OPERATION INSTRUCTION

5

Rotating the Auxiliary Handle, the auxiliary handle

11 can be set to any position for a secure and

low-fatigue working posture.

Turn the bottom part of the auxiliary handle 11 in

counterclockwise direction and swivel the

auxiliary handle 11 to the desired position. Then

retighten the bottom part of the auxiliary handle

11 by turning in clockwise direction.

Pay attention that the clamping band of the

auxiliary handle is positioned in the groove on the

housing as intended for.

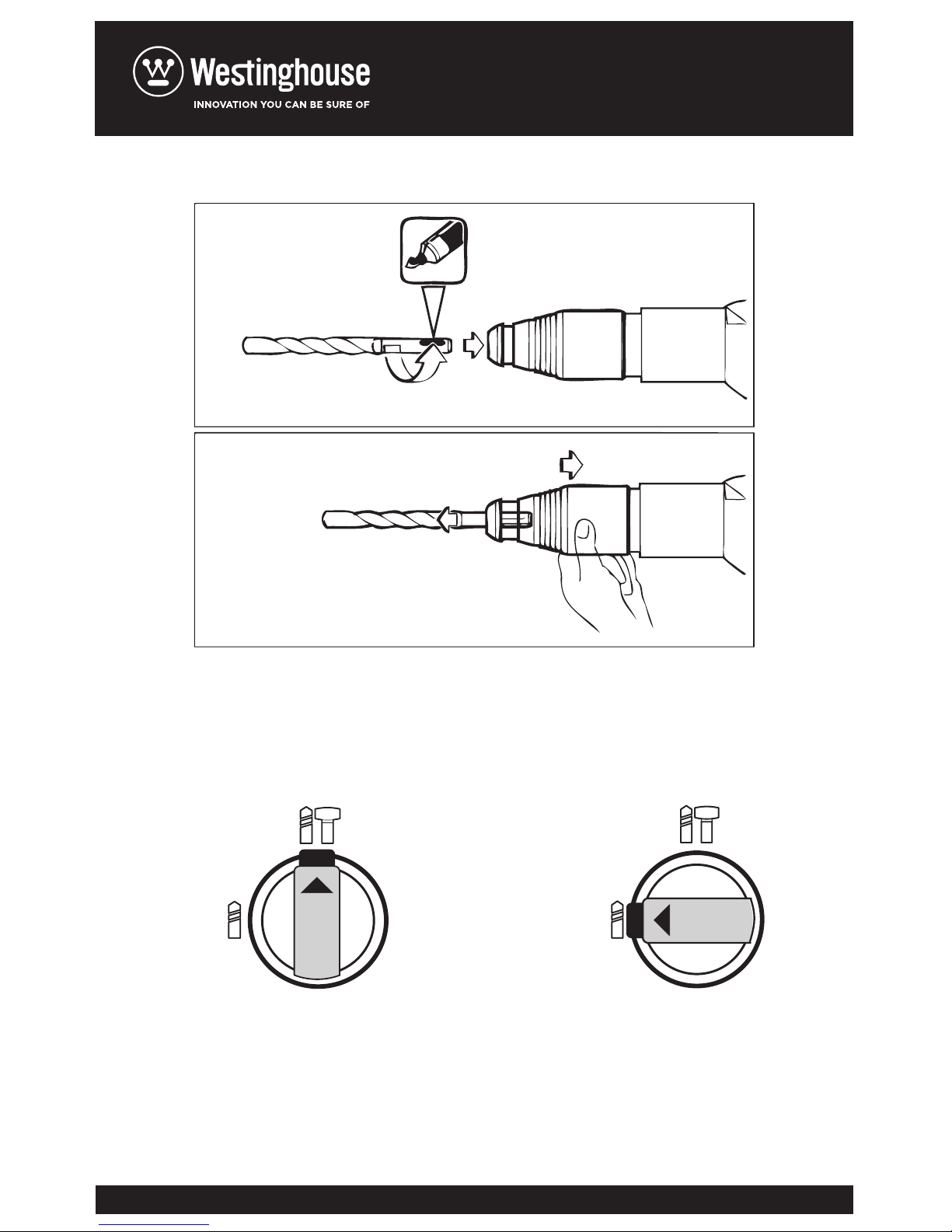

b) Changing the Tool

The dust protection cap 3 largely prevents the

entry of drilling dust into the tool holder during

operation. When inserting the tool, take care that

the dust protection cap 3 is not damaged.

A damaged dust protection cap should be

changed immediately. We recommend having

carried out by an after-sales service.

Inserting SDS-plus Drilling Tools, the SDS drill

chuck allows for simple and convenient changing

of drilling tools without the use of additional tools.

Clean and lightly grease the shank end of the

tool. Insert the tool in a twisting manner into the

tool holder until it latches itself.

Check the latching by pulling the tool.

As a requirement of the system, the SDS drilling

tool can move freely. This causes a certain radial

run-out at no-load, which has no effect on the

accuracy of the drill hole, as the drill bit centre

itself upon drilling.

Removing SDS Drilling Tools, push back the

locking sleeve 4 and remove the tool.

4) Operation

1. Starting Operation

Observe correct mains voltage! The Voltage of

the power source must agree with the voltage

specified on the nameplate of the machine.

Setting the Operating mode, with the selector

switch for drilling/ hammer drilling 9, the operating

mode of the machine is selected. To change the

operating mode, press the release button 8 and

turn the drilling/ hammer drilling selector switch 9

to the desired position until can be heard to latch.

Note: only change the mode of operation while

disconnected from the machine! Otherwise you

may damage the machine.

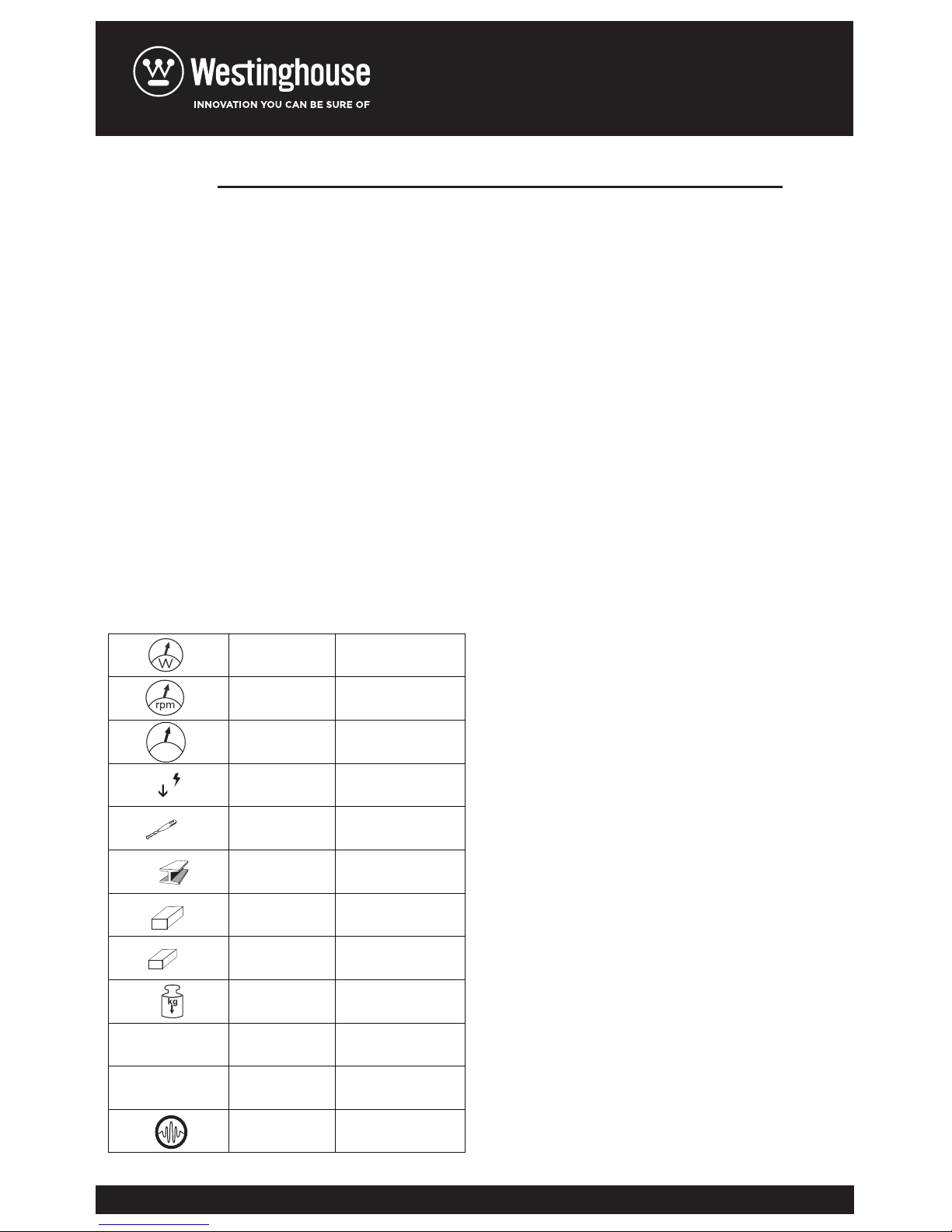

Position for hammer drilling in concrete (fig.12).

Position for drilling without impact in wood, metal,

ceramic and plastic as well as for screw driving

and thread cutting. (fig.14).

Reversing the rotational direction, the rotational

direction switch 5 is used to reverse the rotational

direction of the machine. However, this is not

possible with the On/Off switch 7 actuated.

Right rotation: turn the selector switch for

drilling/hammer drilling 5 on both sides to the stop

in the position.

Left rotation: turn the selector switch for

drilling/hammer drilling 5 on both sides to the stop

in the position.

Set the direction of rotation for hammer drilling,

drilling and chiseling always to right rotation.

Switching On and Off, to start the machine, press

the On/Off switch, keep it pressed and additiona-

lly push the lock-on button 6. To switch off the

machine, release the On/Off switch 7.

When the On/Off switch 7 is locked, press it first

and then release it.

Setting the Speed/ Impact Rate, the speed/impact

rate of the switched on power tool can be variably

adjusted, depending on how far the On/Off switch

7/10 is pressed.

Light pressure on the On/Off switch 7/10 results

in low speed/impact rate. Further pressure on the

switch increases the speed/ impact rate.