33

• Study, understand, and follow all

instructionsprovided withand onthis

devicebeforeuse.

• All WARNING statements must be

carefully observed to help prevent

personalinjury.

•

No alteration shall be made to this

device.

• Always wear protective gear when

operatinghydraulicequipment.

• Keephydraulicequipment away from

ames and heat. Hydraulic uid can

igniteandburn.Donotoperateifleaks

aredetected.

•

Crush Hazard. Keep hands and feet

away from loading area.Avoid pinch

points or crush points that can be

created by the load, cylinder, or any

equipmentofsystem.

•

Toavoidcrushingandrelatedinjuries:

NEVER work on, under or around a

liftedloadbeforeitisproperlysupported

by appropriate mechanical means.

Neverrelyonhydraulicpressurealone

tosupportload.

HYDRAULIC PUMPS

•

Theusermust be aqualiedoperator familiarwiththe correct

operation,maintenance,anduseofpumps.Lackofknowledge

inanyoftheseareascanleadtopersonalinjury.

• Donotexceedratedcapacityofthepumporanyequipmentin

thesystem.

• Neverattempttoliftaloadweighingmorethanthecapacityof

thecylinder.

• Donotsubjectthepumpanditscomponentstoshockloads.

• Burst hazard exists if hose or connection pressure exceeds

ratedpressure.

•

Inspectpump,cylinder,hosesandconnectionsbeforeeachuse

topreventunsafeconditionsfromdeveloping.Donotuseifthey

aredamaged,alteredorinpoorcondition.Donotoperatethe

systemwithbentordamagedcouplerordamagedthreads.

• Neverholdorstanddirectlyinlinewithanyhydraulicconnections

whilepressurizing.

•

Usegaugeorotherloadmeasuringinstrumenttoverifyload.

• Never attempt to disconnect hydraulic connections under

pressure.Releasealllinepressurebeforedisconnectinghoses.

•

Useonlyapprovedaccessoriesandapprovedhydraulicuid.

•

NeverattachANYcomponentnotauthorizedbymanufacturer.

• Alwaysensurethatthechosenapplicationisstabletoworkon

andaround.

• Donotconnecttoapplicationwhichcanreturnmoreoiltothe

reservoirthanthepumpreservoircanhold.

• Donotconnectpumptohydraulicsystempoweredbyanotherpump.

• This device is not suitable for use as support device! As

thesystem loadislifted,useblockingandcribbing toguard

againstafallingload.

• All personnel must be clear before lowering load or

depressurizingthesystem.

• Nevertrytodisassembleahydrauliccylinder,referrepairsto

qualied,authorizedpersonnel.

HYDRAULIC HOSES & FLUID TRANSMISSION LINES

• Avoidshortrunsofstraightlinetubing.Straightlinerunsdo

notprovideforexpansionandcontractionduetopressure

and/ortemperaturechanges.

• Reducestressintubelines.Longtubingrunsshouldbesupported

bybrackets orclips.Beforeoperating thepump, tightenallhose

connections with proper tools. Do not overtighten. Connections

shouldonlybetightenedsecurelyandleak-free.Overtighteningcan

causeprematurethreadfailureorhighpressurettingstoburst.

• Should a hydraulic hose ever rupture, burst or need to be

disconnected, immediately shut off the pump and release all

pressure.Neverattempttograspaleakingpressurizedhosewith

yourhands.Theforceofescapinghydraulicuidcaninictinjury.

• Donotsubjectthehosetopotentialhazardsuchasre,sharp

objects,extremeheatorcold,orheavyimpact.

• Donotallowthehosetokink,twist,curl,crush,cutorbendso

tightlythattheuidowwithinthehoseisblockedorreduced.

Periodicallyinspectthehoseforwear.

• Donotpull,positionormovesetupbythehose.

•

Hose material and coupler seals must be compatible with

hydraulicuidused.Hosesalsomustnotcomeincontactwith

corrosivematerialssuchasbatteryacid,creosote-impregnated

objectsandwetpaint.Neverpaintacouplerorhose.

•

FAILURE TO HEED THESE WARNINGS MAY RESULT IN

PERSONALINJURYASWELLASPROPERTYDAMAGE.

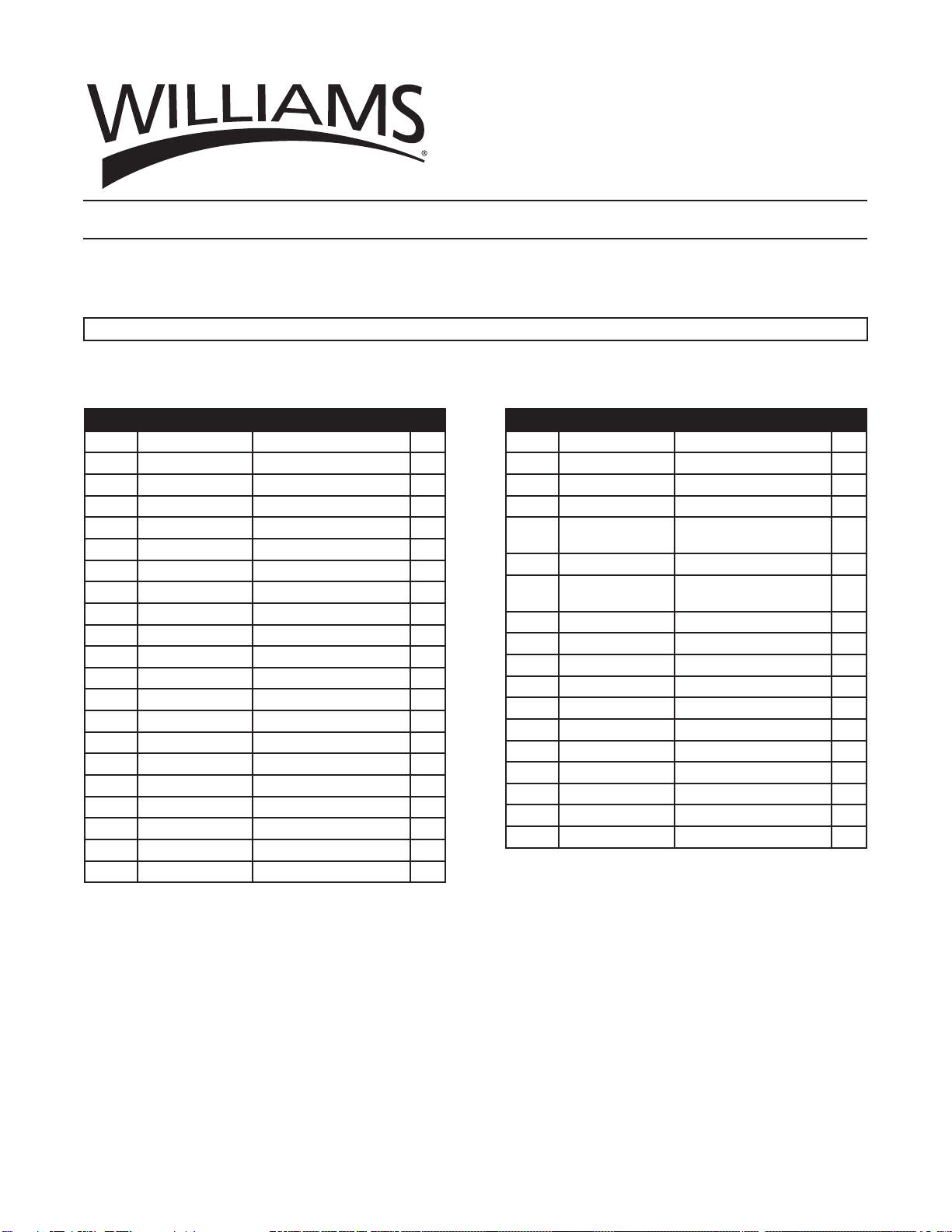

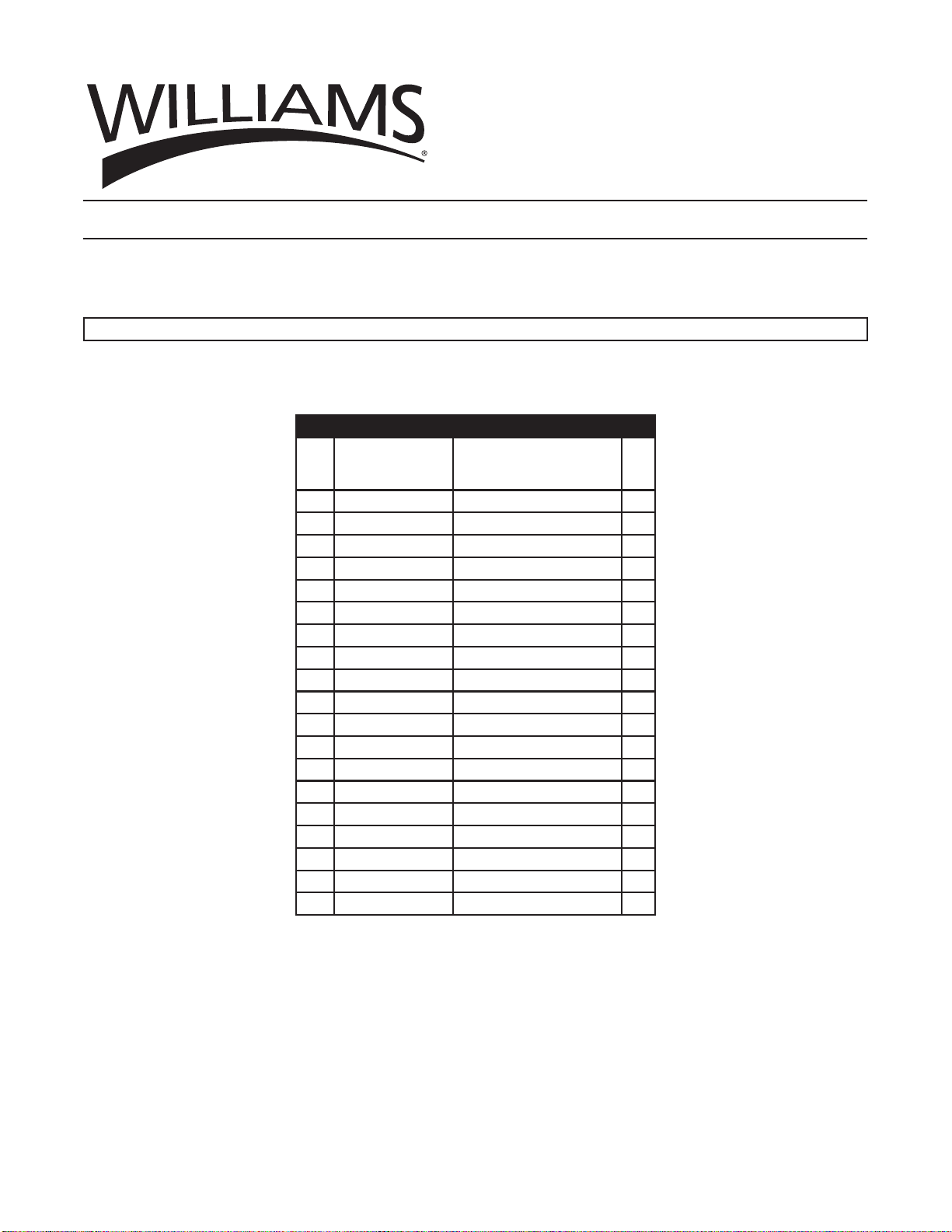

SPECIFICATIONS

Model

Number

Pump

Type

Oil

Capacity

(in³)

Usable Oil

Capacity

(in³)

Used

with

Cylinder

Pressure

Rating (psi)

Oil

Displacement

(in³)

Max.

Operating

Force

(lbs)

Piston

Stroke

(in)

Oil

Outlet

Port

Weight

(lbs)

1st

Stage

2nd

Stage

1st

Stage

2nd

Stage

5HS2S35 Two

Speed

24.9 21.4 Single

Acting 200 10,000

0.2 0.05 81 0.38 1/4"-

18NPTF 6.6

5HS2S100 67.1 61.0 0.81 0.14 99 0.82 3/8"-

18NPTF 13.7

WARNING

!