Vilhelmsborgvej 15 DK-7700 Thisted Tel.: (+45) 97990800 contact@wintexagro.com

The Wintex 2000 does not start.

1) The fuse is blown.

2) The emergency stop is activated.

3) Does not activate all switches.

4) The switches are defect.

5) There is a lack of power supply.

1) Put in a new fuse.

2) Deactivate the emergency

stop.

3) See manual point 1.

4) Change the switches.

5) Charge the battery.

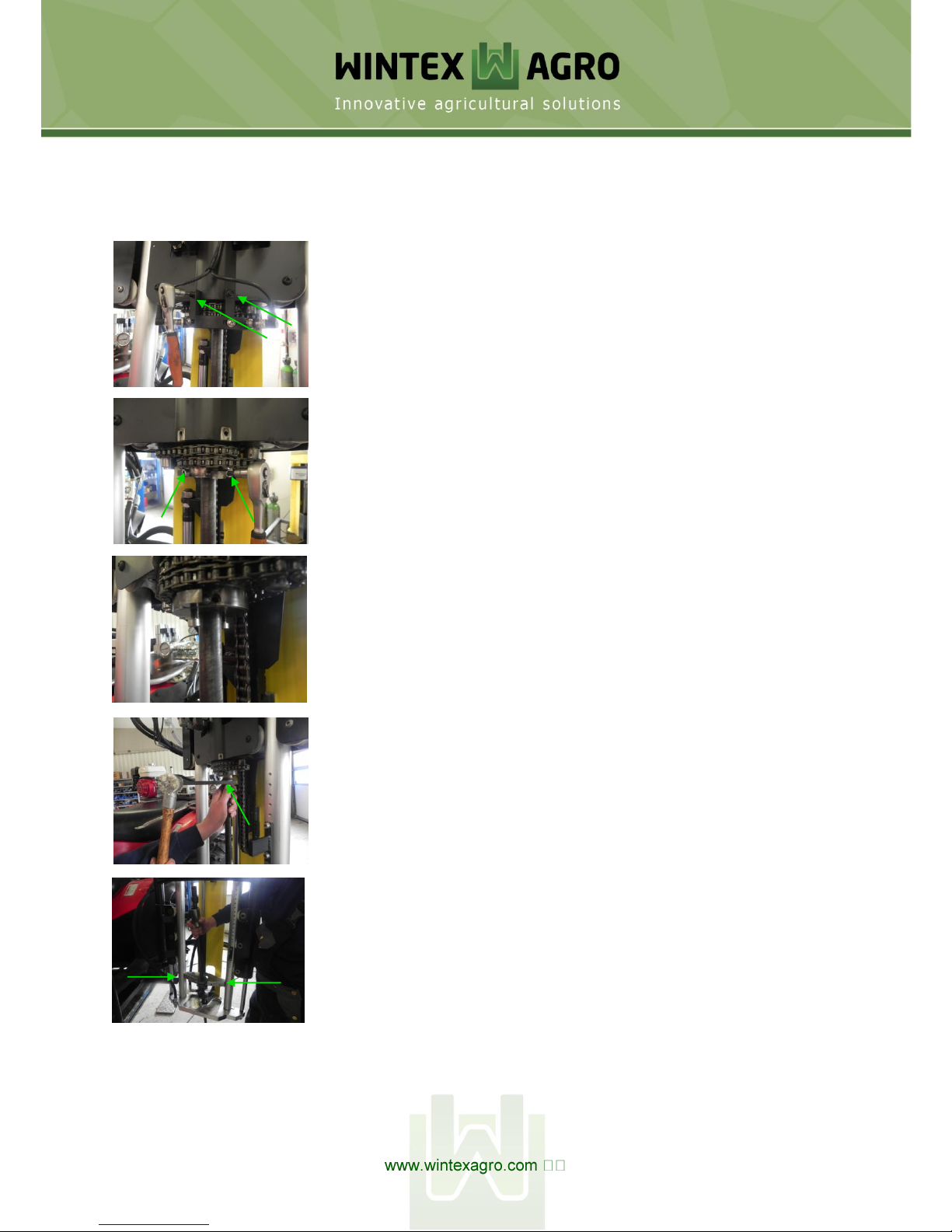

The probe does not rotate.

1) The sensors are not adjusted

correctly.

2) The chain is broken.

1) Adjust the sensors (see

manual point 8).

2) Replace the chain.

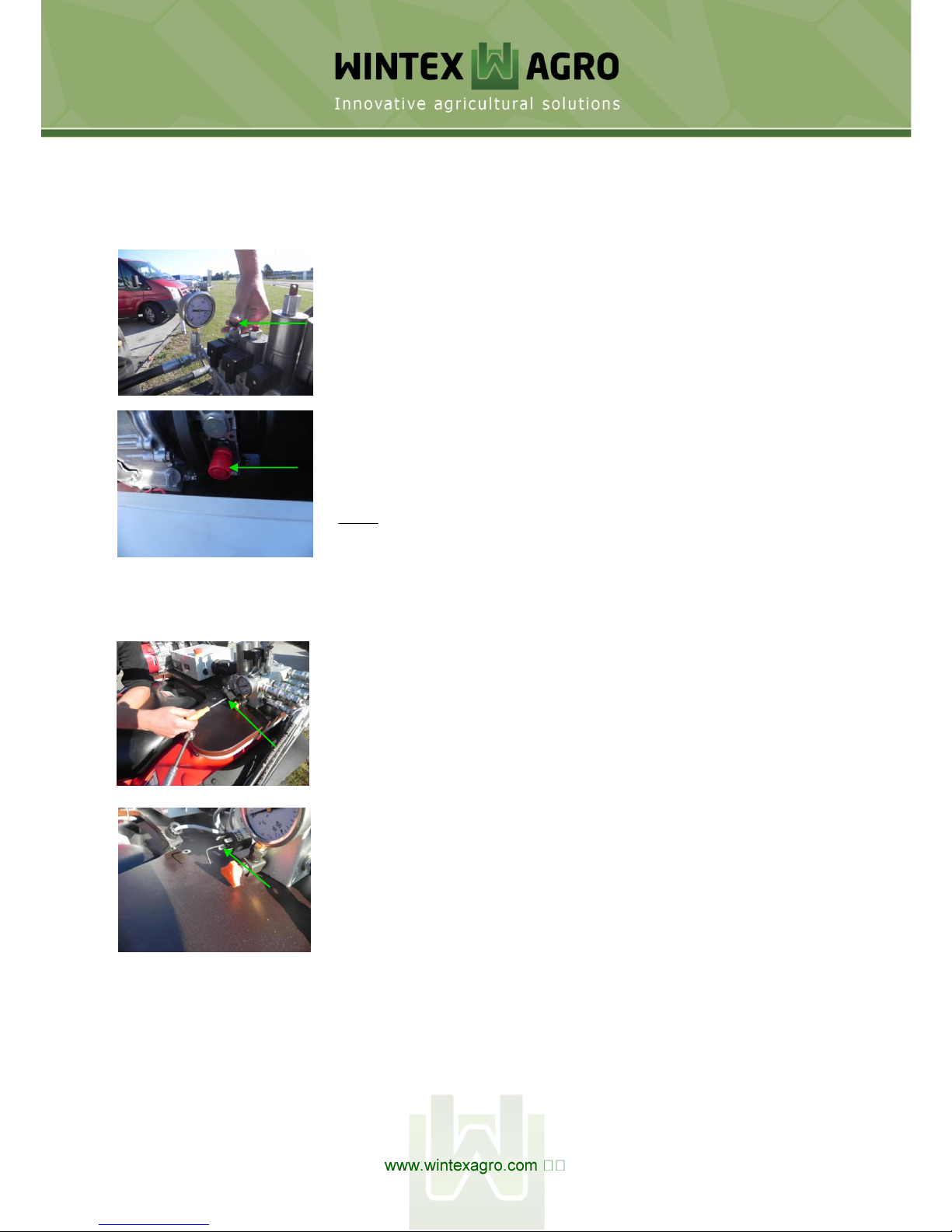

The soil cannot be squeezed out of

the probe.

1) The ejector tip is worn.

2) The probe is choked up with soil.

3) The probe is bent.

4) The O-ring is broken.

1) Change the ejector tip.

2) Clean the probe for soil.

3) Exchange the probe (see

manual point 5).

4) Replace the broken O-ring

with a new.

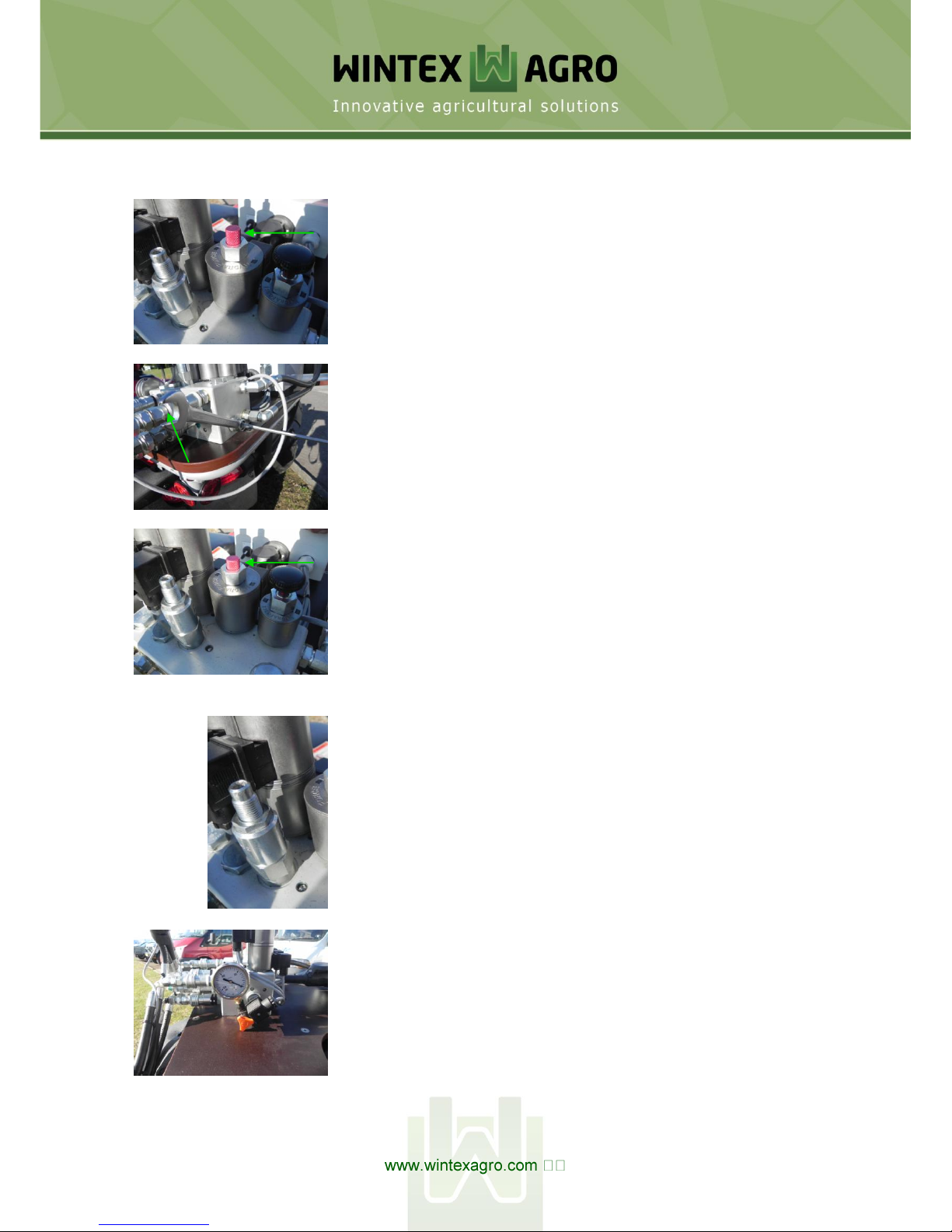

The ATV is being lifted when the

probe shall go into the ground.

1) The pressure against the ground is

too high.

2) The pressure on the cylinder for

the probe is too high.

1) Reduce the oil pressure (see

manual point 6).

2) Reduce the oil pressure (see

manual point 6).