Rev 5.0/3-23 #351051

SPECIFICATIONS .....................................................................................3

SAFETY...................................................................................................4

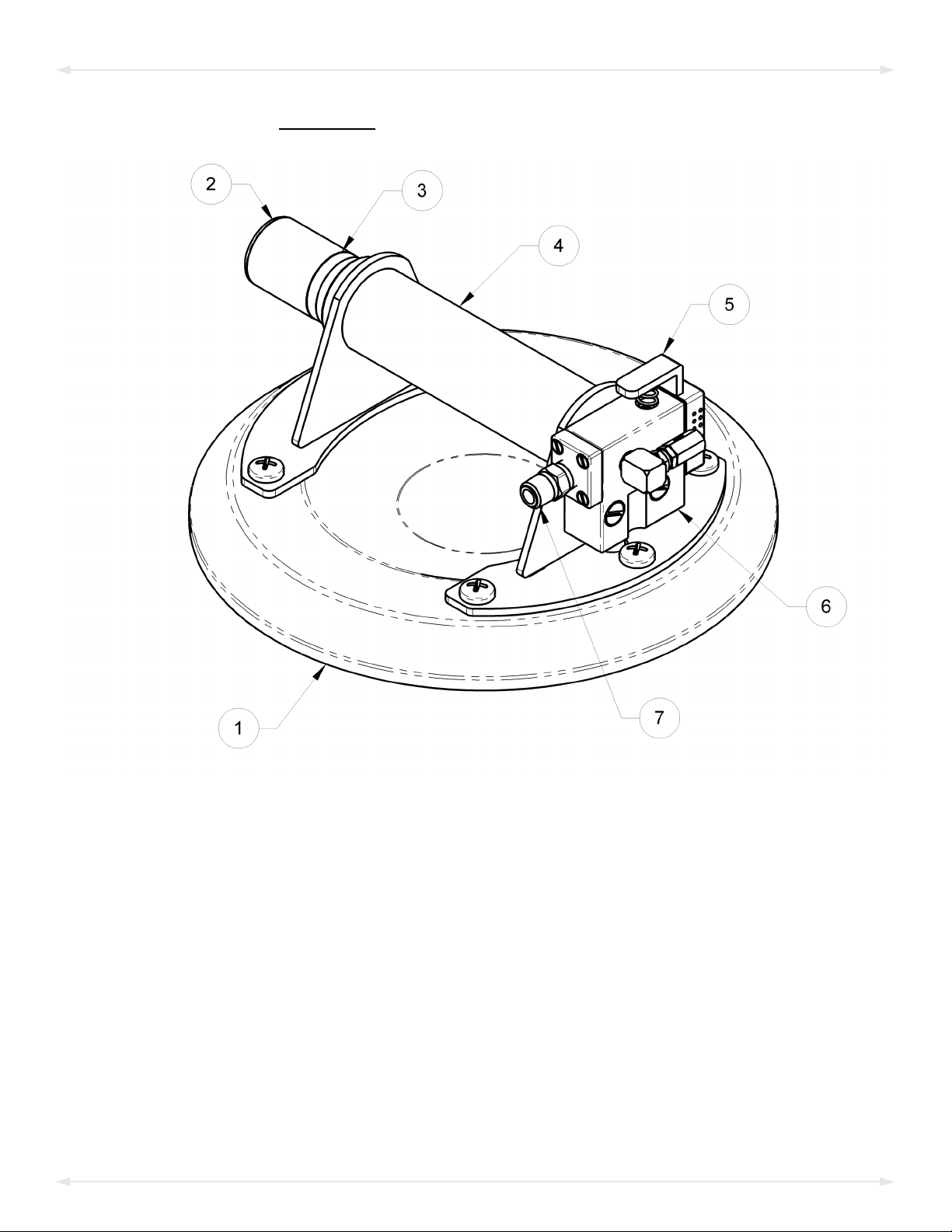

OPERATING FEATURES............................................................................5

ASSEMBLY..............................................................................................6

INTENDED USE .......................................................................................7

LOAD CHARACTERISTICS.................................................................................7

OPERATING ENVIRONMENT............................................................................8

DISPOSAL OF THE HAND CUP .........................................................................8

OPERATION............................................................................................9

BEFORE USING THE HAND CUP ......................................................................9

Taking Safety Precautions ...................................................................................................9

Performing Inspections and Tests .......................................................................................9

TOATTACH THE HAND CUP TO ALOAD ............................................................9

Positioning and Sealing the Pad on the Load......................................................................9

TOLIFT AND MOVE THE LOAD......................................................................11

Interpreting the Red-Line Vacuum Indicator.....................................................................11

Lifting the Load .................................................................................................................11

Monitoring the Red-Line Vacuum Indicator......................................................................11

In Case of Power Failure....................................................................................................12

TORELEASE THE HAND CUP FROM THE LOAD .................................................12

AFTER USING THE HAND CUP ......................................................................13

INSPECTIONS AND TESTS......................................................................14

INSPECTION SCHEDULE ................................................................................14

TESTING ...................................................................................................14

MAINTENANCE ....................................................................................15

VACUUM PAD MAINTENANCE.......................................................................15

Pad-to-Load Friction Coefficient .......................................................................................15

Pad Inspection ..................................................................................................................15

Pad Cleaning .....................................................................................................................16

TOREPLACE SEALING RING IN VPFS10T PADS ...............................................17

REPLACEMENT PARTS...........................................................................18

TABLE OF CONTENTS