UK

WESTFIRE ·WF37

Operating your stove –UNIQ 37

WARNING; CO Alarm

Your installer should have fitted a

CO

alarm in the same roomas the appliance. If the alarm sounds unexpectedly,

follow the instructions given under “Warning Note” above.

Use afireguard in the presence of children, and old and/or infirm people. The fireguard should be manufactured in

accordance with BS 8423:2002, Fireguards for use with solid fuel appliances.

Initial lighting

The heat-resistant paint on your stove will cure and harden the first time youlight your appliance. The curing process

produces agooddeal of smoke and odour, it is therefore important that the first time you light your stove the room

should be well ventilated. During the process it is important to open and close the stove doorperiodically (every

30mins) during the first couple of firings therefore preventing the doorseal cordaround the door from sticking and

coming away from the door. Oncethe Heat-resistant paint has hardened; the stove door must be kept closed except

when lighting the stove, adding firewood or removing ash in order to prevent flue gas from escaping.

Lighting your appliance

Quality Firelighters should be used when lighting the stove. (Never use mentholated spirit, petrol or other

flammable liquids). Lighting your stovewith fire lighters will be morereliable and easier than paper.

To light your stove

1. Place afew smaller pieces of dry wood(kindling) in the stove on top of the non toxic firelighters.

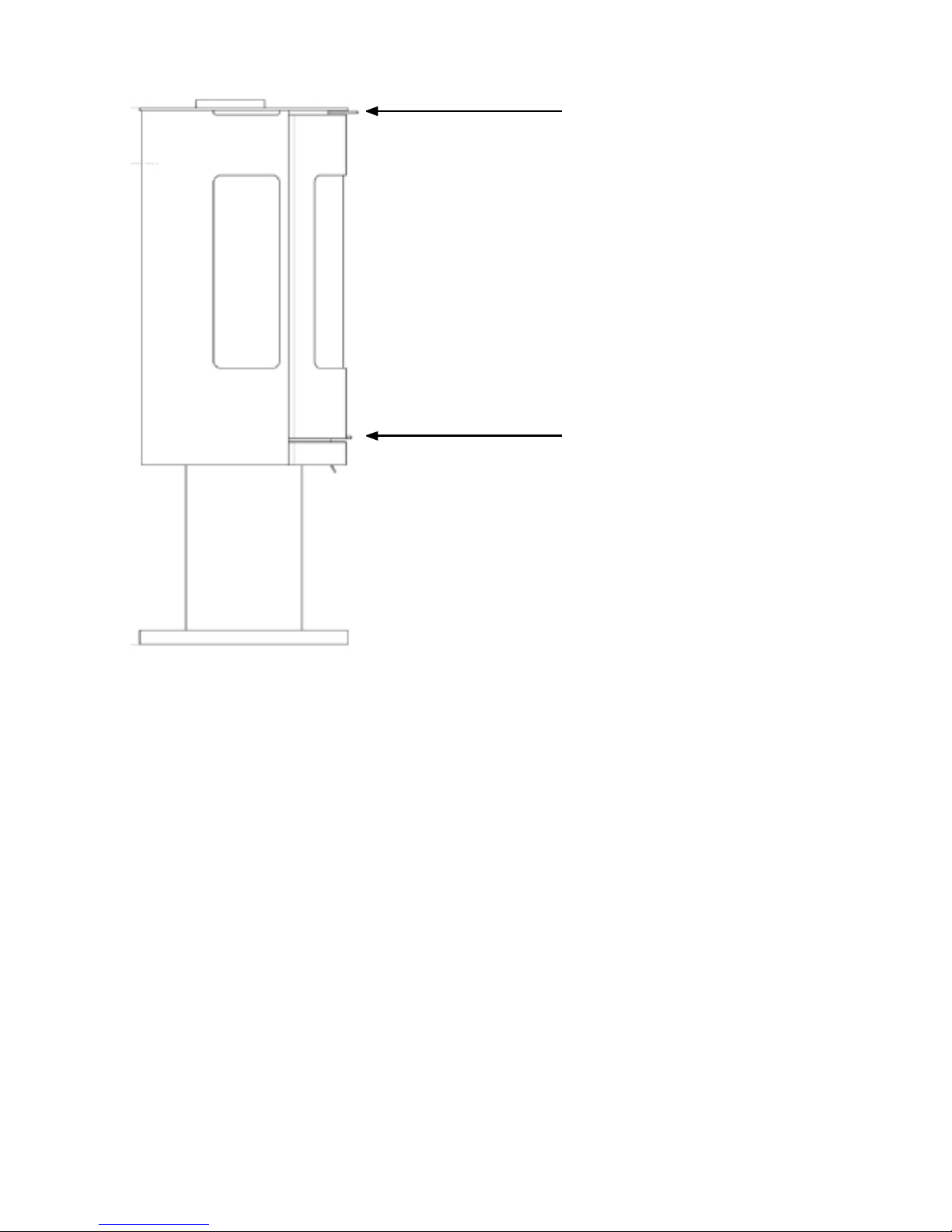

2. Fully pull openthe air slider (Secondary air) and air slider (Primary air) it maybe necessary pull the ash pan

drawer open 1cm as well)

3. Light the firelighters close the door.

4. Oncethe fire has caught, add three pieces of wood measuring approx22cm with acombined weight of approx

2.1kg and close the door.

5. Afterapproximately 3minutes when the fire is burning brightly shut the primary air slider under the ash pan.

6. Afterapproximately another 3minutes close the secondary air slider by 38%, for the stove to burn cleanly

plenty of secondary air is needed, donot be tempted to shut the fire downtoo early as this may cause smoke.

At nominal heat output, expect to refuel your stove approximately once an hour.

WF37 models are all equipped with aair controlsiders for secondary air designed toensure aplentiful supply of oxygen during

firing. When lit, the stove will get very hot and due care must therefore be exercised. Please use aglove when

operating handles and air sliders.

RE -FUELING

To re-fuel in the cleanest way. Before refuelling open secondary air slider fully, also open primary air slider fully and

leave for 5minutes. Opendoorgently, add three pieces of wood measuring approx 22 cm with acombined weight

of approx 2.1kg and close the door. Leave the air sliders open for 10 minutes to allow the fire to reach agood

temperature. Then close primary air slider and slide secondary air slider by 38% .

In the event of achimney fire: Closethe primary and secondary air slidersand the stove door, and call 999 or

your local fire department. If your stoveis over heating close the Primary and secondary air sliders and

ensure doorisfirmly closed, and left until the stove has return tonominal temperatures’.

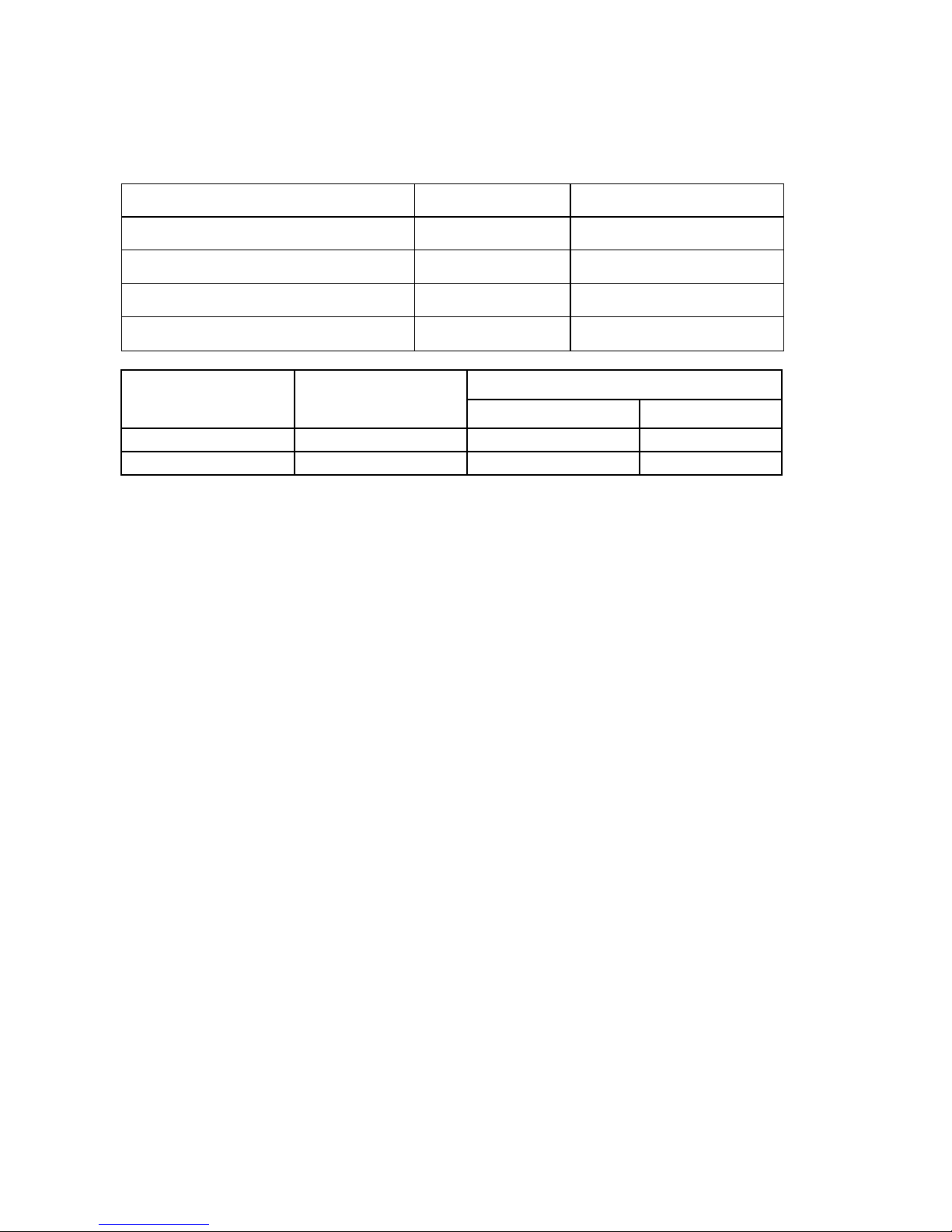

Basic Positions of air sliders duringOperation

You

will need to become familiar with your stove in order to beableto regulate the secondaryair intake correctly,

as factors such as the quality and height of your chimney, the quality of your fuel and the external conditions play a

large role in your stove performance. It is easy to see whether the stove is functioning correctly; however incomplete

combustion may lead to abuild-up of hard, shiny soot onthe inside of your stove and glass.

To prevent sooting of the chamber and glass introduce secondary air, also check that your wood is dry.

It is important to check the draft conditions before lighting your stove. This may be done, for instance, by crumpling

apiece of newspaper, placing it in the combustion chamber and lighting it. The draft conditions are good if the

smoke is drawn away through the chimney.

10