OLYMPIA

ELECTRONIC

COMPACT

PROGRAM

OVERVIEW

The purpose

of

this

training

program

is

to

provide you

with

a

familiarization

of

the

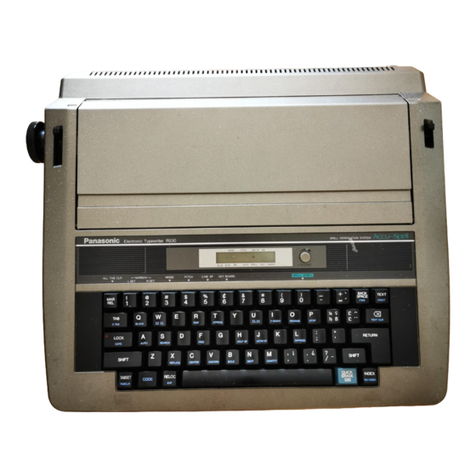

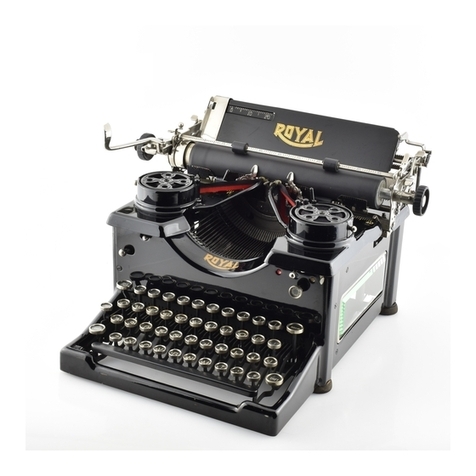

Olympia Electronic Compact, an electronic

typewriter

utilizing

Daisy Wheel

technology which can also be used

as

a slave

printer

for

a host microcomputer.

While

completing this program you

will

learn

about

the

Electronic Compacts' basic

capabilities and

about

the

documentation

which

will

be available

for

you

when

service

is

necessary.

This

training

program

is

made

up

of

the

following

sections

or

MODULES:

MODULE 1 INTRODUCTION

AND

OPERATION

In

this

module

you

will

become acquainted

with

the

installation

of

the

unit

as

well

as

with

its general characteristics such

as

print

speed.

MODULE2 TECHNICAL OVERVIEW

Here you

will

be presented

with

information

concerning

the

actual

operation

of

the

printer.

MODULE

3 SERVICE

DOCUMENTATION

Provides a description

of

the

documentation

you

will

actually

use

to

service

the

unit

as

well

as

some practical application in its

use.

MODULE

4 TROUBLESHOOTING

Discusses

the

troubleshooting

approach supported by

the

service

documentation.

PREREQUISITES

There are no prerequisites

for

this

training

program.

ESTIMATED TIME

TO

COMPLETE

THIS

TRAINING

Approximately 3 hours

REQUIRED

RESOURCES

Olympia Service Spare Parts Catalogue

Olympia Service Description

of

Function (Service Manual)