INOXPA PV-60 Manual

This manual suits for next models

1

Table of contents

Other INOXPA Water Pump manuals

INOXPA

INOXPA SLRT 3-90 Manual

INOXPA

INOXPA HYGINOX SE-15 Manual

INOXPA

INOXPA Hyclean Series Manual

INOXPA

INOXPA ESTAMPINOX ES Series Manual

INOXPA

INOXPA ASPIR Series Manual

INOXPA

INOXPA KIBER KVB-25 Manual

INOXPA

INOXPA SLR Series Manual

INOXPA

INOXPA ESTAMPINOX EFI Manual

INOXPA

INOXPA ASPIR A-50 Manual

INOXPA

INOXPA KIBER KTE Manual

INOXPA

INOXPA HYGINOX SE Series Manual

INOXPA

INOXPA SLR-A Manual

INOXPA

INOXPA KIBER KSF Series Installation and user guide

INOXPA

INOXPA DIN-FOOD Manual

INOXPA

INOXPA PROLAC HCP Ex Manual

INOXPA

INOXPA KIBER KS Series Manual

INOXPA

INOXPA HYGINOX SEN Manual

INOXPA

INOXPA PROLAC HCP Ex Manual

INOXPA

INOXPA HLR Ex Manual

INOXPA

INOXPA TLS Series Manual

Popular Water Pump manuals by other brands

spatex

spatex E-10 instruction manual

ClimaCool

ClimaCool SHC onDEMAND 15 Installation, operation & maintenance manual

YASKAWA

YASKAWA iQpump1000 Setup procedure

SKV-tec

SKV-tec SKV-NS Series Installation and operating instructions

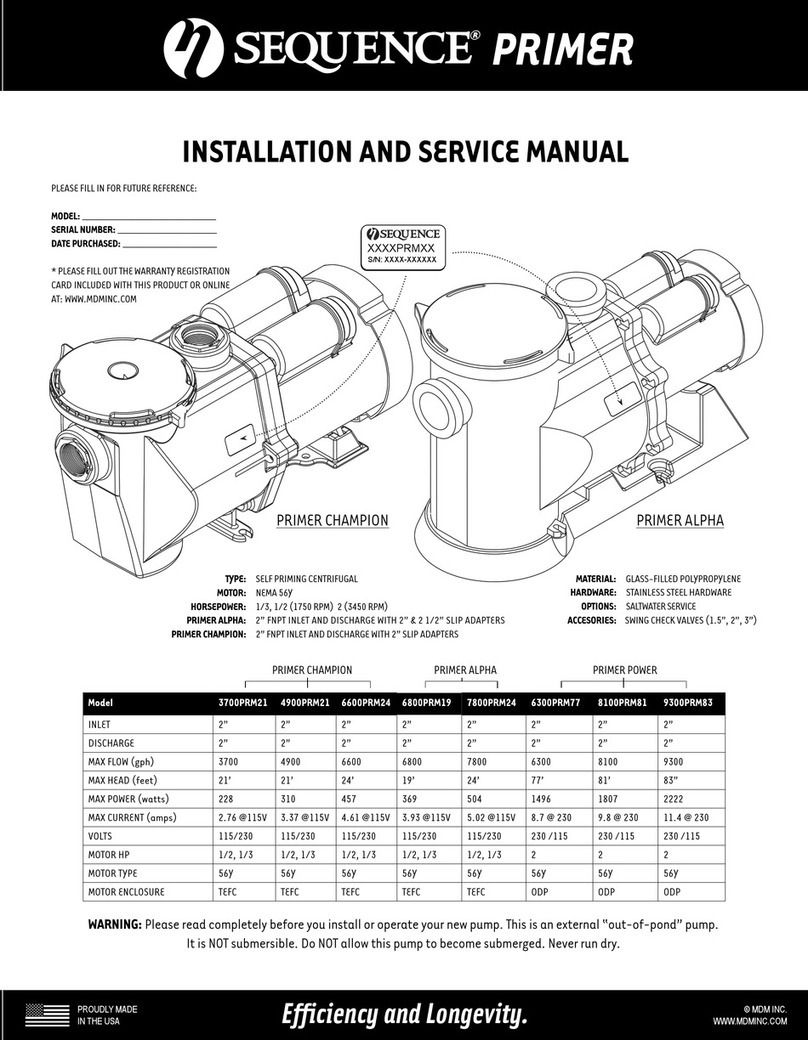

MDM

MDM SEQUENCE PRIMER Series Installation and service manual

Pennington

Pennington Aquagarden inpond 5 in 1 200 manual

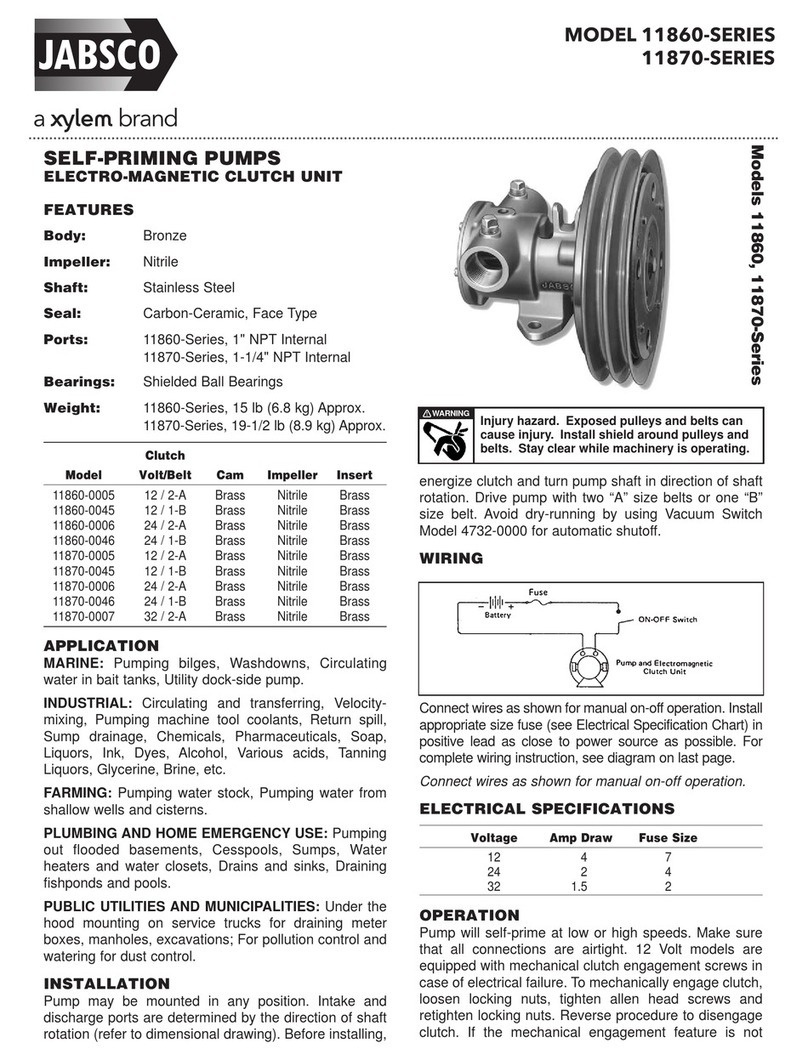

Xylem

Xylem JABSCO 11860 Series manual

Rockwell Labs

Rockwell Labs Foamer Simpson Instructions for use

Leybold vacuum

Leybold vacuum RUVAC WA 151 operating instructions

QED

QED GRACO TORPEDO G1275-2P50 Operation, troubleshooting manual

Speck

Speck NP25/70-100 operating instructions

EINHELL

EINHELL GH-DP 7835 Original operating instructions

Pentair

Pentair Jung Pumpen WCFIX Plus instruction manual

Grundfos

Grundfos CRN 95-6-3 Installation and operating instructions

Gardena

Gardena 6000 operating instructions

Pentair

Pentair VIFFI ICON 2000 Instructions and operating manual

Grundfos

Grundfos JP Basic Booster Installation and operating instructions

KSB

KSB WKTR Installation & operating manual