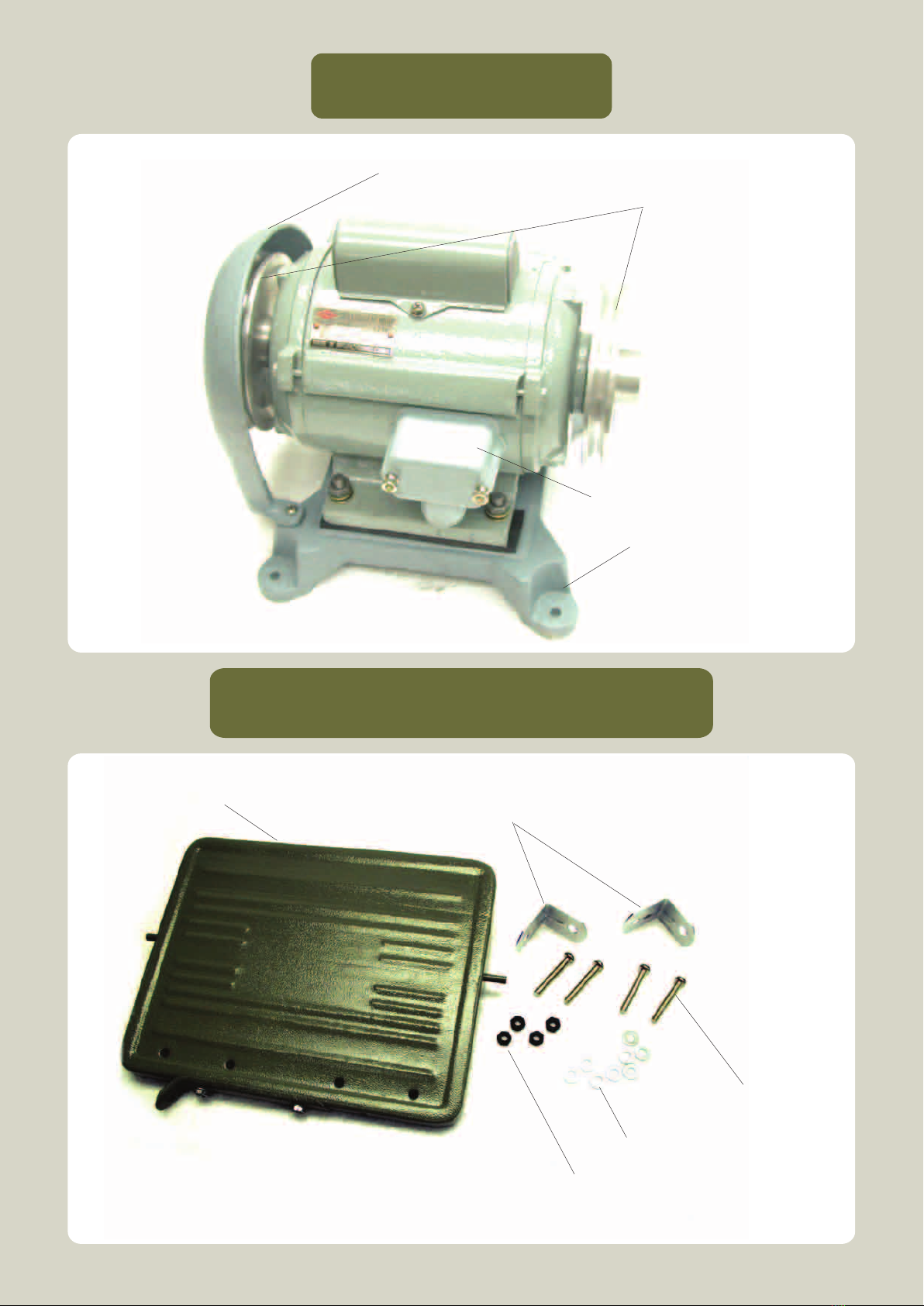

MAIN FEATURES FOR THE COMPONENTS (Main Body)

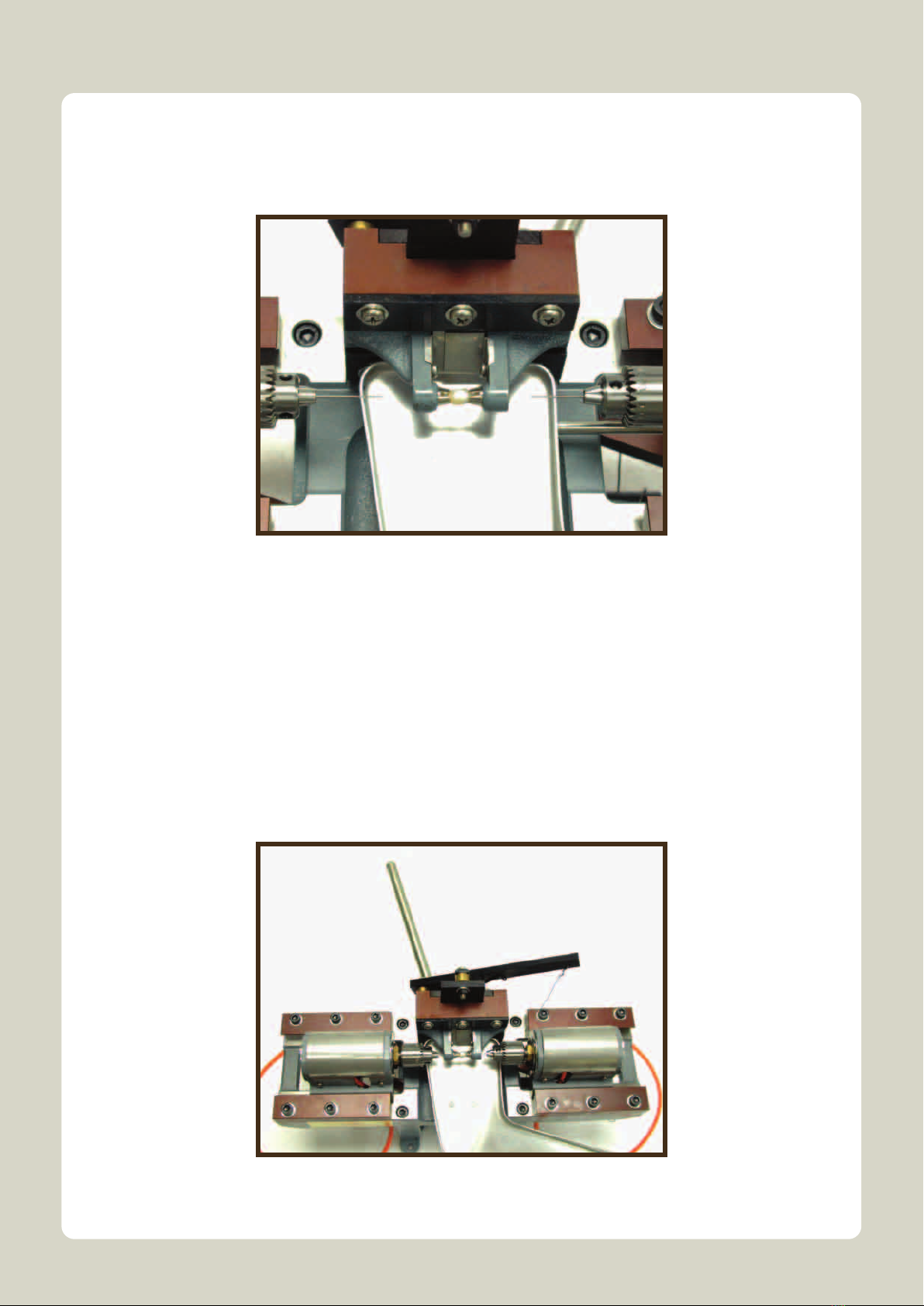

1. Drilling Roller

– To drive the Drilling Chuck with a maximum speed of 16,000 R.P.M.

2. Pearl Clamp

– To mount up the Clamping Head in proper position.

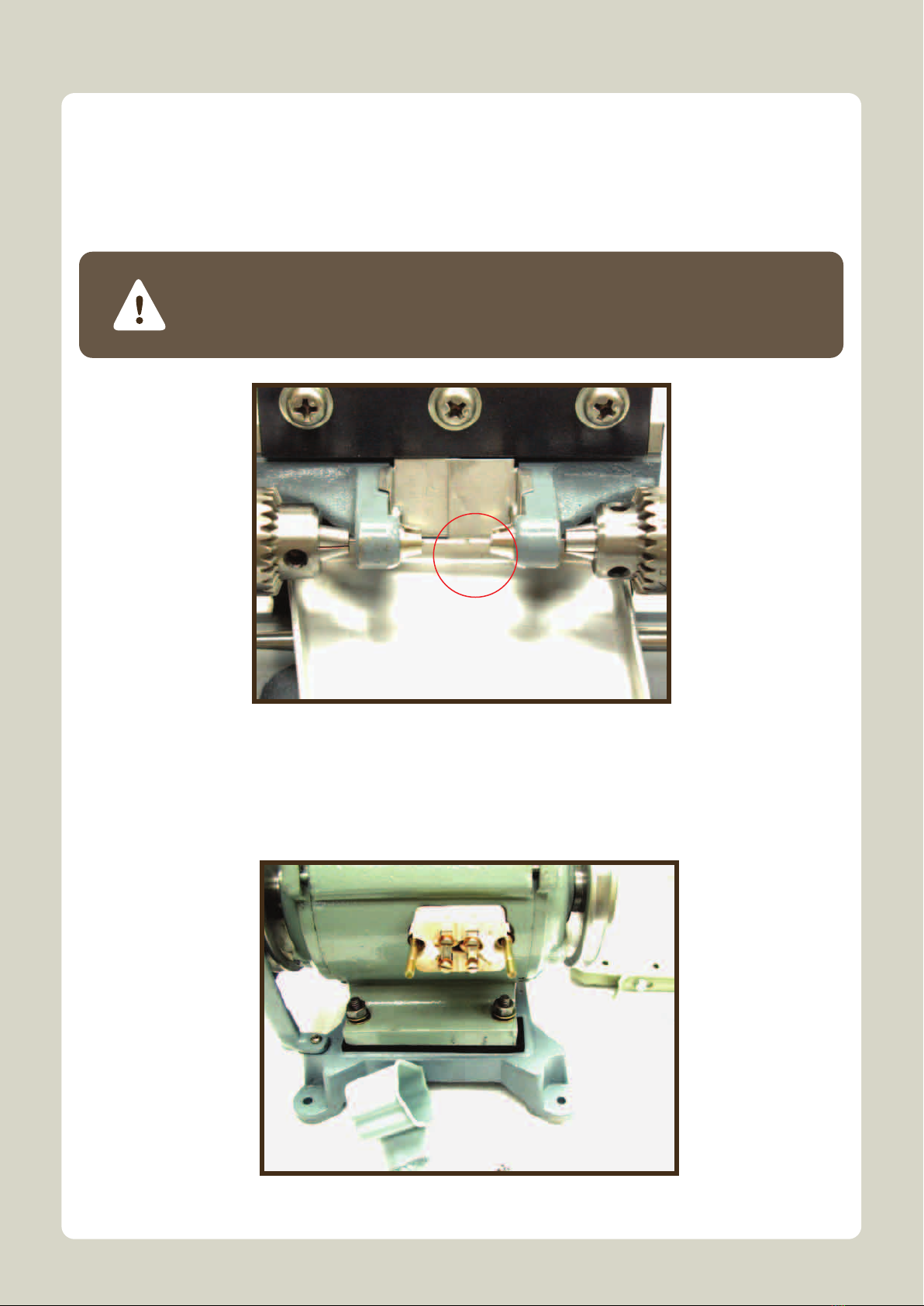

3. Mounting Handle

– To control the movement of Pearl Clamp for mount up or release the Pearl.

4. Drilling Chuck

– To mount up the Ground Bit Insert in proper location.

5. Bench Top

– Support the drilling machine on the worktable and minimize the vibration while

operating.

6. Locking Screw

– For locking the Transfer Pan on the drilling machine.

7. Location Pin

– To adjust the minimum length between the ends of two Ground Bit Inserts in order to

avoid collision when drilling.

8. Rotary Belt

– To connect the Pulleys between the Driving Motor and the Drilling motor.

9. Drilling Handle

– For control the movement of Drilling Motors to drill the Pearl.

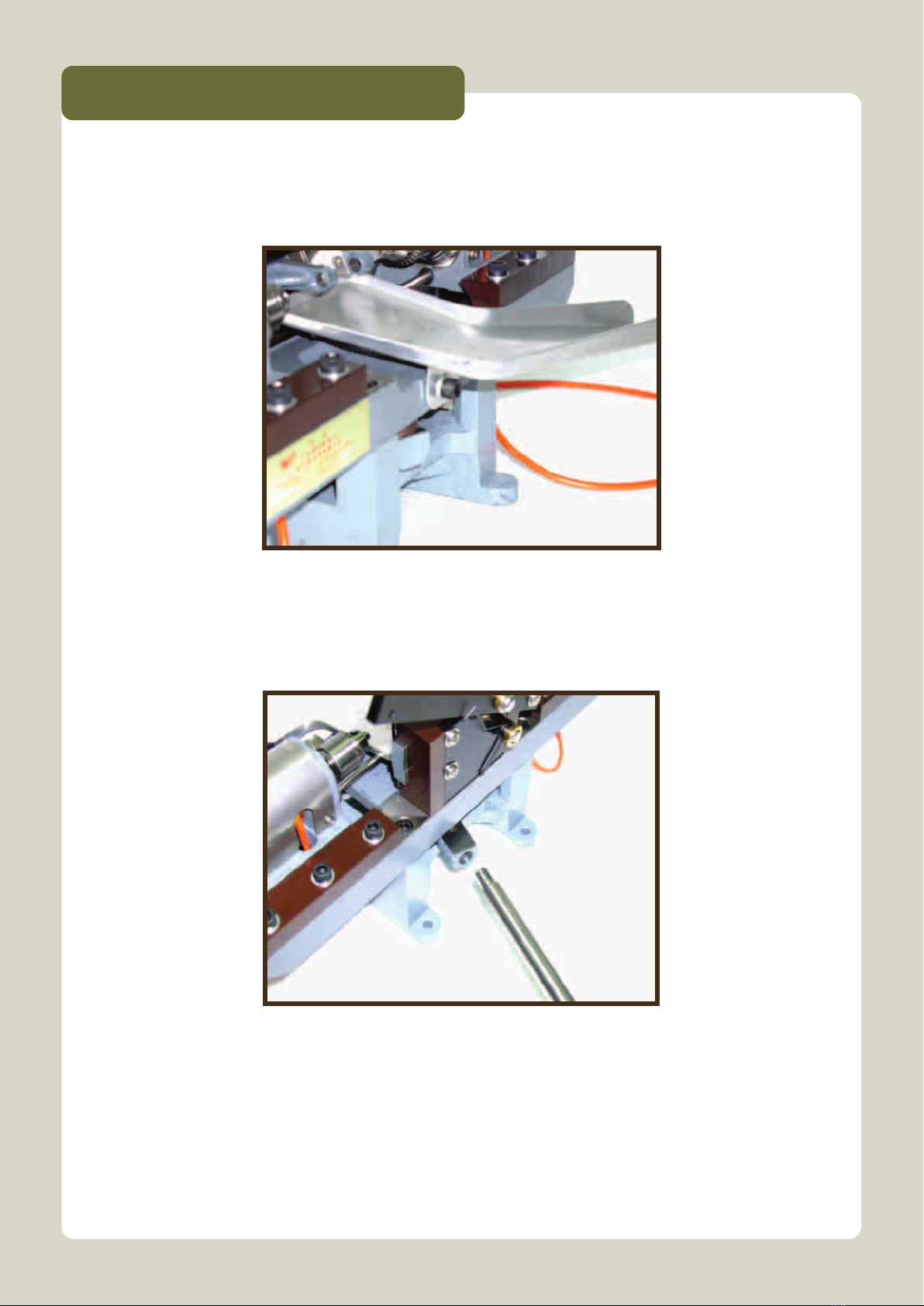

10. Transfer Pan

– For storage and transporting drilled Pearls.

11. Round Head Bolts

– For fabricate the drilling machine on the worktable.

12. Rings

– For fabricate the drilling machine on the worktable.

13. Plastic Pad

– Supporting the drilling machine on worktable and absorbing vibration.

14. Nuts

– For fabricate the drilling machine on the worktable.

15. Chuck Key

– For locking the Ground Bit Inserts on the Drilling Chuck.