Waters 1500-Series Manual

Waters 1500-Series

HPLC Pump and Options

Operator’s Guide

715002013IVD /Revision C

Copyright © Waters Corporation 2014

All rights reserved

ii

Copyright notice

© 2014 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS

DOCUMENT OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY

FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

Waters is a registered trademark of Waters Corporation, and Breeze,

Empower, LAC/E, SAT/IN, and “THE SCIENCE OF WHAT’S POSSIBLE.”

are trademarks of Waters Corporation.

Luer is a registered trademark of Becton, Dickinson, and Company.

PharMed and Tygon are registered trademarks of Saint-Gobain Performance

Plastics Corporation.

Tefzel is a registered trademark of duPont de Nemours and Company, Inc.

TORX is a registered trademark of Acument Global Technologies.

Other registered trademarks or trademarks are the sole property of their

owners.

iii

Customer comments

Waters’ Technical Communications department invites you to tell us of any

errors you encounter in this document or to suggest ideas for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding

the use, transportation, removal, or disposal of any Waters product. You can

reach us via the Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can

pose chemical, biological, and radiological hazards. You must know the

potentially hazardous effects of all substances you work with. Always follow

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact

information for Waters locations worldwide.

Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800

252-HPLC, or fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

iv

Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

Considerations specific to the 1500-Series HPLC pumps and

column heater

Radiation hazard

The equipment does not emit any type of hazardous radiation. It emits a

minimum amount of electromagnetic radiation that is within the limits of

applicable emissions standards (EN61326).

Protective grounding

The pump and column heater requires protective grounding for operation. The

three-conductor electrical cord that supplies power also grounds the device.

This power cord is approved by a nationally recognized testing laboratory (UL

or ETL). It must comprise three, 18-gauge, insulated conductors and be rated

for 300 V.

Back siphoning and draining

Check valves in the fluid pump, installed ahead of the column heater, prevent

the back-siphoning of fluids.

Drainage systems are installed in this equipment. Drip trays inside the pump

and column heater units catch any fluid from leaks or spills. These trays are

connected to external drains on the bottom of the units. Tubing connected to

this drain routes the fluid into an appropriate waste container.

Hazardous waste

During standard operation, this device does not produce any byproducts or

waste. Any waste resulting from a leak or spill is channeled into the drain

located on the underside of the device. Tubing connected to this drain directs

the flow to an appropriate waste container.

Equipment repair or disposal

Direct questions regarding repair or disposal to Waters. Waters carries out

equipment disposal in Europe according to the WEEE directive specific to the

v

country. Waters also accommodates any special requirements for locations

outside of Europe.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

Operating the Waters 1500-Series HPLC pump and

options

When operating these pumps and options, follow standard quality-control

(QC) procedures and the guidelines presented in this section.

vi

Applicable symbols

Audience and purpose

This guide is intended for use by individuals who need to install, maintain,

and/or troubleshoot the Waters 1500-Series HPLC Pump and options. You

should be familiar with HPLC terms, practices, and basic HPLC system

operations such as connecting tubing.

Intended use of the Waters 1500-Series HPLC pump and options

Use the Waters 1525, 1525µ, and 1525EF HPLC pumps and the optional

1500-Series Column Heater and its options to deliver a precisely controlled

amount of solvent to a column, maintaining a consistent and reproducible

mobile phase composition. The Waters 1500-Series HPLC pump and options

are for research use only.

Symbol Definition

Manufacturer

Authorized representative of the European

Community

Confirms that a manufactured product complies

with all applicable European Community

directives

Australia C-Tick EMC Compliant

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

Consult instructions for use

vii

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least

five standards to generate a standard curve. The concentration range for

standards should include the entire range of QC samples, typical specimens,

and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the

operator’s guide for the instrument you are calibrating. In cases where an

overview and maintenance guide, not operator’s guide, accompanies the

instrument, consult the instrument’s online Help system for calibration

instructions.

Quality-control

Routinely run three QC samples that represent subnormal, normal, and

above-normal levels of a compound. Ensure that QC sample results fall within

an acceptable range, and evaluate precision from day to day and run to run.

Data collected when QC samples are out of range might not be valid. Do not

report these data until you are certain that the instrument performs

satisfactorily.

When analyzing samples from a complex matrix such as soil, tissue,

serum/plasma, whole blood, and other sources, note that the matrix

components can adversely affect LC/MS results, enhancing or suppressing

ionization. To minimize these matrix effects, Waters recommends you adopt

the following measures:

• Prior to the instrumental analysis, use appropriate sample

pretreatment such as protein precipitation, liquid/liquid extraction

(LLE), or solid phase extraction (SPE) to remove matrix interferences.

• Whenever possible, verify method accuracy and precision using

matrix-matched calibrators and QC samples.

• Use one or more internal standard compounds, preferably isotopically

labeled analytes.

viii

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with CISPR 11 Industrial

Scientific and Medical (ISM) instruments requirements. Group 1 products

apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment. Class B products are suitable for use in both commercial and

residential locations and can be directly connected to a low voltage,

power-supply network.

EC authorized representative

Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

Table of Contents ix

Copyright notice ................................................................................................... ii

Trademarks ............................................................................................................ ii

Customer comments ............................................................................................ iii

Contacting Waters ............................................................................................... iii

Safety considerations .......................................................................................... iii

Considerations specific to the 1500-Series HPLC pumps and column heater iv

Safety advisories.................................................................................................. v

Operating the Waters 1500-Series HPLC pump and options ...................... v

Applicable symbols .............................................................................................. v

Audience and purpose.......................................................................................... v

Intended use of the Waters 1500-Series HPLC pump and options.................. vi

Calibrating .......................................................................................................... vi

Quality-control .................................................................................................... vi

ISM classification ................................................................................................ vii

ISM Classification: ISM Group 1 Class B ....................................................... vii

EC authorized representative ........................................................................ viii

1 Introduction ............................................................................................ 1-1

HPLC pump operating principles ................................................................. 1-2

Isocratic and gradient LC system operation .................................................. 1-2

Effects of dissolved oxygen on the mobile phase............................................ 1-3

Using in-line degassing to remove gases from eluents.................................. 1-4

Overview of the 1500-series HPLC pumps .................................................. 1-5

Fluid-handling components ........................................................................... 1-7

Electronic components .................................................................................. 1-12

Pump control ................................................................................................... 1-13

Ethernet configuration .................................................................................. 1-14

Table of Contents

x Table of Contents

IEEE-488 configuration................................................................................. 1-14

Options and accessories ................................................................................ 1-15

1500-series column heater............................................................................. 1-15

Integral vacuum degasser ............................................................................. 1-15

Automated plunger seal wash....................................................................... 1-16

Manual injector.............................................................................................. 1-16

Ethernet communications kit........................................................................ 1-16

Gradient mixers ............................................................................................. 1-17

2 Installing the HPLC Pump ................................................................... 2-1

Site requirements ............................................................................................. 2-2

Unpacking ........................................................................................................... 2-3

Connecting power and signal cables ............................................................ 2-4

Connecting the power supply .......................................................................... 2-5

Making ethernet connections.......................................................................... 2-5

Making IEEE-488 connections........................................................................ 2-6

Setting the IEEE-488 address......................................................................... 2-9

Connecting pump inlet and outlet lines .................................................... 2-11

Connecting the eluent supply........................................................................ 2-11

Connecting the pump outlet.......................................................................... 2-14

Connecting fluid waste lines ......................................................................... 2-16

3 Installing Options and Accessories ................................................... 3-1

Installing the 1500-series column heater .................................................... 3-2

Installing a manual injector ........................................................................... 3-4

Connecting to the column or column heater................................................... 3-5

Connecting the inject start signal (for manual injector)................................ 3-5

Installing different eluent mixers ................................................................. 3-8

Installing the integral vacuum degasser ................................................... 3-14

Connecting tubing to the degasser inlet and outlet..................................... 3-15

Installing the degasser vent line................................................................... 3-16

Using the degasser......................................................................................... 3-17

Table of Contents xi

Installing the plunger seal wash system ................................................... 3-17

Preparing the instrument ............................................................................. 3-18

Removing pump head components................................................................ 3-19

Installing head support components (1515/1525 pump only)...................... 3-21

Installing head support components (1525EF pump only).......................... 3-25

Installing head components (1525µ pump only) .......................................... 3-27

Installing the solenoid ................................................................................... 3-29

Installing seal wash tubing ........................................................................... 3-31

Using the seal wash system .......................................................................... 3-33

4 Preparing for Operation ...................................................................... 4-1

Startup and initial preparation ..................................................................... 4-2

Powering-on the pump..................................................................................... 4-2

Pump preparation recommendations ............................................................. 4-2

Dry priming the pump..................................................................................... 4-4

Operating with the integral vacuum degasser............................................... 4-5

Operating with the plunger seal wash system............................................... 4-8

Maximum flow rates for 1500-series pumps ................................................ 4-10

Preparing for Breeze 2 operation ............................................................... 4-10

Priming and purging the pump via Breeze 2 control................................... 4-11

Purging the flow path via Breeze 2 control .................................................. 4-12

Equilibrating the system via Breeze 2 control............................................. 4-13

Preparing for Empower 2 operation .......................................................... 4-15

Priming and purging the pump via Empower 2 control .............................. 4-15

Purging the flow path via Empower 2 control.............................................. 4-16

Equilibrating the system via Empower 2 control ........................................ 4-18

Preparing for MassLynx operation ............................................................ 4-19

Priming and purging the pump via MassLynx control................................ 4-19

Purging the flow path via MassLynx control ............................................... 4-20

Equilibrating the system via MassLynx control .......................................... 4-22

Powering off the pump .................................................................................. 4-23

5 Maintaining the HPLC Pump .............................................................. 5-1

xii Table of Contents

Maintenance considerations .......................................................................... 5-2

Safety and handling......................................................................................... 5-2

Proper operating procedures ........................................................................... 5-2

Spare parts....................................................................................................... 5-2

Contacting Waters Technical Service............................................................. 5-2

Performing pump diagnostic tests ............................................................... 5-3

Retention time stability test ........................................................................... 5-3

Ramp-and-decay test ....................................................................................... 5-3

Replacing and cleaning plunger seals and plungers ................................ 5-6

Preparing for plunger seal replacement ......................................................... 5-6

Cleaning and replacing the plungers.............................................................. 5-9

Replacing check valves .................................................................................. 5-14

Replacing 1515/1525 check valves ................................................................ 5-15

Replacing 1525EF check valves .................................................................... 5-17

Replacing 1525µ check valves ....................................................................... 5-19

Replacing a draw-off valve ........................................................................... 5-22

Removing the draw-off valve......................................................................... 5-23

Installing a draw-off valve ............................................................................ 5-24

Replacing fuses ................................................................................................ 5-25

Replacing the rear panel fuses...................................................................... 5-26

6 Troubleshooting ..................................................................................... 6-1

Troubleshooting pump problems .................................................................. 6-2

Identifying and correcting noises ................................................................. 6-8

Identifying chromatographic problems ...................................................... 6-9

A Safety Advisories .................................................................................. A-1

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Specific warnings ............................................................................................. A-3

Caution symbol .................................................................................................. A-5

Table of Contents xiii

Warnings that apply to all Waters instruments ......................................... A-6

Electrical and handling symbols ................................................................. A-12

Electrical symbols .......................................................................................... A-12

Handling symbols .......................................................................................... A-13

B Specifications ........................................................................................ B-1

C Solvent Considerations ....................................................................... C-1

Introduction ...................................................................................................... C-2

Clean solvents .................................................................................................. C-2

Solvent quality ................................................................................................. C-2

Preparation checklist....................................................................................... C-2

Water ................................................................................................................ C-2

Buffers .............................................................................................................. C-3

Tetrahydrofuran (THF) ................................................................................... C-3

Solvent compatibility ...................................................................................... C-3

Solvents to avoid .............................................................................................. C-3

Solvents to use ................................................................................................. C-3

Solvent miscibility ........................................................................................... C-6

How to use miscibility numbers (M-numbers) ............................................... C-8

Buffered solvents ............................................................................................. C-8

Head height ....................................................................................................... C-9

Solvent viscosity ............................................................................................... C-9

Mobile phase solvent degassing ................................................................... C-9

Gas solubility ................................................................................................... C-9

Eluent degassing methods............................................................................. C-10

Wavelength selection .................................................................................... C-12

UV cutoffs for common solvents.................................................................... C-12

Mixed mobile phases...................................................................................... C-13

Refractive indices of common solvents ......................................................... C-14

Index ..................................................................................................... Index-1

xiv Table of Contents

1-1

1Introduction

This chapter describes key operating principles, pump components, data

control configurations, and available options for the 1500-series HPLC

pumps.

Contents

Topic Page

HPLC pump operating principles 1-2

Overview of the 1500-series HPLC pumps 1-5

Fluid-handling components 1-7

Electronic components 1-12

Pump control 1-13

Options and accessories 1-15

1-2 Introduction

HPLC pump operating principles

This section describes these topics:

• Isocratic and gradient LC system operation

• Effects of dissolved oxygen in the mobile phase

• Removing gases from eluents using in-line degassing

Isocratic and gradient LC system operation

Two basic elution modes are used in HPLC: isocratic elution and gradient

elution.

In isocratic elution, the mobile phase, either a pure solvent or a mixture,

remains the same throughout the run. For LC system operation, a single

pump system, such as the 1515 isocratic pump, delivers a controlled amount of

solvent into the column to maintain consistent and reproducible mobile phase

composition.

In gradient elution, the mobile phase composition changes during the

separation. This mode is useful for samples that contain compounds that span

a wide range of chromatographic polarity. As the separation proceeds, the

elution strength of the mobile phase is increased to elute the more strongly

retained sample components.

In the simplest configuration, there are two bottles of solvent and two pumps,

the case when using a 1525 binary pump. The speed of each pump is managed

by the gradient controller to deliver more or less of each solvent over the

course of the separation. The two streams are combined using a mixer to

create the actual mobile phase composition that is delivered to the column

over time. At the beginning, the mobile phase contains a higher proportion of

the weaker solvent (solvent A). Over time, the proportion of the stronger

solvent (solvent B) is increased according to a predetermined timetable.

Because the mixer is downstream of the pumps, the gradient is created under

high pressure.

Other HPLC systems, such as Waters Alliance systems, are designed to mix

multiple streams of solvents under low pressure, ahead of a single pump. A

gradient proportioning valve selects from the multiple solvent bottles,

changing the strength of the mobile phase over time.

HPLC pump operating principles 1-3

Effects of dissolved oxygen on the mobile phase

Dissolved oxygen in the mobile phase can be of special concern. It can under

certain circumstances interfere with the detection of analytes by UV/Vis,

fluorescence, or electrochemical detectors.1

Effects on UV/Vis detectors

Oxygen can form UV-absorbing complexes with solvents such as methanol or

tetrahydrofuran (THF). These complexes increase the background

absorbance, especially at lower wavelengths. This leads to a small decrease in

sensitivity of detection. More importantly, however, they cause baseline shifts,

or ghost peaks, during gradient separations. Also, a change in the dissolved

oxygen level over time, especially when it results from reabsorption of

ambient gases following an offline degassing technique, causes baseline drift

and irregularity.

Removing dissolved oxygen to a reproducible level greatly enhances the

performance of UV/Vis detectors, especially below 254 nm and in gradient

systems. It also improves sensitivity in certain fluorescence detection

applications.

Effects on fluorescence detectors

For certain analytes at certain wavelengths, oxygen, under certain mobile

phase conditions, can quench fluorescence response. Aromatic hydrocarbons,

aliphatic aldehydes, and ketones are particularly susceptible to quenching,

and decreases in sensitivity of 95% are possible.

Effects on electrochemical detectors

Oxygen can interfere with various electrochemical detection techniques,

particularly reductive electrochemistry.

Effects on refractive index detectors

Refractive index detectors are sensitive to changes in solvent density.

Removing dissolved gases to a consistent level enhances the performance of

refractive index detectors, reducing baseline drift and irregularity.

1. Rollie, Mae E., Gabor Patonay, Isaiah M. Warner, Ind. Eng. Chem. Res., 1987, 26, 1–6.

1-4 Introduction

Using in-line degassing to remove gases from eluents

In-line methods of degassing operate within the chromatographic fluid path.

The 1500-series integral vacuum degasser uses this approach. Because

degassing occurs close to the pump, this method minimizes reabsorption of

ambient gas into the eluent.

The flow rate of eluent through an in-line degasser determines the efficiency

of the degassing. At low flow rates, most of the dissolved gas is removed as the

eluent passes through the vacuum chambers. At higher flow rates, lesser

amounts of gas per unit volume of eluent are removed.

Degassing efficiency

The flow rate of eluent through the degasser determines the efficiency with

which the degasser removes gases. As the flow rate increases, the time

available to remove dissolved gases from the eluent lessens. The following

table shows the relationship between the flow rate of an eluent (water) and

the concentration of a gas (oxygen) dissolved in the eluent.

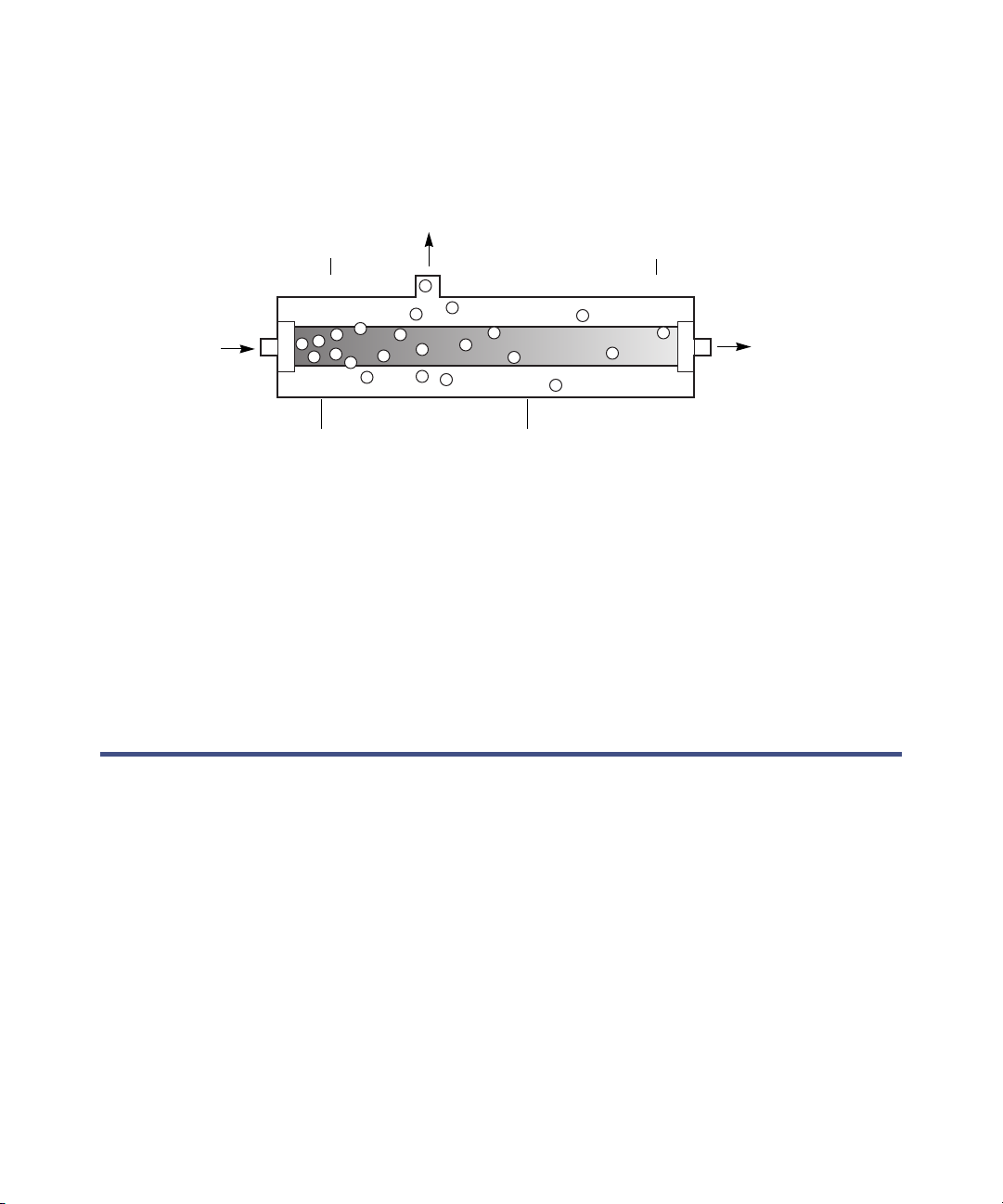

Degasser operating principles

The degasser operates according to Henry’s Law, removing dissolved gases

from the eluent. Henry’s Law states that the mole fraction of a gas dissolved

in a liquid is proportional to the partial pressure of that gas in the vapor phase

above the liquid. If the partial pressure of a gas on the surface of the liquid is

reduced–by evacuation, for example–then a proportional amount of that gas

comes out of solution.

The degasser uses a gas-permeable polymer membrane channel to carry the

eluent through the vacuum chamber. When the eluent enters the vacuum

chamber, the vacuum creates a large differential in gas concentration across

the membrane. This differential accelerates the rate at which the dissolved

gases diffuse through the polymer membrane into the vacuum chamber. The

Effect of flow rate on final dissolved gas concentration

Flow rate

(mL/min)

Final oxygen

concentration (ppm)

1≤1

2≤1.3

5≤2.3

Overview of the 1500-series HPLC pumps 1-5

gases are then carried away by the vacuum pump. The following figure is a

simplified schematic diagram of the vacuum chamber.

Vacuum chamber schematic

The longer the eluent is exposed to the vacuum, the more dissolved gases are

removed. Two factors affect the amount of time the eluent is exposed to the

vacuum:

• Flow rate – A lower flow rate increases the amount of time the eluent is

exposed to the vacuum. “Degassing efficiency” on page 1-4, addresses the

effect of different flow rates on the concentration of remaining gas.

• Surface area of degassing membrane – The length of the degassing

membrane is fixed in each vacuum chamber.

Overview of the 1500-series HPLC pumps

The 1500-series HPLC pumps combine the most important aspects of eluent

delivery for HPLC: high precision, reliability, and smooth eluent flow. All

pumps perform their intended functions equally well:

• The 1515 isocratic HPLC pump is designed for precise isocratic

analyses, with flow rates up to 10 mL/minute.

• The 1525 binary HPLC pump achieves reproducible, binary gradient

delivery, with exceptionally smooth concurrent-stream blending with

flow rates of up to 10 mL/minute.

Degassed

eluent out

Gas out

(to vacuum pump)

Vacuum chamberEluent channel

More gas

in solution

Less gas

in solution

Gas-saturated

eluent In

1-6 Introduction

• The 1525EF (Extended Flow) binary HPLC pump is a field-upgrade of

the standard 1525 binary pump designed for increased flow rates of up

to 22.5 mL/minute.

• The 1525µ binary HPLC pump is designed for precise, reproducible

gradient delivery at low flow rates up to 5 mL/minute.

In an HPLC system, the 1500-series pump is controlled by Waters Breeze™ 2,

Empower™ 2, or MassLynx™ data control software (see page 1-13).

Tip: For detailed information about specific data control software versions and

requirements, refer to the release notes for the Waters 1500-series HPLC

pumps.

The microprocessor-controlled stepper motor and noncircular gears of each

pump ensures smooth and precise flow regardless of backpressure, flow-rate

setting, or eluent compressibility.

These optional components are available for the 1500-series pump to suit your

HPLC applications and site requirements:

• 1500-series column heater – Enables preheating of fluids passing

through chromatographic columns.

• Integral vacuum degasser – Provides HPLC pumps with an automatic,

continuous method of removing dissolved gasses from mobile phases.

The degasser is standard on the 1525µ pump and is available as an

option on the 1515 isocratic pump and 1525 and 1525EF binary pumps.

• Plunger seal wash system – Extends the life of pump seals by

lubricating the plunger and flushing away solvent or dried salts forced

past the plunger seal from the high-pressure side of each piston

chamber.

• Manual injector – For use in place of an autosampler to provide precise

manual control of HPLC sample injections.

For more details, see page 1-15.

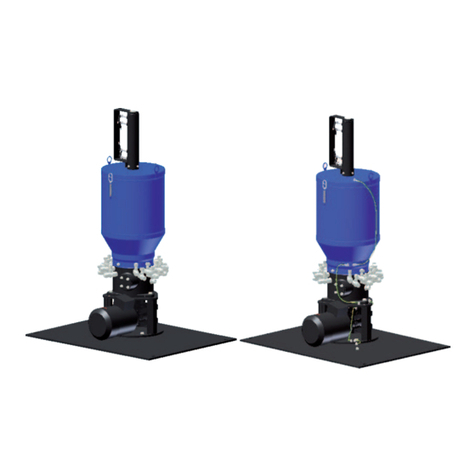

The following figure shows a 1525 binary pump with an optional column

heater.

This manual suits for next models

3

Table of contents

Other Waters Water Pump manuals

Popular Water Pump manuals by other brands

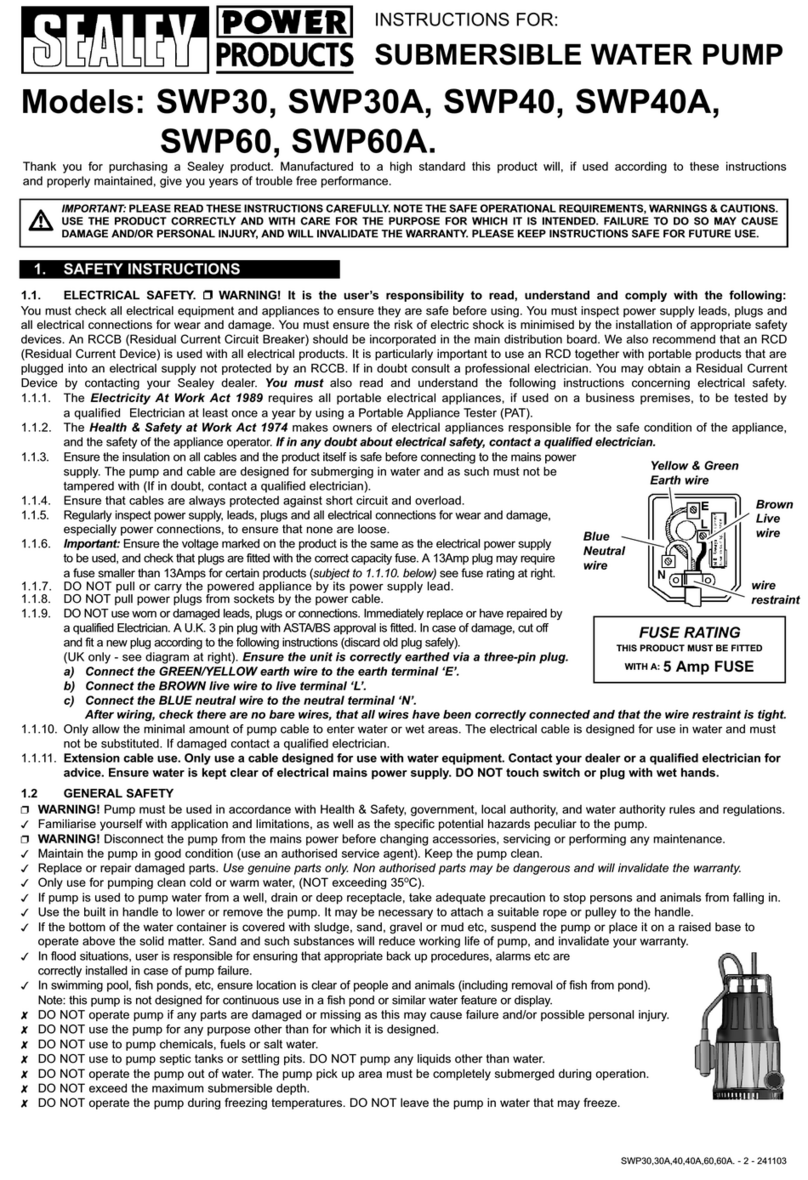

Sealey

Sealey SWP30 instructions

stellar labs

stellar labs HESC Series Installation, operation and maintenance manual

SKF

SKF FB Assembly instructions

Homa

Homa TCV 408 Series Original instruction manual

OLIJU

OLIJU Dreno R 30 Series Installation and operation instructions

ProMinent

ProMinent DULCO Trans 32/700 PVDF Assembly and operating instructions