CJ2A Operation and Care

Manual -- Inspections and Precautions

At assembly a restrictor is placed between the intake manifold and the carburetor to limit the road speed to approximately 42

mph. To protect the vehicle, leave the restrictor in position for the first 500 miles of road operation, or e uivalent in industrial

operation, after which remove and discard it.

It is an obligation of the Selling Dealer to carefully inspect and adjust your Universal Jeep before delivery. After your vehicle has been

operated 1000 miles, return it to your dealer for the 1000 Mile Inspection in accordance ith Factory Form, Ser. 3455. This inspection is free

ith the exception of engine oil and anti-freeze solution used.

1000 Mile Free Inspection

Check steering system and front heel alignment.

Check spring clip nuts and spring shackles.

Check rear axle for oil and leaks.

Adjust body bolts.

Test service and hand brakes -- inflate tires.

Check cooling system for leaks and anti-freeze and fan belt adjustment.

Adjust clutch pedal.

Check operation of transmission and transfer case -- Check for oil level and leaks.

Check battery, generator output, headlamps and horn.

Tighten universal joint companion flange bolts.

Check operation of ammeter, heat indicator, fuel and oil gauges.

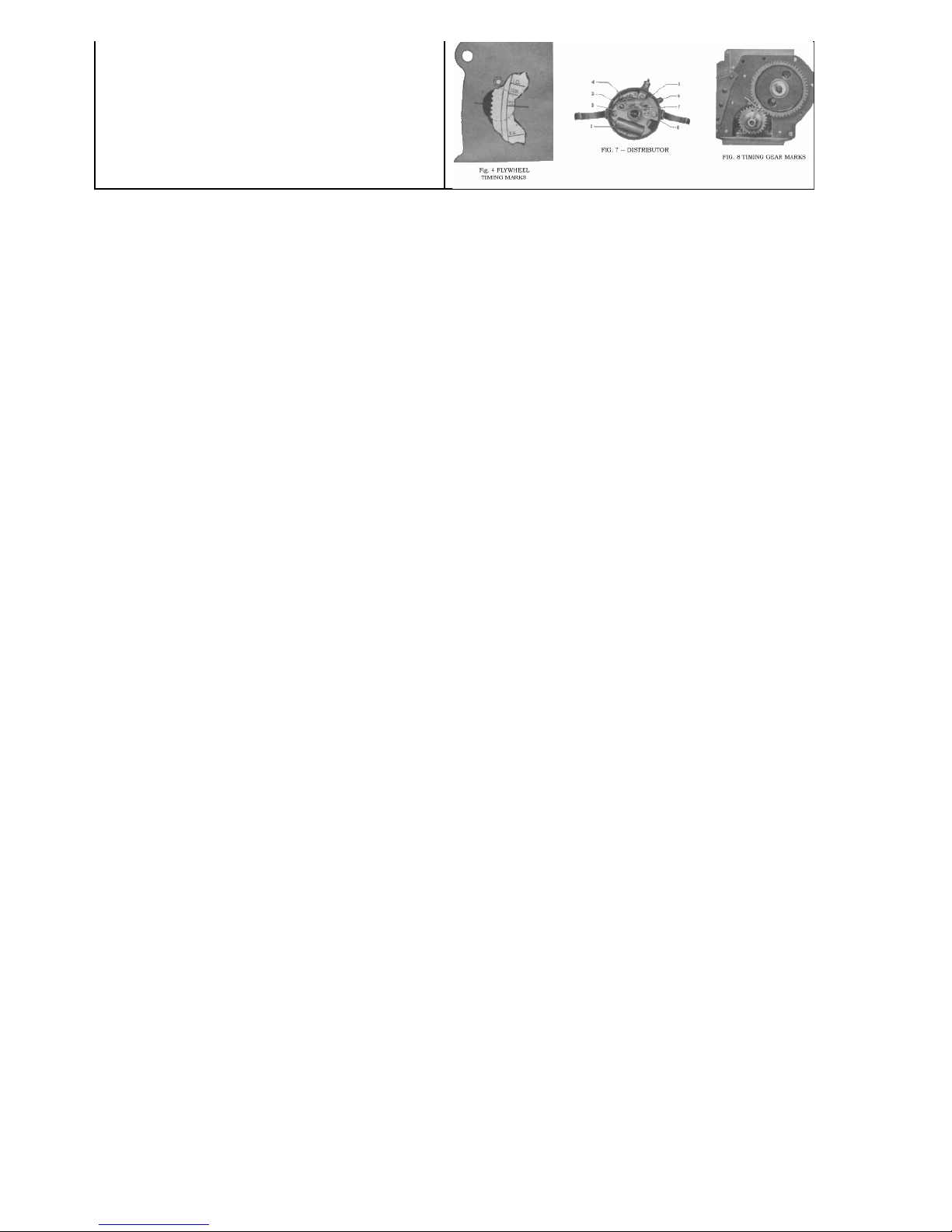

Tighten cylinder head nuts -- Check timing and distributor points.

Set spark plugs -- Adjust carburetor -- Check throttle controls.

Check engine for oil leaks -- Check fuel line connections.

Adjust valve tappets, if required.

Change engine oil (charge for oil) -- Lubricate vehicle.

Clean and refill air cleaner.

Clean fuel pump sump and strainer.

Check extra equipment attaching scre s -- Check for oil level and leaks.

FILL IN FOR YOUR REFERENCE

Vehicle Serial Number ____________________

Engine Serial Number ____________________

Purchase Date __________________________

Ignition Key Number _____________________

WILLYS-OVERLAND MOTORS, INC.

Proper Operation

DRIVING A NEW "JEEP"

Do not run your "Universal Jeep" faster than 40 miles an hour for the first 500 miles or if used on the farm or for industrial

operation, use care when pulling heavy loads in the lower gear ratios. If the vehicle is operated at high speeds while new or

used for heavy pulling for a long period, the closely fitted parts might possibly become overheated, resulting in scored pistons,

cylinders or burned bearings. During its entire life, never race the engine while making adjustments or when the vehicle is

standing idle. It the vehicle is not properly lubricated, our Warranty is null and void. Be sure to have your Willys-Overland

Dealer inspect your vehicle at the end of 1000 miles or e uivalent usage and every 2500 miles thereafter.

SPECIAL PRECAUTIONS

There are several points of difference bet een the Universal Jeep and a conventional vehicle to receive attention. As a general precaution

and for your information e are listing these "cautions" belo :

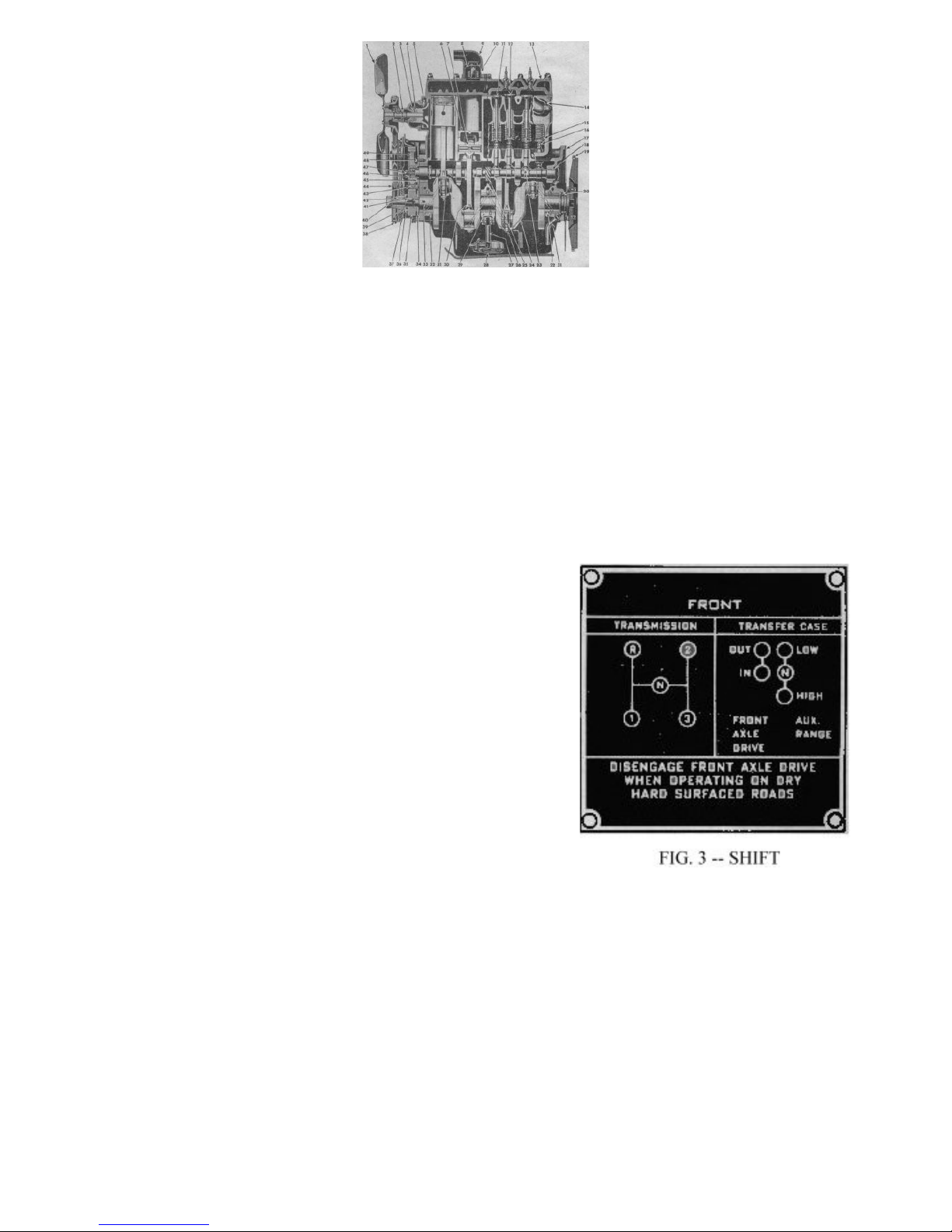

The Jeep is equipped ith a transfer case and four- heel drive to provide additional traction and a lo er gear ratio for use on difficult

terrain. Use the front heel drive only hen necessary. Consider the front heel drive and the transfer case as a lo er gear ratio than the

standard transmission lo gear and use it only hen greater po er is required.

The use of four- heel drive on hard surfaced high ays ill result in rapid tire ear and hard shifting of the transfer case, particularly hen

the front heels are steered even at a slight angle from the straight ahead position. If hard shifting occurs, disengage the clutch, start engine,

shift transmission into reverse gear, back the vehicle a fe feet, and disengage clutch. If transfer case is in lo range, shift into high then

shift front axle into "out" position (lever for ard).

T o drain cocks are provided to drain the cooling system. A drain cock is located under the left side of the radiator, ho ever, it is necessary

to drain the cylinder block separately. The cylinder block drain is located at the right front corner of the block directly under the generator.

Loosen the radiator cap to break the seal and permit complete draining.

Check the level of the lubricant often in the transmission and transfer case. Be sure the lubricant is at filler level in both units at all times.

As a standard, the clutch pedal is adjusted ith 1" free travel. As the clutch ears this becomes less. Be sure that there is free travel at all

times to prevent continuous operation of the clutch release bearing and rapid ear and slippage of the clutch. This adjustment is made by

lengthening or shortening the clutch control cable.

The ventilator valve, mounted in the intake manifold, must be free to operate. If it is stuck open very uneven engine operation at lo speed

ill result.

Be sure the exhaust manifold heat control valve is free at all times and the thermostatic control spring is above the stop.

Six scre s are used to attach the front heel brake backing plate and spindle to the spindle housing. These scre s are standard in dimensions

and thread pitch, ho ever, they are made of special steel and receive special heat treatment. Safety demands that only genuine factory scre s

be used at this point.