EmectricaI Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter,

Do not use an extension cord.

Faimureto follow these }nstruct}ons can resumt }n death,

fire, or emectr}ca{ shock.

A 120-volt, 60-Hz., AC-only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate circuit

serving only this appliance be provided.

To minimize possible shock hazard, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

IMPORTANT: The washer/dryer must be electrically grounded

in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure the

washer/dryer is properly grounded.

Do not have a fuse in the neutral or ground circuit.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected washer/dryer:

This washer/dryer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This washer/dryer is equipped with a cord

having an equipment-grounding conductor and a grounding

plug. The piug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with

all local codes and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the washer/dryer

is properly grounded. Do not modify the plug provided with

the washer/dryer: if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

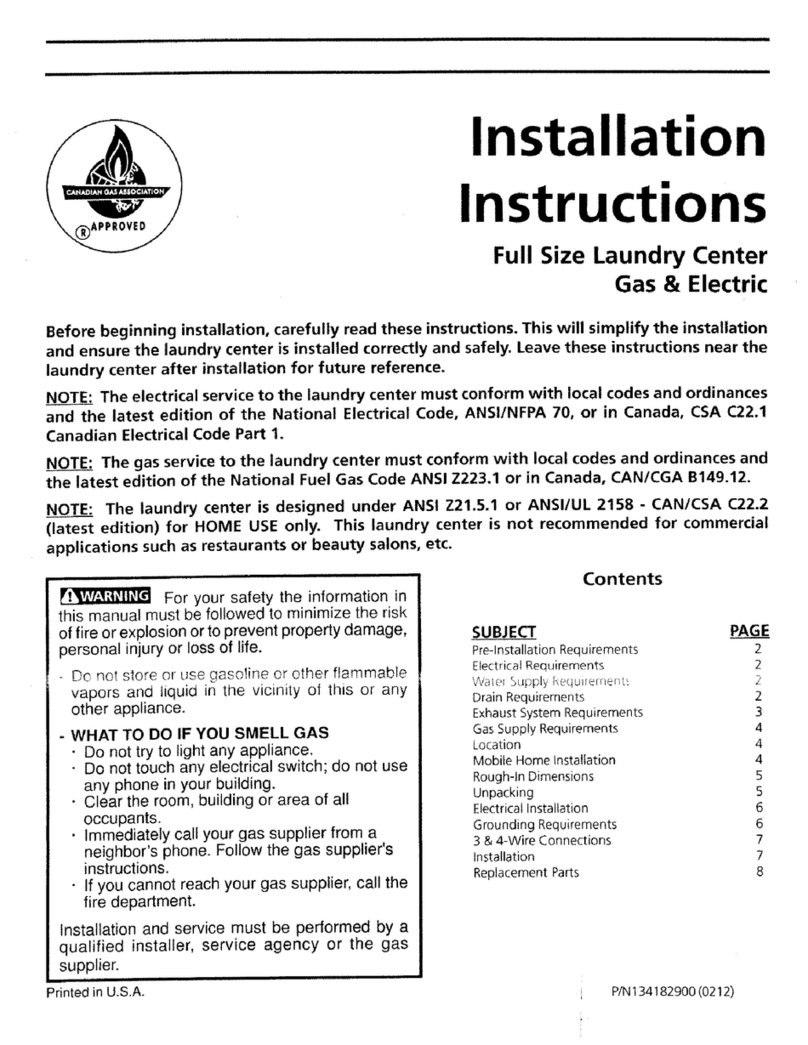

Explosion Hazard

Use a new AGA or CSA approved gas supply mine.

Install a shut-off valve.

Securemy tighten aH gas connections.

ff connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (33 cm) water

comumn.

Exampmes of a quamified person include:

licensed heating personnem,

authorized gas company personnel, and

authorized service personnel

Failure to do so can resuJt in death, explosion, or fire.

Gas Type

Natural Gas:

This washer/dryer is equipped for use with Natural gas. It is

design-certified by CSA International for LP (propane or butane)

gases with appropriate conversion.

•Your washer/dryer must have the correct burner for the type of

gas in your home. Burner information is located on the rating

plate in the door well of your dryer. Ifthis information does not

agree with the type of gas available, contact your dealer or call

the phone numbers referenced on the front page of your

"Washer/Dryer User Instructions."

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes,

or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54.

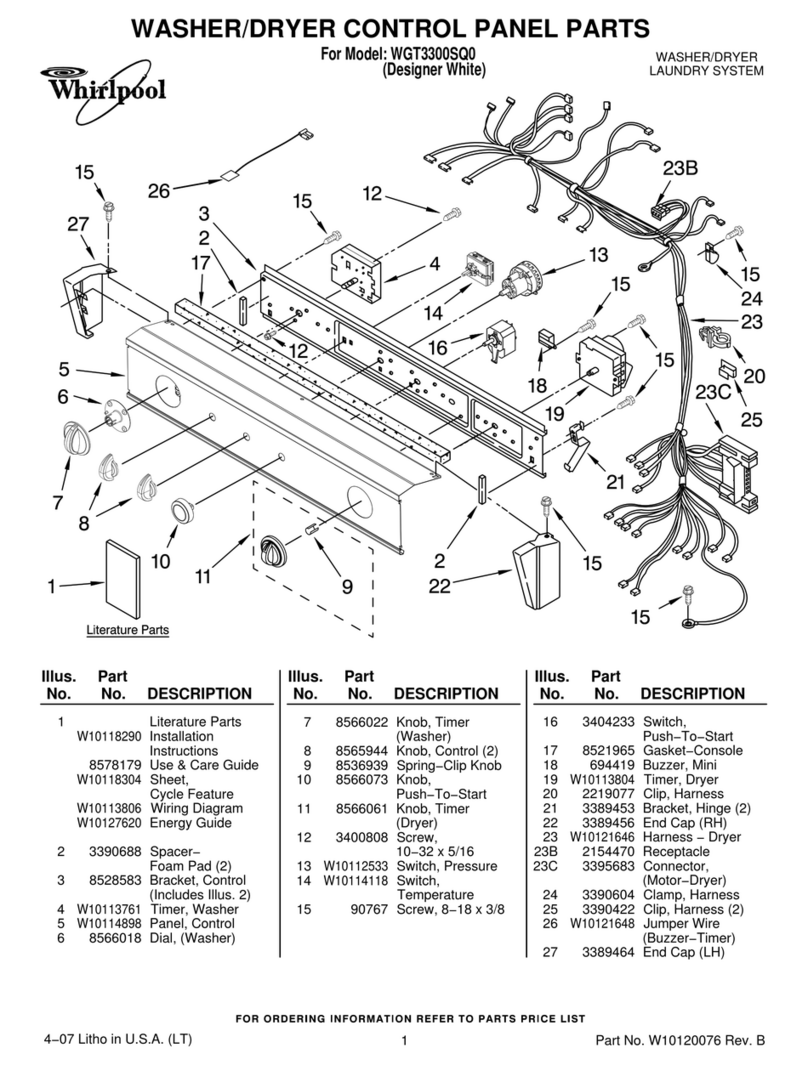

Gas Supply Line

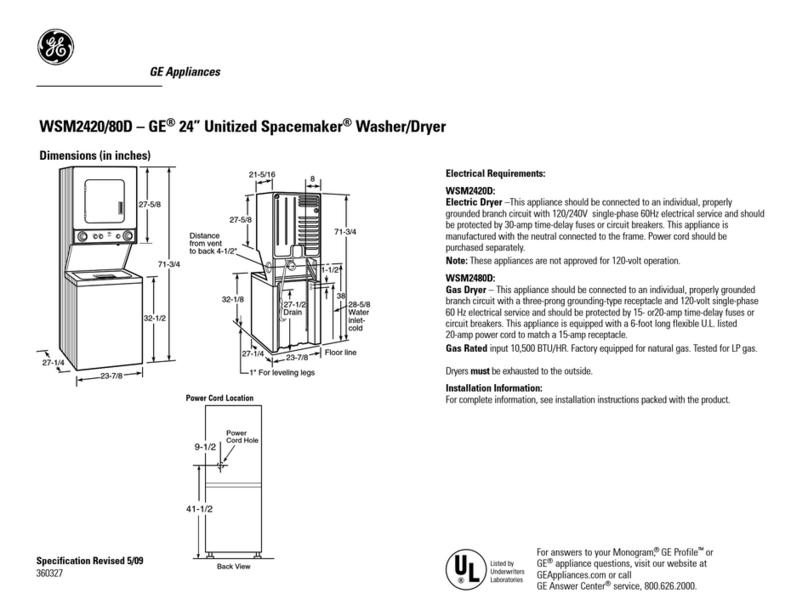

• 1/2"IPS pipe is recommended.

• 3/8"approved tubing is acceptable for lengths under

20 ft (6.1 m) if local codes and gas supplier permit.

• Lengths over 20 ft (6.1 m) should use larger tubing.

• Must include 1/3"NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

supply connection to the dryer (see illustration).

• Gas supply line coupling must be 34" (86.4 cm) to 37" (94 cm)

from the floor.