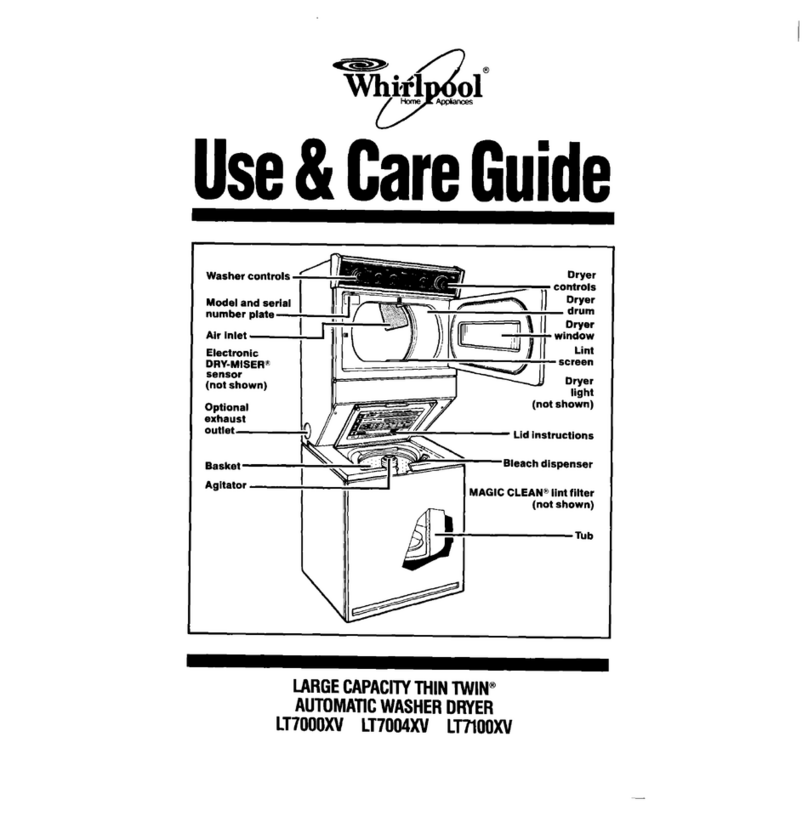

Beforeyou

start...

Mark an X across the letter or

number as you complete each

Step. phllllpsscrewdrlver

You need these tools to install your

Whirlpool washer/dryer. Get them

toaether in one olace to keeo .

washer/dryer..proper

installation is your responsibility

Make sure you have everything

necessaryforproper installation.

You’ll need:

To meet code requirements:

some codes keep from or limit

installation of clothes dryers In

garages. closets, mobile homes

and sleeolna auarten. fCheck

with you~loc~l bulldlng‘inspector.)

Important: observe all governlng

codes and ordinances.

Location

Size: Must be large enough to fully

open dryer door. For recessed or

closet installations see Panel F for

spacing. for product dimensions

see back page of these

instructions.

SUPpOWlhe fibor inusi be able

t0 SUppOrt the appliance weight

of 375 pounds.

Level Floor: Maximum floor slope

under washerjdryert inch.

Protectlon from the weather:

Proper operation of dryer cycles

reaulres temoeratures above 45°F

As home woier remoins In the

washer do not store or operale the

wosher below 32°F For storaoe

below 32’F see Laundry Guise for

“Winterizing:’

Moblle Homes: Washer/dryer

must be secured to the mobile

home using Mobile Home

lnstallotion Klt 693900.

CAUTION:

l

It Is the personal responsibility

of the customer to ensure that

gasoline. paint. thinners and

other flammoble materials are

not used or stored near the

washer/dryer. Fumes from these

materials could result in fire or

explosion.

l

Never install the washer/dryer

up against draperies or curtains

and be sure to keep any and oil

Items from falling or collecting

behlnd the washer/dwer

l

Replace all access or sen.ice

panels before operaiing

washer/dryer.

Electrical Requirements

WARNING: Improper connectlon

of the equlpmenl grounding

conductor can result In a risk of

electrlcal shock.

1. A three-wire single phase 120R40

volt 60 Hz AC only with a fourth wire

as a grounding wire electriml

supply Is requi&f A seporaie 30

amDere circutt fused on both sides

of the line must be used [A three

wire 120/208 volt with 0 fourth wire

os c~~rwndlng wire is required if

specified Cn nameplate.) Time-

delay fuse or circuit breaker is

reccmmei-dedDorwthavea

PANEL A

fuse on the neutralor ground ctrculi.

2. This washer/dryer is

manufactured with

wire. flexible type

power supply cord

mm) and 0 u L.nc n12ed,lraln

U.L. recognized ~~$,&~,~;poI

strain relief (see one~Khno~s.

Figure I). It mUSt be plugged into

a matlna 30 amo receotacle

3. IF THE POWER SUPPLY CORE

REMOVED, THE WASHER/DRYER

MUST BE CONNECTED WITH 10

GAUGE COPPER WIRE ONLY

Aluminum wfre must not be used

01 the washer/dryer appliance

terminal block. to ovold

potentially unsatisfactory

connectlons. See Panel F.

Alternate Electrcal Connection.

for detalled instructions

4. When removing the power supply

cord (pigtail], the appliance

moy be connected directly to the

fused disconnect [or circuit

breaker] box through flexible

armored or non-metallic sheathed

10 gauge copper cable It is the

personal responsibility and obli-

gation of the customer to contact

a qualified instoller to assure that

the electrical installation ISade-

quate and is in conformonce

with the National Electrical Code

and local codes and ordinances.

Allow slack in the line between

the wall and the appliance so

that It can be moved II servicing

is ever necessary. A U.L. recognized

strain relief must be provided at

each end of the power supply

cable (at the appliance and at

the junction box] Wire sizes [lo

aauae COPPER WIRE ONLY1 and

conr?ection must conform with the

rotino of the aooliance 130

AN EXTENSION CORD.

Figure 3 [IO-JOR)

3.wire receptacle

5. If you mUSt Change t0

120/240 volt 60 I& AC electrical

supply system, and local codes

permit, a power supply cord

(plgtoll) with o recepfocle of

NEMA type 10.30R may be used

(See Figure 3). (Thn power supply

cofd must have three No. 10 Qauge

copper ccnductws with spade

0T ring terminals on the washer/

dryer end and terminating In b

NEMA tvpe lo-30P plug on supply

eno Cord should be type SRD or

SRDT. and be at least 3 feet and no

n-me than 6 feet long. The three-

wire power supply cord is not

provided with the washer/dryer A

kti. Part No. 687104 is avoiloble]

NOTE. If local codes require per-

manentlv connected wlnno. see Alter-

nate Electrical Connectio& Panel F

To convert to three-wire electrlcal

syslem the four-wire power supply

cord must be removed and the

appliance frame must be

grounded according to local codes

either by using the neutral terminal

or a Seporote QrOundlng wire (See

Panel F,Alternote ElectrIcal Con-

nection. for detailed instrucllons ]

Exhaust requirements

Four Inch Metal Exhaust Duck IS

required. (Do not use 3 Inch

exhaust duct.) Metal flexible duct

may be used. Non-metallic

flexible duct is not recommended

For Safety:

l

Do not exhaust dryer Into a

chimney, furnace cold air duct,

at%c or crawl space, or any

other duct used for venting

Accumulated llnl could

become a fire hazard or

moisture could cause damage

l

The exhaust system should be

cleaned periodically, ot leost

everv 2 years.

I

l

Flexible duct should never be

installed concealed in walls,

ceiling or floor. Use Duct Tape

to seal all joints.

Exhausting the

dryer outslde is

recommended If

you cannot exhaust

the dryer to the outsid

use Exhaust Deflect0

LCK45OO ovoilable fr

Whirlpool dealer

Exhausting the dryer through

the side is available with use

of Side Exhaust Kit LCK4600. Follow

the installation instructions with the

kit for orooerexhoust lnstalloiion

For Mbbiie Home Exhoust

Reauirements see Panel F.

Alternate Exhaust Methods, for

detailed instructions.

The Exhaust Duct should end

with an exhaust hood to prevent

exhausted air returning Into dryer

The outlet of the hood must be

at least 12 inches from the ground

or anyihlng else that may be In

the oath of the exhaust.

A 2iz Inch outlet Exhaust Hood

should be used with short systems

only. This outlet creates greater

backward pressure than other

hood tYpes.

Exhaust Hoods with magnetic

latches should not be used

The Maxlmum length of the

exhaust system depends upon the

type of duct used. number of

elbows and type of exhaust hood

The maximum length for both rlgid

and flexible duct is shown In chart

Exhaust Svstems lonaerthan

specified ‘~111: -

l

Shorten the life of the dryer

l

Reduce the performance, such

as cause longer dying times

and increase the use of energy

l

Accumulate lint

Hot ind Cold water faucets

within 4 feet of back of the

washer/dryer and enough

pressure (5-100 PSI) are required

Water Heater should be set to

deliver 130°F or above water to

the washer for best results

To Droln the Whirlpool washer, you

need either o 20 Qallon laundry

corv-away

copaclty of A1

17 gallons per rnlnute ’

The top of the tub or the top of the

slandpipe cannot be lower than

26 Inches or higher than 48 inches

from the bottom of the

washer Use a floor drain

only If o siphon break

(air valve to equalize

pressure) ISinstalled

[A siphon breok. Port No

285320 is available from

WhIrlpool authorrzed

parts distributor) Standplpe