Ford Transit London

3

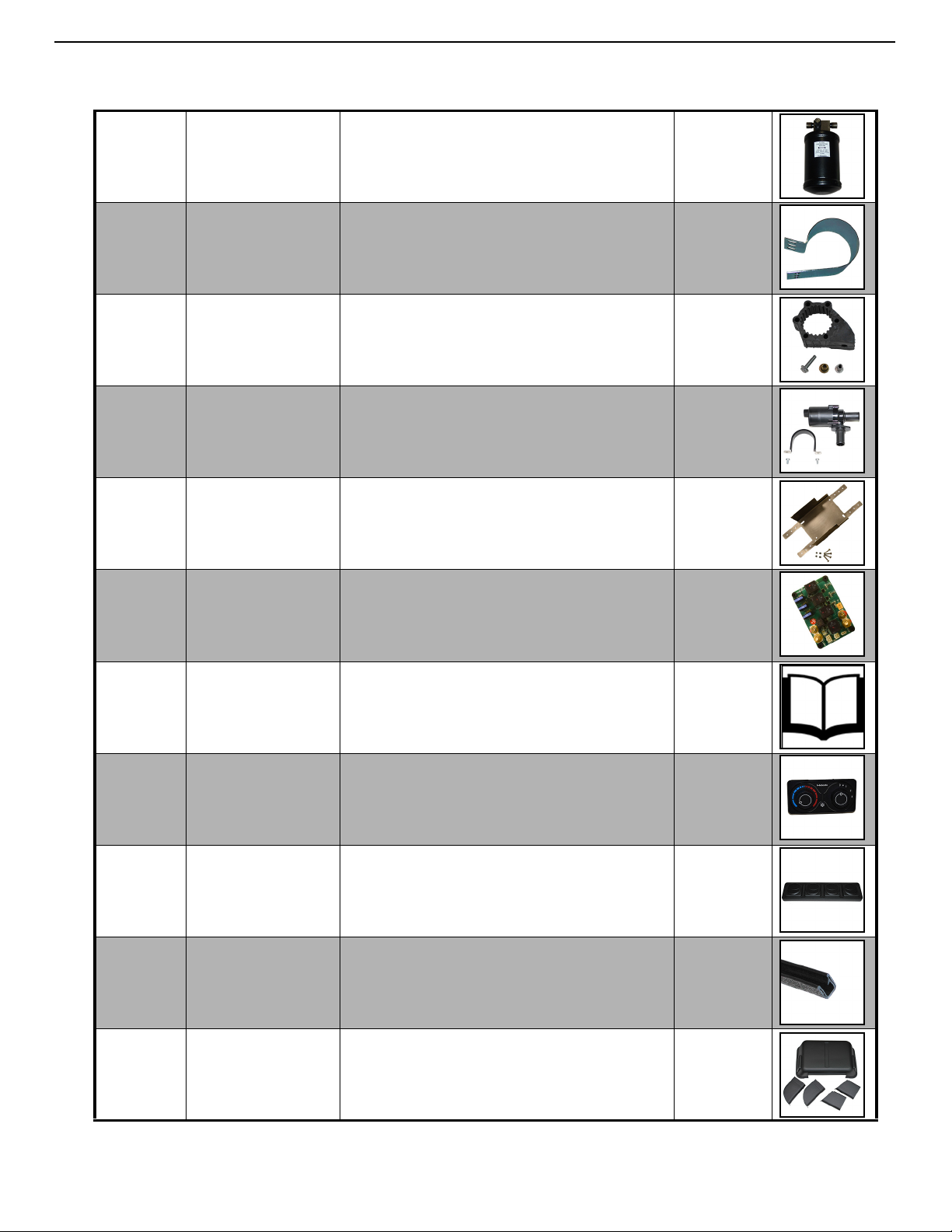

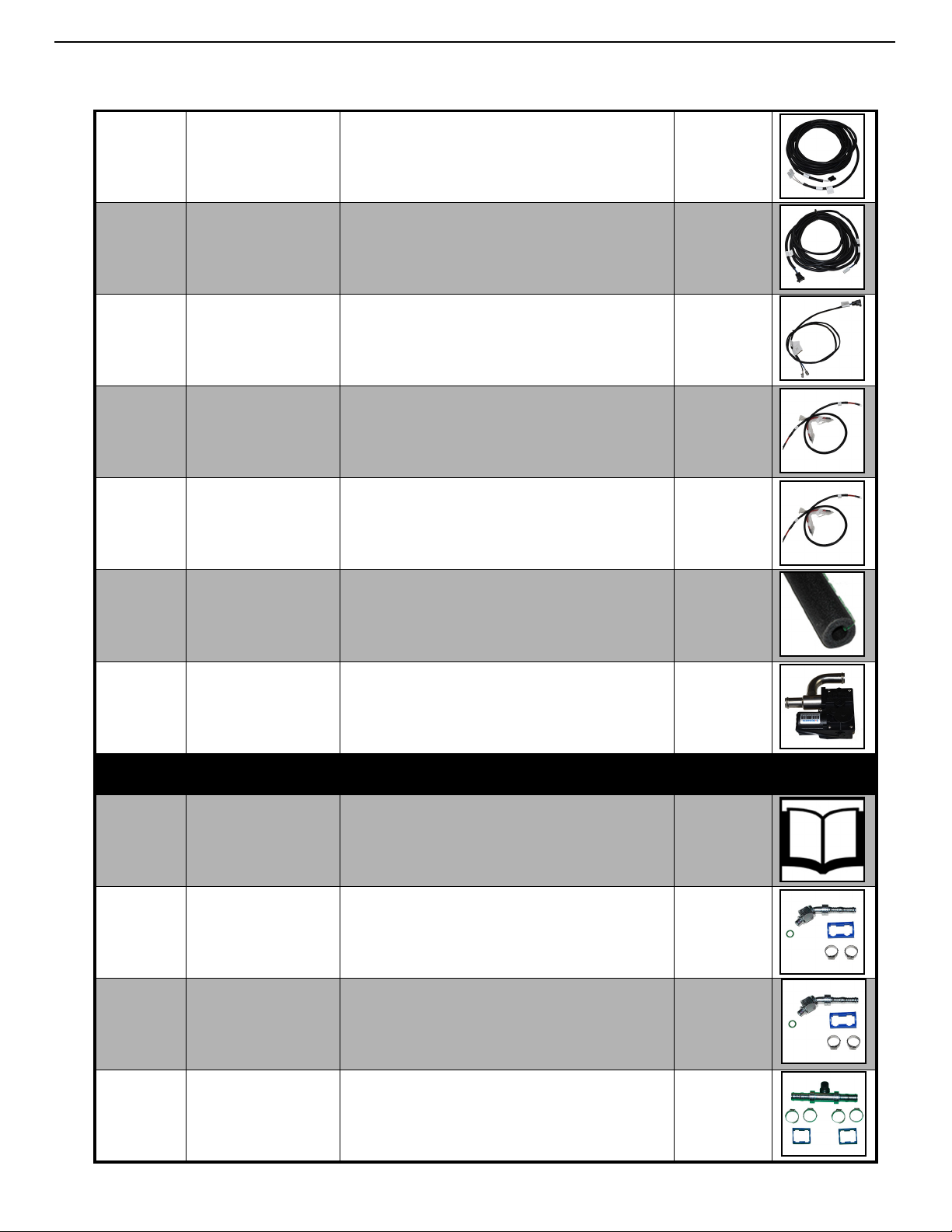

Kit CoTable of Contentsntents

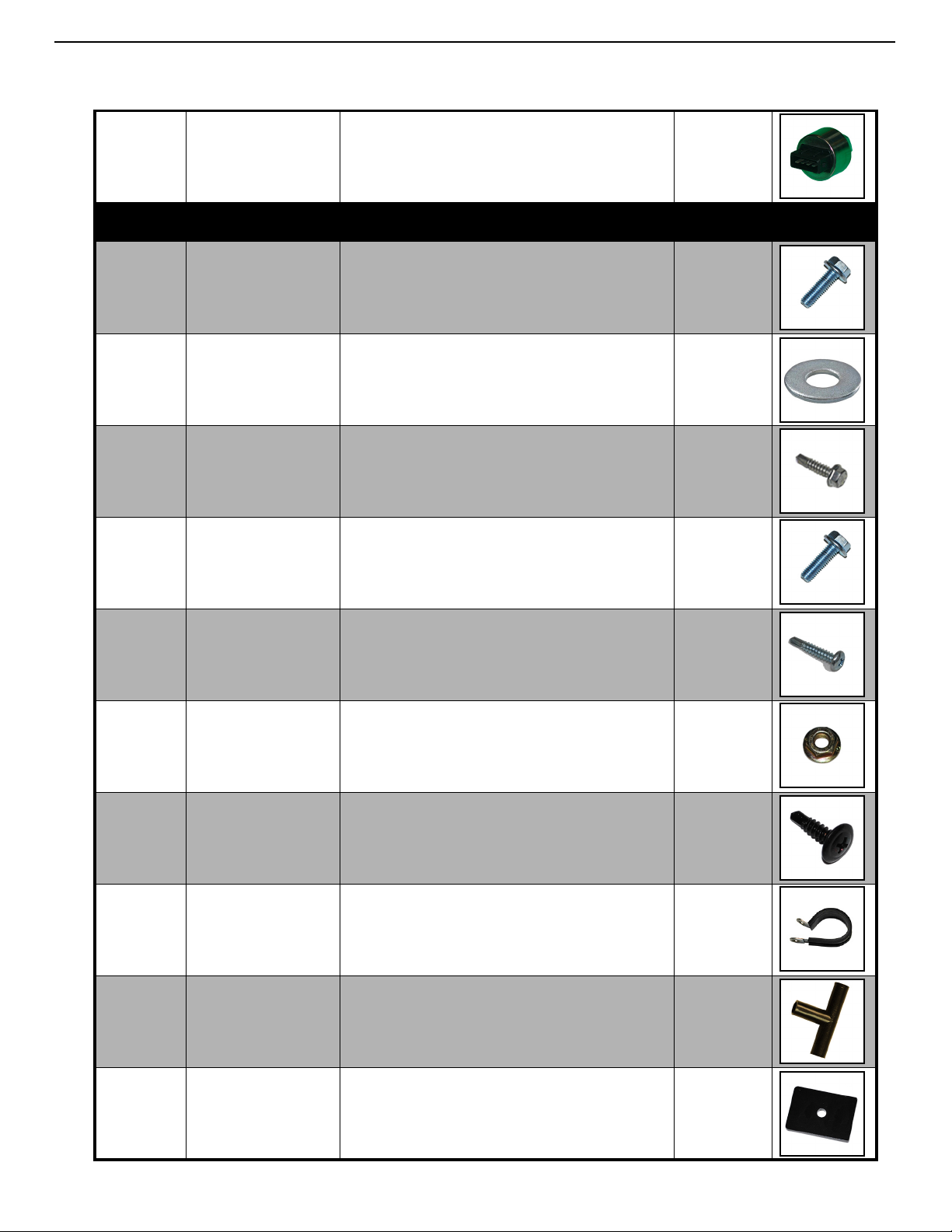

Kit Contents with Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.0 General Service and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Refrigerants and Other Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 System Flushing, Purging, and Pressure Testing for Leaks . . . . . . . . . . . . 11

1.3 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Applicability of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Meaning of Warnings, Cautions and Notes . . . . . . . . . . . . . . . . . . . . . . 12

1.6 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7 Legal Provisions for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8 Prohibition on Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vehicle and kit preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

London HVAC Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring Harness Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Extreme Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

A/C Hose Crimping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Hose Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

A/C Hose Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Heater Hose installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Initial Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

A/C System: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Coolant System: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

NEO 2 Extreme Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Extreme Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43