A.R. Wilfley and Sons, Inc.

October 2018

5870 E. 56th Avenue, Commerce City, CO 80022 USA • Toll Free: 1-800-525-9930 • Phone: +1 (303) 779-1777 • Fax: +1 (303) 779-1277 • www.wilfley.com • pumps@wilfley.com

Table of Contents

Foreword.....................................................................................................................................................................3

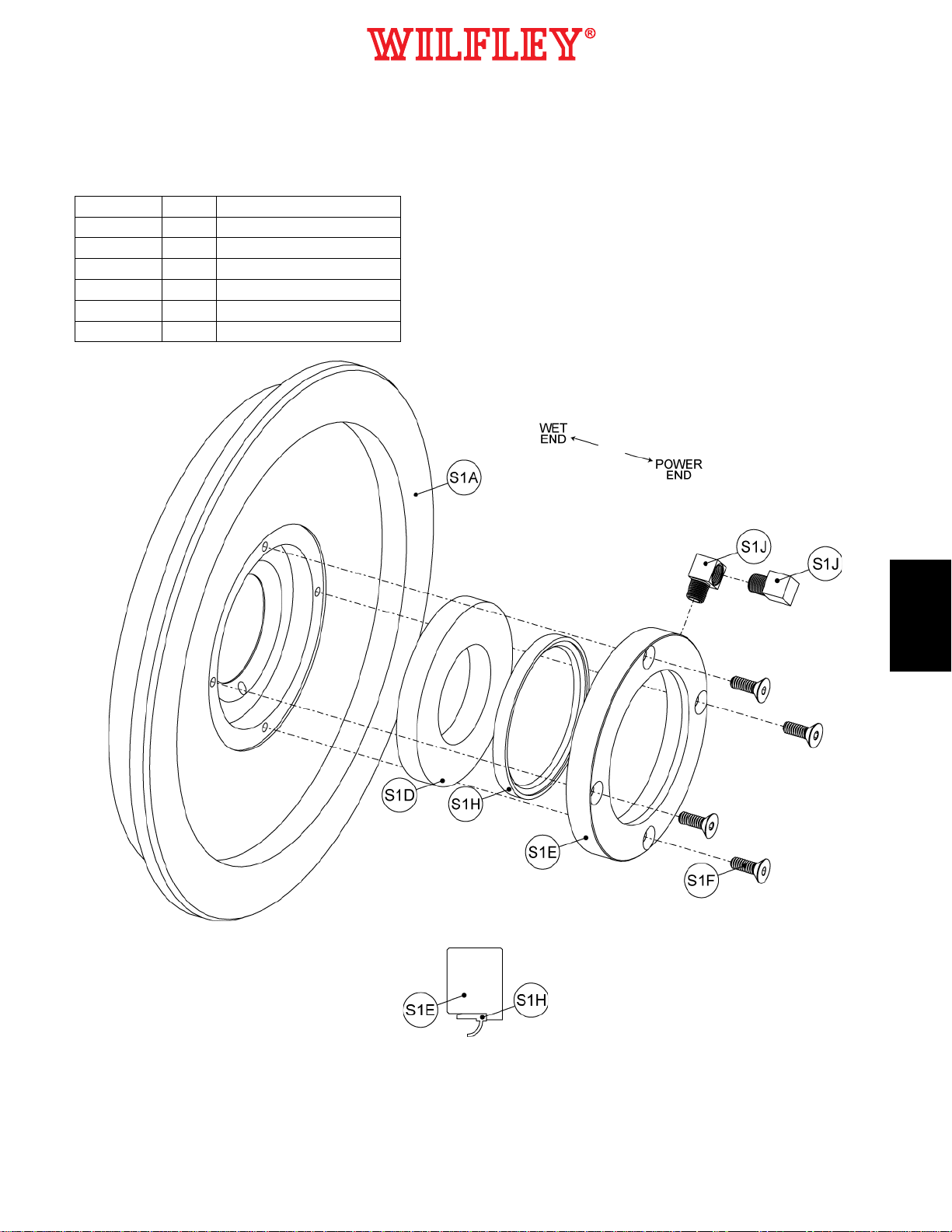

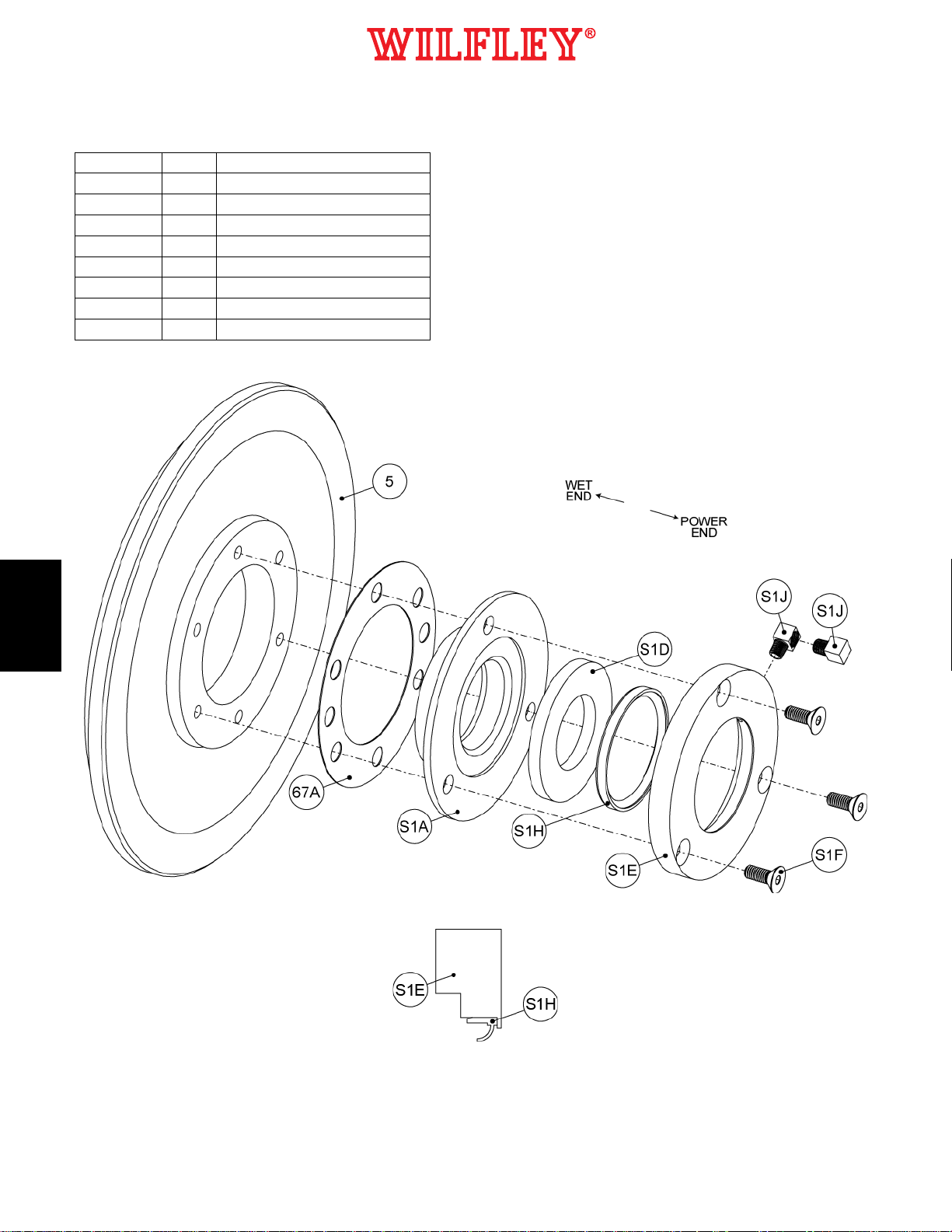

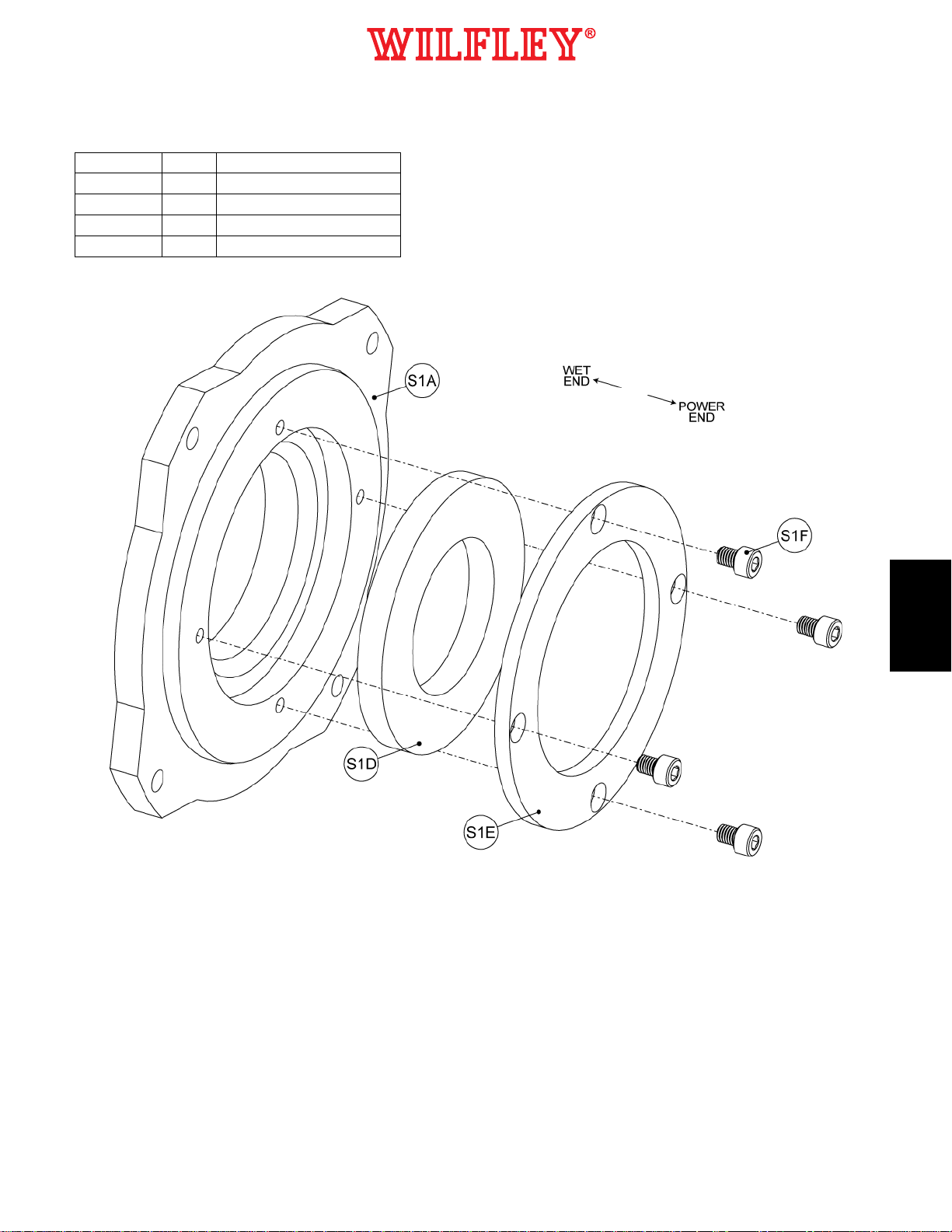

1.0 Stationary Seal Subassembly...............................................................................................................................7

1.1 A7/A9 Chemical Pump (Purge Port Configuration)........................................................................................7

1.2 AF Chemical Pump (Purge Port Configuration) ............................................................................................8

1.3 EMW®Slurry Pump (Standard Configuration) ..............................................................................................9

1.4 EMW®Slurry Pump (Purge Port Configuration) ..........................................................................................10

1.5 HD Slurry Pump – 8x4 & 8x6 (Standard Configuration) .............................................................................11

1.6 Kpro®Slurry Pump (Standard Configuration) .............................................................................................12

1.7 Kpro®Slurry Pump (Purge Port Configuration) ...........................................................................................13

1.8 S3 Chemical Slurry Pump............................................................................................................................14

1.9 S3 Chemical Slurry Pump (Lip Seal Configuration).....................................................................................15

2.0 Rotary Seal Subassembly ..................................................................................................................................16

2.1 Step 1...........................................................................................................................................................16

2.2 Step 2...........................................................................................................................................................17

3.0 Pump Assembly..................................................................................................................................................18

4.0 SolidLock®Seal Adjustment...............................................................................................................................19

5.0 Quantity of Springs Based on Operating Speed ................................................................................................20

6.0 Cross Section .....................................................................................................................................................21

6.1 Standard Configuration ................................................................................................................................21

6.2 Purge Port Configuration..............................................................................................................................22

7.0 Revision History..................................................................................................................................................23