Contents

Solar Pump Drive | 3

CONTENTS

ABOUT THE MANUAL ..............................................................................4

ABBREVIATIONS AND DEFINITIONS..................................................................................................... 4

NUMERICAL REPRESENTATION........................................................................................................... 4

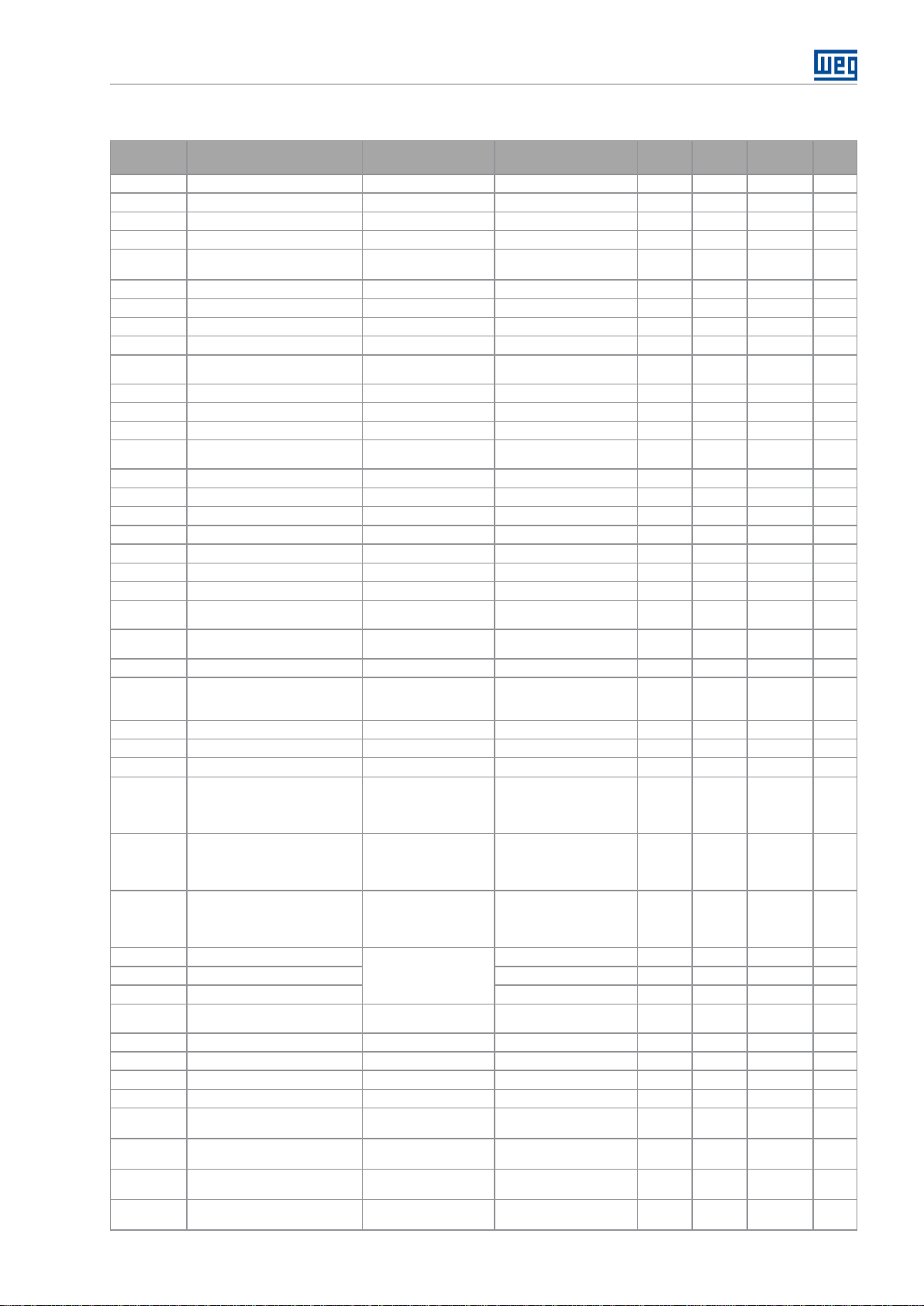

QUICK PARAMETER REFERENCE..........................................................5

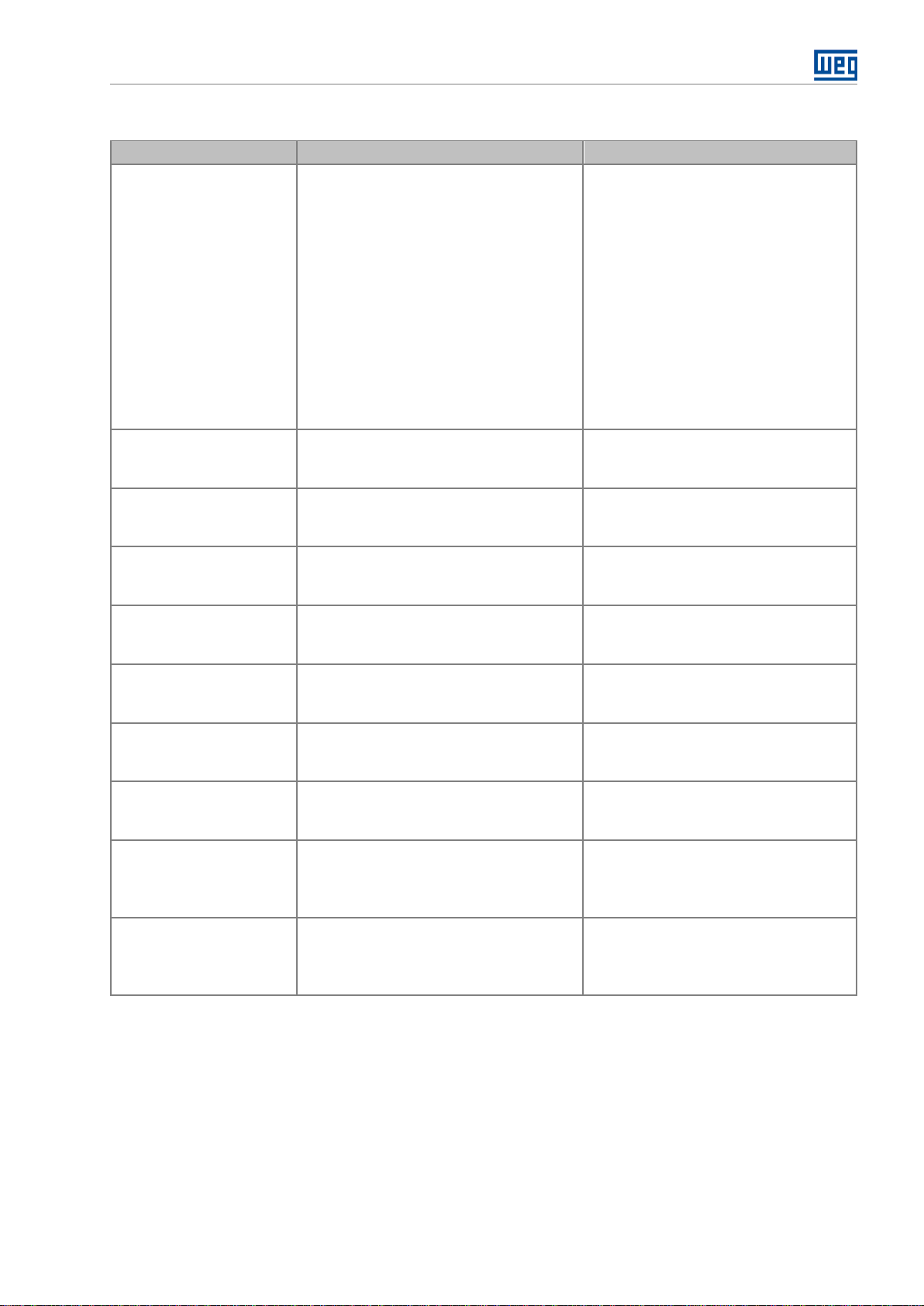

FAULTS AND ALARMS.............................................................................7

1 SAFETY INSTRUCTIONS.......................................................................8

1.1 SAFETY WARNINGS IN THIS MANUAL............................................................................................ 8

1.2 SAFETY WARNINGS IN THIS PRODUCT ......................................................................................... 8

1.3 PRELIMINARY RECOMMENDATIONS............................................................................................. 8

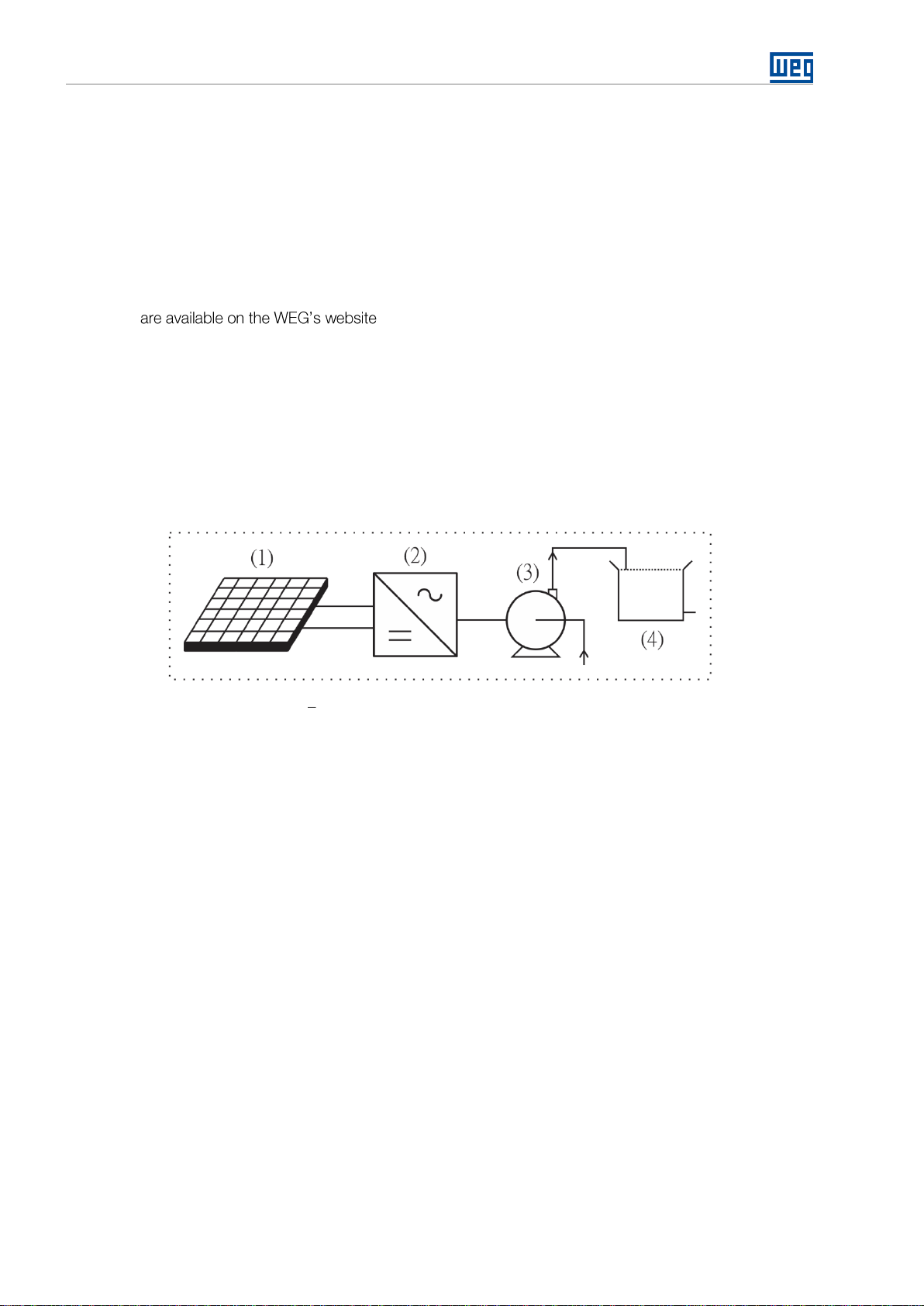

2 PHOTOVOLTAIC WATER PUMPING SYSTEM...................................10

2.1 OVERVIEW OF THE CFW700 IN PHOTOVOLTAIC SYSTEMS ....................................................... 10

2.2 GENERAL CHARACTERISTICS OF THE SOLAR PUMP................................................................ 10

3 INSTALLATION ....................................................................................12

3.1 SIZING OF PHOTOVOLTAICS SOLAR MODULES......................................................................... 12

3.2 CONNECTIONS............................................................................................................................... 15

3.2.1 T4 Model................................................................................................................................... 15

3.2.2 T4 Model with Hybrid Power.................................................................................................... 16

4 CONTROL METHOD BY MAXIMUM POWER POINT TRACKING .....17

5 PARAMETERS DESCRIPTION ............................................................18

5.1 VOLTAGE REGULATOR.................................................................................................................. 18

5.1.1 Voltage Setpoint Limits............................................................................................................ 18

5.1.2 Voltage PID Controller ............................................................................................................. 19

5.1.3 Cloud/Load Controller ............................................................................................................. 19

5.1.4 System Start Configuration ..................................................................................................... 20

5.1.5 Solar Detector.......................................................................................................................... 21

5.2 PRESSURE CONTROLLER............................................................................................................. 23

5.2.1 Pressure PID Controller........................................................................................................... 24

5.2.2 Sleep Mode............................................................................................................................... 25

5.3 PROTECTIONS................................................................................................................................ 25

5.3.1 Dry Pump.................................................................................................................................. 26

5.3.2 Minimum Output Pressure....................................................................................................... 27

5.3.3 Maximum Output Pressure...................................................................................................... 27

5.4 CONTROL SETPOINT..................................................................................................................... 28

5.5 HMI MONITORING.......................................................................................................................... 29

5.6 READING PARAMETERS................................................................................................................ 29

6 POWER UP AND START UP................................................................31