IBM 01 Operating manual

Other IBM Typewriter manuals

IBM

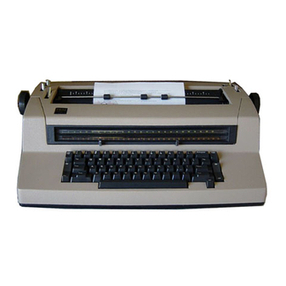

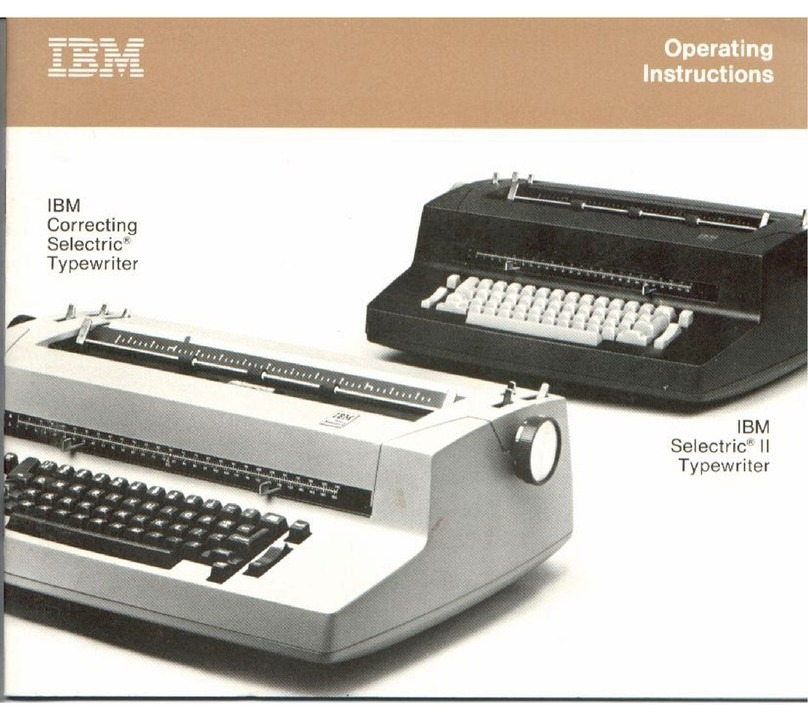

IBM Selectric User manual

IBM

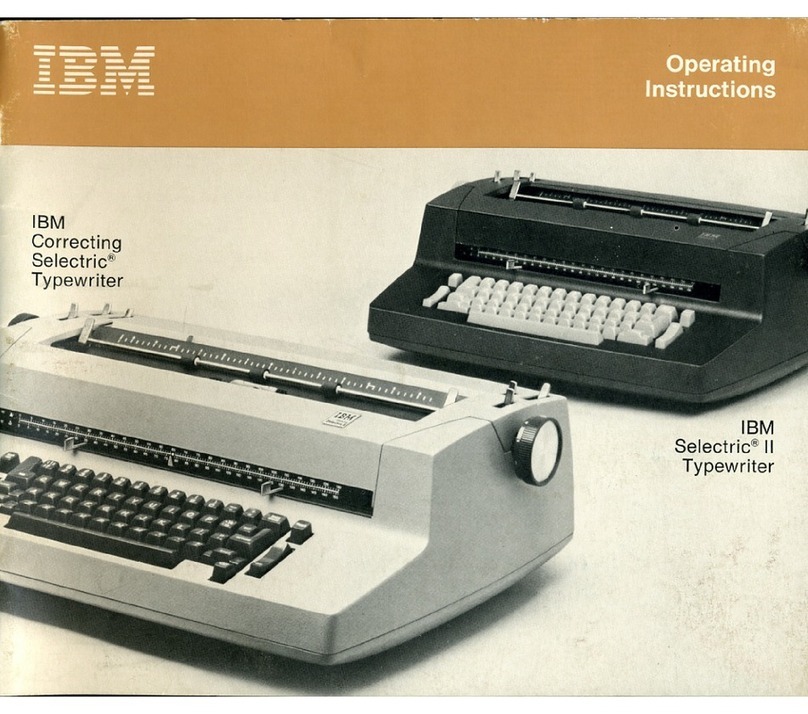

IBM Selectric II User manual

IBM

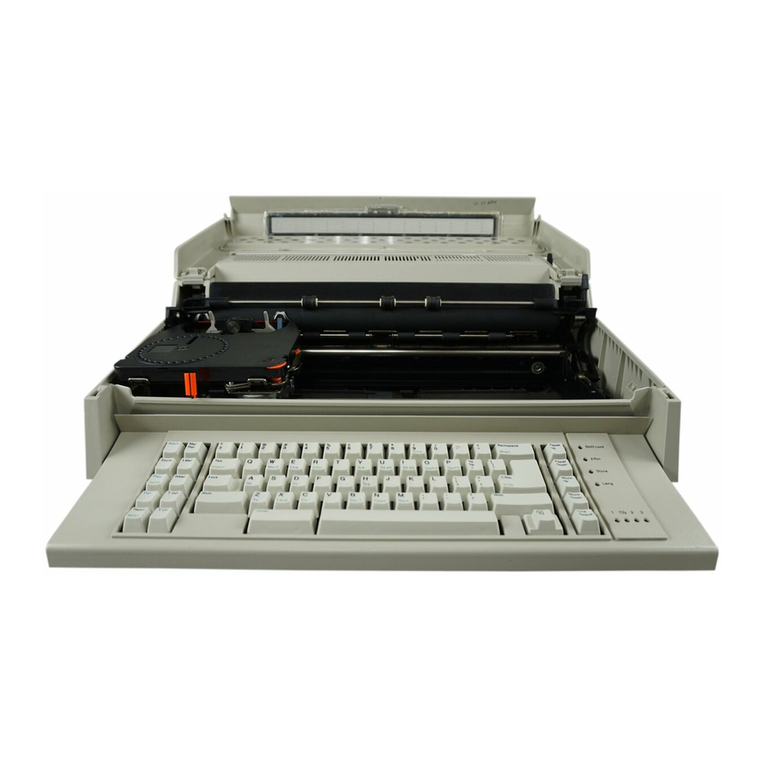

IBM Selectric III Operating instructions

IBM

IBM C-1 User manual

IBM

IBM Selectric User manual

IBM

IBM Wheelwriter 5 Manual

IBM

IBM Selectric User manual

IBM

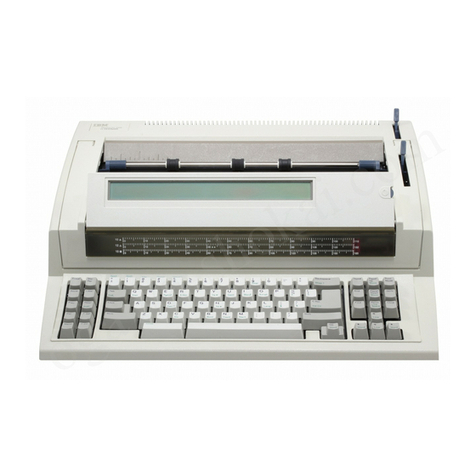

IBM Wheelwriter 10 - IBM Wheelwriter 10 Professional... Manual

IBM

IBM Selectric Personal Typewriter User manual

IBM

IBM Selectric II User manual

Popular Typewriter manuals by other brands

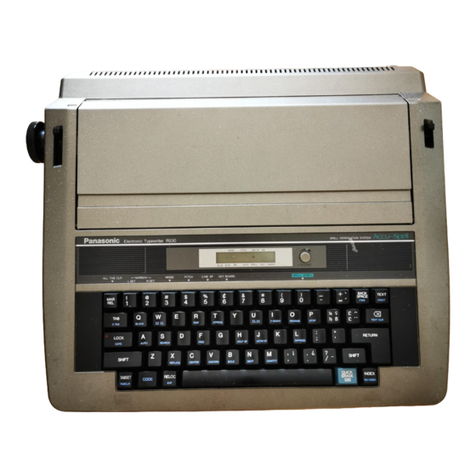

Panasonic

Panasonic KX-R530 - Electronic Typewriter operating instructions

Brother

Brother AX-425 parts reference list

Scheidegger

Scheidegger TYPOMATIC-TMS Instruction handbook

Siemens

Siemens 1000 CA operating instructions

Olivetti

Olivetti LINEA 88 Service manual

Remington Rand Inc.

Remington Rand Inc. Noiseless 10 Mechanical Instructions