IMPORTANT SAFETY

INSTRUCTIONS

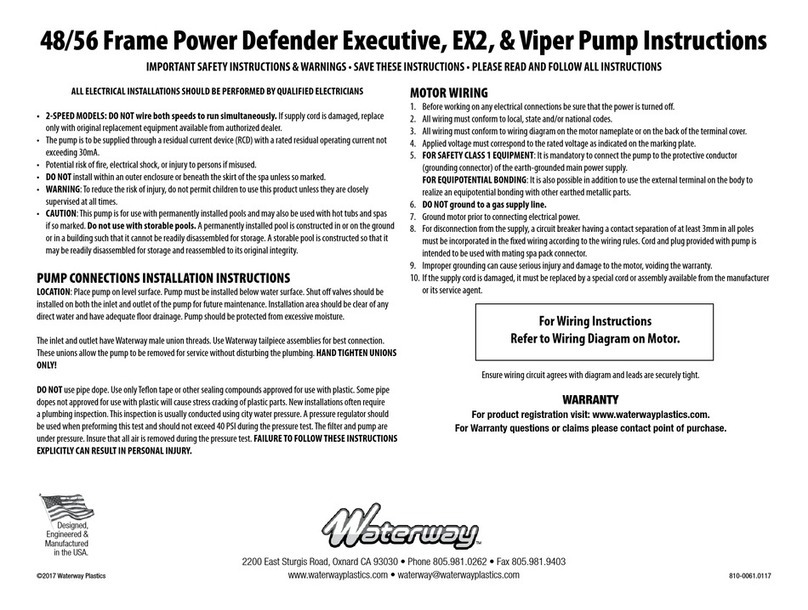

INSTALLATION INSTRUCTIONS ELECTRICAL WIRING

INSTRUCTIONS

WARNING: When installing and using this electrical equipment,

basic safety precautions should be followed, including the following:

WARNING: When using electrical products, basic safety precautions

should always be followed, including the following:

WARNING: For ALL installations, an access panel must be provided

which is in a suitable location for pump inspection. ENSURE POWER

TO MOTOR IS TURNED OFF PRIOR TO WORKING WITH THE MOTOR.

1. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL.

2. READ AND FOLLOW INSTRUCTIONS AS SET FORTH IN THE OWNER’S MANUAL

FROM THE MANUFACTURER OF THE HYDROMASSAGE BATH TUB.

3. WARNING: To reduce risk of injury, DO NOT PERMIT CHILDREN TO

OPERATE THIS UNIT WITHOUT THE SUPERVISION OF AN ADULT AT ALL

TIMES.

4. WARNING: The Genesis Generation Bath Pump is intended for use in a

Hydromassage bath tub (whirlpool bath) only, as described in this manual.

The Genesis Generation Bath Pump is not for use in any other application.

Do not use attachments not recommended by the manufacturer.

5. All electrical wiring in the motor installation must be done by a licensed electrician

in accordance with applicable electrical codes.

6. WARNING: The unit must be connected to a supply circuit that is protected

by a Ground Fault Circuit Interrupter (GFCI) as required by the applicable

electrical codes. Such a GFCI should be provided by the installer of the

unit and should be tested on a regular basis. Consult the GFCI

manufacturer’s instructions for correct testing and operation.

7. WARNING: For permanently connected units, a green colored terminal

(or a wire connector marked “G”, “GR”, “Ground”, or “Grounding”) is provided

within the terminal compartment. To reduce the risk of electric shock,

connect this terminal or connector to the grounding terminal of your

electric service or supply panel with a conductor equivalent in size to the

circuit conductors supplying this equipment.

8. DO NOT operate this pump unit without the motor end cover in place.

9. WARNING: Motors driving the pumps may operate at high temperatures.

To avoid burns, NEVER touch the motor shell during operation of the motor.

10. DO NOT drop, insert, or place any object into the pump assembly or motor

at any time.

11. No modications, additions, or deletions should be made to the pump or motor

assembly.

12. DO NOT use insulation around or near the pump/motor assembly. The motor may

overheat causing nuisance tripping of the thermal overload protector.

13. DO NOT run pump dry. No warranty on damaged seal due to dry running of pump.

14. WARNING: Before starting the pump/motor, make certain that the water

level covers all water outlets to avoid excess splashing.

• The pump should be installed on the outside of the tub as close to the tub unit as

possible.

• For a whirlpool tub installation, the pump should be mounted in such a fashion that

there is a continual rise from the suction tting to the pump to allow air to be

expelled from the piping. While at the same time, the pump should be mounted in

such a way that the pump suction is below the normal operating level of the water.

• All tub piping must be water tight for proper pump operation.

• The pump/motor assembly should be securely mounted onto a base to avoid noise

and vibration. The weight of the piping should be supported independently and not

carried by the pump.

• The pump should be connected to the piping with union connectors as supplied

with the pump. The union sleeves and nuts are made of PVC plastic. Sleeves should

be attached to the piping with solvent weld cement suitable for use with PVC. Refer

to the warnings supplied with solvent weld cements to verify compatibility. The nut

will secure the sleeve to the pump. HAND TIGHTEN the union nut only! Excessive

torque is unnecessary and may cause damage to the union and pump. DO NOT

use a pipe wrench or over-torque the nut! There is a gasket supplied with the sleeve

connector. If the connector is tightened properly there is no need for any sealant or

lubricant to be used on the gasket. CONTAMINANT SUCH AS PIPE COMPOUNDS OR

OVER TIGHTENING OF THE NUT CAN CAUSE THE UNION TO FAIL.

• Pumps are equipped with a self-lubricating mechanical shaft seal. As with any

mechanical seal, it may eventually leak as a result of wear or if particles of dirt

become lodged between the seal faces. It is recommended that a drip pan be

installed so that any leakage can be readily seen and to avoid water damage.

• CAUTION: Pump motors are equipped with an automatic thermal overload

protector to prevent motor damage from overheating. THESE MOTORS WILL

RESTART AUTOMATICALLY AS THE MOTOR COOLS DOWN. DO NOT WORK

ON THE MOTOR WITHOUT FIRST SHUTTING OFF THE ELECTRICITY AT THE

SOURCE. Nuisance thermal tripping can be avoided if proper ventilation is

provided to the pump. Insulation should not be put around or near the pump

motor.

• All airswitch actuators and electronic keypads which are used to operate the pump

unit must be located above the tub’s maximum water level.

• All electronic keypads must be routed clear of grounded metal and high voltage

wiring.

• All internal motor wiring is done at the factory. No additional wiring is necessary.

• WARNING: RISK OF ELECTRIC SHOCK. Connect only to a circuit protected by

a ground fault circuit interrupter.

• WARNING: Grounding is required. The unit should be installed by a qualied

service representative and grounded. Install to permit access for servicing.

• WARNING: All electrical work must be done by a licensed electrician. Before

working on the motors, be certain that the electrical power is o at the main

junction box. Disconnect the fuse or the circuit breaker and tag the main

switch: “DO NOT ENERGIZE THIS SWITCH. PERSONNEL WORKING ON

EQUIPMENT”.

• WARNING: All aspects of the installation must conform to the requirements

of the NEC, including article 430 (motor circuits and controllers), and all local

codes.

• Pump/motor must be wired to the system with the correct incoming voltage ONLY

by a licensed electrician in accordance with applicable electrical codes. Motor

voltage, ampere draw, and frequency appear on the motor nameplate. DO NOT

EXCEED NAMEPLATE VOLTAGE.

• The wire used to supply power to the motor must be large enough to carry the

necessary amperes for the required length without excessive voltage drop. Cord

connected units are pre-wired at the factory. No additional wiring is necessary.

• If pump/motor is supplied without a pre-wired cord assembly, a proper strain

relief tting should be used to secure the wire in the motor conduit hole. The motor

wire must also be of the correct size, but not smaller than 16 gauge. the pump/

motor must be wired for the proper voltage in accordance with the wiring diagram

supplied on the motor. All wiring must be done by a licensed electrician in

accordance with local codes. Be certain the motor frame is GROUNDED and that the

motor and metal parts of the tub or spa and piping are BONDED in accordance with

applicable codes. A green-colored screw is provided inside the terminal

compartment for a grounding connection. This should be connected to the

grounding terminal in the supply panel with a continuous copper wire equivalent

in size to the circuit conductors supplying this equipment, but no smaller than 14

gauge. The wires should be sized such that the yare large enough to carry the proper

amperes without causing unnecessary voltage drop. A wiring diagram is supplied on

the pump nameplate for assistance in connecting the main power supply lines to the

correct motor terminal (stud, at washer, cup washer, and nut). A solid copper

bonding connector, no smaller than 8 AWG (3.27mm) must be connected from

the accessible wire connector on the motor to all metal parts of the whirlpool bath

structure, and to all electrical equipment, metal conduit, and metal piping, within

5 feet (1.5m) of the inside walls of the whirlpool bath or spa when the motor is

installed within 5 feet of the inside walls of the whirlpool bath.

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS

GENERAL INFORMATION

This pump is intended solely for use with hydromassage bath tub (whirlpool bath)

applications. The pump unit was designed to circulate water through a whirlpool bath

system supplying jets with water. Each pump has been thoroughly tested prior to

leaving the factory and should be free of defects.

The actual pump may be supplied with no cord, a three-wire cord with plug (-C), or a

three-wire cord with leads for hard wiring to a junction box (-CC).

INSTALLATION INSTRUCTIONS

SAVE THESE INSTRUCTIONS

FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE