13

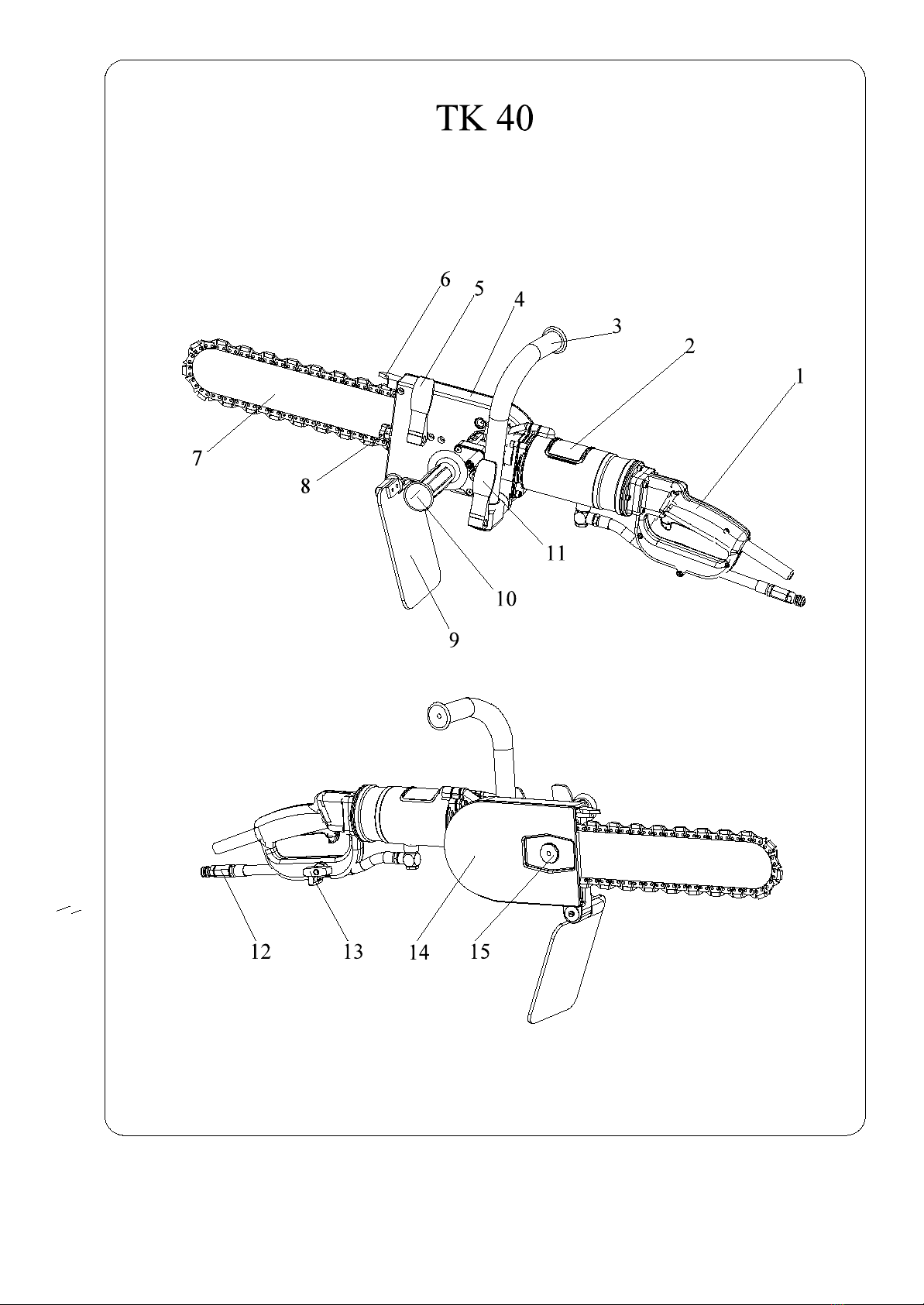

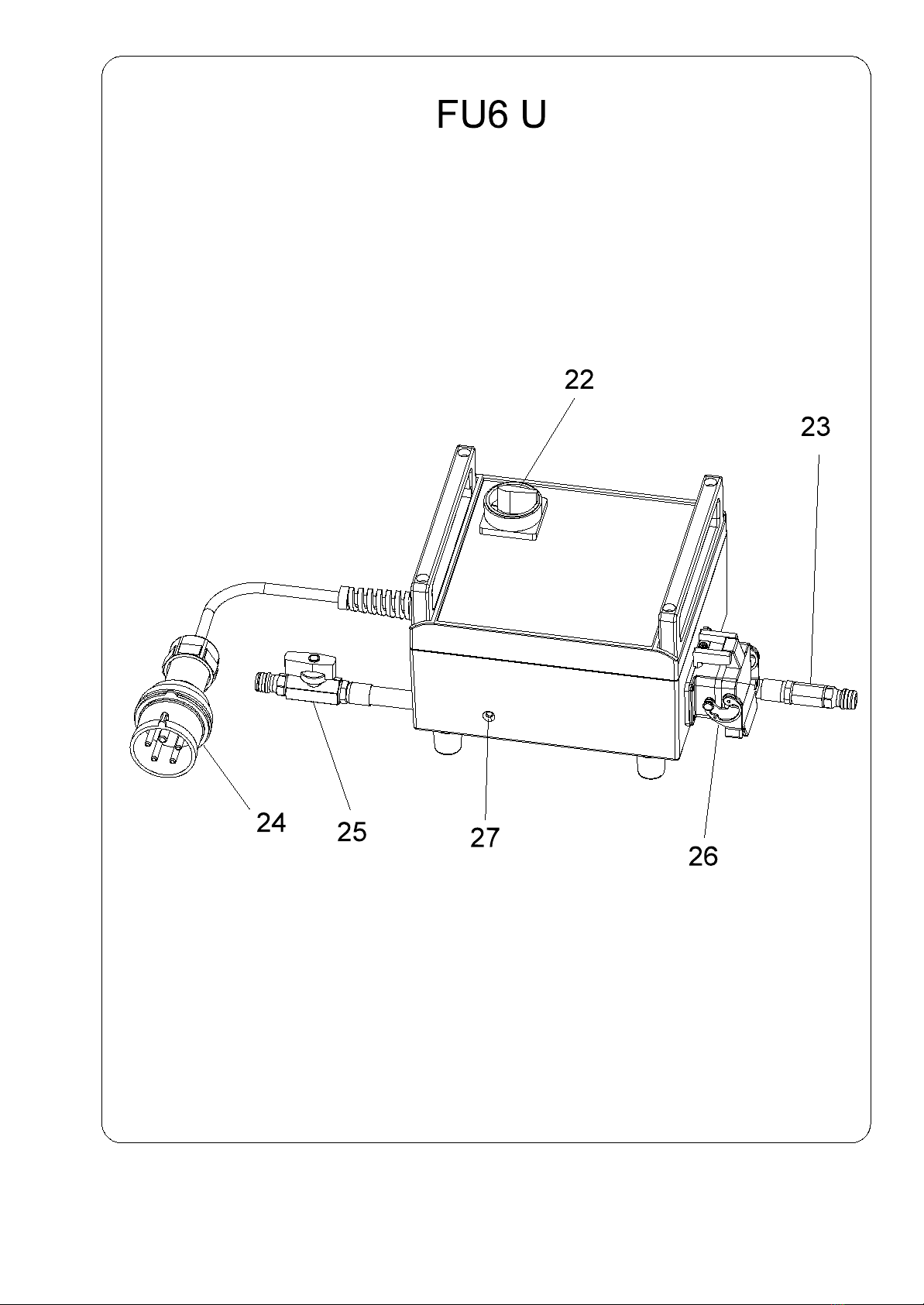

EN OPERATING INSTRUCTIONS - DIAMOND CHAIN SAW TK40

Please read these instructions carefully before starting up the machine!

In the WEKA diamond disc saw you have an outstanding quality product with which you will be very satisfied,

provided you use it properly.

1. G E N E R A L S A F E T Y P R E C A U T I O N S

WARNING! Read all safety precautions and instructions. Failures in the compliance with

these safety precautions and instructions can cause electric shock, fire and/or heavy injuries.

Please keep these safety precautions and instructions for the future.

The term “electric tool” used in the safety precautions corresponds to mains operated electric tools (with

mains cord) and to battery operated electric tools (without mains cord).

1) Security of employment

a ) Keep your working area clean and well illuminated. Disorder or unilluminated working

areas can cause accidents.

b ) Do not work in explosive ambiances with the electric tool, in which there are

flammable liquid, gases or dusts. Electric tools generate sparks which can inflame the

dust or vapors.

c ) Keep children and other persons away from the electric tool while using it. When

being distracted, you can lose the control on the device.

2) Electrical safety

a ) The mains plug of the electric tool must fit into the socket. The plug must not be

changed in any kind. Do not use adapter plugs together with earthed electric tools.

Unmodified plugs and fitting sockets reduce the risk of electric shock.

b ) Avoid body contact with earthed surfaces, like tubes, heatings, cookers and fridges.

There is a higher risk of electric shock when your body is earthed.

c ) Keep your electric tool away from rain or wetness. The infiltration of water into an

electric tool increases the risk of an electric shock.

d ) Do not divert the cord from its intended use from carrying or hanging up the electric

tool, or for pulling the plugs from the socket. Keep the cord away from heat, oil,

sharp edges or moving device parts. Damaged or tangled cords increase the risk of an

electric shock.

e ) If you work outside with your electric tool, only use extension cords that are

appropriate for outside use. The use of a extension cord which is appropriate for outside

use reduces the risk of an electric shock.

f ) If the use of the electric tool in humid areas is inevitable, use a ground fault circuit

interrupter (GFCI). The use of a GFCI reduces the risk of an electric shock.

3) Personal safety

a ) Be attentive, pay attention to what you do and go to work with the electric tool with

reason. Do not use an electric tool when you are tired or under the influence of

drugs, alcohol or pharmaceuticals. One moment of carelessness while using an electric

tool can cause serious injuries.

b ) Wear personal protective equipment and always goggles. The wearing of personal

protective equipment, like dust mask, skid-proof shoes, protection helmet or hearing

protection, depending on the kind and use of the electric tool reduces the risk of injuries.

c ) Avoid unintended start up. Make sure that the electric tool is switched off before

connecting it to the mains and/or the battery, picking it up or carrying it. When you

have your finger on the switch while carrying the electric tool or connect the device to the

mains when it is switched on, this can cause accidents.

d ) Remove adjusting tools or wrenches before switching on the electric tool. A tool or

wrench which is located on a turning device can cause injuries.