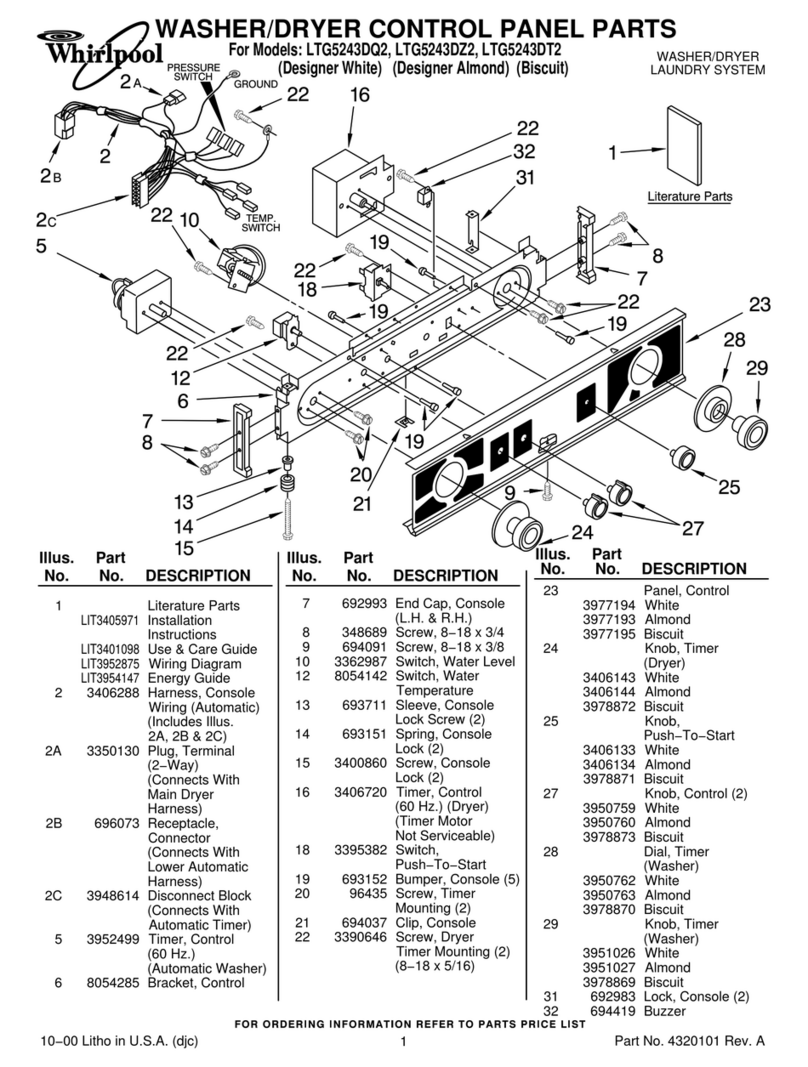

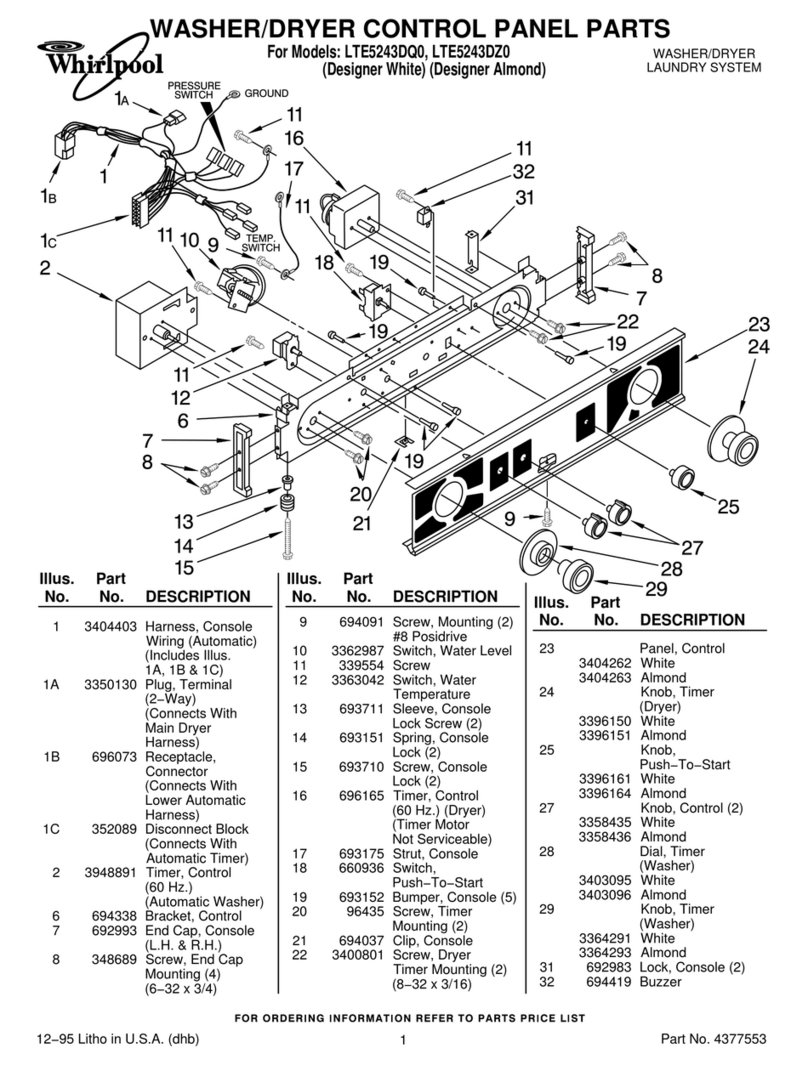

Panel C

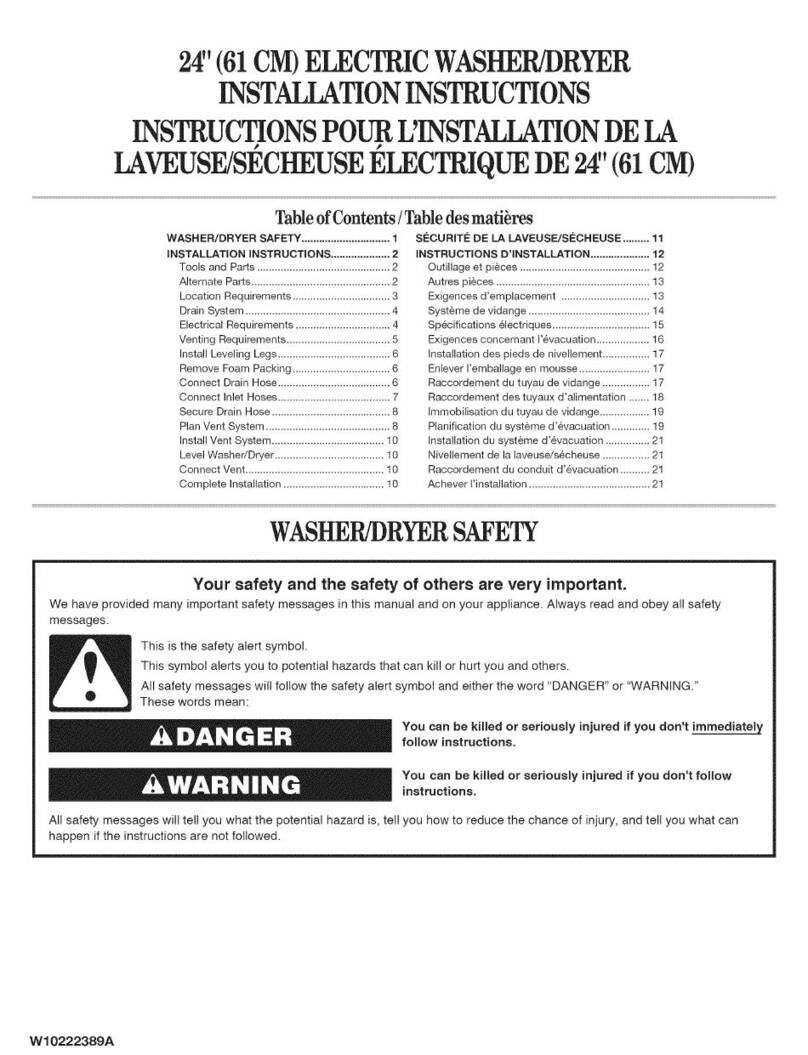

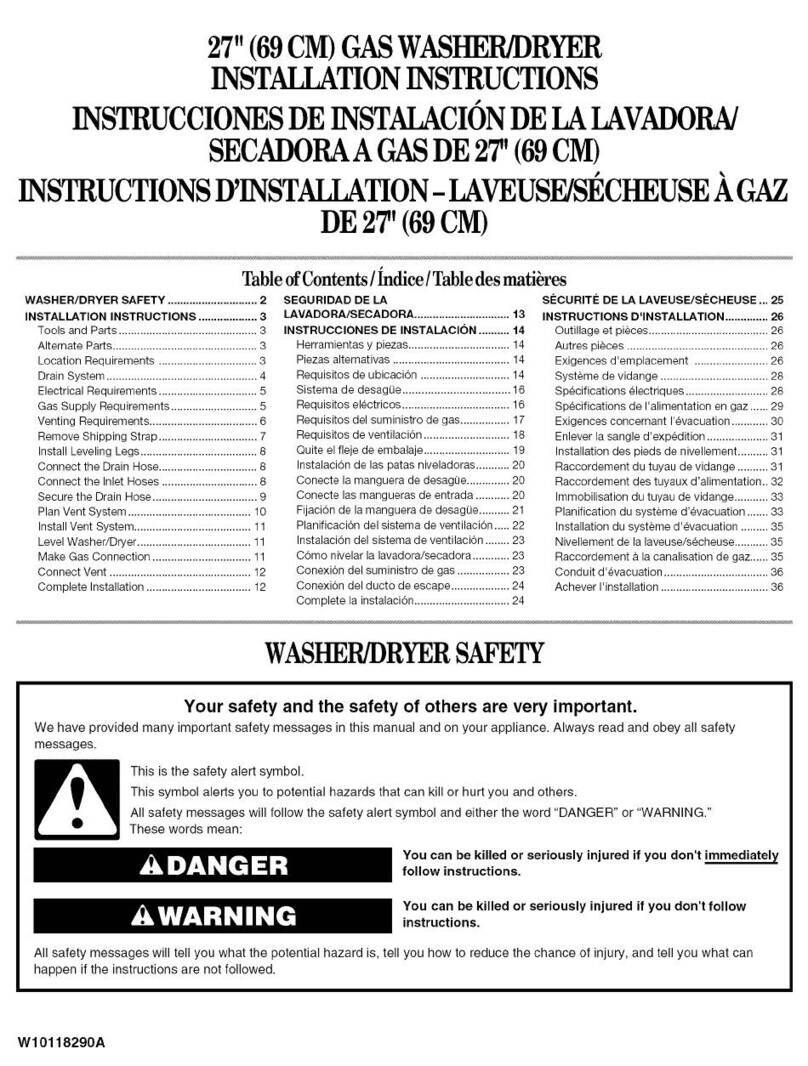

Exhaust requirements

POWER SUPPLY CORD

OR DIRECT WIRE

Where local codes DO NOT permit

connecting the cabinet-ground

conductor to the neutral (white)

wire:

Where local codes permit

connecting cabinet-ground

conductor to the neutral wire of the

power suppl cable:

Where local codes permit

connecting cabinet-ground

conductor to the neutral wire:

Three-wire connection...

B.

POWER SUPPLY CORD

Figure 8

center silver-colored

terminal block screw and

neutral white wire

ground wire (green

with yellow stripes)

1. Disconnect the power suppl .

2. Remove terminal block cover.

3. Install copper three-wire power supply

cord throu h strain relief.

4. Remove the round wire ( reen with

yellow stripes) from under center, silver-

colored terminal block screw and

connect to external round connector

(see Fi ure 8).

5. Connect the neutral wire (white or

center) of the power supply cord to the

center, silver-colored terminal screw of

the terminal block. Connect the other

wires to the outer terminals. Ti hten

screws firmly.

6. Ti hten strain relief screws.

7. Replace the terminal block cover.

external ground connector

DIRECT WIRE

1. Disconnect the power suppl .

2. Remove terminal block cover.

3. Strip 3-1/2 inches of outer coverin from

end of cable. If usin three-wire cable

with I wire, cut the bare wire even with

outer coverin . Strip 1 inch of insulation

from the end of each insulated wire (see

Fi ure 9).

Important: Observe all governing codes

and ordinances.

It is recommended that ou exhaust

our dr er to the outside for best

performance. Moisture and lint indoors

may cause:

• Lint to ather around the dryer where

it can be fuel for a fire.

• Moisture dama e to woodwork,

furniture, paint, wallpaper, carpet,

etc.

• Housecleanin problems and health

problems.

If the washer/dr er is installed in a

confined area such as a bedroom,

bathroom or closet, it must be

exhausted to the outside and provision

must be made for enou h air for

ventilation. Check overnin codes and

ordinances. Also refer to the “Recessed

and closet installation instructions” on

Panel G.

Dura SafeTM vent products are

recommended and are available from

our dealer. See Panel G.

Four-inch diameter vent is required.

Use a heav metal vent. Do not use plastic or

metal foil vent.

• Do Not use non-metal flexible vent, or

exhaust hoods with ma netic latches.

• Do Not exhaust dryer into a chimney,

furnace, cold air vent, attic or crawl space,

or any other vent used for ventin .

• Do Not install flexible vent in enclosed walls,

ceilin s or floors.

Rigid metal vent is recommended to prevent

crushin and kinkin .

Flexible metal vent must be fully extended

and supported when the dryer is in its final

position.

Remove excess flexible vent to avoid

sa in and kinkin that may result in

reduced air flow.

An exhaust hood should cap the exhaust

vent to prevent rodents and insects from

enterin the home.

Exhaust outlet hood must be at least 12

inches from the round or

any object that may be in

the path of the exhaust

(such as flowers, rocks or

bushes, etc.).

If using an existing exhaust

s stem, clean lint from entire

length of s stem and make sure exhaust

hood is not plugged with lint.

Replace any plastic or metal foil vent with

ri id metal or flexible metal vent.

Use clamps to seal all joints. Do not use duct

tape, screws or other fastenin devices that

extend into the interior of the vent to secure

vent.

Service check: Back pressure in any exhaust

system used must not exceed 0.6 inches in

water column measured with an incline

manometer at the point that exhaust vent

connects to dryer.

Direct wire preparation

Figure 9

10-gauge, 3-wire or,

10-gauge, 3-wire with

ground wire (Romex)

3/4" U.L.-listed

strain relief

Bare wire cut short. Wire is not

used. Dryer is grounded through

direct wire cable.

to disconnect

box

red

white

black

NEUTRAL

1"

3-1/2"

wires stripped

of insulation

Figure 10

Shape the end of each

wire into a “U” shaped

hook (see Fi ure 10).

u-shaped

hook

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to do so can result in death or

fire.

Three-wire connection...

ground wire (green with

yellow stripes)

center silver-colored

terminal block screw and

neutral white wire

external ground connector

Figure 11

4. Install copper, three-wire power supply

cable throu h strain relief.

5. Remove the round wire ( reen with

yellow stripes) from under center, silver-

colored terminal block screw and

connect to external round connector

(see Fi ure 11).

6. Slide the hook end of the neutral (white

or center) wire from the three-wire

power supply cable under the center,

silver-colored terminal screw of the

terminal block. Squeeze the hook end of

the wire to ether. Ti hten screw.

7. Connect the other wires to the

outer terminals usin the same method.

Ti hten screws firmly (see Fi ure 11).

8. Ti hten strain relief screws.

9. Replace the terminal block cover.

WARNING

Fire Hazard

Use a new UL approved 30 ampere

power supply cord.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire) must

be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire) must

be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

12" min.

Connect separate copper ground wire

from external ground connector

to approved ground.

separate copper

ground wire

external

ground

connector

ground wire (green

with yellow stripes)

Figure 12

center silver-colored

terminal block screw and

neutral white wire

1. Disconnect the power suppl .

2. Remove terminal block cover.

3. Install solid copper, power supply cord or

cable throu h strain relief.

4. Remove the round wire ( reen with

yellow stripes) from the external round

connector.

5. Connect the round wire ( reen with

yellow stripes) and the neutral (white)

wire of the power supply cord or direct

wire cable to the center, silver-colored

terminal screw of the terminal block.

Connect the other wires to the outer

terminals. Ti hten screws (see Fi ure 12).

6. Connect a separate copper round wire

(No.-10 minimum) from the external

round screw to an adequate round.

7. Ti hten strain relief screws.

8. Replace the terminal block cover.