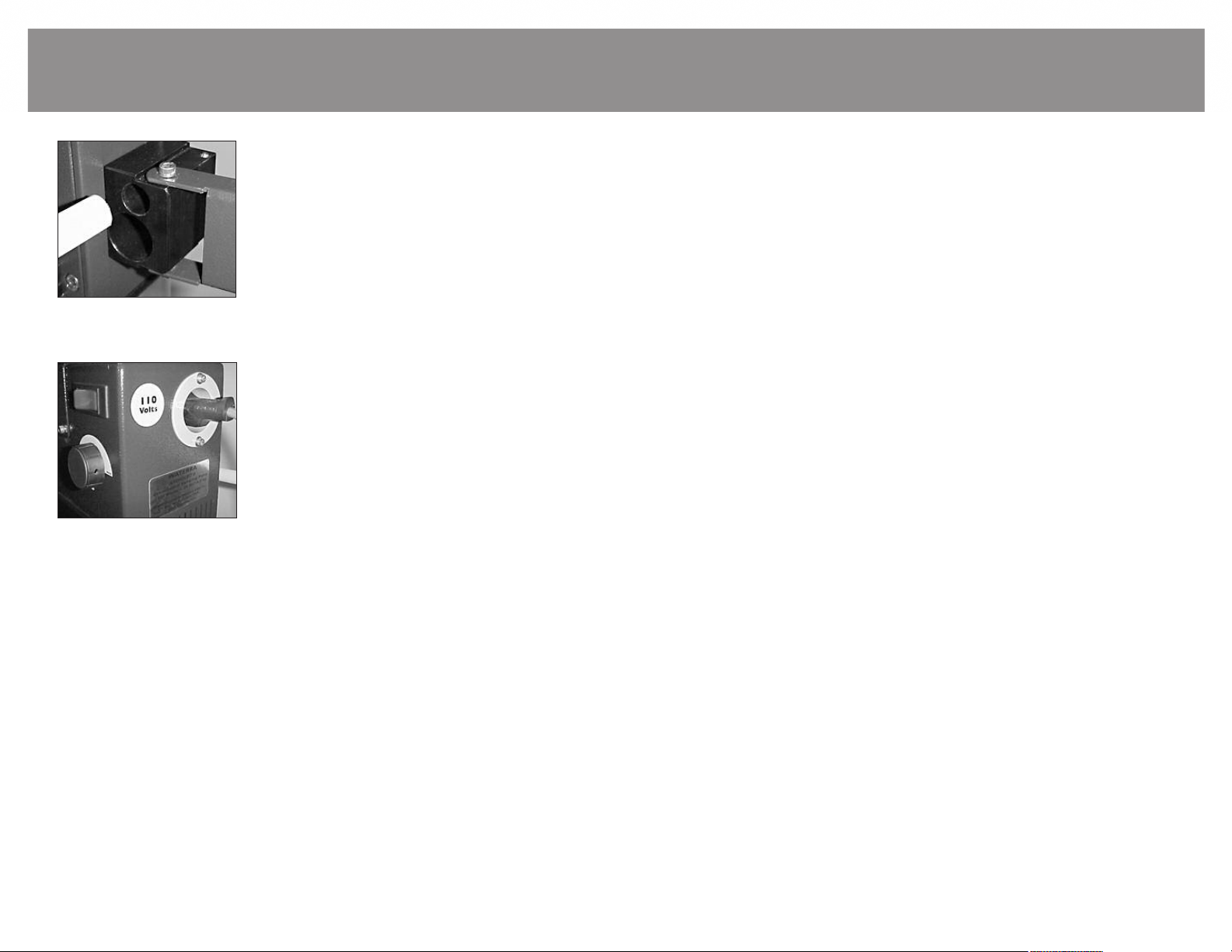

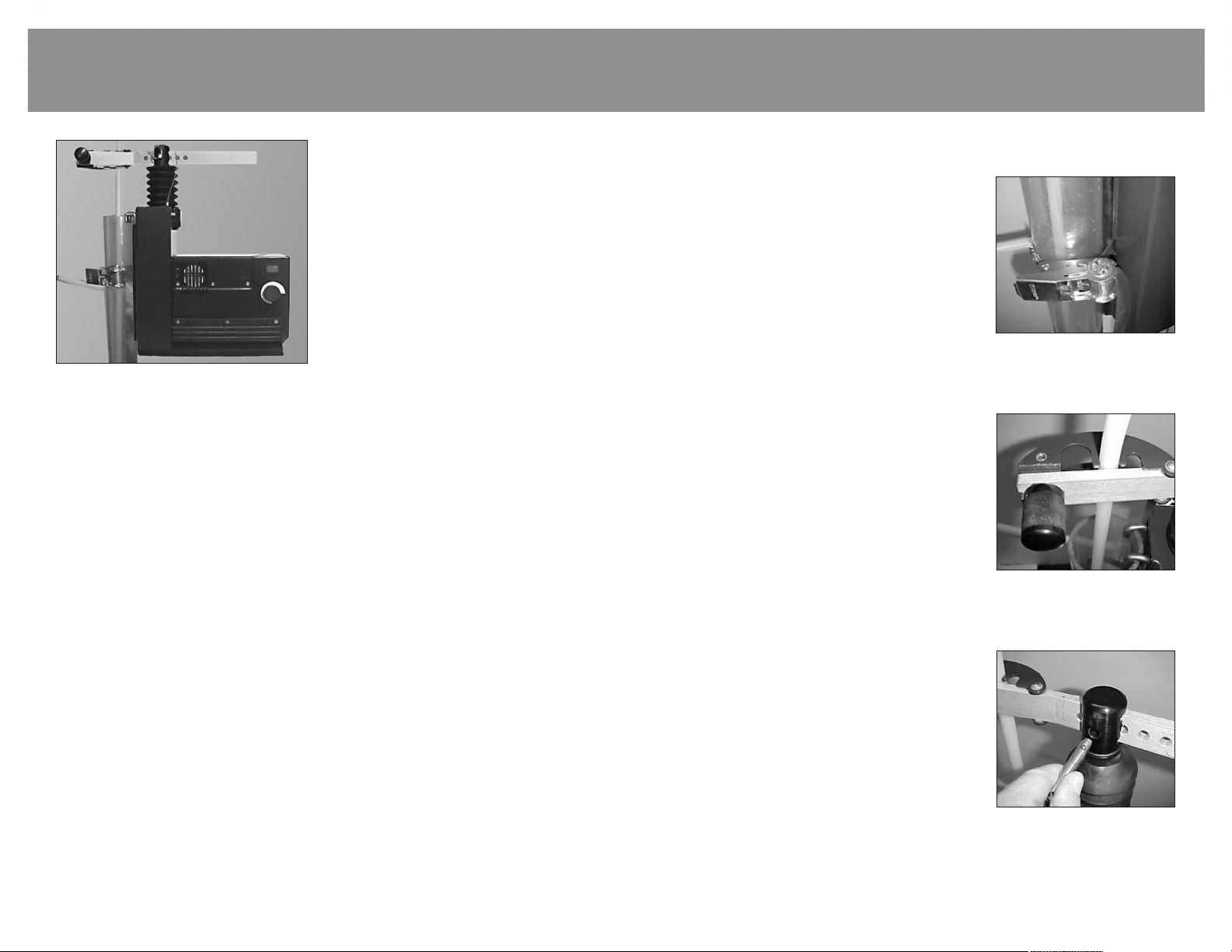

When us ng a Waterra Hydrol ft-2 pump to

purge and sample a monitoring well, it is very impor-

tant that the Hydrolift be firmly attached to the well.

If the pump is not properly attached it may fall off the

casing causing injury and possibly damaging the pump

and other equipment. Hang the Hydrolift-2 on the

PVC or protective casing by the front forks on the

Hydrolift. The Hydrolift is supplied with a ratchet

t e-down belt. The belt is looped through the gap

behind the front forks of the Hydrolift and around the

protective casing and tightened until the Hydrolift is

firmly attached to the casing.

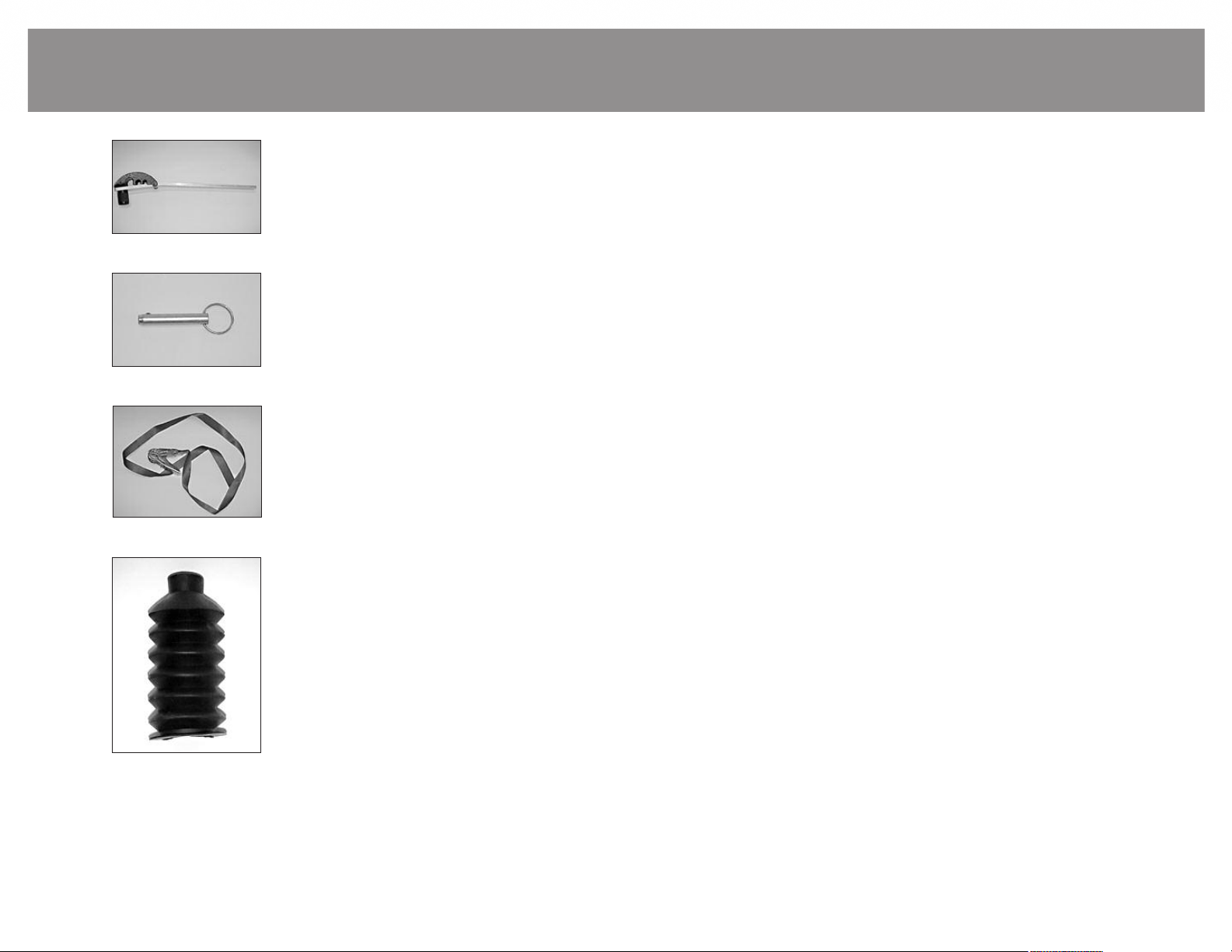

Open the Tub ng Clamp located on the

adjustable clamp arm and place the tubing in the

clamp’s jaws, leaving enough tubing (approximately 5

feet) above the jaws to allow the tubing to reach the

tubing discharge clamp, and then tighten the clamp

until the jaws are completely closed.The tubing clamp

is designed to accept 1" OD, 5/8" OD and 1/2" OD

polyethylene or Teflon tubing. Now position the tub-

ing such that it will not chafe on the well casing and

lock the clamp arm in place by inserting the clevis pin

through the fork and the mating hole in the clamp

arm.

Features

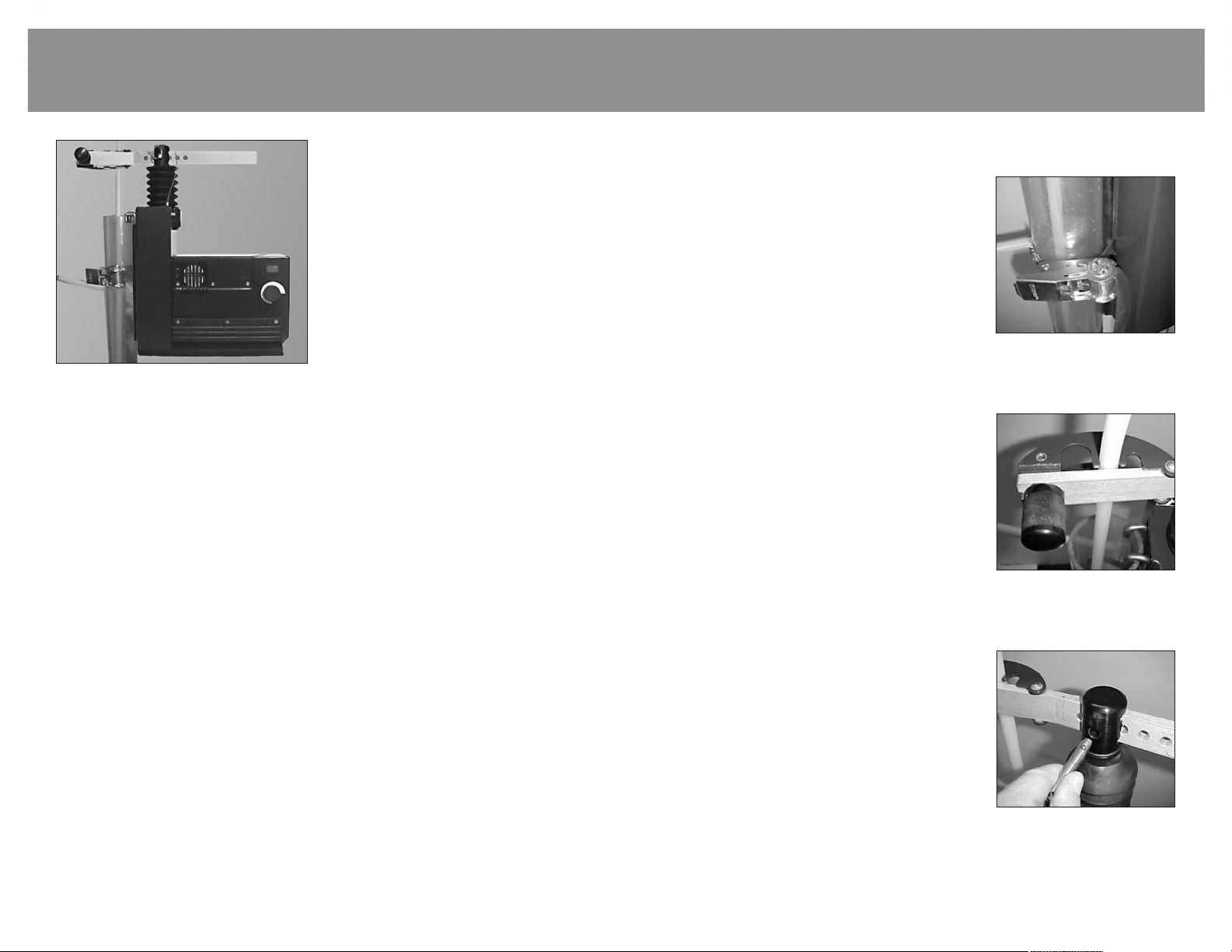

The Waterra Hydrol ft-2 is an elec-

trically powered mechanical drive

mechanism which pumps water by

repeatedly lifting and dropping a tubing

and footvalve assembly that is extended

below the water surface in a well. The

Hydrolift-2 components include a 700

watt (3/4 hp) electric D.C. motor inte-

gral with a 15:1 gear reducer which dri-

ves a linear pump mechanism.This drive

mechanism includes a sliding post that

extends beyond the pump body and

supports the tubing clamp arm. The

pump is designed to hang from the protective well casing and is secured in

place with a ratchet belt.All components on the pump are fully adjustable to

permit operation in wells of varying diameters. The pumping speed is also

fully adjustable to accommodate variable well depths and flow rate require-

ments.

Safety First

Stand clear of the Hydrolift-2 when in use.The rapid up and down motion

of the drive shaft creates a potential hazard.

Always secure your pump to the well casing securely before starting the

pump, making sure that adequate clearance exists between the reciprocating

shaft and the well head. Never move the pump when connected to a power

source.

Before start ng your Waterra Hydrolift-2 pump, be sure that there is

enough tubing (approximately 5 feet) between the tubing clamp and the tub-

ing discharge clamp. Also ensure that the tubing clamp and pump are posi-

tioned so that the tubing will not chafe on the well casing. Lastly, ensure that

the Hydrolift-2 is firmly strapped onto the protective casing or PVC pipe and

will not come loose while in operation.

Waterra Hydrolift-2

Ratchet tie-down belt

Tubing clamp

Clevis pin and clamp arm