rative When Mechanism

2. Switch contacts worn, dirty or broken.

(a) Clean contacts or replace. See "Speed

Equalization Switch Adjustment".

1. Damaged or worn cam and shaft assembly

(35A). (a) Replace.

ADJUSTMENTS

Pressure Pad And Lever Adjustments-

Cleaning, adjusting or replacing pressure pad

assembly and lever assemblies should be done in the

following manner:

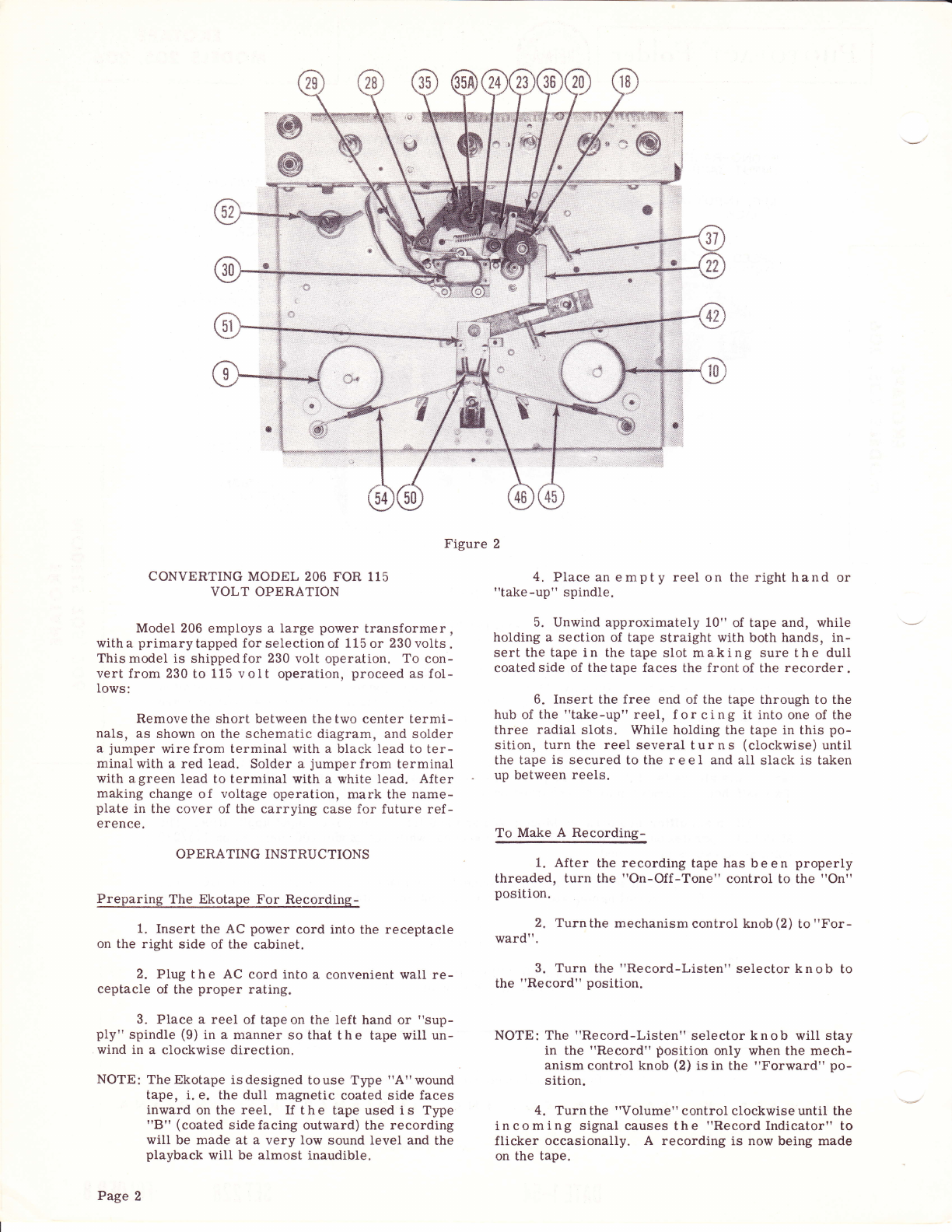

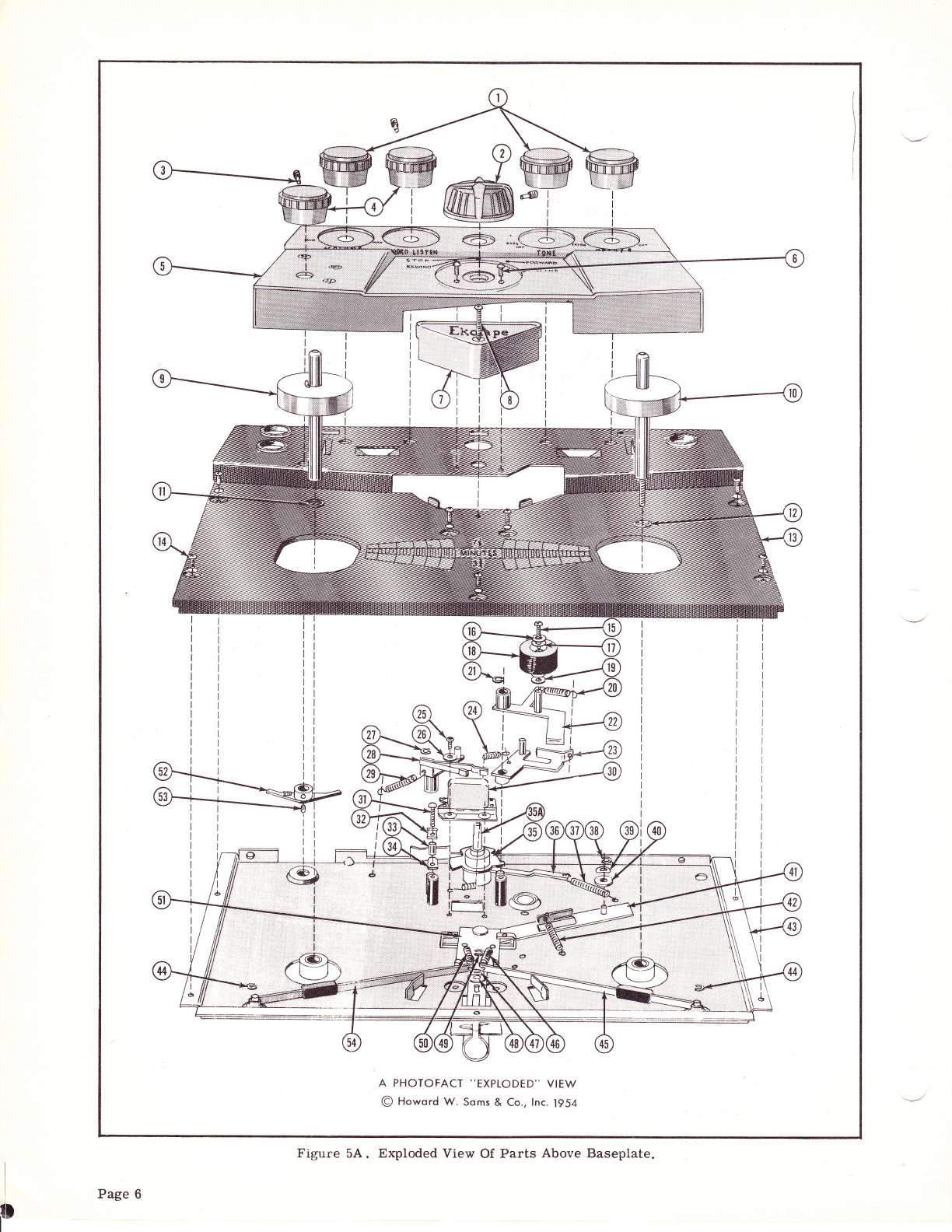

1. To adjustpressure padassembly(28), remove

back cover (5) and top panel (13). To remove

assembly f or cleaning, repair or adjustment,

remove spring (29) and retaining ring (2?). Ro-

tatethe pressurepad assemblyslightly counter-

clockwise and lift off. Reassemble in reverse

orderand lubricate (see "Lubrication"). Adjust

by turning cam and shaft assembly (35A) to "For-

ward" position and check to be sure pressure

pads engage groove of head properly.

NOTE: Be sure flat of pad presses against the erase

and record pole pieces. To adjust properly,

bend levers accordingly.

Improper Rewind Operation-

Ifthe unit doesnot perform the rewind operation

properly, check.as follows:

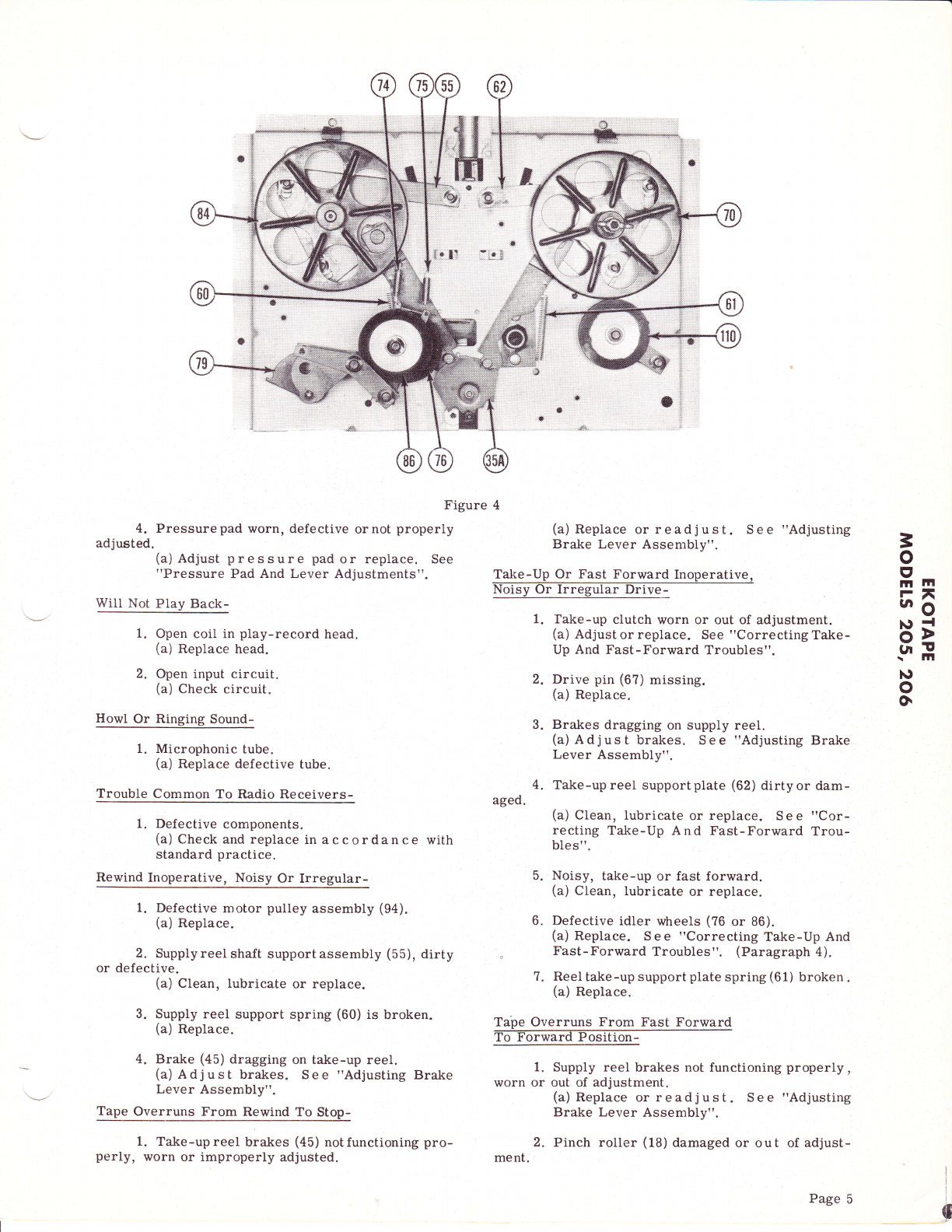

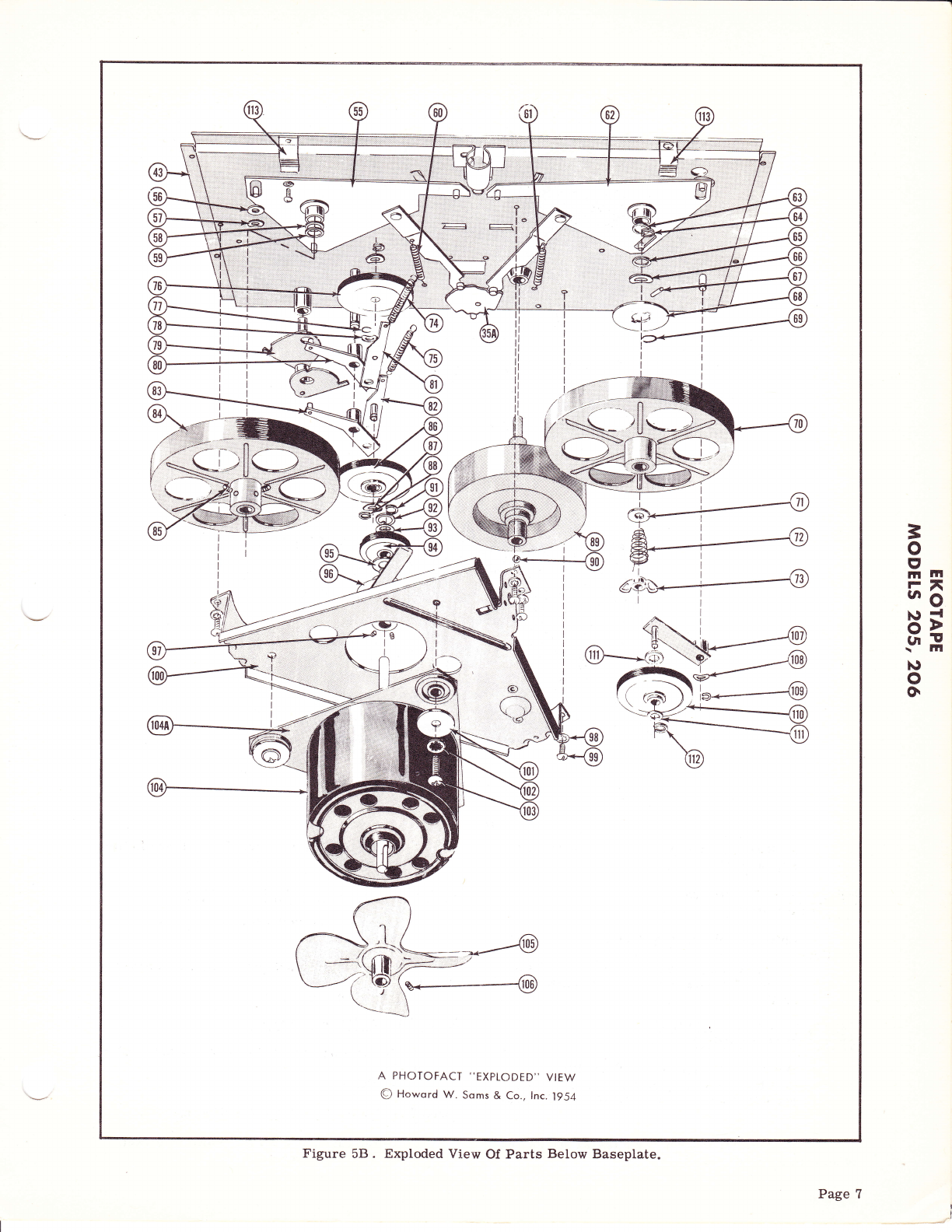

1. Adefectivemotorpulley(94) maybe the cause

of improper rewind. To replace a defective

motorpulleyassembly, remove the three mount-

ingscrews (103) from motor and plateassembly

(104). Carefully remove theassembly so as not

to damage the drive idler assemblies (?6 and 86).

Before removing the motor pulley measure and

note distance from hub to motor. Loosen the

twoAllen head set screws andremove themotor

pulley a.ssembly. Reassemble witha irew pulley

inreverse order. Be surepulley hub is correct

distance from motor as previously noted.

2. Adirty or defective supply reelshaft support

assembly (55) may be responsible for improper

rewind. To correctfaulty operation, clean, re-

pair or replace any damaged or worn parts.

Adjusting Brake Lever Assembly (45 and 54)-

If tape overruns from "Rewind" to "Stop" posi-

tion, adjust, clean or replace brake lever assembly

(45).

1. To ad just brake lever assembly (45), turn

camand shaft assembly (35A) to"Rewind" posi-

tion. Adjust either by bending the brake lever

assembly (45) or by slightly bending the stop on

mechanism panel just enough to clear the cup

disc on reel shaft (10). Clearance should not

exceed 1/64 inch. Adjust brake lever (45) so

that remote lever (51) returns to "Stop" posi-

tion. Check to be sure brake lever (54) on the

supply reel (9) is being held in its stop position

Page 10

by the remote lever assembly (51). If not, turn

camand shaftassembly (35A) to "Fast Forward"

andadjust brake lever assembly(54) as outlined

above. Before reassembly of top panel, thread

recorder with tape and checkunit for any further

trouble.

2. If tape overruns from "Fast Forward" to

"Forward", check operation of bral<e lever (54)

as explained in above paragraph with this ex-

ception; turn cam and shaft assembly (35A) to

"Fast Forward" position and adjust brake Iever

(54) on the supply reel (9). Check brake lever

(45) on the tale-up reel to be sure it is held in

its stop position by the remote lever assembly

(51). If not, turn cam and shaft assembly (35A)

to "Rewind" and adjust brake lever as covered

in above paragraph.

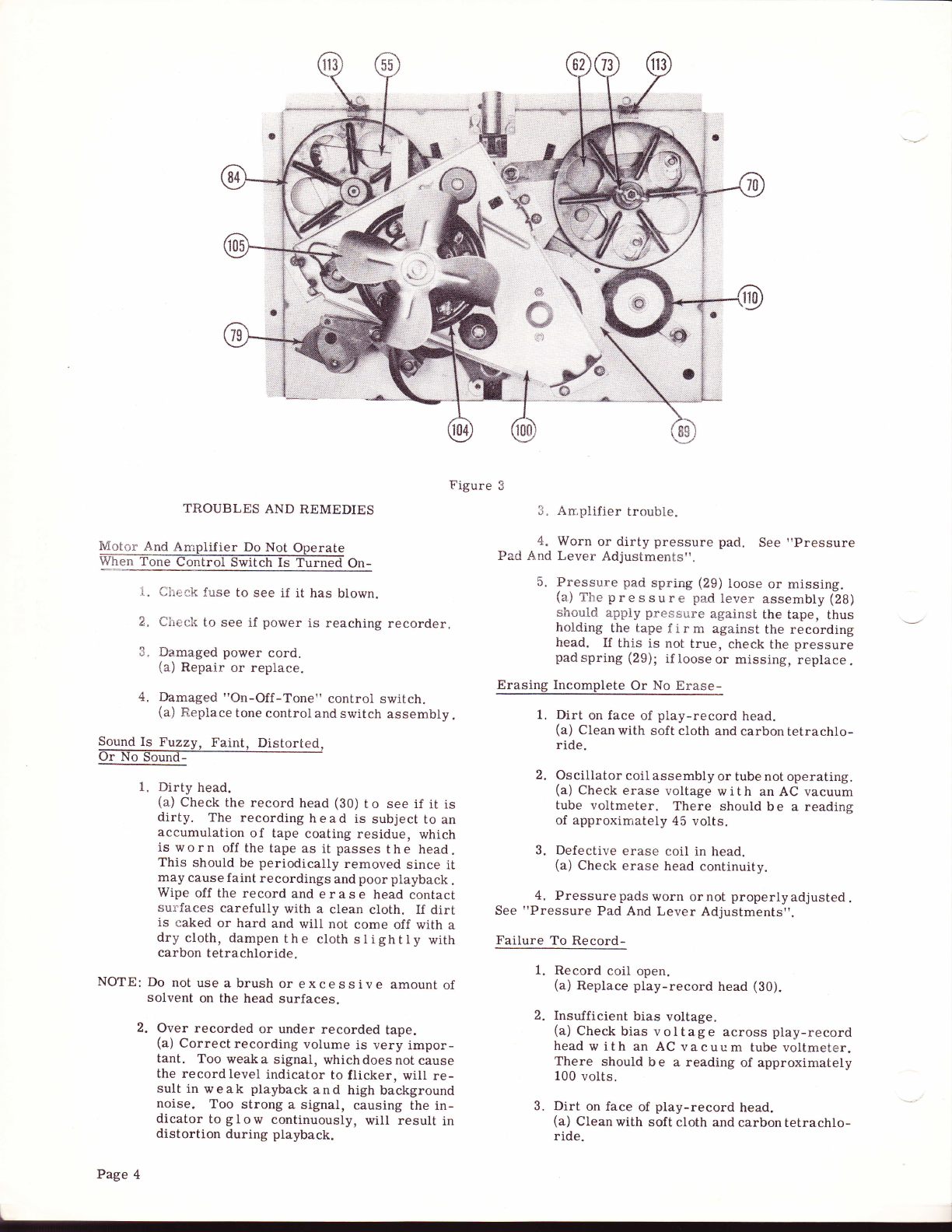

Adjusting Brake Arm Assembly (113)-

If af ter completing adjustments as covered in

"Adjusting Brake Lever Assembly", the overrun on

"Rewind" and "Fast Forward" is not corrected, re-

move the unit from the case and check as follows:

1. Check "Rewind" position first and adjust or

replace brake arm assembly (113). First be

sure brake pad is still attached to arm. Turn

cam and shaft assembly (35A) to the "Rewind"

position and adjust the brake arm (113) so pad

just clears the reel pulley assembly (?0) but by

no more than 1/64 inch.

2. Check "Fast Forward" position and adjust or

replace brake arm assembly (113). First be

sure brake pad is still attached to arm. Turn

cam and shaf t assembly (35A) to "Fast For-

ward" position and adjust bral<e arm (113) so

thatthe pad clears reel pulley assembly (Ba) by

no more than 1/64 inch.

Correcting Take-Up And Fast

Forward Troubles-

If take-up and fast forward drive does not func-

tion properly, r e m o v e unit from case and check as

follows:

1. If the take-up or fast-forward drive is weak,

screw the self-locking wing nut (?3) on the reel

shaJt (10) s o spring (?2) witt produce a greater

friction drive,

2. lf af.ler adjusting the self-locking wing nut

(?3) a weak drive still exists, then remove wing

nut, spring (?2), washer (?1) and reel pulley

assembly (70) and check f e I t pad on pulley. If

pad is worn badly, replace assembly (70), but

if pad shows no excessive wear, remove clutch

disc (68) and check to see if drive pin (6?) is in

place. Replace pin if missing and reassemble

in reverse order and adjust wing nut.

3, If unit i s noisy in "Forward" or "Fast-For-

ward" position, check to s e e if idler assembly

(110) isdirty or damaged. Or it may be the re-

sult of dirty bearings on the take-up shaft or

pulley assembly. To check, inspect idler

assembly (110) and determine if dirty or defec-

tive. Remove retainingring (112), fibre washer

(111), idler assembly (110), and fibr e washer

(111). Clean any dirt or oil from idler tire and