Operation manual 20997-Duftdos-UNPL (09/16) Page 1 von 9

Duftdos –UNPL –with contact sensor

Table of contents Page

1. Instruction fort the manual............................................................................................................................................................. 2

1.1 Validity ...............................................................................................................................................................................2

1.2 Target group .......................................................................................................................................................................2

1.3 Storage of the manual .........................................................................................................................................................2

1.4 Further informations ............................................................................................................................................................ 2

1.5 Used symbols.......................................................................................................................................................................2

2. Saftey............................................................................................................................................................................................3

2.1 Technical safety advice.........................................................................................................................................................3

2.2 Use in accordance with regulations....................................................................................................................................... 4

3. Delivery.........................................................................................................................................................................................4

4. Function ........................................................................................................................................................................................4

5. Technical Data...............................................................................................................................................................................5

6. Fragrance pump.............................................................................................................................................................................5

6.1 Change the hose set ............................................................................................................................................................. 6

6.2 Sparepartlist persitaltic pump frangrance.............................................................................................................................. 6

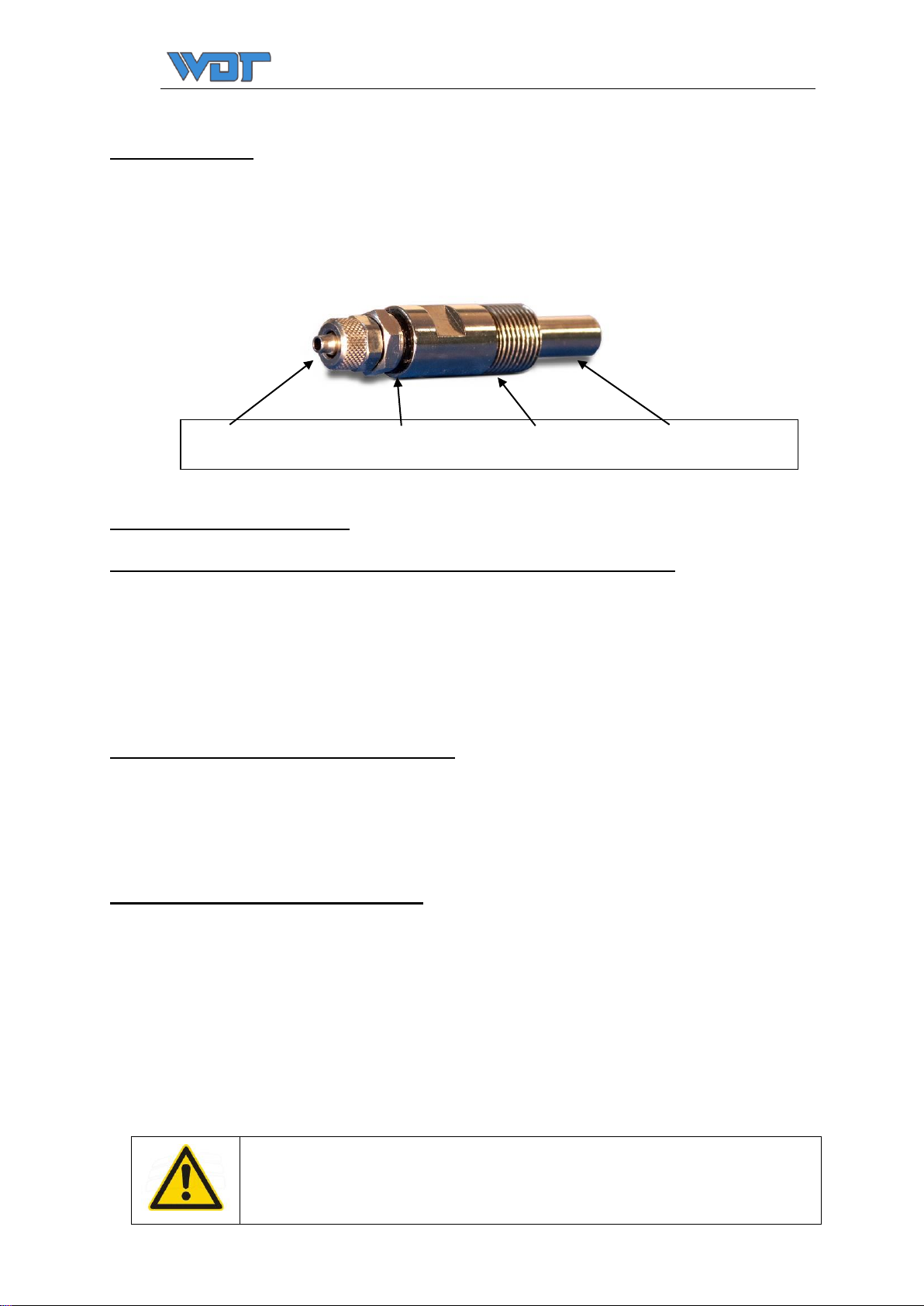

6.3 Dosing valve.......................................................................................................................................................................7

6.4 Spare part list dosing valve...................................................................................................................................................7

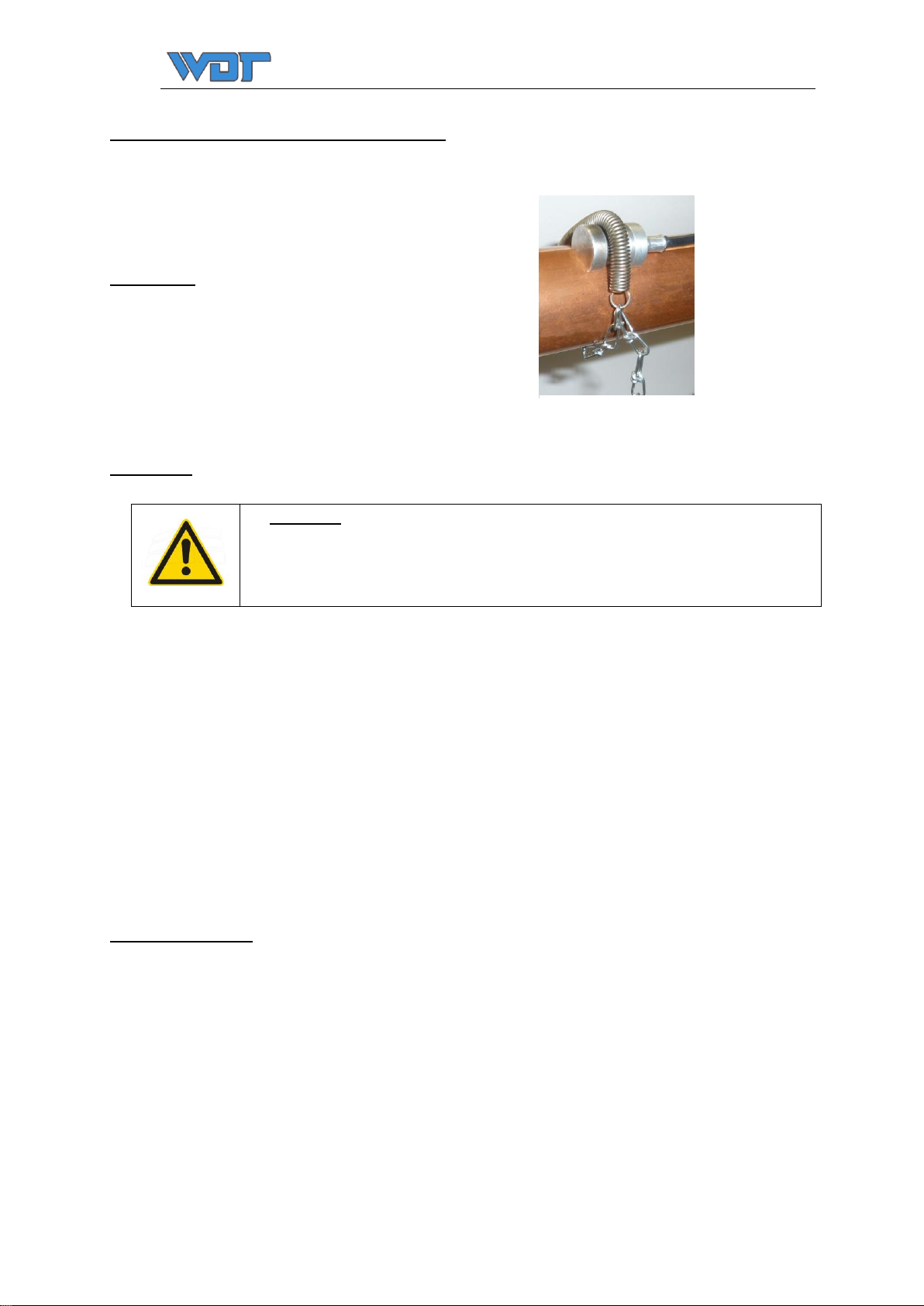

7. Console for frangrance canister (optional).......................................................................................................................................7

8. Installation / Commissioning / Dosing............................................................................................................................................. 7

9. Maintenance..................................................................................................................................................................................8

10. Wiring diagramme.........................................................................................................................................................................9

11. Change the set switching temperature............................................................................................................................................. 9